Aluminium Alloy 6061 Specs Decoded (UNS A96061, 6061-T6)

Start with the essentials of aluminium alloy 6061

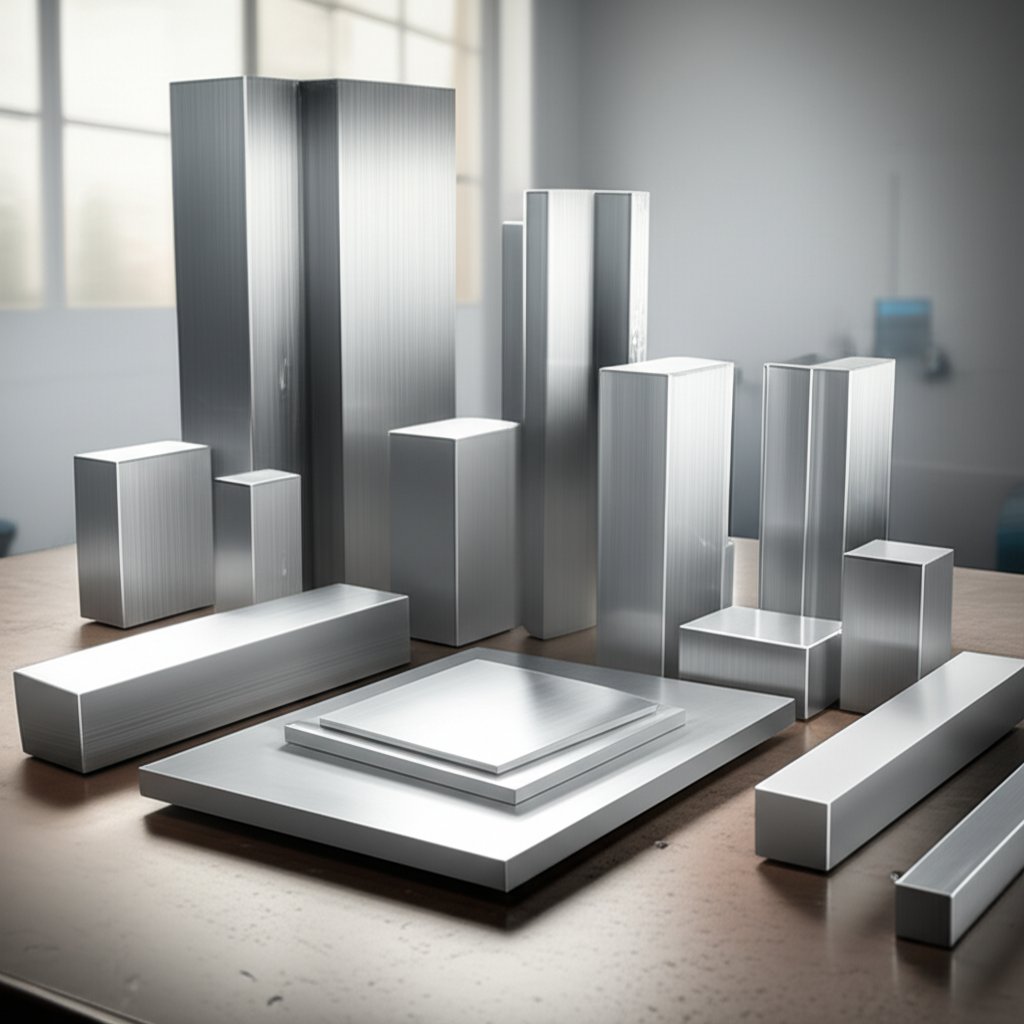

What Makes Aluminium Alloy 6061 So Versatile

When you scan a catalog for aluminum extrusions, plates, or sheets, one name pops up again and again: aluminium alloy 6061. But what exactly is it, and why is it everywhere in engineering, fabrication, and manufacturing? If you’re looking for a material that balances strength, workability, and corrosion resistance, 6061 aluminum is often the go-to choice. It’s not just a single product, but a family of material forms and temper conditions tailored for everything from bicycle frames to aerospace components.

- Solid strength-to-weight ratio for structural applications

- Excellent extrudability—ideal for complex profiles and shapes

- Balanced corrosion resistance for indoor and outdoor use

- Good weldability and machinability

- Broad availability in plate, sheet, bar, and extrusion forms

- Compatible with a wide range of finishes and coatings

How the 6xxx Series and Precipitation Hardening Work

Aluminium 6061 sits within the 6xxx series—a group of alloys that use magnesium and silicon as their main alloying elements. Sounds complex? Here’s the simple version: when magnesium and silicon are combined in the aluminum matrix, they form tiny, hard particles (precipitates) during a controlled heat treatment process known as precipitation hardening or age hardening. These particles block the movement of dislocations in the metal’s crystal structure, making the material stronger and tougher without making it brittle. This unique mechanism is what sets 6061 aluminum alloy apart from many other grades, giving designers a blend of formability in the soft state and strength after heat treatment (learn more about precipitation hardening).

Common Product Forms and Temper Codes You’ll See

When browsing supplier catalogs or standards, you’ll notice that a6061 material comes in a variety of shapes and tempers. The temper code (like T6 or O) tells you how the alloy was processed—whether it’s soft and formable, or hard and strong. Here’s a quick look at the typical product forms and where you might encounter them:

| Product Form | Typical Use-Cases |

|---|---|

| Extrusions | Frameworks, profiles for construction, automotive parts, custom shapes |

| Plate | Machined components, tooling, structural panels |

| Sheet | Enclosures, body panels, formed covers |

| Bar | Fasteners, shafts, small structural elements |

Each form can be supplied in multiple tempers, such as O (annealed), T4 (solution heat-treated and naturally aged), or T6 (solution heat-treated and artificially aged for maximum strength). Knowing which 6061 aluminum alloy temper you need is crucial for matching the material to your fabrication process and end-use requirements.

6061 is the general-purpose structural aluminum: reliable, adaptable, and specified worldwide for its balance of strength, workability, and corrosion resistance.

So, whether you’re searching for aluminium 6061 for a high-strength extrusion or a6061 material in plate for machining, this alloy’s combination of properties and broad availability makes it a trusted choice for engineers and fabricators alike. Understanding how it’s different from other aluminum alloys—and how the temper and product form affect its behavior—will help you make informed, confident decisions as you move deeper into the world of aluminum design.

Understand performance drivers and property tradeoffs

Strength, Stiffness, and Density Explained

When you design with aluminium alloy 6061, you’re balancing a set of properties that determine whether your part will perform as expected. Ever wondered why 6061 is so popular in both structural frames and precision-machined parts? It’s all about the interplay between strength, stiffness, and density. Let’s break down what that means in practice.

Strength refers to how much force the material can withstand before deforming or breaking. For most engineering applications, you’ll look at tensile strength (pulling apart) and yield strength (when permanent deformation begins). In the T6 temper, 6061 aluminum achieves a strong balance—enough for most load-bearing structures, yet not so hard that it becomes brittle or difficult to machine.

Stiffness, measured by the modulus of elasticity, tells you how much a part will flex under load. 6061’s modulus is typical for aluminum alloys, meaning it offers moderate rigidity—ideal for lightweight frames that must resist bending but don’t need the stiffness of steel. The density of 6061 aluminum is about 2.7 g/cm³, which is roughly one-third the density of steel. This low weight is a key reason why 6061 is used in aerospace and transportation, where every gram counts.

| Property | Typical Value (T6 Temper) | Notes |

|---|---|---|

| Ultimate Tensile Strength | 310 MPa (45,000 psi) | Varies by product form and thickness |

| Tensile Yield Strength | 276 MPa (40,000 psi) | AA; Typical |

| Modulus of Elasticity | 68.9 GPa (10,000 ksi) | Average of tension and compression |

| Density | 2.7 g/cm³ | No significant difference between T4 and T6 |

| Thermal Conductivity | 167 W/m-K | Typical at 77°F (25°C) |

| Electrical Resistivity | 3.99 × 10-6 ohm-cm | Typical at 68°F (20°C) |

| Corrosion Resistance | High | Improved by temper and surface finish |

Thermal and Electrical Behavior for Real-World Design

When you’re building something that needs to manage heat or carry electrical current, aluminum 6061 material properties come into play. Its thermal conductivity is high compared to most metals, making it a solid choice for heat sinks, housings, and panels that need to dissipate heat efficiently. The electrical resistivity is low (though not as low as pure aluminum), so it’s suitable for many electrical enclosures and connectors—but not for high-performance conductors.

Here’s a practical example: If you’re designing a drone frame or a bicycle component, the combination of low density, good strength, and high thermal conductivity means your part will be light, strong, and less likely to overheat during use. This is why 6061 t6 properties are often referenced in performance-critical applications.

How Temper and Product Form Influence Properties

Did you know that the exact numbers for 6061 aluminum properties depend not just on the alloy, but also on how it’s processed? The temper code (like T4 or T6) tells you the heat treatment path, which directly affects strength and ductility. T6 temper, for example, means the material has been solution heat-treated and artificially aged for maximum strength. O temper (annealed) is softer and more formable, ideal for parts that need to be bent or deep drawn before final strengthening.

Product form also matters. Plate, sheet, and extrusions can show slight differences in measured properties due to grain orientation, thickness, and processing history. That’s why it’s important to confirm the actual aa 6061 material properties for your specific product and temper, using supplier datasheets or trusted references (ASM MatWeb).

Match temper to the required strength and forming sequence to avoid re-heat-treating later.

- Anisotropy: Properties can vary with direction (rolling or extrusion direction), so check if your part is loaded along or across the grain.

- Thickness Effects: Thicker sections may have slightly lower strength due to slower cooling during processing.

- Surface Finish: Machined or coated surfaces can improve corrosion resistance and affect fatigue life.

Understanding these aluminium alloy 6061 properties helps you make smarter choices—whether you need a lightweight, stiff frame or a heat-dissipating enclosure. Next, we’ll explore how heat treatment tempers like T6 and T651 are developed, and why choosing the right temper is critical for both performance and fabrication success.

Master tempers and heat treatment for 6061

What Each 6061 Temper Means in Practice

When you see terms like O, T4, T6, or T651 next to aluminum alloy 6061, you might wonder—what do these codes really mean for your project? These temper designations describe the thermal and mechanical treatments the alloy has undergone, directly shaping its final properties in your hands. Choosing the right temper is key: it determines whether your 6061 part is easy to bend, ready for high-strength use, or optimized for precision machining.

- O (Annealed): The softest state. Maximum ductility and formability for deep drawing or complex bending. Used when extensive forming is required before final strengthening.

- T4 (Solution Heat-Treated & Naturally Aged): Good strength with high formability. Ideal for parts that need to be shaped after heat treatment but before final hardening.

- T6 (Solution Heat-Treated & Artificially Aged): The most common high-strength temper for 6061. Provides an excellent balance of strength, machinability, and corrosion resistance—think aerospace structures, bike frames, or automotive parts.

- T651 (T6 + Stress-Relieved by Stretching): Like T6, but with an extra step to minimize internal stresses. Chosen for tight-tolerance machining or when dimensional stability is critical.

From Solution Heat Treatment to Aging

Sounds technical? Imagine you’re baking a cake—timing and temperature matter. The heat treatment journey for 6061 tempers involves several precise steps to unlock the alloy’s full strength. Here’s how it works at a conceptual level:

- Solution Heat Treatment: The alloy is heated to a high temperature (about 530°C for 6061) so magnesium and silicon dissolve evenly into the aluminum matrix (see technical details).

- Quenching: The hot metal is rapidly cooled—often in water—to lock those elements in place, creating a supersaturated solid solution.

- Stress Relief (T651 only): After quenching, the material is stretched slightly (about 1-3%) to relieve internal stresses. This step is what distinguishes 6061-T651 from standard T6.

- Aging: The alloy is then heated at a lower temperature (around 175°C for 8 hours for 6061) to allow fine Mg2Si particles to form. This artificial aging dramatically increases the strength and hardness—what makes 6061 t6 aluminium so widely used in demanding applications.

Each step must be tightly controlled. Even small deviations in time or temperature can affect the final 6061-t6 aluminum properties and performance. For precise schedules, always consult the relevant ASTM, AMS, or Aluminum Association standards.

When to Choose T6 Versus T651

So, how do you decide between 6061 t6 aluminum and 6061-T651? It comes down to your project’s priorities. T6 is the default for most high-strength needs, but if you’re machining large, flat, or thin-walled parts, T651’s extra stress relief helps prevent warping and ensures better dimensional accuracy. Think of T651 as the go-to for CNC machining, molds, or critical jigs where even minor distortion could cause problems.

| Temper | Strength | Machinability | Formability | Residual Stress Control |

|---|---|---|---|---|

| O (Annealed) | Low | Moderate | Excellent | High |

| T4 | Medium | Good | Good | Moderate |

| T6 | High | Excellent | Moderate | Moderate |

| T651 | High | Excellent | Moderate | Excellent |

T651 goes one step further than T6—by stretching the alloy after quenching, residual stresses are minimized, making 6061-T651 the top pick for precision machining and dimensional stability.

For most applications, aa 6061 t6 will deliver the strength, hardness, and reliability you expect. But if you’re pushing the limits on part flatness or need to avoid distortion during heavy machining, 6061-t651 is worth the extra attention. Always verify your choice with supplier certifications and reference the Aluminum Association’s temper definitions or the latest ASTM/AMS standards for your specific product and application.

Now that you know how 6061 t6 density, temper, and process affect your finished part, it’s time to look at how welding and fabrication steps can influence the alloy’s final properties—especially in demanding structural projects.

Weld 6061 with confidence and fewer defects

Choose the Right Process for 6061 Welds

Ever struggled with cracks, porosity, or warping when welding 6061 aluminum? You’re not alone—this alloy’s high thermal conductivity and stubborn oxide layer make it challenging, but with the right approach, you can achieve strong, professional results. The most common processes for welding 6061 are TIG (GTAW) and MIG (GMAW), each with its own strengths. TIG welding gives you precise control and the cleanest welds, especially on thin material or intricate joints. MIG welding, on the other hand, is faster and better suited for thicker sections or production runs. Both methods require pure argon shielding gas and the right equipment—think AC-capable TIG machines or spool guns for MIG to handle soft aluminum wire.

Filler Metal Selection and Joint Prep

Choosing the right filler wire and prepping your joint are crucial for avoiding hot cracking and ensuring weld strength. For 6061-t6, ER4043 (Al-Si) and ER5356 (Al-Mg) are the go-to filler wires. ER4043 is less prone to cracking and offers good fluidity, while ER5356 provides higher strength and better color match for post-weld anodizing. Your choice depends on the application and finishing needs.

- Crack Sensitivity: Use ER4043 to minimize hot cracking in most 6061 welds.

- Color Match: Pick ER5356 if the part will be anodized and appearance matters.

- Corrosion Resistance: Both fillers offer good corrosion resistance, but always check compatibility if welding to other alloys.

- Post-Weld Strength: Neither filler fully restores 6061 t6 aluminum yield strength in the heat-affected zone (HAZ).

Preparation is everything. Cleanliness is non-negotiable—remove all grease, oils, and, most importantly, the oxide layer using a dedicated stainless steel or aluminum wire brush. Proper joint design (like V-grooves for thick plate) and fixturing help control distortion and ensure full penetration. Here’s a quick prep checklist:

- Degrease with a suitable solvent

- Remove oxide layer with a stainless/aluminum brush

- Fit-up parts with a small root gap (about 1/16")

- Tack weld at intervals to maintain alignment

- Control interpass temperature—don’t let parts overheat

- Post-weld cleaning to remove flux or oxidation

Inspection and Avoiding Common Weld Defects

Worried about hidden flaws? 6061 aluminum is prone to certain defects, but knowing what to look for—and how to prevent them—makes all the difference.

- Porosity: Caused by contamination or inadequate shielding. Prevent by meticulous cleaning and ensuring proper gas coverage.

- Hot Cracking: Minimized with the right filler (ER4043) and heat control.

- Lack of Fusion: Avoid by using correct travel speed and heat input.

For inspection, destructive and non-destructive methods can be used:

- Dye Penetrant Testing: Reveals surface-breaking cracks or porosity.

- Macro-Etch: Shows weld structure and fusion quality.

- Bend Testing: Assesses ductility and confirms absence of internal defects.

For code or safety-critical work, refer to standards like AWS D1.2 for specific acceptance criteria. Otherwise, focus on methodical visual and mechanical checks to ensure weld integrity.

The heat-affected zone in 6061-T6 will lose significant strength after welding—expect the 6061 t6 aluminum yield strength to drop by 30–50%. Only a full solution heat treatment and artificial aging can restore it to original levels. For most applications, design for a yield strength of 24 ksi (per AWS D1.2) in the HAZ, not the original T6 value. (see expert discussion)

In summary, welding aluminum 6061-t6 is a test of preparation, process control, and inspection discipline. Always remember: the yield strength of 6061 aluminum in the welded zone is not the same as in the parent T6 material—plan your designs and inspections accordingly to avoid surprises. Next, we’ll look at how to machine, cut, and form 6061 for the best results in your fabrication workflow.

Fabricate 6061 efficiently from saw to finished part

Machining 6061 for Accuracy and Finish

Ever wondered why some 6061 aluminum sheet metal parts machine cleanly while others suffer from burrs or chatter? The answer often lies in the temper and tooling strategy you choose. Machining 6061-T6—its most common high-strength form—offers excellent results with modern carbide tools. But if you need to bend or form parts before machining, starting with the softer O or T4 temper can make life much easier. After forming, you can always re-age to T6 for final strength.

| Operation | Recommended Tooling | Coolant/Lubrication | Notes |

|---|---|---|---|

| Milling | Sharp carbide end mills (2 or 3 flute, 35–45° helix) | Flood coolant or mist | Climb milling for best finish; use chipbreaker tools for high removal rates |

| Drilling | Polished carbide or HSS drills | Flood coolant or wax/oil stick | Peck drilling helps evacuate chips |

| Turning | Sharp carbide inserts, high-shear geometry | Light oil or mist coolant | Minimize dwell to reduce built-up edge |

| Sawing | Carbide-tipped blades (10–14 TPI for thick plate) | Light oil (WD-40) or cutting wax | Clamp securely; use lower TPI for thick 6061 plate |

For 6061 aluminum plate or 6061 t6 aluminum sheet, chip evacuation is critical—aluminum forms large, stringy chips that can clog flutes. Use tools with larger chip valleys and apply plenty of coolant or lubricant. High-efficiency milling strategies and variable helix tools can also help reduce chatter and improve surface finish.

Forming and Bending Without Cracks

When you try to bend 6061-T6, do you sometimes see cracks along the bend line? That’s because T6 temper is strong but not very ductile. If your part design allows, start with O (annealed) or T4 temper for forming, then heat treat to T6 after bending. If you must bend T6 directly, use larger inside bend radii and align bends across or diagonal to the grain direction to minimize cracking (see bending advice).

- Check grain direction: Bend across or diagonal to the grain for best results.

- Use generous inside radii: The thicker the 6061 t6 aluminum plate, the larger the minimum bend radius needed to avoid cracks.

- Consider annealing: Heat the bend area to soften before forming, then re-age if needed.

- Air-bend with relieved dies: This reduces cracking and springback, especially for thicker sheets.

- Fixture for post-bend heat treatment: Prevents distortion during re-aging.

Cutting and Sawing Best Practices

Cutting 6061 aluminum sheet or plate is straightforward when you use the right blade and setup. For thick sections, a band saw with a coarse blade (10–14 TPI) and high speed works well. For straight cuts in thinner 6061 sheet, a carbide-tipped circular saw blade designed for non-ferrous metals gives a clean edge. Always clamp your work securely—aluminum vibrates more than steel, so a steady setup prevents chatter and improves safety. Lubricate blades with WD-40 or cutting wax to avoid chip buildup and overheating.

- Clamp the workpiece firmly to reduce vibration and ensure straight cuts.

- Protect finished surfaces with masking tape to avoid scratches from chips.

- Use guides or fences for straight cuts—especially with circular saws.

- For curved cuts, use a jigsaw or reciprocating saw with metal blades and wax lubricant.

- Always wear proper PPE: full-face shield and gloves for safety.

Always deburr and break sharp edges after cutting or machining 6061—this reduces crack initiation sites and improves fatigue resistance, especially in parts subject to cyclic loading.

Troubleshooting: Surface Issues and Remedies

- Galling: Use high-shear geometry tools and lubricants to minimize material sticking to the tool.

- Built-up Edge: Increase cutting speed, use sharp tools, and maintain coolant flow to reduce aluminum welding onto tool edges.

- Surface Smearing: Avoid excessive tool dwell and use polished flutes for a cleaner finish.

By following these practical steps, you can fabricate 6061 aluminum sheet, 6061 t6 aluminum sheet, or 6061 t6 aluminum plate with fewer defects and higher productivity. Next, we’ll give you actionable checklists for troubleshooting and inspection—so you can catch issues early and keep your shop running smoothly.

Troubleshoot faster with inspection checklists

Weld Porosity and Cracking Rapid Diagnosis

When you spot bubbles, cracks, or weak joints in your 6061 aluminum welds, it’s tempting to blame the process or the welder. But often, the root cause is hidden in the details—contamination, gas coverage, or prep work. Want to catch issues before they ruin your part? Use this quick checklist to diagnose and fix common weld defects:

-

Porosity:

- Check for oil, grease, or moisture on base metal

- Ensure the oxide layer was removed with a dedicated brush

- Verify shielding gas purity and flow (pure argon, no leaks)

- Reduce humidity in the shop environment

-

Cracking:

- Review filler wire selection (ER4043 for lower crack risk)

- Control heat input—avoid overheating or excessive passes

- Ensure proper joint design and fit-up (adequate root gap)

- Confirm slow, even cooling post-weld to minimize stress

Machining Defects and Dimensional Control

Ever notice burrs, rough surfaces, or inconsistent dimensions in your finished parts? These issues can lead to assembly problems or premature failure, especially when working with the density aluminum 6061 t6 is known for. Here’s how to spot and address machining defects:

-

Burrs and Edge Deformation:

- Use sharp, high-shear carbide tools

- Optimize chip load and feed rates for aluminum

- Apply adequate coolant or lubrication to prevent built-up edge

- Deburr immediately after machining to prevent crack initiation

-

Surface Finish Issues:

- Check for tool wear or incorrect geometry

- Increase coolant flow to clear chips

- Reduce tool dwell time to avoid smearing

- Adjust cutting speed for smoother finish

-

Dimensional Variation:

- Confirm machine calibration and tool offset

- Account for thermal expansion—aluminum 6061 density and thermal conductivity can affect tolerances

- Use fixtures to minimize vibration and movement

Verifying Heat Treatment and Temper

How do you know if your part really achieved the targeted temper, especially with properties like al 6061 t6 yield strength or young's modulus of 6061 t6 aluminum? Here’s a practical inspection sequence:

- Perform hardness checks (Brinell or Rockwell) on a sample coupon

- Conduct comparative bend tests to assess ductility and confirm temper

- Track dimensional changes after heat treatment—unexpected shrinkage or warping may signal process errors

- Document lot traceability and keep records of process parameters for each batch

| Defect | Likely Cause | Corrective Action |

|---|---|---|

| Porosity (Weld) | Contamination, poor gas shielding | Clean thoroughly, check gas system, remove oxide |

| Cracking (Weld) | High heat input, wrong filler, rapid cooling | Lower heat, use ER4043, slow cooling |

| Burrs (Machining) | Dull tools, incorrect feed, lack of deburring | Use sharp tools, optimize feed, deburr after machining |

| Poor Surface Finish | Tool wear, chip buildup, insufficient coolant | Replace tools, improve chip evacuation, increase coolant |

| Inconsistent Temper | Improper heat treatment, uneven aging | Verify oven calibration, check hardness, repeat process if needed |

Validate a sample with hardness or tensile testing before scaling production to ensure the targeted temper and properties were achieved.

Using calibrated instruments for checks and documenting your results builds confidence that properties like 6061-t6 yield strength and al 6061 elastic modulus are on target. This approach helps you catch issues early—before parts reach your customer or assembly floor. Next, we’ll compare 6061 to other alloys, so you can make the best material choice for your next project.

Choose 6061 over alternatives with confidence

6061 vs 6063 for Structural Extrusions

When you’re selecting an aluminum alloy for a new design, the choice often comes down to subtle tradeoffs. Ever wondered why some projects specify 6061, while others lean toward 6063? It’s not just about numbers—it’s about matching the alloy’s strengths to your real-world needs. Imagine you’re designing a load-bearing frame, or perhaps an architectural profile that must look flawless after anodizing. Let’s break down how aluminum 6061 vs 6063 compares in the scenarios you’re most likely to face.

| Alloy | Relative Strength | Fatigue Behavior | Formability | Corrosion Resistance | Machinability | Anodizing Response | Typical Applications |

|---|---|---|---|---|---|---|---|

| 6061 | High (structural grade) | Good | Moderate | Good | Very good | Good, but not as smooth as 6063 | Frames, machine parts, automotive, aerospace, welded assemblies |

| 6063 | Moderate (lower than 6061) | Good | Excellent | Very good (better than 6061) | Good | Excellent—best for decorative anodizing | Architectural shapes, window frames, trim, railing, furniture |

| 2024 | Very high | Good | Moderate | Fair (needs coating) | Fair (work hardens) | Moderate | Aerospace, high-stress structures |

| 7075 | Highest | Moderate | Poor (brittle) | Good | Poor (difficult to machine) | Moderate | Aircraft, high-load gears, critical components |

| 6082 | High (similar to 6061) | Good | Good | Good | Good | Good | European structural extrusions |

You’ll notice that 6061 alloy consistently offers a strong balance—especially for structural extrusions where strength, machinability, and weldability are all priorities. In contrast, 6063 is the go-to for applications where complex shapes, smooth surfaces, and superior anodizing are more important than maximum strength.

When 6082, 2024, or 7075 Make Sense

But what if your project pushes the limits—think aerospace, racing, or demanding industrial environments? Here’s how the alternatives stack up:

- 2024: Chosen for its very high strength-to-weight ratio, especially in aerospace structures. However, it’s less corrosion-resistant and more expensive to fabricate than 6061. Needs protective coatings for most environments.

- 7075: Offers the highest strength among these alloys, but at the cost of machinability and toughness. It’s also more brittle and difficult to form, making it ideal for critical aircraft parts but rarely used for general fabrication.

- 6082: Commonly used in Europe, 6082 is similar to 6061 in strength and corrosion resistance, but is less available in North American markets. If you’re designing for global production, check local supply chains and standards.

For most multi-purpose manufacturing, 6061 is the most versatile and cost-effective choice, especially where a good balance of strength, weldability, and corrosion protection is needed.

A Practical Selection Checklist

How do you decide between 6061, 6063, and the high-strength alternatives? Start by answering these practical questions before you commit to a material:

- What is the minimum required strength for your application?

- Does your part need to be formed, bent, or machined after extrusion?

- Will the final product be anodized or require a decorative finish?

- Is corrosion resistance a top priority for the intended environment?

- Do you need to weld the parts during assembly?

- What is your target cost per part, and how does 6061 aluminum price compare to alternatives?

- Is local or global material availability a concern?

For many structural extrusions, 6061 balances strength, availability, and cost—while 6063 often wins for superior extrudability and surface finish when strength demands are lower.

Choosing the right aluminum alloy is about more than just specs on a datasheet. By weighing your project’s true requirements against the strengths of each material, you’ll make a confident, cost-effective choice that stands up in the real world. Next, we’ll help you navigate standards and specification language so you can source and certify the right product for your application.

Navigate 6061 standards and specifications clearly

Decoding Alloy and Temper Designations

When you’re sourcing aluminium alloy 6061 for a project, you’ll quickly notice a mix of codes and standards—UNS numbers, AA designations, ASTM specs, and even legacy military codes like QQ-A-250/11. Sounds complex? Here’s how to make sense of it all, so you can confidently specify and certify the right product for your needs.

The basic alloy identifier for 6061 is straightforward: the Aluminum Association (AA) designates it as “6061,” while the Unified Numbering System (UNS) uses “A96061.” You might also see terms like al alloy 6061 or al6061 alloy in supplier catalogs—these all refer to the same fundamental material. Temper codes (like T6, T651, O, or T4) tell you how the alloy has been heat treated, directly impacting aluminum 6061 t6 properties such as strength and machinability.

ASTM, AMS, and Legacy Specifications

Imagine you’re ordering extrusions for a high-strength frame or an al 6061 t6 plate for machining. Which standards should you reference? Here’s a quick mapping of common product forms to their typical standards, including legacy and international equivalents:

| Product Form | Common Standard | Designation Notes |

|---|---|---|

| Extrusions | ASTM B221 | UNS A96061, AA 6061 |

| Plate | ASTM B209 | UNS A96061, AA 6061, QQ-A-250/11 (legacy) |

| Sheet | ASTM B209 | UNS A96061, AA 6061 |

| Bar & Rod | ASTM B211 | UNS A96061, AA 6061 |

| Seamless Tube | ASTM B210 | UNS A96061 |

| Drawn Tube | ASTM B210 | UNS A96061 |

For aerospace or defense work, you might encounter AMS (Aerospace Material Specifications) or the older QQ-A-250/11 standard, which is still referenced for historical or legacy projects. European and Japanese standards (like EN AW-AlMg1SiCu or JIS H4040) also exist, so always confirm with your supply chain if you’re working internationally (see full list of equivalents).

How to Write Clear Purchase Specs

Not sure what to include in your RFQ or purchase order? A clear specification ensures you get the right aluminum alloy 6061-t6 product every time. Here’s a practical checklist for your procurement language:

- Alloy: Specify “6061” or “A96061” (UNS)

- Temper: T6, T651, O, or as required for your application

- Product Form: Plate, sheet, extrusion, bar, tube, etc.

- Dimensions/Tolerances: Thickness, width, length, and any critical tolerances

- Applicable Standard: ASTM B209, ASTM B221, or legacy codes as needed

- Test Methods: Mechanical, chemical, and, if needed, corrosion tests per the cited standard

- Certification: Require Mill Test Reports (MTRs) for traceability

- Finish Requirements: Mill finish, anodized, or other surface treatments

Always require mill test reports (MTRs) and traceability—these documents verify chemistry, temper, and mechanical test results per the cited standard, ensuring your 6061 product truly meets the intended specification.

By following these guidelines and referencing the right aluminum specifications, you’ll minimize risk, streamline procurement, and ensure compliance—whether you’re sourcing a standard extrusion, a custom al 6061 t6 plate, or a legacy part built to qq-a-250/11. Next, we’ll walk through how to find and evaluate the right partners for extruded and fabricated 6061 components, especially for demanding automotive and precision applications.

Find the right partner for 6061 extrusions and parts

How to Vet an Extrusion and Machining Partner

When you’re sourcing extruded or fabricated material 6061—especially for automotive or precision-critical projects—the right supplier makes all the difference. Imagine you need a run of custom aluminum sheet 6061 t6 profiles for EV battery trays, or a batch of 6061 aluminum alloy plate for structural brackets. How do you know which partner will deliver the quality, consistency, and support your project demands?

Start by evaluating capabilities, quality systems, and engineering support. Does your supplier offer robust die design, full CNC machining, and advanced surface finishing? Can they handle complex PPAP/ISIR documentation for automotive compliance? Here’s a comparison of key capabilities you should look for:

| Supplier | Die Design Support | Extrusion Press Range | CNC Machining | Welding | Surface Finishing | PPAP/ISIR Readiness | Inspection Depth |

|---|---|---|---|---|---|---|---|

| Shaoyi Metal Parts Supplier | Expert in DFM & custom die design | Comprehensive (multiple presses for small to large parts) | Full in-house CNC (prototyping to production) | Integrated (robotic/MIG/TIG) | Anodize, powder, e-coat, custom color | Yes, IATF 16949 certified | 8-step QC protocol, 100% traceability |

| Domestic General Supplier | Standard dies, limited DFM | Small/medium presses | Basic CNC, some outsourcing | Manual, limited automation | Mill/anodize (standard colors) | Partial, ISO 9001 only | Spot checks, partial traceability |

| Global Distributor | No custom die support | Stock profiles only | None/in-house not available | Not offered | Mill finish only | No | Basic incoming checks |

Choosing a supplier with deep experience in aluminum 6061 t6 fabrication—like Shaoyi—means you get both technical guidance and reliable delivery for your most demanding applications. Their informatized production system and IATF 16949 certification ensure your components meet strict automotive standards, while their DFM (Design for Manufacturability) support helps optimize parts before a single billet is extruded.

RFQ and DFM Essentials for 6061 Projects

Getting accurate quotes and avoiding costly surprises starts with a well-prepared RFQ (Request for Quotation). Whether you’re ordering t6061 aluminum extrusions for crash structures or 6061 aluminum alloy plate for precision assemblies, your RFQ should cover every critical detail. Here’s a checklist to help you communicate requirements clearly:

- Specify alloy and temper (e.g., 6061-T6, material 6061 t6, or equivalent)

- Include fully dimensioned CAD/2D files with all tolerances

- Define profile straightness, flatness, and surface finish (Ra/Rz values if needed)

- Outline heat-treatment path and certification requirements

- List welding/assembly needs and any special joining methods

- Indicate finish or anodize color, thickness, and performance standards

- State test and inspection plans (e.g., FAI, CMM, SPC, MTRs)

- Clarify packaging, labeling, and logistics (palletization, export docs, Incoterms)

- Include projected volumes and delivery timeline requirements

For high-precision or regulated industries, don’t forget to request PPAP/ISIR documentation, full traceability, and evidence of similar project success. Sharing your design intent and end-use application also allows your supplier to suggest DFM improvements—such as optimizing wall thickness or corner radii for better extrusion yield and lower cost.

Supplier Comparison and Shortlist

How do you narrow down your shortlist? Beyond technical capabilities, consider responsiveness, global support, and proven track record. A supplier like Shaoyi, with a global sales network and advanced informatized management, is often better equipped to support automotive launches or multi-site production. For smaller runs or less complex parts, a local or regional supplier may suffice.

Involve your supplier early—DFM collaboration on wall thickness, corner radii, and quench paths can dramatically improve dimensional stability, reduce scrap, and lower costs across your entire production run.

By following these steps and rigorously vetting your supplier’s experience with material 6061 and material 6061 t6, you’ll set your project up for success—from prototype to full-scale launch. Ready to start? Explore Shaoyi’s aluminum extrusion parts for a one-stop solution to your automotive and precision 6061 needs.

Turn 6061 knowledge into production results

Key Design and Manufacturing Takeaways

Ready to translate your understanding of 6061 aluminium into real-world results? Imagine you’re about to launch a new product, and every decision—material, temper, process—shapes your cost, quality, and delivery. Here’s how to ensure your aluminium 6061 t6 project moves smoothly from concept to finished part, avoiding costly missteps and rework.

- Confirm alloy and temper: Always specify the exact alloy (e.g., 6061) and temper (T6, T651, O, etc.) in your drawings and RFQs. The 6061 aluminum composition and heat treatment directly influence strength, ductility, and corrosion resistance.

- Validate forming vs. heat-treat order: Plan your process sequence—form and bend in the soft (O or T4) temper, then heat-treat to T6 for final strength. This avoids cracking and reduces the need for rework.

- Choose welding process and filler wisely: Select the right process (TIG or MIG) and filler wire (ER4043 or ER5356) for your application, and remember that welding in the T6 condition reduces local strength unless re-aged.

- Lock machining strategy: Use sharp carbide tools, proper lubrication, and optimized feeds to machine material 6061 aluminium efficiently, especially in the T6 state.

- Define inspection plans: Specify hardness, tensile, or bend tests to verify temper and 6061 properties—especially if your part will see critical loads or fatigue.

- Secure supplier commitments with MTRs: Require Mill Test Reports for every lot to confirm chemistry, temper, and mechanical performance.

Choose temper to fit the fabrication path, not just the datasheet strength.

Your Next Steps for a Successful 6061 Build

When you’re ready to move from prototype to production, a few practical steps can make all the difference. Start by compiling any open questions about standards, testing, or supplier alignment—don’t wait until you’re in the middle of a production run to clarify requirements. Double-check that your team understands the impact of 6061 thermal conductivity if your design involves heat dissipation, or if tight tolerances are required due to thermal expansion.

- Review all drawings and specs for clarity—ambiguous or missing details can cause delays.

- Align on DFM (Design for Manufacturability) early with your supplier to optimize wall thickness, radii, and extrusion details.

- Confirm finishing requirements—whether you need anodizing, powder coating, or a specific surface roughness.

- Document your inspection and acceptance criteria so both you and your supplier know what “good” looks like.

Where to Get Expert Help

Need hands-on support for sourcing, extrusion design, or precision machining of al 6061? For teams tackling structural or thermal-critical applications, it’s smart to partner with a supplier who knows the ins and outs of 6061 aluminium from raw billet to finished part. Shaoyi Metal Parts Supplier stands out as a leading precision auto metal parts provider in China, delivering end-to-end solutions for custom aluminium 6061 t6 extrusions and assemblies. Their expert engineering team, IATF 16949 quality systems, and global track record make them a trusted choice for automotive, energy, and industrial projects.

Explore their aluminum extrusion parts to align on DFM, tolerances, and finishing early in your project. Early engagement ensures you avoid last-minute surprises and achieve the perfect fit for your application.

By following these steps and leveraging the right partners, you’ll turn your knowledge of material 6061 aluminium into production-ready parts—on time, on spec, and built to last.

Frequently Asked Questions about Aluminium Alloy 6061

1. What is aluminium alloy 6061 and where is it commonly used?

Aluminium alloy 6061 is a versatile, precipitation-hardened alloy containing magnesium and silicon, widely used for its balance of strength, workability, and corrosion resistance. It is commonly found in structural extrusions, plates, and sheets for applications in automotive, aerospace, construction, and general fabrication due to its adaptability and broad availability.

2. How does the temper of 6061 aluminum affect its properties?

The temper of 6061 aluminum, such as O, T4, T6, or T651, determines its strength, formability, and machinability. For example, T6 provides high strength for structural parts, while O temper is softer and better for forming. T651 is stress-relieved, making it ideal for precision machining where dimensional stability is critical.

3. Can 6061 aluminum be welded, and what should be considered?

6061 aluminum is weldable using processes like TIG or MIG, but welding in the T6 condition reduces local strength in the heat-affected zone. Choosing the right filler wire (ER4043 or ER5356), maintaining cleanliness, and proper joint design are essential to avoid defects such as porosity or cracking. Post-weld heat treatment may be required to restore strength.

4. How do you select between 6061 and other aluminum alloys like 6063, 2024, or 7075?

Choose 6061 for its strong balance of strength, machinability, and corrosion resistance, especially in structural or welded applications. 6063 is preferred for superior extrudability and decorative finishes, while 2024 and 7075 are selected for higher strength in aerospace or high-stress uses but may sacrifice weldability or corrosion resistance.

5. What should be included when specifying or sourcing 6061 aluminum components?

When sourcing 6061 components, specify the alloy, temper, product form, dimensions, relevant standards (such as ASTM B209 or B221), and certification requirements like Mill Test Reports (MTRs). For automotive or precision parts, partnering with a supplier like Shaoyi ensures full traceability, quality control, and expert support for custom extrusion and fabrication needs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —