Sheet Metal Fabrication Companies: 9 Costly Mistakes Killing Your Project

What Sheet Metal Fabrication Companies Actually Do

Ever wondered how the metal enclosure protecting your computer's components came to be? Or how about the sleek stainless steel surfaces in commercial kitchens? Behind every precisely formed metal product stands a specialized manufacturing process that transforms raw materials into functional components.

Sheet metal fabrication companies handle this transformation daily, yet many buyers approach these partnerships without truly understanding what happens on the shop floor. This knowledge gap often leads to costly project mistakes that could have been avoided with foundational understanding.

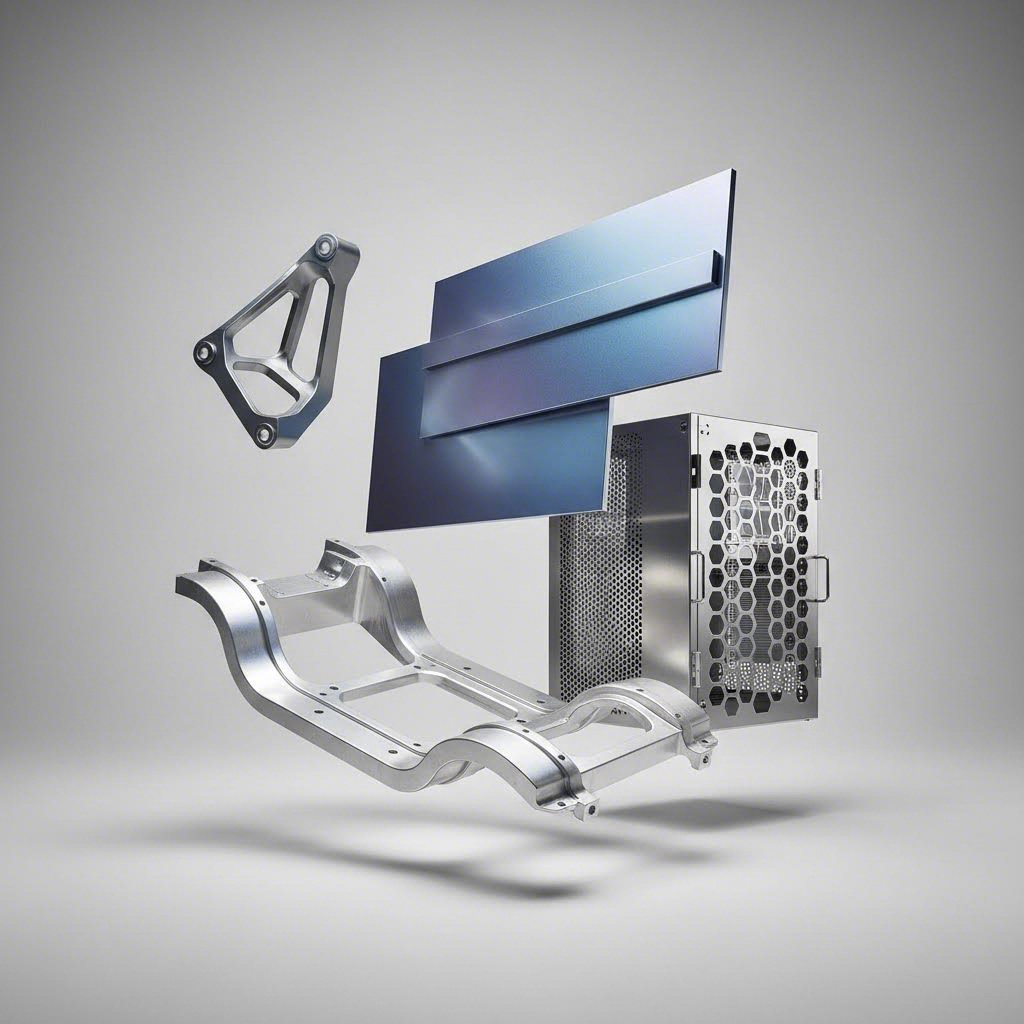

Sheet metal fabrication is the process of turning flat sheets of steel or aluminum into metal structures or products through cutting, punching, folding, and assembling. Sheet metal can be cut, bent, or stretched into nearly any shape, making it one of the most versatile manufacturing processes available.

From Flat Sheets to Functional Parts

Imagine starting with a flat piece of aluminum or steel—nothing more than a uniform sheet of metal. Through a series of carefully orchestrated steps, fabricators transform this raw material into complex three-dimensional components. The journey involves multiple processes working in harmony.

First, designers create detailed specifications using computer-aided design (CAD) software. Understanding the CNC meaning—Computer Numerical Control—is essential here, as these automated systems translate digital designs into precise machine movements. This technology enables fabricators to achieve remarkable accuracy and repeatability across production runs.

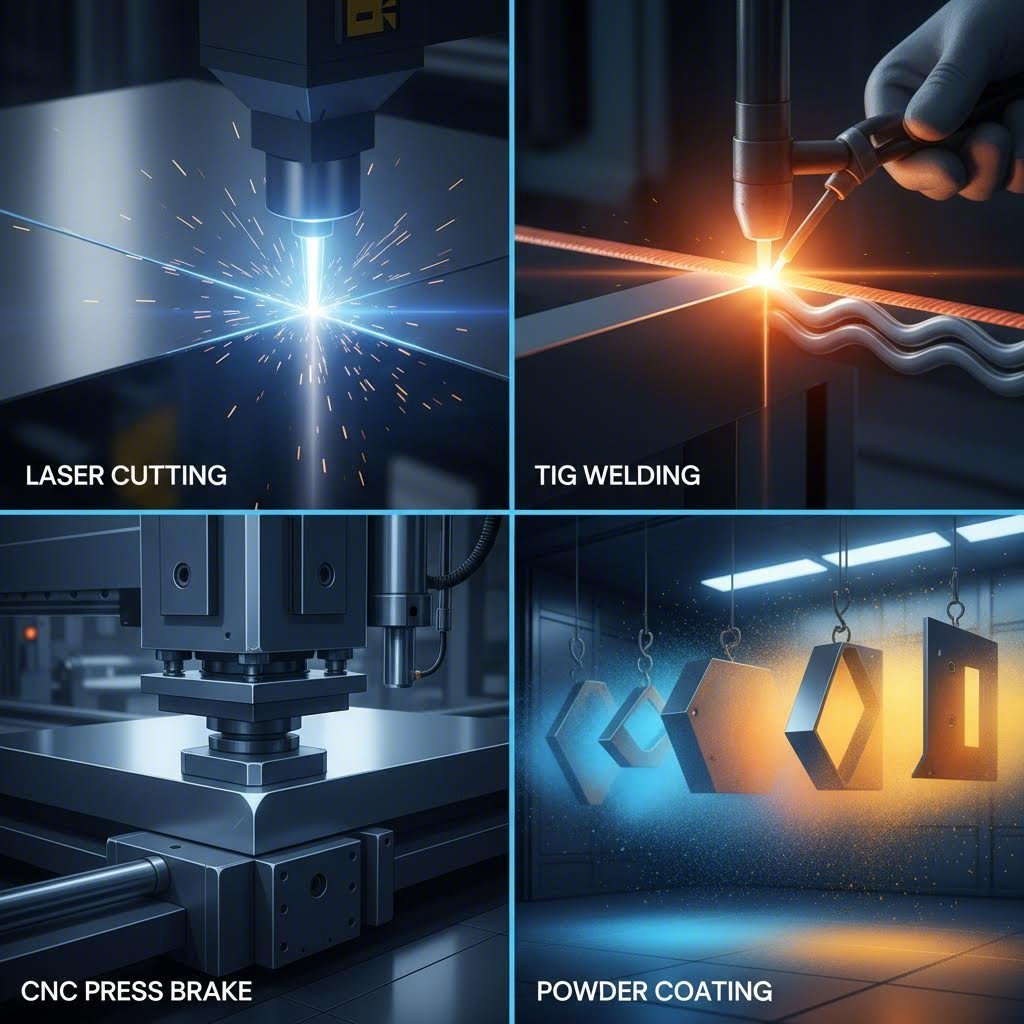

The actual fabrication begins with cutting operations. Laser cutting stands out as one of the most precise methods, with lasers following programmed paths to slice through material with minimal waste. From there, bending and forming processes reshape the flat pieces into curved or angled components. Finally, welding and assembly bring multiple parts together into finished products.

The Manufacturing Process Behind Everyday Metal Components

Steel fabrication and metal fabrication touch more industries than you might realize. That security door at your office building? Fabricated metal. The display racks at your favorite retail store? Also fabricated. Emergency vehicle components, vending machine housings, architectural elements—the list extends far beyond what most people imagine.

The process typically follows this workflow:

- Design and engineering: CAD models define exact specifications before any cutting begins

- Material preparation: Raw sheets are selected based on required properties and thickness

- Cutting operations: Laser cutting, punching, or shearing removes excess material

- Forming and bending: Press brakes and forming machines create angles and curves

- Welding and joining: Individual components are assembled using various welding techniques

- Finishing: Surface treatments like powder coating, polishing, or anodizing complete the product

Each step requires specialized equipment and expertise. Quality sheet metal fabrication companies invest heavily in both, ensuring consistent results whether producing a single prototype or thousands of identical parts.

Why Industries Depend on Precision Metal Forming

Construction, aerospace, automotive, electronics, food service, healthcare—these sectors share a common reliance on precision sheet metal fabrication. Why? Three key factors drive this dependence.

First, versatility matters. Sheet metal can be shaped into virtually any form, from simple brackets to complex enclosures with tight tolerances. This flexibility makes it suitable for countless applications.

Second, durability stands out. Properly fabricated metal components withstand demanding environments, from the vibration of transportation equipment to the corrosive conditions in food processing facilities.

Third, cost-effectiveness plays a crucial role. Compared to other manufacturing methods, sheet metal fabrication offers attractive economics, especially for medium to high-volume production runs.

Understanding what these fabricators actually do positions you to ask better questions, set realistic expectations, and ultimately avoid the costly mistakes that derail projects. With this foundation in place, you're ready to explore the specific techniques and considerations that separate successful fabrication partnerships from frustrating failures.

Core Fabrication Techniques and When Each Applies

Now that you understand what sheet metal fabrication companies do at a high level, let's dive deeper into the specific techniques that make everything possible. Each method serves distinct purposes, and knowing when to use which approach can save you significant time, money, and headaches.

Think of these techniques as tools in a craftsman's toolbox. A skilled fabricator doesn't just own these tools—they know exactly when each one delivers optimal results. Your job as a buyer? Understanding enough about these processes to communicate effectively and recognize when recommendations align with your project needs.

Laser Cutting and CNC Punching Explained

When precision matters most, laser cutting typically takes center stage. A high-powered laser beam focuses onto the metal surface, vaporizing material in a controlled manner that creates remarkably clean edges. The process generates a narrow cut width called the kerf—often measuring just fractions of a millimeter—which minimizes material waste and enables intricate designs.

A laser cutter excels at producing custom patterns and complex geometries that mechanical methods struggle to achieve. Imagine needing decorative perforations with varying hole sizes or irregular shapes. Laser cutting cutting through these challenges with minimal material deformation makes it ideal for architectural applications, electronic enclosures, and precision components.

CNC punching takes a different approach. Here, mechanical force drives a die into the metal sheet, physically removing material to create holes and shapes. The and CNC punching method offers speed advantages for high-volume production runs where standard hole patterns repeat across many parts.

So which should you choose? Consider these factors:

- Design complexity: Intricate patterns favor laser cutting; simple, repetitive holes suit punching

- Production volume: Higher quantities often justify punching's faster throughput

- Material waste: Laser cutting's focused beam typically generates less scrap

- Edge quality: Laser cuts produce cleaner edges with minimal burring

- Cost structure: Punching carries lower operational costs for standard patterns

Interestingly, some fabricators combine both methods. They might use punching for standard features and laser cutting for custom elements on the same part—maximizing efficiency without sacrificing design flexibility.

Bending and Forming Metal Into Shape

Flat metal sheets rarely serve as finished products. The magic happens when bending and forming operations transform two-dimensional blanks into three-dimensional components. Press brakes—machines that apply controlled force along a linear axis—create precise angles and bends according to programmed specifications.

Bending might seem straightforward, but numerous variables affect outcomes. Material thickness, grain direction, bend radius, and even ambient temperature influence how metal responds to forming pressure. Experienced fabricators account for phenomena like springback, where metal partially returns toward its original shape after pressure releases.

More complex forms require specialized equipment. Roll forming gradually shapes metal through successive stations, creating consistent profiles for applications like structural channels. Hydroforming uses fluid pressure to push metal into mold shapes, enabling complex curves that conventional bending cannot achieve.

The distinction between CNC router CNC machines for cutting and CNC press brakes for bending matters here. Both rely on computer-controlled precision, but they serve fundamentally different functions in the fabrication workflow.

Welding and Assembly Techniques

Individual components eventually need joining. Welding fuses metal parts through localized melting, creating bonds that often exceed the base material's strength. Several welding methods serve different applications.

MIG (Metal Inert Gas) welding offers speed and versatility for general fabrication work. TIG (Tungsten Inert Gas) welding delivers superior precision and cleaner results, making it preferable for visible joints or thin materials. Aluminum welding presents unique challenges—the metal's thermal conductivity and oxide layer require specialized techniques to achieve quality results.

Beyond welding, fabricators employ various joining methods:

- Spot welding: Creates localized fusion points, common in automotive applications

- Riveting: Mechanical fastening without heat, useful for dissimilar materials

- Hardware insertion: Press-fit nuts, studs, and standoffs for assembly points

- Adhesive bonding: Structural adhesives for specific applications

The joining method affects not just strength but also appearance, cost, and production speed. Understanding your priorities helps fabricators recommend appropriate approaches.

Surface Finishing Options

Raw fabricated metal rarely ships directly to end users. Surface finishing protects against corrosion, enhances appearance, and sometimes improves functionality. Common finishing options include powder coating (durable colored finishes), anodizing (electrochemical treatment for aluminum), and galvanizing (zinc coating for steel protection).

Each finish carries tradeoffs between cost, durability, and aesthetics. Powder coating offers extensive color options and scratch resistance. Anodizing preserves aluminum's natural appearance while adding a protective layer. Galvanizing provides robust corrosion protection but limits color choices.

| Technique | Best Applications | Material Compatibility | Precision Level |

|---|---|---|---|

| Laser Cutting | Intricate patterns, custom shapes, precision components | Steel, stainless steel, aluminum, copper, brass | Extremely high (±0.1mm typical) |

| CNC Punching | High-volume production, standard hole patterns, perforations | Mild steel, stainless steel, aluminum | High (±0.25mm typical) |

| Press Brake Bending | Angles, channels, enclosure walls, brackets | Most sheet metals up to 12mm thickness | High (±0.5° angular tolerance) |

| MIG Welding | General fabrication, structural assemblies, high-speed production | Steel, stainless steel, aluminum | Moderate to high |

| TIG Welding | Visible joints, thin materials, precision assemblies | All weldable metals including titanium | Very high |

| Powder Coating | Exterior components, decorative parts, corrosion protection | Steel, aluminum (with proper prep) | N/A (surface finish) |

Understanding these core techniques empowers you to have meaningful conversations with potential fabrication partners. When a fabricator recommends laser cutting over punching for your project, you'll understand the reasoning—and you'll know when to ask clarifying questions. With techniques covered, the next critical consideration involves material selection and understanding the specifications that affect your project outcomes.

Materials and Metal Grades Used in Fabrication

You've got cutting methods figured out. You understand bending and welding basics. But here's where many projects go sideways—material selection. Choosing the wrong metal grade or thickness can doom an otherwise well-planned fabrication project before production even begins.

With thousands of alloys available, how do you narrow down your options? Let's break this down into manageable pieces, starting with the most commonly fabricated materials and their practical applications.

Steel and Stainless Steel Options

Steel remains the workhorse of sheet metal fabrication. Its strength, availability, and cost-effectiveness make it the default choice for countless applications. However, "steel" encompasses dozens of variants with dramatically different properties.

Carbon steel gets its name from its carbon content, ranging from 0.05 to 2.1%. This material requires protection against rust—either through oiling, powder coating, or galvanizing. Common grades include:

- A36: The go-to choice for plate measuring ¼" and thicker, ideal for structural applications

- A1011: Hot-rolled steel with a rougher appearance, typically requiring blasting before coating

- A1008: Cold-rolled steel with a pristine surface finish, preferred for sheet measuring up to 3/16" thick

- A572: High-strength steel with added manganese and silicon, suitable for demanding structural applications

When corrosion resistance matters, stainless steel sheet metal becomes the preferred option. Three grades dominate fabrication shops:

- 304 stainless steel: The general-purpose champion, used in roughly 90% of enclosures. Cost-effective with reliable corrosion resistance for land-based applications away from extreme environments

- 316 stainless steel: Contains approximately 2% molybdenum, providing enhanced protection against chlorides and caustic environments—ideal for marine or chemical processing applications

- 430 stainless steel: Less corrosion-resistant due to lower nickel content, but offers magnetic properties useful for specific applications like kitchen equipment

The chromium and nickel content in stainless steel creates that excellent corrosion resistance, while keeping carbon content low maintains formability and weldability.

Aluminum Grades for Different Applications

When weight matters—think aerospace, transportation, or handheld products—aluminum sheet metal takes center stage. This lightweight material also offers natural corrosion resistance, though different alloys serve different purposes.

Understanding aluminum sheet grades helps you communicate requirements clearly to fabricators:

- 3003 aluminum: Easy to form and weld, commonly used interchangeably with 5052 for general fabrication work

- 5052 aluminum: Stronger than 3003 with superior corrosion resistance, particularly in marine environments. The highest strength among non-heat-treatable alloys makes it excellent for structural parts near salt water

- 5083 aluminum: Exceptional corrosion resistance with excellent weldability and formability—the premium choice for marine applications requiring durability

- 6061 aluminum: The primary alloy for plate measuring 3/16" and thicker, extruded shapes, and precision machined parts. Heat-treatable for increased strength but more brittle than other alloys—fabricators typically avoid forming this grade

One important consideration: all aluminum alloys develop an oxide layer when left unprotected. If cosmetic appearance matters for your project, plan for finishing processes like powder coating or anodizing from the start.

Understanding Metal Gauge and Thickness

Here's where confusion runs rampant. Ask ten engineers about sheet metal thickness, and you'll likely hear measurements in gauges, inches, and millimeters—sometimes all three in the same conversation.

The critical point? Gauge numbers vary by material. A 16-gauge stainless steel sheet measures 0.0625 inches, while 16-gauge aluminum measures only 0.0508 inches. Using the wrong gauge size chart can result in parts that don't fit, bend incorrectly, or fail under load.

Lower gauge numbers indicate thicker material. This counterintuitive relationship trips up many first-time buyers. Think of it this way: 10-gauge steel (0.1345") is significantly thicker than 24-gauge steel (0.0239").

Why does thickness matter so much? It directly affects:

- Structural strength: Thicker gauges increase rigidity and load capacity

- Formability: Thinner sheets bend with less force and reduce tool wear

- Weight: Critical for transportation, aerospace, and portable products

- Weldability: Thin sheets risk burn-through; thick sheets need more heat penetration

For RFQs, list both gauge and thickness measurements—for example, "16 ga steel (0.0598 in / 1.519 mm)"—to eliminate ambiguity. For precision parts, verify actual material thickness with a caliper before fabrication begins, as mill tolerances can introduce slight variations.

| Gauge | Steel (inches/mm) | Stainless Steel (inches/mm) | Aluminum (inches/mm) |

|---|---|---|---|

| 10 | 0.1345 / 3.416 | 0.1406 / 3.571 | 0.1019 / 2.588 |

| 12 | 0.1046 / 2.659 | 0.1094 / 2.779 | 0.0808 / 2.052 |

| 14 | 0.0747 / 1.897 | 0.0781 / 1.984 | 0.0641 / 1.628 |

| 16 | 0.0598 / 1.519 | 0.0625 / 1.588 | 0.0508 / 1.290 |

| 18 | 0.0478 / 1.214 | 0.0500 / 1.270 | 0.0403 / 1.024 |

| 20 | 0.0359 / 0.912 | 0.0375 / 0.952 | 0.0320 / 0.813 |

| 22 | 0.0299 / 0.759 | 0.0313 / 0.794 | 0.0253 / 0.643 |

| 24 | 0.0239 / 0.607 | 0.0250 / 0.635 | 0.0201 / 0.511 |

Keep this sheet metal gauge chart handy when specifying materials. Notice how the same gauge number represents different actual thicknesses across materials—mixing up these charts ranks among the most common specification errors that delay fabrication projects.

Selecting the right material involves balancing function, environment, process requirements, and tolerances. Define whether your part is structural, cosmetic, or protective. Consider exposure to moisture, chemicals, or temperature extremes. Plan for cutting, bending, and fastening methods. With material specifications understood, you're ready to explore what actually happens once your project enters a fabrication shop's workflow.

The Complete Fabrication Workflow From Design to Delivery

You've selected your material. You understand the techniques involved. Now comes the question that separates experienced buyers from first-timers: what actually happens once you contact a metal fab shop with your project?

Surprisingly few resources explain this end-to-end journey. Most fabrication shops near me searches lead to company listings without context about what working with these partners actually involves. Let's change that by walking through each stage—from initial concept to packaged parts arriving at your facility.

Design Review and Engineering Support

Every successful fabrication project begins long before any cutting or bending occurs. The design review phase catches problems while they're still easy (and cheap) to fix.

When you submit CAD files or drawings to steel fabricators, their engineering team examines your specifications for manufacturability issues. This Design for Manufacturability (DFM) review identifies potential problems like:

- Impossible bend radii: Internal radii smaller than material thickness cause cracking

- Insufficient clearances: Features too close to bend lines or edges create forming issues

- Tolerance conflicts: Specifications that can't be achieved with standard equipment

- Material selection mismatches: Grades unsuitable for specified forming operations

Quality fabricators don't just identify problems—they suggest solutions. Perhaps a slight dimension adjustment eliminates a secondary operation. Maybe repositioning a hole pattern allows better material utilization. These collaborative improvements often reduce costs while improving part quality.

During this phase, engineers may reference a drill chart or drill size chart to ensure specified hole sizes align with standard tooling. Using non-standard drill sizes adds cost and lead time, so experienced designers specify common dimensions whenever possible.

Prototyping Before Full Production

Here's where theory meets reality. Prototyping produces physical samples that validate your design before committing to production quantities. Even designs that look perfect in CAD software sometimes reveal issues once fabricated.

Rapid prototyping techniques, such as laser cutting and 3D printing, facilitate iterative design refinement before full-scale production. A prototype might reveal that a formed feature interferes with assembly, or that a welded joint doesn't achieve expected strength. Better to discover this with one sample part than thousands.

What should you evaluate during prototyping?

- Dimensional accuracy: Do critical features meet tolerance requirements?

- Fit and assembly: Does the part work with mating components?

- Functionality: Does the finished part perform its intended purpose?

- Appearance: Are surface finish and cosmetic quality acceptable?

Some buyers skip prototyping to save time or money. This shortcut frequently backfires. Metal fabrication near me services may seem accessible for quick jobs, but rushing past validation often means discovering problems during production—when fixes become exponentially more expensive.

Quality Control Throughout the Process

Quality assurance isn't a single checkpoint at the end. Effective fabrication shops embed inspection throughout their workflow, catching deviations before they compound into scrapped parts or delayed deliveries.

The complete workflow typically follows this sequence:

- Raw material verification: Incoming sheets are inspected for correct grade, thickness, and surface condition before entering production

- First article inspection: The initial parts from each production run receive thorough dimensional verification against specifications

- In-process monitoring: Operators check critical dimensions at regular intervals during production runs

- Weld inspection: Visual examination and, for critical applications, non-destructive testing of welded joints

- Post-finishing verification: Confirmation that coating thickness, color, and adhesion meet requirements

- Final dimensional audit: Random sampling from completed batches ensures consistency across the entire order

Working with experienced fabricators means having partners who understand these quality requirements. Their in-process monitoring and dimensional verification ensure fabricated parts meet your standards—not just once, but consistently across every unit produced.

From Quote to Delivery Timeline

Understanding realistic timelines helps you plan projects effectively. Here's what typical lead times look like at each stage:

| Stage | Typical Duration | Factors That Extend Timeline |

|---|---|---|

| Quote preparation | 24-72 hours | Complex designs, incomplete specifications, custom materials |

| DFM review | 1-3 days | Design revisions, engineering discussions, tolerance negotiations |

| Prototyping | 3-10 days | Multiple iterations, specialty finishes, complex assemblies |

| Production | 1-4 weeks | Order quantity, equipment availability, secondary operations |

| Finishing | 3-7 days | Custom colors, specialty coatings, batch curing requirements |

| Shipping | 1-5 days | Destination, packaging requirements, freight method |

Total project duration varies dramatically based on complexity, quantity, and how smoothly each phase proceeds. A simple bracket might move from quote to delivery in two weeks. A complex welded assembly with custom finishing could require eight weeks or more.

Communication patterns significantly affect outcomes. Projects where buyers respond quickly to questions, approve samples promptly, and provide clear feedback move faster than those with communication gaps. The best fabrication partnerships feel collaborative rather than transactional.

With workflow expectations established, you're equipped to engage fabrication shops near me with realistic project timelines. But how do these dynamics change when you're producing one prototype versus one thousand production units? That distinction shapes virtually every decision in your fabrication partnership.

Prototyping Versus Production Runs

Here's a question that trips up even experienced buyers: should you invest in prototyping, or jump straight to production? The answer shapes everything from your budget to your timeline—and getting it wrong ranks among the costliest mistakes in sheet metal fabrication.

Understanding this distinction isn't just academic. According to manufacturing research, companies that skip proper prototyping phases often face expensive reworks, manufacturing defects, or field failures that could have been caught early. Industries like aerospace and automotive require parts to be perfect—even small design flaws can lead to major problems downstream.

Let's break down when each approach makes sense and how to scale intelligently between them.

When Rapid Prototyping Makes Sense

Prototyping serves one primary purpose: reducing risk before you commit significant resources. When you're testing a new product concept, validating fit with mating components, or exploring design variations, prototypes let you fail cheaply.

Rapid prototyping typically applies when you need:

- Design validation: Confirming that CAD models translate correctly into physical parts

- Functional testing: Verifying that components perform under real-world conditions

- Stakeholder approval: Providing tangible samples for decision-makers to evaluate

- Assembly verification: Ensuring parts integrate properly with existing systems

- Market feedback: Gathering user input before finalizing specifications

Early prototypes generally fall into two categories. "Works-like" prototypes focus on validating core functionality—they might look rough but prove the concept works. "Looks-like" prototypes simulate the final product's form and finish, useful for investor pitches or marketing materials without the full functionality.

The cost of building a few prototypes is often surprisingly close to building just one. Why? Setup time, material handling, and programming costs get amortized across multiple units. Services like SendCutSend and Oshcut have made small-batch prototyping more accessible, offering online quoting for quick-turn laser cutting and bending. Metal fabricators near me searches often surface local shops capable of similar rapid turnaround.

Most importantly, having extra prototypes proves invaluable during ongoing development. You can leave samples with key customers for feedback without worrying about losing your only test unit.

Scaling from Prototype to Production

The journey from one-off prototype to full-scale manufacturing involves critical inflection points where costs drop significantly. Understanding these transitions helps you plan investments wisely.

Small production runs (10-20 units) offer the first major cost reduction. Instead of fabricating parts one at a time, processes like laser cutting and CNC machining optimize material use across multiple parts. Batch assembly allows workflow optimizations, and buying fasteners in minimum order quantities becomes practical. A single prototype might cost $500, while ten identical units might total $1,200—a dramatic per-unit savings.

Mid-volume production (100-200 units) unlocks additional opportunities. At this scale, sheet metal forming and die cut machine operations become more cost-effective compared to purely laser-cut parts. Simple automation aids—pneumatic presses, fixture-based assembly, guided fastener placement—improve consistency while reducing labor costs. These investments, when spread across the production run, drive further savings on follow-up orders.

Full production (1,000+ units) introduces supply chain optimization, systematic quality controls, and ongoing value analysis. Established supplier relationships, just-in-time inventory, and negotiated material rates continue lowering piece prices throughout the program lifecycle.

A common mistake? Over-tooling too soon based on optimistic sales projections. Investing in expensive production tooling, only to require modifications after discovering manufacturing issues or receiving new user insights, wastes resources that could have funded additional prototyping iterations.

Cost Considerations at Different Volumes

The economics of prototyping versus production differ dramatically. Understanding these tradeoffs prevents budget surprises and helps you allocate resources appropriately.

| Factor | Prototyping | Production Runs |

|---|---|---|

| Per-unit cost | Higher due to setup amortization across few parts | Lower as fixed costs spread across many units |

| Tooling investment | Minimal—uses flexible processes like laser cutting | Potentially significant for dies, fixtures, and automation |

| Lead time | Days to weeks depending on complexity | Weeks to months including tooling development |

| Design flexibility | High—changes cost little beyond reprinting/recutting | Low—tooling modifications expensive once committed |

| Quality consistency | Variable—acceptable for validation purposes | Highly controlled with statistical process monitoring |

| Typical methods | Laser cutting, 3D printing, manual assembly | Progressive dies, die cut machine stamping, automated welding |

| Best for | Validation, iteration, small-batch needs | Proven designs with confirmed demand |

Simple low-cost prototypes might run $100 to $1,000. Functional prototypes with moderate complexity typically cost $1,000 to $10,000. Production-ready, high-fidelity prototypes can exceed $10,000—but catching a critical flaw at this stage still costs far less than discovering it during mass production.

The key insight? Prototyping isn't an expense to minimize—it's an investment in risk reduction. Each dollar spent validating designs before production potentially saves ten or more dollars in avoided rework, scrapped parts, and field failures.

When evaluating sheet metal fabrication companies, look for partners who understand this progression. The best fabricators don't just execute orders—they help you determine the appropriate scale for each project phase, balancing validation needs against timeline and budget constraints. With volume considerations understood, the next question becomes: how do these dynamics change across different industry applications?

Industry Applications and Specialized Requirements

So you understand fabrication techniques, materials, and workflow stages. But here's what many buyers overlook: sheet metal fabrication companies don't serve all industries equally. Each sector brings unique requirements, certifications, and component specifications that shape how fabricators approach projects.

Why does this matter? Choosing a fabricator unfamiliar with your industry's demands often leads to costly mistakes—rejected parts, failed inspections, or components that don't perform under real-world conditions. Let's explore what different sectors actually require from their fabrication partners.

Automotive and Transportation Components

The automotive sector represents one of the largest consumers of fabricated metal sheet components. From structural chassis elements to decorative trim pieces, vehicles contain hundreds of sheet metal parts that must meet exacting standards.

What makes automotive fabrication unique? Consider these industry-specific demands:

- IATF 16949 certification: This automotive quality management standard builds on ISO 9001, adding specific requirements for defect prevention, reduction of variation, and waste elimination in the supply chain

- Tight dimensional tolerances: Body panels and structural components must fit precisely within complex assemblies—variations of just 0.5mm can cause alignment problems

- High-volume consistency: Automotive production runs often exceed tens of thousands of units, requiring statistical process control throughout manufacturing

- Weight optimization: Fuel efficiency regulations drive demand for lighter components without sacrificing strength or crash protection

Common automotive components produced through sheet metal fabrication include body panels, floor pans, frame rails, brackets and mounting plates, bumper reinforcements, and fluid tanks. According to industry analysis, over 50% of car parts and components are manufactured from sheet metal using various fabrication processes.

Transportation extends beyond passenger vehicles. Buses, lorries, trailers, rail cars, and even marine vessels rely heavily on fabricated metal plate and sheet components. Ships, submarines, and commercial vessels require galvanized sheet metal or marine-grade alloys to withstand saltwater exposure.

Electronics Enclosures and Housings

Ever opened a server rack, industrial control panel, or telecom cabinet? Those precision enclosures protecting sensitive electronics represent some of the most demanding sheet metal fabrication work.

Electronics fabrication requires attention to factors that don't apply in other industries:

- EMI/RFI shielding: Enclosures must block electromagnetic interference—this requires specific material choices and seamless construction without gaps that allow signal leakage

- Thermal management: Precision ventilation patterns, heat sink mounting provisions, and airflow optimization keep components within operating temperatures

- Cosmetic finish quality: Consumer-facing electronics demand flawless surfaces—every scratch, dent, or coating imperfection becomes visible

- Access and serviceability: Removable panels, hinged doors, and captive fasteners enable maintenance without specialized tools

Beyond enclosures, electronics applications include chassis for computing equipment, brackets and mounts for circuit boards, heat sinks and thermal spreaders, and custom metal signs and nameplates for product identification. The corrugated metal patterns sometimes seen on equipment housings aren't just decorative—they add structural rigidity without increasing material thickness.

One question that occasionally arises: is aluminum a metal suitable for electronics enclosures? Absolutely—aluminum's combination of light weight, electrical conductivity for grounding, and corrosion resistance makes it ideal for many electronic housing applications.

Construction and Architectural Applications

Walk through any modern building and you'll encounter fabricated sheet metal at every turn. From structural elements hidden within walls to decorative facades defining a building's character, construction consumes enormous quantities of fabricated metal components.

The Walt Disney Concert Hall in Los Angeles exemplifies what's possible—its iconic stainless steel exterior features complex curves created through advanced sheet metal fabrication techniques. But architectural applications extend far beyond landmark buildings:

- Exterior cladding and facades: Weather-resistant metal panels protect building envelopes while creating distinctive appearances

- Roofing systems: Standing seam metal roofs, flashings, and copings require precise forming to ensure watertight performance

- HVAC components: Ductwork, diffusers, and equipment housings move and condition air throughout buildings

- Interior elements: Elevator interiors, wall panels, ceiling systems, and decorative metalwork define interior spaces

- Structural supports: Brackets, hangers, and connection plates transfer loads throughout building frames

Material selection in construction applications often involves copper for its distinctive aging patina, architectural bronze (what is brass made of at its core—copper alloyed with zinc and other elements), and various stainless steel grades depending on environmental exposure.

Construction projects frequently require galvanized sheet metal for steel components exposed to moisture. The zinc coating protects base metal from corrosion, extending service life in demanding environments. For coastal buildings, fabricators might specify Muntz metal or naval brass—alloys specifically designed to resist saltwater corrosion.

Industrial equipment represents another major fabrication sector, with manufacturers producing machine guards, control panel enclosures, conveyor components, and structural frames. These applications often prioritize durability and functionality over cosmetic appearance, allowing different finishing approaches than consumer-facing products.

Understanding your industry's specific requirements helps you evaluate whether potential fabrication partners have relevant experience. A shop excelling at automotive components might struggle with the cosmetic demands of electronics enclosures. Conversely, a fabricator specializing in architectural metalwork may lack the certifications required for aerospace applications.

This industry-specific knowledge becomes even more valuable when you understand the common mistakes that derail projects across all sectors—mistakes that experienced fabricators help you avoid from the start.

Common Project Mistakes and How to Avoid Them

Here's an uncomfortable truth: nearly half of sheet metal fabrication projects experience significant delays due to preventable errors. According to manufacturing research, a staggering 50% increase in project delays can occur due to insufficient planning alone. And about 25% of project budgets get lost to fabrication mistakes.

The good news? Most of these errors follow predictable patterns. Once you recognize them, you can sidestep the pitfalls that trip up less-informed buyers. Think of this as insider knowledge that separates smooth projects from frustrating failures.

Design Specification Pitfalls to Avoid

Design errors rank among the most expensive mistakes in sheet metal fabrication. Why? Problems discovered during production cost exponentially more to fix than issues caught during design review. Yet buyers routinely submit specifications with preventable flaws.

Consider the most common design-related mistakes and their solutions:

- Mistake: Holes placed too close to bends. When features sit within one material thickness of bend lines, forming operations distort or damage them. Solution: Maintain minimum clearances—typically 2.5 times material thickness plus bend radius—between holes and bend locations.

- Mistake: Overly tight tolerances on non-critical features. Specifying ±0.1mm when ±0.5mm works perfectly fine drives up costs and rejection rates without improving functionality. Solution: Apply functional tolerancing—tight specifications only where assembly or performance actually requires them.

- Mistake: Ignoring grain direction. Metal sheets have a grain direction that affects formability. Bending perpendicular to grain produces cleaner results than bending parallel. Solution: Specify grain orientation for critical bends, or consult fabricators during design review.

- Mistake: Impossible internal radii. Specifying bend radii smaller than material thickness causes cracking during forming. Solution: Use minimum bend radius equal to or greater than material thickness for most applications.

- Mistake: Incomplete drawings. Missing dimensions, unclear tolerances, or ambiguous finishing requirements force fabricators to guess—and guesses often prove wrong. Solution: Provide complete CAD files with explicit callouts for every critical dimension, surface finish, and hardware requirement.

The underlying principle? Design for manufacturability from the start. Industry best practices recommend early collaboration between design engineers and fabrication suppliers to catch issues before they become expensive problems.

Material Selection Mistakes

Choosing the wrong material derails projects in ways that aren't always immediately obvious. Studies indicate that approximately 51% of fabrication errors stem from material selection issues.

What goes wrong? Designers often focus on strength or appearance while overlooking factors like bendability, corrosion resistance, and forming limits. Here's what to watch for:

- Mistake: Selecting based solely on cost. The cheapest material rarely proves cheapest overall when processing difficulties, rework, or premature failure enter the equation. Solution: Evaluate total lifecycle cost including fabrication complexity, finishing requirements, and expected service life.

- Mistake: Ignoring environmental conditions. Carbon steel in humid environments corrodes rapidly. Standard aluminum grades fail in saltwater exposure. Solution: Match material properties to the actual operating environment—marine applications need marine-grade alloys.

- Mistake: Overlooking formability requirements. Some alloys bend beautifully; others crack. 6061 aluminum, for instance, is excellent for machining but problematic for tight bends. Solution: Verify that selected materials can withstand your specific forming operations.

- Mistake: Confusing similar-sounding specifications. 304 versus 316 stainless steel might seem interchangeable until chloride exposure causes premature failure of the wrong grade. Solution: Understand exactly why specific grades are specified and resist substitutions without engineering review.

One question that occasionally arises during material discussions: what is brass made of, and how does it compare to bronze? Brass combines copper with zinc, while bronze alloys copper with tin and other elements. Understanding these distinctions matters when specifying decorative or corrosion-resistant components.

Similarly, buyers sometimes ask: is aluminum a metal suitable for their specific application? Absolutely—but with over a dozen common alloys offering different properties, selecting the right grade requires understanding your performance requirements.

Timeline and Communication Best Practices

Even perfect designs and optimal materials can't save projects plagued by poor communication or unrealistic expectations. About 30% of structural failures trace back to welding and fabrication errors that proper communication could have prevented.

Consider these timeline and communication pitfalls:

- Mistake: Underestimating lead times. Complex assemblies need weeks, not days. Specialty finishes add time. Holiday schedules affect availability. Solution: Discuss realistic timelines during quoting—then add contingency for unexpected issues.

- Mistake: Slow response to fabricator questions. When fabricators ask clarifying questions, delayed answers stall production. A two-day response delay can cascade into a two-week schedule slip. Solution: Designate a single point of contact authorized to make decisions quickly.

- Mistake: Changing specifications mid-production. Design changes after fabrication begins often require scrapping completed work and starting over. Solution: Freeze specifications before production starts; save changes for the next order.

- Mistake: Assuming fabricators will catch your errors. Quality shops provide DFM feedback, but they can't read minds. Unclear requirements lead to parts built exactly as specified—even when specifications contain mistakes. Solution: Take responsibility for thorough specifications and actively participate in design reviews.

Welding-specific considerations deserve special attention. When comparing mig vs tig welding approaches, understand that each method suits different applications. MIG welding offers speed for general fabrication, while TIG welding delivers precision for visible joints or thin materials. The tig vs mig welding choice affects both cost and quality—discuss requirements with your fabricator early.

Similarly, when decorative appearance matters, understanding brass vs bronze characteristics helps specify appropriate materials. Bronze typically offers better corrosion resistance; brass provides easier machining and a brighter appearance.

The overarching lesson? Fabrication success depends as much on partnership quality as technical specifications. Communication research confirms that companies establishing clear channels, regular check-ins, and documented expectations experience fewer misunderstandings and faster issue resolution.

Avoiding these common mistakes positions your project for success. But identifying reliable fabrication partners who help you sidestep these pitfalls—rather than letting you stumble into them—requires knowing what capabilities and credentials to evaluate.

How to Evaluate Sheet Metal Fabrication Partners

You've learned the techniques, understood materials, and identified common pitfalls. Now comes the decision that determines whether your project succeeds or struggles: choosing the right fabrication partner. This isn't simply about finding the lowest quote—it's about identifying a partner whose capabilities, quality systems, and communication practices align with your specific requirements.

According to manufacturing industry research, partnering with the right metal fabricator is crucial to ensure product quality, yet finding that partner remains easier said than done. Every fabrication company offers something unique, but only a handful will meet your complete checklist of requirements.

What separates adequate fabricators from exceptional partners? Let's examine the evaluation criteria that matter most.

Certifications That Matter

Certifications provide independent verification that fabricators maintain consistent quality systems. While certifications alone don't guarantee excellent results, their absence often signals inadequate process controls.

Here's what to look for:

- ISO 9001: The foundational quality management standard. If a fabricator lacks even this basic certification, question whether they maintain documented processes and systematic quality controls.

- IATF 16949: Essential for automotive supply chains. This certification builds on ISO 9001, adding specific requirements for defect prevention, variation reduction, and waste elimination. Fabricators serving automotive OEMs or Tier 1 suppliers typically require this credential. Companies like Shaoyi (Ningbo) Metal Technology maintain IATF 16949 certification specifically to meet automotive industry demands for chassis, suspension, and structural components.

- AS9100: The aerospace equivalent of automotive's IATF 16949. Required for aviation, space, and defense applications where component failure carries catastrophic consequences.

- ITAR registration: Necessary when projects involve defense-related articles. ITAR compliance ensures proper handling, documentation, and traceability for controlled items.

- NADCAP accreditation: Validates special processes like welding, heat treatment, or non-destructive testing meet aerospace requirements.

Beyond certifications, ask about inspection processes. First-article inspections verify initial production parts meet specifications. In-process checks catch drift before problems compound. Final audits ensure consistency across completed batches. Fabricators with stringent quality assurance can deliver defect-free production—a critical factor when your components require specific tensile strength values or precise dimensional tolerances.

Evaluating Equipment and Capabilities

Equipment capabilities directly affect what your partner can produce—and how efficiently. Modern CNC equipment, well-maintained tooling, and appropriate capacity for your volumes all matter.

When evaluating potential partners, investigate these capability areas:

- Material processing range: What thickness can they handle? What materials—steel, 316 stainless steel, aluminum, copper—do they work with regularly? If your project requires specialty alloys, confirm relevant experience.

- Precision capabilities: How tight are achievable tolerances? Some equipment achieves ±0.1mm repeatability; other machines cannot consistently hold ±0.5mm. Match capabilities to your actual requirements.

- Production capacity: Can they handle your volumes without creating bottlenecks? A shop running at 100% capacity struggles to accommodate rush orders or unexpected demand spikes.

- Secondary services: Do they offer in-house powder coating services, anodizing, hardware insertion, or assembly? Industry analysis confirms that all-in-one partners help streamline production and improve turnaround time while reducing costs.

- Prototyping speed: Quality fabricators offer rapid prototyping capabilities—some delivering prototypes within 5 days—enabling design validation before committing to production tooling.

The best partners invest in modern equipment that balances precision with efficiency. Ask about recent capital investments. Shops running decades-old equipment may struggle with tight tolerances or complex geometries that newer machines handle routinely.

Questions to Ask Potential Partners

Beyond certifications and equipment lists, direct conversations reveal how fabricators actually operate. The right questions uncover whether a potential partner will deliver smoothly or create headaches.

Start with these essential inquiries:

- Can you build a prototype first? This reveals their flexibility and allows you to assess quality before committing to production quantities.

- What's your typical quote turnaround? Responsive fabricators provide quotes within 12-24 hours for standard projects. If quoting requires weeks, expect similar delays throughout your project. Some industry-leading fabricators, including Shaoyi, offer 12-hour quote turnaround to accelerate project timelines.

- Do you provide DFM support? Design for Manufacturability feedback catches problems early. Fabricators offering comprehensive DFM support help optimize your designs for efficient production—reducing costs while improving quality.

- Who will be my point of contact? Knowing your dedicated contact streamlines communication. Projects bouncing between multiple people often experience miscommunication and delays.

- What's your on-time delivery rate? Top performers achieve 98% or better on-time delivery. Rates below 90% suggest systemic issues with scheduling or capacity management.

- How do you handle design changes mid-production? Flexibility matters, but so does understanding the cost and schedule implications of changes.

- What finishing options do you offer? Powder coat finishes, anodized aluminum surfaces, and other treatments often occur in-house at full-service fabricators—eliminating the need to coordinate with separate finishing vendors.

Don't hesitate to request samples of previous work. Industry experts recommend examining samples to determine quality levels and verify they match your requirements. Samples reveal more about actual capabilities than any brochure or website ever could.

Also inquire about repeatability. If some parts in a batch prove exceptional while others are nearly unusable, your production becomes unreliable. Consistent quality across every unit—whether you're ordering 10 parts or 10,000—distinguishes professional fabricators from shops producing inconsistent results.

For automotive and precision manufacturing applications, partners combining rapid prototyping, certified quality systems, and comprehensive engineering support deliver the reliability your projects demand. The evaluation process takes time upfront but prevents costly problems downstream.

With evaluation criteria established, you're ready to translate this knowledge into action—preparing your project requirements and initiating partnerships that deliver results.

Taking the Next Steps With Your Fabrication Project

You've covered substantial ground—from understanding fabrication techniques and material specifications to recognizing common pitfalls and partner evaluation criteria. Now comes the moment that transforms knowledge into action. Whether you're exploring options for the first time, comparing potential fabricators, or ready to launch your next project, specific next steps apply to your situation.

Think of this as your roadmap forward. Each stage of the fabrication journey requires different preparation, and approaching partners with the right information dramatically improves your outcomes.

Preparing Your Project Requirements

Before reaching out to any fabricator, invest time organizing your project documentation. According to manufacturing industry guidance, thorough preparation ensures faster quotes, accurate pricing, and shorter lead times.

Gather these essential elements:

- Complete CAD files and drawings: Provide both 2D prints showing dimensions, tolerances, and specifications alongside 3D models that reveal interior features and assembly relationships

- Material specifications: Identify exact grades—not just "steel" but "304 stainless steel" or "5052 aluminum"—along with thickness requirements using both gauge and decimal measurements

- Quantity requirements: Specify initial order quantities plus anticipated annual volumes, as this affects tooling recommendations and pricing structures

- Tolerance callouts: Apply functional tolerancing—tight specifications only where performance demands them—to avoid unnecessary cost increases

- Finishing requirements: Detail surface treatments, coating specifications, and any special marking or labeling needs

- End-use context: Explain your application so fabricators can make informed recommendations and catch potential issues

This preparation demonstrates professionalism that fabricators appreciate. As industry experts note, thorough documentation builds the foundation for strong partnerships—fewer misunderstandings, more accurate quotes, and reliable parts.

Getting Started With Your First Quote

With documentation prepared, you're ready to engage potential partners. Rather than blasting RFQs to every metal cutter or fabricator you can find, be selective based on the evaluation criteria discussed earlier.

Follow this approach for effective quoting:

- Research capabilities first: Verify that potential partners handle your material types, thickness ranges, and production volumes before sending inquiries

- Submit complete packages: Include all drawings, specifications, and context in your initial request—incomplete RFQs delay responses and often produce inaccurate quotes

- Request DFM feedback: Ask fabricators to identify potential design improvements alongside their pricing—this reveals their engineering depth

- Compare apples to apples: Ensure all quotes address identical specifications before comparing prices—variations in assumptions create misleading comparisons

- Evaluate responsiveness: Quote turnaround time indicates how communication will flow throughout your project

For buyers sourcing metal sheets and raw materials separately from fabrication services, online metals suppliers offer convenient purchasing. However, most fabricators prefer quoting with material included to ensure specifications match their processing requirements.

Building Long-Term Fabrication Partnerships

The most successful buyers don't just find vendors—they develop strategic partnerships that improve over time. Supply chain research confirms that clearly defined expectations, consistent communication platforms, and tracked performance metrics create relationships benefiting both parties.

Consider these partnership-building practices:

- Start with prototypes: Test relationships with smaller projects before committing to large production runs

- Establish communication protocols: Define preferred contact methods, response time expectations, and escalation procedures from the beginning

- Track key metrics: Monitor on-time delivery performance, quality consistency, and cost alignment against quotes

- Provide constructive feedback: Share both positive results and improvement opportunities—partners can't improve without knowing where they fall short

- Plan for growth: Discuss future volume projections so partners can invest in appropriate capacity and capabilities

For automotive or precision manufacturing applications requiring IATF 16949-certified quality, rapid prototyping capabilities, and comprehensive DFM support, partners like Shaoyi (Ningbo) Metal Technology exemplify the combination of certifications, engineering depth, and responsive service discussed throughout this article. Their 5-day prototyping and 12-hour quote turnaround demonstrate the operational capabilities that distinguish premium fabrication partners.

Your fabrication journey doesn't end with finding the right partner—it evolves as projects progress and relationships deepen. Apply the knowledge you've gained, avoid the costly mistakes that derail projects, and build partnerships that deliver reliable results order after order.

Frequently Asked Questions About Sheet Metal Fabrication Companies

1. What services do sheet metal fabrication companies provide?

Sheet metal fabrication companies transform flat metal sheets into functional components through cutting, bending, welding, and assembly processes. Services typically include laser cutting, CNC punching, press brake bending, MIG and TIG welding, hardware insertion, and surface finishing options like powder coating and anodizing. Many fabricators also offer design consultation, DFM (Design for Manufacturability) reviews, prototyping, and quality inspection services. Full-service partners like IATF 16949-certified manufacturers provide comprehensive engineering support from initial design through final delivery.

2. How do I find the best sheet metal fabrication companies near me?

To find quality sheet metal fabrication partners, evaluate certifications (ISO 9001, IATF 16949 for automotive), equipment capabilities, and production capacity. Request samples of previous work to assess quality levels. Ask about quote turnaround times, DFM support offerings, on-time delivery rates, and in-house finishing services. Compare multiple fabricators based on their experience with your specific materials, thickness ranges, and industry requirements. Local searches can identify nearby options, but don't overlook specialized manufacturers who offer overnight shipping from facilities optimized for your application.

3. What materials are commonly used in sheet metal fabrication?

Common materials include carbon steel (A36, A1011, A1008), stainless steel (304, 316, 430 grades), and aluminum alloys (3003, 5052, 5083, 6061). Carbon steel offers strength and cost-effectiveness but requires corrosion protection. 304 stainless steel suits general-purpose applications, while 316 stainless provides enhanced chloride resistance for marine environments. Aluminum grades vary in formability and strength—5052 excels in marine applications, while 6061 is preferred for machined parts. Material selection should balance mechanical properties, corrosion resistance, formability, and total lifecycle cost.

4. How much does custom sheet metal fabrication cost?

Fabrication costs depend on material type, thickness, complexity, quantity, and finishing requirements. Simple prototypes may cost $100-$1,000, while functional prototypes with moderate complexity typically range from $1,000-$10,000. Per-unit costs decrease significantly with volume—setup costs spread across more parts, and batch processing improves efficiency. Production runs of 100+ units unlock additional savings through optimized tooling and automation. Request quotes with complete specifications including CAD files, material grades, tolerances, and finishing requirements for accurate pricing.

5. What is the difference between sheet metal fabrication and metal stamping?

Sheet metal fabrication uses flexible processes like laser cutting, CNC bending, and welding to create custom components—ideal for prototypes and low-to-medium volumes. Metal stamping uses dedicated dies to produce high-volume parts through progressive or transfer press operations. Fabrication offers design flexibility with minimal tooling investment, while stamping provides lower per-unit costs at production quantities exceeding thousands of units. Many manufacturers, including automotive suppliers like Shaoyi, offer both capabilities—fabrication for prototyping and stamping for mass production—enabling seamless scaling from development to full production.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —