Stamping Automotive Structural Reinforcements: The Engineering Guide

TL;DR

Stamping automotive structural reinforcements is a high-stakes manufacturing discipline that balances two opposing forces: maximizing crashworthiness and minimizing vehicle weight (lightweighting). The industry standard for safety-critical components like A-pillars and door rings has shifted toward Hot Stamping (Press Hardening) of Boron steels, which achieves tensile strengths exceeding 1,500 MPa without the issue of springback. However, Cold Stamping remains vital for aluminum EV battery housings and less complex geometries where cost-efficiency is paramount. Success in this sector requires navigating advanced materials, managing tight tolerances, and selecting the right press tonnage for mass production.

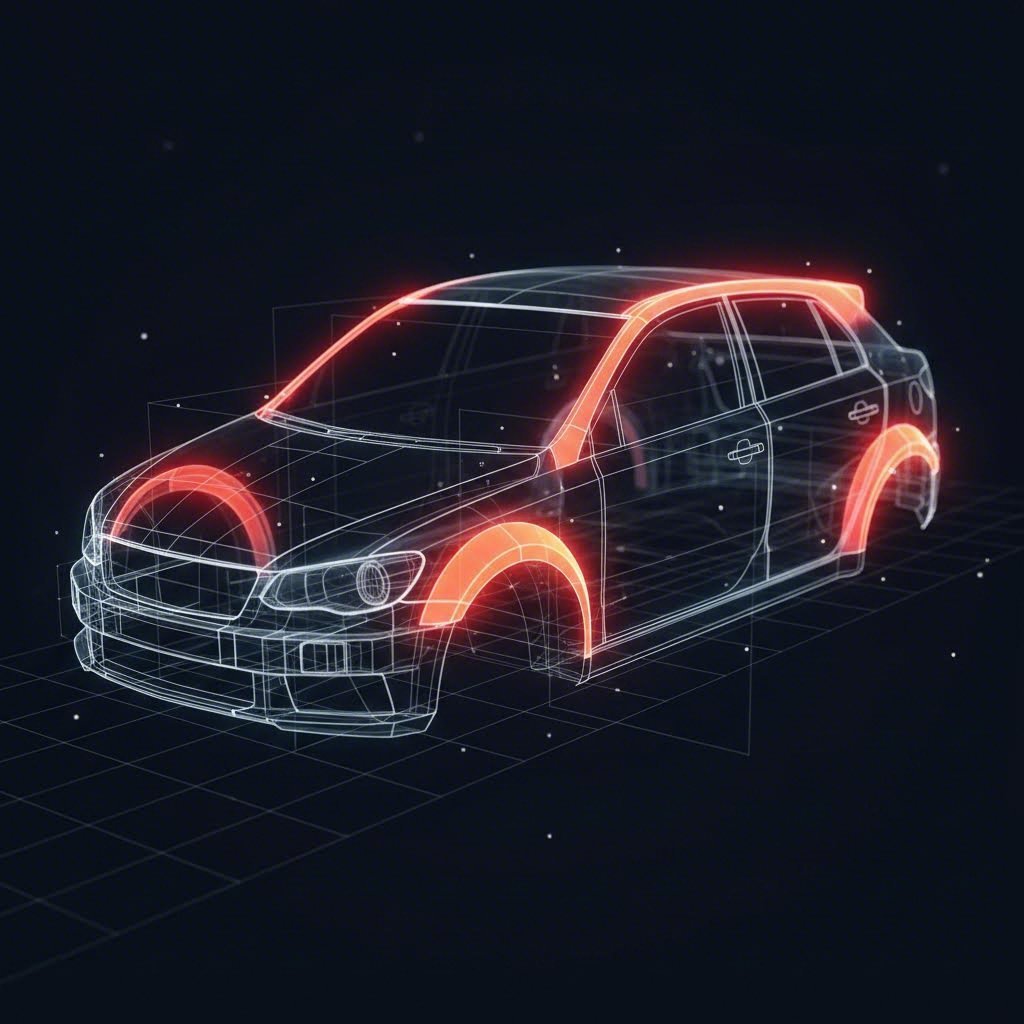

The Engineering Challenge: Why Structural Reinforcements Are Unique

In the context of the automotive Body-in-White (BIW), structural reinforcements are the skeleton that protects occupants during a collision. Unlike cosmetic body panels (skin), these components—including A-pillars, B-pillars, rocker panels, roof rails, and cross-members—must absorb and redirect immense kinetic energy. The fundamental engineering challenge lies in the "lightweighting imperative." As emission regulations tighten and electric vehicles (EVs) demand range maximization, engineers cannot simply add thicker steel to increase safety.

Instead, the industry relies on Advanced High-Strength Steels (AHSS) and aluminum alloys. While mild steel typically offers a yield strength of around 200 MPa, modern press-hardened steels used in reinforcements can exceed 1,500 MPa (approx. 217 ksi). This allows for thinner gauges that reduce weight while maintaining or improving structural integrity.

However, stamping these high-performance materials introduces significant manufacturing hurdles. The primary enemy in cold stamping high-strength materials is springback—the tendency of the metal to return to its original shape after the forming force is removed. This makes achieving tight tolerances in complex geometries notoriously difficult, often requiring sophisticated simulation software and servo-press technology to compensate.

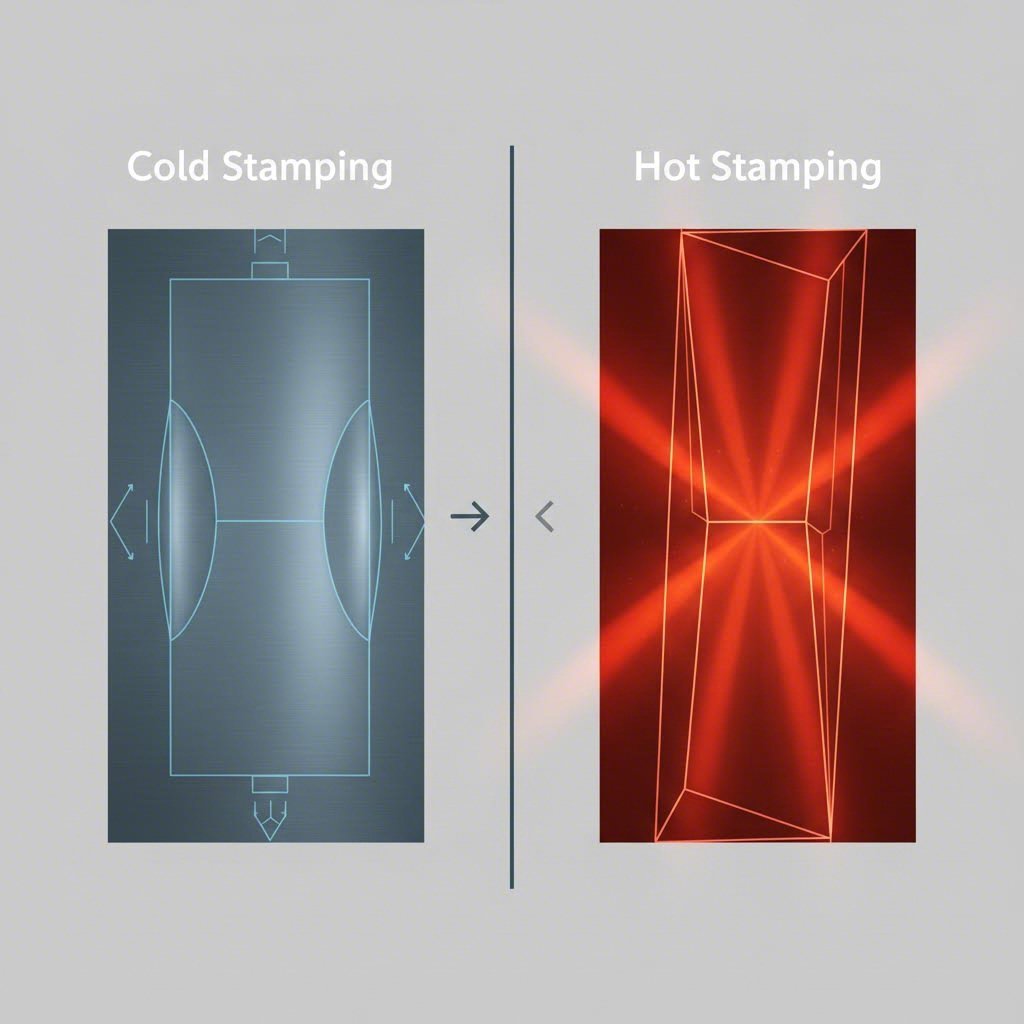

Process Comparison: Hot Stamping (Press Hardening) vs. Cold Stamping

The choice between hot and cold stamping is the central process decision for structural reinforcements. Each method has distinct mechanics, costs, and material implications.

Hot Stamping (Press Hardening)

Hot stamping, or press hardening, is the dominant method for safety-critical cage components. The process involves heating Boron steel blanks to approximately 900°C (1,650°F) until they reach an austenitic state. The red-hot blank is then transferred quickly to a water-cooled die where it is formed and quenched simultaneously.

This rapid cooling transforms the steel’s microstructure from austenite to martensite, locking in the geometry and eliminating springback entirely. According to industry data, this process can elevate the tensile strength of Boron steel from an initial 50 ksi to over 200 ksi (approx. 1,380 MPa). This is why hot stamping produces safety-critical parts like door reinforcements and bumper beams that are both ultra-strong and dimensionally precise.

Cold Stamping

Cold stamping occurs at room temperature and relies on the material's plasticity. While it is faster and energy-efficient (no heating required), it faces limitations with ultra-high-strength materials due to work hardening and springback. However, advancements in servo press technology—which allows for precise control of ram speed and dwelling force—have expanded cold stamping's capabilities. It remains the preferred method for aluminum components and structural parts with simpler geometries or lower strength requirements.

| Feature | Hot Stamping (Press Hardening) | Cold Stamping |

|---|---|---|

| Primary Material | Boron Steel (e.g., 22MnB5) | AHSS, Aluminum, Galvanized Steel |

| Tensile Strength | Extremely High (1,500+ MPa) | High (up to 1,180 MPa typical) |

| Springback | Virtually Eliminated | Significant (requires compensation) |

| Cycle Time | Slower (due to heating/cooling) | Fast (high strokes per minute) |

| Typical Parts | A/B Pillars, Door Rings, Bumper Beams | Cross Members, Brackets, Rails |

Material Science: AHSS, Boron Steel, and Aluminum

The performance of a stamped reinforcement is dictated by its material. The automotive sector has moved far beyond basic mild steel.

Boron Steel (22MnB5)

Boron steel is the backbone of hot stamping. The addition of boron significantly increases hardenability. In its initial state, it is relatively soft and formable, but after the press hardening process, it becomes exceptionally hard. This dual nature allows for the creation of complex shapes that rigidify into unyielding safety structures.

Aluminum Alloys (5xxx and 6xxx Series)

With the rise of EVs, aluminum is surging in popularity for battery enclosures and shock towers to offset heavy battery packs. Metal stamping plays a critical role in EV manufacturing by forming these lightweight alloys. However, aluminum is prone to cracking and tearing during deep drawing, requiring specialized lubricants and often multiple draw steps compared to steel.

Galvanized Steel

For underbody structural components exposed to road salt and moisture, corrosion resistance is non-negotiable. Galvanized steel, which features a zinc coating, is widely used for chassis components and rails. Stamping galvanized material requires careful die maintenance, as the zinc coating can flake (galling) and build up on the tooling, affecting part quality.

Bridging the Gap: From Prototype to Mass Production

Selecting a stamping partner for structural reinforcements is not just about finding the lowest piece price; it is about finding a supplier with the versatility to handle the entire product lifecycle. Automotive programs typically move from rapid prototyping to low-volume validation and finally to high-volume mass production. A fragmented supply chain where prototypes are made by one shop and production parts by another can lead to critical "translation errors" in tooling design and tolerance realization.

Ideally, an OEM or Tier 1 supplier should engage with a partner capable of scaling seamlessly. Essential capabilities include a wide range of press tonnages (e.g., 100 to 600 tons) to accommodate different part sizes and material gauges, as well as in-house tooling expertise to manage the transition from soft tooling to progressive hard dies.

For manufacturers seeking this level of integration, Shaoyi Metal Technology exemplifies the necessary competence. Certified to IATF 16949:2016 standards, they bridge the gap between engineering validation and volume manufacturing. Their capabilities range from delivering 50 prototype pieces in as little as five days to producing millions of critical components like control arms and subframes annually. Leveraging presses up to 600 tons and offering comprehensive secondary processes like welding and e-coating, they provide a streamlined solution for complex automotive structural needs.

Critical Applications: Key Structural Components

Different areas of the vehicle require distinct stamping strategies based on load paths and crash scenarios.

- The Safety Cage (Pillars & Door Rings): The A-pillar and B-pillar are the primary vertical supports preventing roof crush during a rollover. Modern manufacturing often utilizes "laser-welded blanks"—joining sheets of different thicknesses before stamping—to create a single B-pillar that is thick at the top (for strength) and thinner at the bottom (to manage deformation modes).

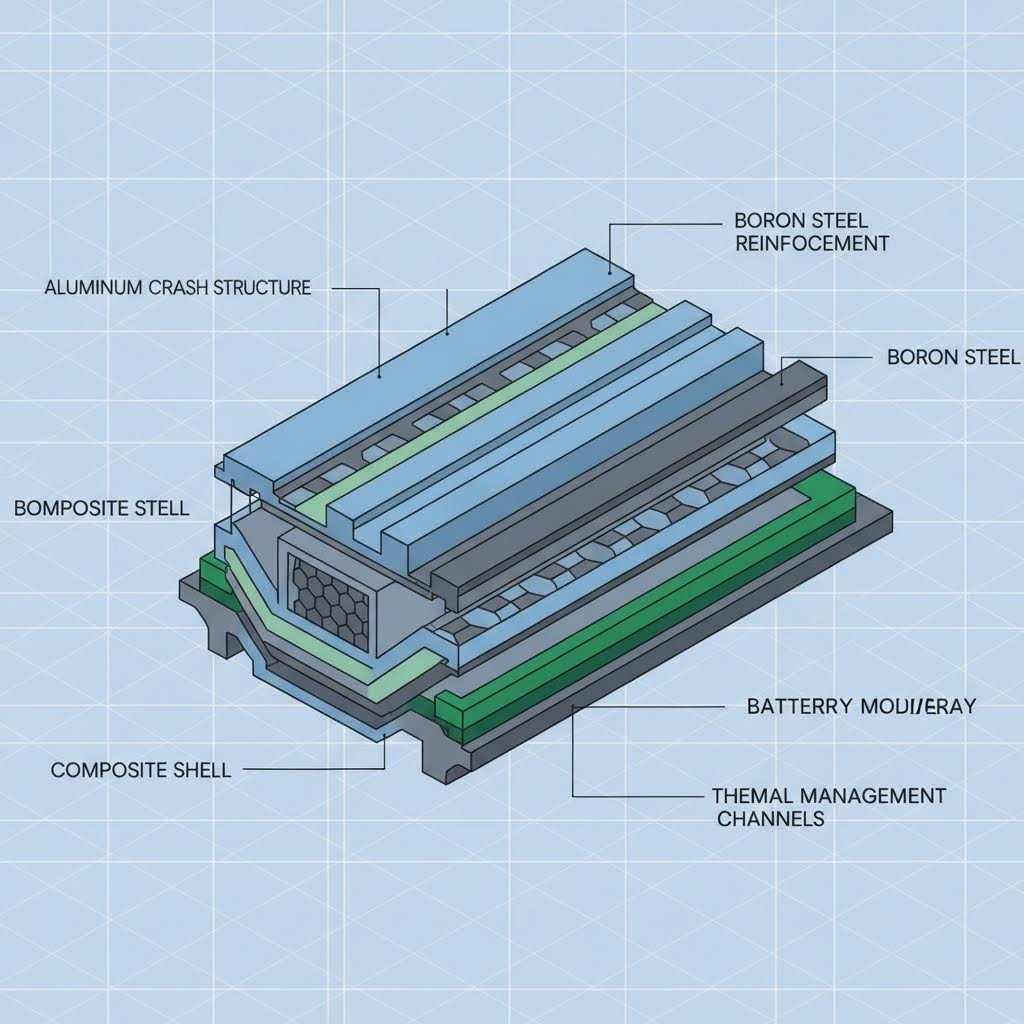

- EV Battery Enclosures: The battery tray is the most critical structural element in an electric vehicle. It must protect the battery modules from road debris and side-impact intrusion. These are typically large, shallow-drawn components often stamped from high-strength aluminum to keep weight down. Precision is vital here; the sealing surface must be perfectly flat to prevent water ingress.

- NVH Reduction Components: Not all structural parts are for crash safety. Brackets and cross-members often serve to stiffen the chassis to reduce Noise, Vibration, and Harshness (NVH). Precision stamping processes produce NVH reduction brackets that dampen road noise, contributing to the premium feel of the vehicle cabin.

Conclusion: The Multi-Material Future

The future of stamping automotive structural reinforcements lies in "the right material in the right place." We are moving away from monolithic steel bodies toward multi-material hybrids where hot-stamped boron steel pillars are joined to aluminum shock towers and composite roof rails. For engineers and procurement teams, this means the definition of a capable stamping partner is evolving. It is no longer enough to just stamp steel; the ability to simulate, form, and join diverse high-performance materials is the new benchmark for structural manufacturing excellence.

Frequently Asked Questions

1. What are the main advantages of hot stamping over cold stamping?

Hot stamping (press hardening) virtually eliminates springback, which is a major issue in cold stamping high-strength steels. It allows for the creation of complex geometric shapes with tensile strengths exceeding 1,500 MPa, making it ideal for safety-critical parts like B-pillars and door rings where dimensional accuracy and maximum strength are required.

2. How does the rise of EVs affect automotive stamping?

Electric vehicles require significant lightweighting to offset heavy battery packs, driving a shift toward aluminum stamping for structural parts like battery housings and subframes. Additionally, EV architectures require new types of reinforcements to protect the battery pack during side impacts, leading to larger, more integrated stamped components.

3. What is the role of IATF 16949 certification in stamping?

IATF 16949 is the global technical standard for quality management systems in the automotive industry. For a stamping supplier, this certification demonstrates they have rigorous processes for defect prevention, supply chain variation reduction, and continuous improvement, which is mandatory for supplying safety-critical structural parts to OEMs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —