Precision Metal Fabricators Exposed: 8 Insider Secrets Buyers Miss

What Precision Metal Fabrication Really Means

When you hear the term "precision metal fabrication," what comes to mind? If you're imagining standard welding shops or general metalworking facilities, you're missing a critical distinction that separates ordinary manufacturing from engineering-grade production. The difference isn't just about quality—it's about measurements so exact they're invisible to the naked eye.

Precision metal fabrication is a specialized manufacturing approach that achieves dimensional tolerances between ±0.001 to ±0.010 inches, utilizing advanced CNC equipment, rigorous quality systems, and engineered consistency to produce components where even microscopic deviations can determine product success or failure.

This article serves as your comprehensive guide to understanding precision metal fabricators—whether you're a procurement professional evaluating potential suppliers, an engineer specifying critical components, or someone exploring career opportunities in this high-demand field. You'll discover the insider knowledge that most buyers miss and learn exactly what separates exceptional fabricators from the rest.

What Sets Precision Apart from Standard Fabrication

Imagine ordering a steel plate that's 1 inch thick. In standard fabrication, that plate might arrive anywhere between 0.970 and 1.030 inches—a variation of ±0.030 inches that's perfectly acceptable for construction frameworks or basic enclosures. Now consider the same plate produced by precision metal fabricators: the thickness would fall between 0.995 and 1.005 inches, a tolerance of just ±0.005 inches.

That sixfold improvement in accuracy doesn't happen by accident. Precision fabrication demands advanced fiber laser systems, robotic CNC press brakes with angle measurement systems, and coordinate measuring machines that verify accuracy across complex geometries. Standard shops simply can't replicate these capabilities with general-purpose equipment.

Understanding Tolerance Standards in Metal Work

Tolerances represent the permissible limit of variation in any manufactured component. Here's where metal precision truly matters: different processes achieve dramatically different results.

According to industry standards, milling and turning operations can achieve tolerances as tight as ±0.0001 inches, while laser cutting typically delivers ±0.005 to ±0.010 inches depending on material thickness. Compare this to plasma cutting at ±0.010 to ±0.020 inches, or standard bending operations at ±0.010 to ±0.030 inches.

Why does this matter to you? Because a 0.020-inch deviation might render an aerospace component completely unusable, while the same variance in general construction would go unnoticed. Precision fabrication typically maintains tolerances between ±0.005 and ±0.010 inches across complex parts—a standard that general fabrication simply cannot match.

The investment in achieving these tight tolerances pays dividends through eliminated rework, faster assembly times, and products that perform exactly as designed. As you'll discover throughout this guide, understanding these distinctions is the first secret that separates informed buyers from those who learn expensive lessons the hard way.

Core Processes Behind Precision Metal Fabrication

So you understand what tolerances mean—but how do precision metal fabricators actually achieve those incredibly tight specifications? The answer lies in a carefully orchestrated combination of advanced processes, each contributing unique capabilities to the final product. Understanding these core methods helps you evaluate potential suppliers and communicate more effectively about your project requirements.

Here are the primary fabrication methods that define precision metal fab operations:

- CNC Machining: Computer-controlled milling, turning, and drilling that removes material with sub-thousandth-inch accuracy

- Laser Cutting: High-powered beams that vaporize material along programmed paths, delivering clean edges without mechanical contact

- Precision Stamping: Cold-forming processes using engineered dies to shape metal components at high speeds with repeatable accuracy

- Welding: Joining operations that maintain base material properties while achieving structural integrity

- Finishing Operations: Surface treatments that protect components and add dimensional precision to final parts

CNC Machining and Computer-Controlled Accuracy

What makes CNC machining the backbone of precision metal crafters? It's the marriage of computerized control with mechanical cutting that eliminates human variability from the equation. Every movement of the cutting tool follows preprogrammed instructions, executing the same path with identical speed and depth on the first part and the thousandth.

CNC routing, for instance, holds tolerances of ±0.005 inches—roughly the thickness of a single sheet of paper. This 2D process offers precision similar to traditional milling but with greater affordability for appropriate applications. The technology works by translating your CAD file into machine movements, ensuring that what you design is exactly what gets manufactured.

Modern precision metal fab inc operations combine multiple CNC processes within single facilities. A part might begin on a CNC lathe for turning operations, move to a vertical machining center for milling features, then receive final drilling and tapping—all controlled by integrated programming that maintains consistent dimensional relationships throughout.

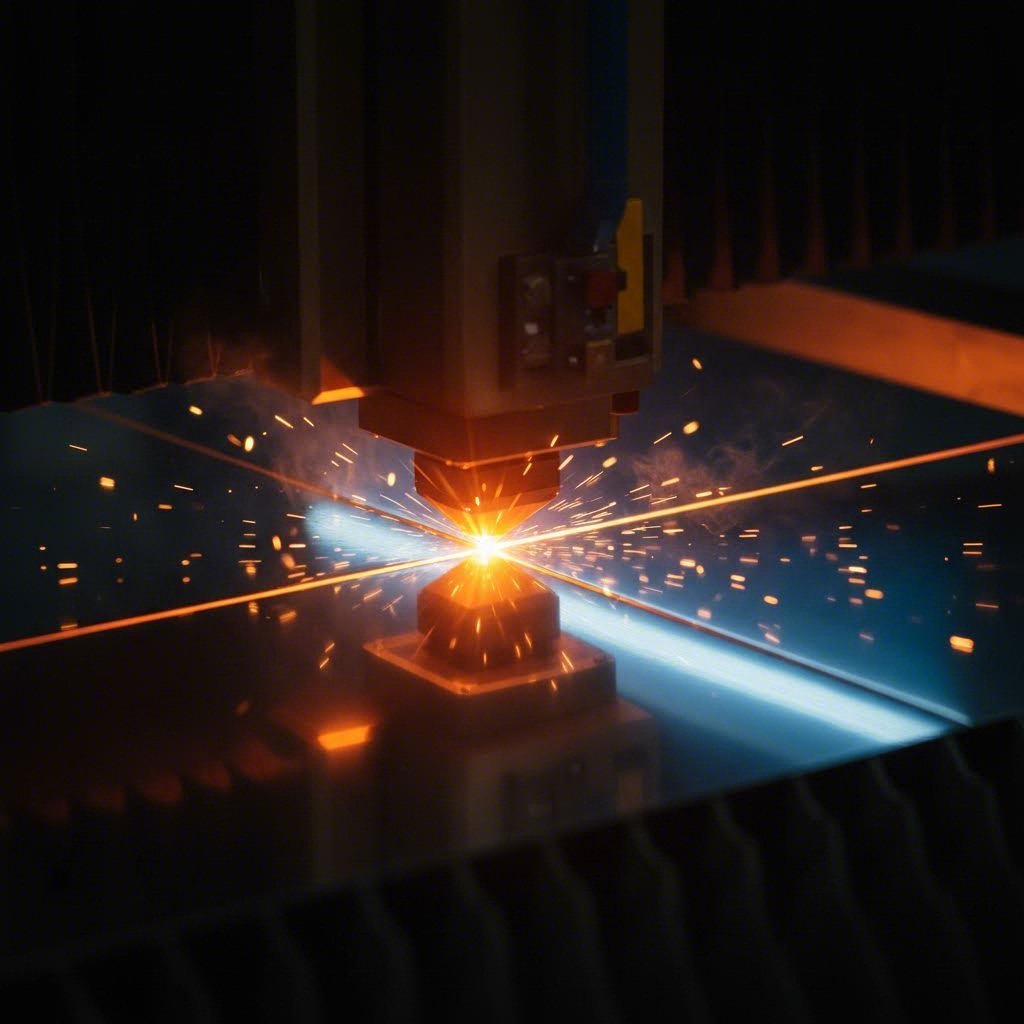

Laser Cutting for Intricate Component Design

Sounds complex? Laser cutting actually simplifies the production of intricate geometries that would challenge conventional cutting methods. Using computer numerical control, a high-powered laser beam vaporizes material along precisely programmed paths, leaving behind high-quality finished edges without the mechanical stress of physical tooling contact.

The precision achievable varies by material type. Metals typically hold tolerances of ±0.005 inches, while plastics and wood materials achieve approximately ±0.009 inches. What's remarkable is that this tolerance consistency holds regardless of feature size—whether you're cutting a 0.25-inch hole or a 6-inch profile, the ±0.005 inch accuracy remains constant.

Applications span from automotive parts and electronics enclosures to agricultural equipment and medical devices. The technology excels at producing complex shapes with minimal setup time, making it ideal for both prototyping and production runs where design flexibility matters.

Precision Stamping and Cold-Forming Processes

When you need thousands of identical components produced at high speed, precision stamping delivers. This cold-forming method uses engineered dies and stamping presses to shape sheet metal into consistent forms, achieving repeatability that laser cutting alone cannot match for high-volume production.

The process works particularly well for power tools, mounting brackets, chassis components, and fastening solutions. Unlike cutting operations that remove material, stamping reshapes it—meaning you're not paying for material that ends up as scrap. For production volumes where tooling costs can be amortized across thousands of parts, stamping often delivers the lowest per-piece pricing.

Welding and Joining Technologies

Precision welding goes far beyond simply fusing two pieces of metal together. Advanced techniques like TIG welding, laser welding, and robotic MIG welding allow fabricators to join components while maintaining tight tolerances across the completed assembly. The challenge lies in controlling heat input to prevent warping and distortion that would throw carefully machined features out of specification.

Quality control measures during welding include real-time monitoring of parameters like amperage, voltage, and travel speed. Many precision operations use fixturing systems that hold components in exact alignment during the welding process, then verify dimensional accuracy afterward using coordinate measuring equipment.

Finishing Operations and Dimensional Impact

Here's something many buyers overlook: finishing operations affect your final dimensions. Coatings aren't just surface treatments—they add measurable thickness that must be accounted for in your design specifications.

According to fabrication data, different coatings add varying amounts to part dimensions:

- Nickel Plating: adds 0.0002 inches per side

- Zinc Plating: adds 0.0003 inches per side

- Anodizing: adds 0.0002 to 0.0009 inches per side

- Powder Coating: adds 0.002 to 0.005 inches per side

Consider a precision hole designed for a 0.250-inch pin. If you powder coat that part without accounting for coating thickness, you could add up to 0.010 inches to the hole diameter—suddenly your press-fit becomes a slip-fit. Experienced precision metal fabricators build these considerations into their design review process before production begins.

Understanding how these processes interact reveals why material selection matters just as much as process capability. The next section explores the metals that precision fabricators work with most frequently—and why the right material choice can make or break your project.

Materials Used by Precision Metal Fabricators

You've seen how advanced processes achieve tight tolerances—but here's a secret many buyers miss: even the most sophisticated CNC equipment can't compensate for the wrong material choice. The metal you select fundamentally determines what tolerances are achievable, how your component performs in service, and ultimately what your project costs. Precision sheet metal fabricators understand this relationship intimately, which is why material selection happens early in every successful project.

Think of it this way: choosing a metal for precision fabrication is like selecting ingredients for a recipe. Each metal brings intrinsic qualities that make it suitable for specific applications. Stronger metals handle greater loads, while others offer superior corrosion protection or elevated melting temperatures. Understanding these properties helps you make informed decisions rather than learning expensive lessons after production begins.

Stainless Steel and Aluminum for High-Performance Applications

When buyers ask precision sheet metal shop inc operations about their most commonly processed materials, two names consistently top the list: stainless steel and aluminum. These metals dominate precision fabrication for good reasons.

Stainless Steel earns its reputation through exceptional strength and corrosion resistance. Grades like 304 and 316 stainless resist degradation in harsh environments, making them essential for medical, food processing, and marine applications. According to industry specifications, stainless steel is harder to machine than aluminum—requiring more time and specialized tooling—but delivers long-term durability and structural integrity that justify the investment.

What about tolerance achievability? Cold-rolled stainless steel offers tighter thickness tolerances than hot-rolled alternatives. For sheets under 1.0mm thick and narrower than 1250mm, fabricators typically achieve thickness tolerances of ±0.030 to ±0.035mm. This consistency matters when you're stacking components or working with tight clearances.

Aluminum stands as the most versatile choice in precision fabrication due to its lightweight nature, excellent machinability, and natural corrosion resistance. The 6061 grade balances strength and workability beautifully, while 7075 aluminum delivers superior strength for high-performance aerospace and automotive components. Because aluminum machines more easily than steel, you'll often see faster turnaround times and lower per-part costs for equivalent geometries.

Carbon Steel and Cold-Rolled Alternatives

Need strength without the stainless premium? Carbon steel delivers an attractive combination of mechanical properties, low cost, and good machinability. Grades like 1018 and 1045 provide varying hardness levels to suit different milling and forming processes. Penn metal fabricators frequently recommend carbon steel for structural and industrial components where corrosion exposure is limited or protective coatings can be applied.

Here's something worth noting: the rolling process dramatically affects what tolerances you can expect. Hot-rolled steel—processed at temperatures above 1,700°F—exhibits larger thickness variations due to uncontrolled cooling. Cold-rolled steel undergoes additional processing at room temperature, improving strength, surface finish, and dimensional accuracy. For precision applications, cold-rolled material typically proves worth the modest price premium.

Specialty Metals for Demanding Environments

Some applications demand materials beyond the standard options. Copper, brass, and titanium each fill specific niches in precision fabrication.

Copper offers outstanding electrical and thermal conductivity, making it indispensable for electrical contacts, heat exchangers, and industrial components. Though softer and more easily deformed than steel, copper holds tight tolerances and achieves excellent surface finishes through careful CNC machining.

Brass combines excellent electrical conductivity with corrosion resistance and a striking gold-like appearance. Beyond aesthetics, brass machines exceptionally well—reducing tool wear and increasing production efficiency. Electrical components, plumbing hardware, and decorative architectural elements all benefit from brass fabrication.

Titanium commands attention in aerospace, medical, and high-performance engineering for its exceptional strength-to-weight ratio and biocompatibility. Yes, it's difficult to machine and requires specialized tooling. But when you need medical implants or airframe components, titanium's unique properties justify the additional manufacturing complexity.

Material Selection Criteria That Drive Decisions

How do experienced fabricators guide material selection? They evaluate five fundamental properties against your application requirements:

- Tensile Strength: The force a metal withstands without fracturing—critical for components experiencing significant loads

- Corrosion Resistance: Essential for salt water exposure, wet environments, or chemical contact

- Weldability: Metals that weld easily reduce manufacturing time and costs

- Machinability: How readily the material cuts with standard tooling affects lead times and pricing

- Ductility and Formability: Determines what shapes are achievable without cracking or breaking

| Material Type | Key Properties | Common Applications | Tolerance Achievability |

|---|---|---|---|

| Stainless Steel (304/316) | High strength, excellent corrosion resistance, durable | Medical devices, food processing, marine equipment | ±0.030 to ±0.060mm thickness (cold-rolled) |

| Aluminum (6061/7075) | Lightweight, excellent machinability, corrosion resistant | Aerospace components, automotive parts, electronics enclosures | ±0.03 to ±0.24mm thickness depending on gauge |

| Carbon Steel (1018/1045) | High strength, cost-effective, good machinability | Structural components, industrial machinery, fasteners | ±0.17 to ±0.46mm thickness (hot-rolled) |

| Cold-Rolled Steel (SPCC) | Improved strength, smooth finish, tighter tolerances | Precision assemblies, automotive panels, appliances | ±0.05 to ±0.22mm thickness |

| Copper | Outstanding electrical/thermal conductivity, soft, formable | Electrical contacts, heat exchangers, bus bars | Excellent tolerance holding in CNC operations |

| Brass | Good conductivity, corrosion resistant, easy machining | Electrical components, plumbing hardware, decorative parts | Low tool wear enables consistent precision |

| Titanium | Exceptional strength-to-weight, biocompatible, corrosion resistant | Aerospace structures, medical implants, high-performance engineering | Requires specialized tooling; achieves tight tolerances with proper setup |

Notice how tolerance achievability varies significantly across materials? This variation explains why experienced precision fabricators discuss material selection before quoting your project. The right material choice optimizes performance, manufacturability, and cost simultaneously.

Understanding materials is essential—but knowing which industries demand precision fabrication reveals why these capabilities matter so much. The next section explores the sectors where tight tolerances aren't just preferred, they're absolutely required.

Industries That Rely on Precision Metal Fabrication

Here's what separates casual buyers from informed procurement professionals: understanding that precision metal fabrication isn't a luxury—it's an absolute requirement in certain industries. When a component fails in your consumer electronics, you face an inconvenient warranty claim. When a component fails in an aircraft at 35,000 feet or inside a patient's body, the consequences are catastrophic. This reality explains why specific sectors demand fabrication capabilities that general metalworking simply cannot deliver.

The industries requiring precision metal fabricators share common characteristics: strict regulatory oversight, zero tolerance for failure, and components where microscopic deviations determine whether products perform or people get hurt. Let's examine what each sector demands and why precision capabilities matter so critically.

- Aerospace and Defense: Flight-critical components with AS9100 certification requirements and FAA/EASA compliance

- Automotive: Chassis, suspension, and structural parts requiring IATF 16949 quality systems

- Medical Devices: Surgical instruments and implants governed by FDA QSR and ISO 13485 standards

- Electronics: Enclosures, heat sinks, and shielding components with EMI/RFI considerations

- Pharmaceutical and Food Processing: Sanitary equipment meeting FDA compliance and hygienic design standards

Aerospace and Defense Component Requirements

When you're manufacturing components that keep aircraft flying and defense systems functioning, there's no margin for error. Aerospace metal fabrication represents one of the most demanding applications for precision manufacturing—and the certification requirements reflect this reality.

According to aerospace fabrication specialists, precision is paramount because intricate components must adhere to strict tolerances and quality standards to ensure the structural integrity and reliability of final products. This isn't just corporate messaging—it's regulatory requirement. The Federal Aviation Administration (FAA) enforces Federal Aviation Regulations covering certification, materials, quality management, design, and safety testing. European manufacturers face equivalent oversight from the European Union Aviation Safety Agency (EASA).

What certifications should you verify when selecting aerospace fabricators? AS9100 certification stands as the industry gold standard. This quality management system builds upon ISO 9001 but adds aerospace-specific requirements addressing configuration management, risk assessment, and product safety. Earning AS9100 certification requires demonstrating compliance with stringent manufacturing and quality management standards—not every precision metal fabricators inc operation achieves this threshold.

Material selection carries particular weight in aerospace applications. Fabricators working with aerospace-grade alloys must understand specific finishing and hardening requirements. Components range from aircraft frames to engine parts, avionics systems, and structural elements where failure isn't an option. The tools enabling this precision include CNC machining for tight tolerances, laser cutting for speed and reduced material waste, and increasingly, 3D printing for complex geometries and rapid prototyping.

Medical Device Manufacturing Standards

Imagine a surgical instrument that's 0.015 inches longer than specified. In most industries, that deviation wouldn't matter. Inside an operating room, it could mean the difference between successful surgery and patient harm. Medical device manufacturing demands precision fabrication backed by comprehensive quality systems—and the FDA takes compliance seriously.

The FDA classifies medical devices into three risk-based categories, each imposing different manufacturing requirements:

- Class I (lowest risk): Basic equipment like examination gloves requiring general controls and Good Manufacturing Practices

- Class II (moderate risk): Surgical instruments and patient monitoring equipment requiring 510(k) premarket notification and comprehensive quality system compliance

- Class III (highest risk): Life-sustaining devices like implantable pacemakers requiring premarket approval, clinical trial data, and the most stringent manufacturing controls

The FDA's Quality System Regulation (21 CFR Part 820) establishes mandatory requirements that precision fabricators must understand. According to medical manufacturing compliance experts, key elements include design controls, document management systems, process validation, and comprehensive traceability through device history records. For metal fabrication specifically, welding validation, heat treatment controls, and validated cleaning procedures require documented evidence of consistent results.

Material considerations differ significantly from commercial applications. Stainless steel grade 316L dominates implantable devices and surgical instruments due to its corrosion resistance and biocompatibility. Titanium alloys like Ti-6Al-4V serve applications requiring both strength and osseointegration properties. The critical difference from commercial materials? Complete documentation—medical-grade metals require full mill test reports, heat lot numbers, and chemical/mechanical property certification enabling lot-specific recalls if problems arise.

What does FDA compliance add to manufacturing costs? Expect 15-30% higher unit costs compared to commercial production, with additional time for process validation (typically 6-12 weeks) and first article inspection. Initial medical device builds often require 10-18 weeks versus 4-6 weeks for comparable commercial components.

Automotive Precision Requirements

The automotive sector presents unique challenges for precision metal fabricators: high-volume production demands, tight cost constraints, and zero-defect quality expectations. Whether manufacturing chassis components, suspension parts, or structural assemblies, automotive suppliers must balance precision capabilities with production efficiency.

IATF 16949 certification represents the automotive industry's quality management standard. This specification builds on ISO 9001 while adding automotive-specific requirements for production part approval, control plans, and failure mode analysis. Humanetics precision metal works and similar automotive suppliers invest heavily in maintaining these certifications because major OEMs require them for supplier qualification.

Chassis and suspension components exemplify why precision matters in automotive applications. These parts experience continuous stress during vehicle operation—vibration, impact loads, and environmental exposure. Dimensional accuracy ensures proper fit during assembly line installation, while consistent material properties guarantee long-term durability. Components that vary outside specification create warranty claims, recalls, and damaged supplier relationships.

Electronics and Thermal Management

Electronics enclosures and heat management components represent a growing application for precision sheet metal fabrication. As devices become smaller and more powerful, thermal management becomes critical—and heat sinks require precise dimensional control to make proper contact with components they're designed to cool.

EMI/RFI shielding presents additional precision requirements. Electromagnetic interference shielding effectiveness depends on complete enclosure integrity—gaps or poor fits create paths for interference that defeat the shielding purpose. Fabricators producing these components must maintain tight tolerances on all mating surfaces while ensuring proper grounding contact.

Pharmaceutical and Food Processing Equipment

When equipment contacts food products or pharmaceutical ingredients, regulatory requirements extend beyond dimensional precision into sanitary design. FDA compliance for food and pharmaceutical equipment focuses on preventing contamination, enabling thorough cleaning, and eliminating bacterial harborage points.

Surface finish specifications in these industries go beyond aesthetics. Rougher surfaces harbor bacteria that survive cleaning procedures, creating contamination risks. Precision fabricators serving food and pharmaceutical markets often specify precise surface roughness values (measured as Ra) and employ specialized finishing processes to achieve hygienic surfaces. Welded joints receive particular attention—incomplete penetration or rough weld profiles create cleaning challenges that can compromise product safety.

York metal fabricators inc and similar regional manufacturers serving these industries maintain documentation systems tracking material certifications, cleaning validations, and process controls that satisfy FDA inspection requirements.

Construction and Industrial Applications

While construction and industrial applications may tolerate wider tolerances than aerospace or medical, precision fabrication still delivers significant value. Structural steel connections with tight dimensional control reduce field fitting time and ensure design load capacities. Industrial equipment components with consistent dimensions simplify maintenance and parts replacement.

The difference lies in where precision matters. A building's structural connection might accept ±0.030-inch tolerance overall while requiring ±0.005-inch accuracy on bolt hole locations. Understanding these nuanced requirements allows fabricators to apply precision capabilities where they add value without over-engineering components where looser tolerances suffice.

Recognizing which industries demand precision capabilities helps you understand market expectations—but knowing how to build a career in this field opens different opportunities. The next section explores pathways from entry-level positions through master fabricator credentials.

Career Paths in Precision Metal Fabrication

So you're considering a career working with precision metal fabricators—but where do you actually start? Unlike many skilled trades where pathways remain vague, precision metal fabrication offers structured progression from complete beginner to nationally-recognized journey-level professional. The investment is substantial: typically 4,000 hours of on-the-job training combined with formal classroom instruction. The reward? A credential that opens doors across aerospace, medical, automotive, and advanced manufacturing sectors.

Here's what most career guides won't tell you: precision metal fabrication represents an intermediate apprenticeship occupation that reinforces foundational fabrication skills while building specialized capabilities in blueprint reading, machine tool operation, and precision measuring. Completion doesn't just mean employment—it positions you for advancement into roles like Machinist, Quality Control Inspector, CNC Programmer, or Shift Lead Supervisor.

From Entry-Level to Master Fabricator

What does the journey from newcomer to credentialed professional actually look like? The Aerospace Joint Apprenticeship Committee (AJAC) provides one of the most structured pathways available, offering a clear progression through four defined steps:

- Step 1 (Hours 0-1,000): Entry-level apprentices earn 60% of journey-level wages while mastering bench work fundamentals and sheet metal shop basics. This foundation phase focuses on reading blueprint drawings, calculating dimensions, and understanding basic tolerances using micrometers and calipers.

- Step 2 (Hours 1,001-2,000): Wage progression to 70% of journey rate accompanies deeper immersion in CNC setup and operations. Apprentices begin programming and operating high-tech cutting machines while building competency with punch press equipment.

- Step 3 (Hours 2,001-3,000): At 80% of journey wages, focus shifts to press brake operations and laser cutting technology. This phase emphasizes precision forming, bending calculations, and understanding material properties that affect fabrication outcomes.

- Step 4 (Hours 3,001-4,000): The final progression to 90% of journey rate covers advanced inspection techniques, CAD/CAM operations, and comprehensive materials knowledge. Completion triggers eligibility for journey-level certification.

Using AJAC's base established wage of $20.00 per hour as reference, apprentices progress from $12.00/hour at entry to $18.00/hour before achieving full journey-level status. Upon completion, sheet metal workers in Oregon currently earn a minimum journey-level wage of $34.80 per hour—representing significant earning potential for those who complete the full apprenticeship pathway.

Skills Developed Through Apprenticeship Programs

What exactly will you learn during those 4,000 hours? The structured on-the-job training breaks down across specific competency areas:

| OJT Competency | Approximate Hours | Skills Developed |

|---|---|---|

| Bench Work | 100 | Hand tool proficiency, layout techniques, basic assembly |

| Sheet Metal Shop Basics | 1,100 | Material handling, shop safety, fabrication fundamentals |

| CNC Setup and Operations | 800 | Machine programming, setup procedures, operational troubleshooting |

| Punch Press | 500 | Die setup, material feeding, quality verification |

| Press Brake | 500 | Bend calculations, tooling selection, angle measurement |

| Lasers and Cutting Technology | 200 | Laser operation, cutting parameters, material considerations |

| Inspection | 400 | Measuring instruments, tolerance verification, quality documentation |

| Materials and Properties | 200 | Metal characteristics, forming behavior, material selection |

| CAD/CAM | 200 | Computer-aided design, manufacturing programming, file interpretation |

Classroom training runs parallel to on-the-job learning. AJAC apprentices complete eight college-level classes, each consisting of 50 hours of lecture and practical application. Classes meet one evening per week—typically Tuesday, Wednesday, or Thursday from 5:00 pm to 9:00 pm—allowing apprentices to work full-time while advancing their education.

Educational Prerequisites and Getting Started

Wondering if you qualify? The requirements remain accessible for motivated candidates:

- High school diploma or equivalent

- Minimum age of 17 years

- Ability to perform physical requirements of the occupation

- Minimum scores on COMPASS test, ASSET test, WOWI assessment, or completion of college-level math and English classes (score of 90 or greater)

The pathway to enrollment involves identifying an employer partnered with apprenticeship programs, receiving company approval for participation, and signing an apprenticeship agreement. Registered apprentices automatically receive 50% reduced tuition, and over half of partnering employers elect to cover remaining tuition costs—making the entire apprenticeship free for many participants.

For those seeking related credentials, community colleges like Lane Community College offer programs combining apprenticeship with associate degree pathways. Their sheet metal program spans four years with 144 hours of related training annually plus 8,000 hours of on-the-job experience—culminating in eligibility for journeyman licensing through the Oregon Building Codes Division.

The career pathway is clear, the wage progression is documented, and the skills you'll develop open doors across multiple industries. But whether you're building a career or evaluating potential suppliers, understanding how to select the right precision metal fabricator requires knowing what separates exceptional operations from average ones.

How to Evaluate and Select a Precision Metal Fabricator

You've identified your project requirements and understand what precision metal fabricating involves—now comes the decision that determines whether your project succeeds or becomes an expensive lesson. Selecting the right fabrication partner isn't simply about finding the lowest quote. It's about identifying a manufacturer whose capabilities, quality systems, and communication style align with your specific needs. Get this wrong, and you'll face delays, quality issues, and costs that dwarf any savings from choosing a cheaper supplier.

The evaluation process requires examining five critical factors that experienced procurement professionals prioritize: industry experience, in-house capabilities, engineering support, quality certifications, and scalability with communication. Let's break down exactly what to look for in each area.

Quality Certifications That Matter

Here's an insider secret many buyers miss: certifications aren't just logos on a website—they represent documented systems that ensure consistent results. Different industries require different certifications, and partnering with a fabricator lacking appropriate credentials can disqualify your final product from your target market entirely.

What certifications should you verify? According to quality management specialists, both IATF 16949 (automotive) and AS9100 (aerospace) build upon ISO 9001 foundations while adding sector-specific requirements:

- ISO 9001: The baseline quality management standard demonstrating documented processes and continuous improvement commitment

- IATF 16949: Automotive-specific standard focused on defect prevention, variation reduction, and waste elimination in supply chains—mandatory for most OEM suppliers

- AS9100: Aerospace standard emphasizing configuration management, risk assessment, and product safety for flight-worthy components

- ISO 13485: Medical device manufacturing standard addressing regulatory compliance and design controls

The distinction matters significantly. Automotive certification (IATF 16949) emphasizes extremely high consistency with high volumes, where process improvements and time/cost savings prove crucial. Aerospace certification (AS9100) focuses primarily on making flight-worthy parts with controls needed to accomplish that mission. Both require rigorous auditing and ongoing compliance—not one-time achievements.

For automotive applications specifically, manufacturers like Shaoyi (Ningbo) Metal Technology demonstrate how IATF 16949 certification combines with practical capabilities like 5-day rapid prototyping and comprehensive DFM support to accelerate supply chain performance for chassis, suspension, and structural components.

Evaluating Production Capabilities and Lead Times

Not all fabrication shops offer equivalent capabilities—and outsourced operations create gaps that affect your timeline and quality consistency. When a fabricator cuts metal in-house but sends machining, finishing, or assembly to subcontractors, you face potential delays, communication breakdowns, and inconsistent quality standards.

Full-service, integrated facilities streamline your entire project under one roof. According to fabrication industry analysts, key capabilities to verify include:

- Laser cutting, plasma cutting, or waterjet cutting

- CNC machining and turning

- Precision forming and press brake bending

- TIG/MIG welding and robotic welding

- Powder coating, anodizing, or other finishing options

- Assembly and testing support

Modern equipment and automation ensure repeatability, efficiency, and scaling ability. Ask potential partners about their machine age, maintenance schedules, and backup capacity. A fabricator running aging equipment near maximum capacity presents schedule risk that newer, automated operations avoid.

Engineering and Design Support

Successful precision metal fabricating doesn't begin at the machine—it begins with engineering collaboration. The best fabricators review your drawings, CAD files, tolerances, and functional requirements before quoting, identifying potential manufacturing challenges while solutions remain inexpensive.

Design for Manufacturability (DFM) support proves particularly valuable. Experienced engineers spot opportunities to refine designs for cost-effective production without compromising performance. This might mean suggesting alternative bend sequences that reduce handling, recommending material gauge changes that improve formability, or identifying tolerance specifications tighter than necessary for your application.

When evaluating partners, ask whether they provide:

- CAD/CAM support and file compatibility

- Prototype testing and validation

- Engineering consultation during design phase

- Material and design optimization recommendations

Fabricators offering rapid quote turnarounds—some provide responses within 12 hours—demonstrate engineering capacity to review projects quickly. This responsiveness matters when you're comparing options or facing tight development schedules.

Experience and Industry Knowledge

Years in business translate into deeper material knowledge, refined processes, and the ability to anticipate challenges before they become costly problems. Experienced fabricators understand how different metals—aluminum, stainless steel, carbon steel, specialty alloys—behave during cutting, forming, and welding operations.

Before choosing a partner, investigate:

- How long have they fabricated complex metal parts?

- Do they have documented experience in your industry or with similar applications?

- Can they share case studies, examples, or customer references?

Industry-specific experience proves particularly important for regulated sectors. A fabricator experienced with precision steel in Roanoke VA construction applications may lack the documentation systems required for medical device manufacturing. Conversely, aerospace-focused operations may over-engineer solutions for applications where simpler approaches suffice.

Scalability and Communication Standards

Your ideal partner supports both current prototype needs and future production volumes without sacrificing quality. Evaluate whether fabricators can scale from single prototypes through full production runs—and whether their quality systems maintain consistency across volume changes.

Transparent communication prevents costly surprises. Reliable fabricators provide clear timelines, proactive project updates, and realistic expectations from the outset. Ask about their communication protocols: Will you have a dedicated project contact? How frequently will you receive status updates? What's their process for handling design changes or unexpected issues?

| Evaluation Criteria | What to Look For | Why It Matters |

|---|---|---|

| Quality Certifications | ISO 9001 baseline; IATF 16949 for automotive; AS9100 for aerospace; ISO 13485 for medical | Certifications demonstrate documented quality systems and industry-specific compliance—often mandatory for supplier qualification |

| In-House Capabilities | Comprehensive services from cutting through finishing and assembly under one roof | Reduces lead times, improves communication, ensures consistent quality standards throughout production |

| Engineering Support | DFM consultation, CAD/CAM capabilities, prototype testing, material recommendations | Early engineering collaboration identifies issues while solutions remain inexpensive; optimizes designs for manufacturability |

| Industry Experience | Documented projects in your sector; understanding of industry-specific standards and materials | Experienced fabricators anticipate challenges, understand regulatory requirements, and deliver appropriate solutions |

| Production Scalability | Capacity for both prototypes and production volumes; modern equipment with backup capacity | Ensures your supplier can grow with your needs without quality degradation or excessive lead time extension |

| Lead Time Performance | Rapid prototyping (5-day or faster); quick quote turnaround (12-24 hours); realistic production schedules | Speed to market advantages; responsive partners adapt to changing requirements without schedule disruption |

| Communication Quality | Dedicated project contacts; proactive updates; clear escalation procedures | Transparent communication prevents surprises and keeps projects aligned from concept through delivery |

Remember: hiring a fabricator isn't just a purchasing decision—it's a long-term investment in your product's performance and reliability. The right partner contributes engineering expertise, advanced technology, certified quality systems, and collaborative communication that adds value beyond the metal itself.

Understanding evaluation criteria gives you the framework for supplier selection, but knowing exactly what each certification requires—and why specific industries demand them—helps you ask the right qualifying questions during vendor assessment.

Quality Certifications and Industry Standards

You've learned how to evaluate potential fabrication partners—but here's where many buyers stumble: understanding what those certification logos actually mean. An ISO 9001 certificate hanging on a facility wall tells you something fundamentally different than an IATF 16949 or AS9100 certification. Knowing the distinction helps you ask better qualifying questions and avoid suppliers whose credentials don't match your application requirements.

Think of certifications as documented proof that a precision metal fabrication inc operation maintains specific systems, processes, and controls. According to manufacturing certification experts, quality certifications demonstrate commitment to the customer and to their profession, producing premium components while providing an added layer of assurance for buyers that the manufactured items meet all of their requirements.

Here's the certification landscape you need to understand:

- ISO 9001: Universal quality management baseline applicable across all industries

- IATF 16949: Automotive-specific standard building on ISO 9001 with supply chain requirements

- AS9100: Aerospace certification emphasizing safety, configuration management, and traceability

- ISO 13485: Medical device manufacturing standard focused on regulatory compliance and patient safety

- ISO 14001: Environmental management systems for sustainable operations

Understanding IATF 16949 for Automotive Applications

Why does the automotive industry require its own certification beyond general ISO 9001? Because automotive supply chains operate at volumes and consistency levels that demand specialized controls. IATF 16949 was developed by the International Automotive Task Force specifically to address these unique requirements.

According to industry certification specialists, this global quality management standard is tailored specifically for the automotive industry, building upon ISO 9001 and encompassing additional requirements in product design, production processes, improvement, and customer-specific standards.

What does IATF 16949 certification actually require? Fabricators must demonstrate:

- Defect prevention systems that catch problems before they reach assembly lines

- Variation reduction programs minimizing dimensional inconsistency across production runs

- Waste elimination initiatives driving continuous cost improvement

- Customer-specific requirements compliance for major OEM specifications

- Advanced Product Quality Planning (APQP) implementation

- Production Part Approval Process (PPAP) documentation capabilities

For buyers, IATF 16949 certification signals that a fabricator understands high-volume production demands where every tenth of a percent in defect reduction translates to thousands of avoided failures. Major automotive OEMs—Ford, GM, Toyota, Volkswagen—typically require this certification as a minimum supplier qualification threshold.

Aerospace and Medical Device Certification Requirements

Aerospace and medical applications share a critical characteristic: component failure can cost lives. This reality drives certification requirements far more rigorous than general manufacturing standards.

AS9100 for Aerospace

The AS9100 certification is specific to the aerospace industry and aircraft parts. According to certification authorities, this certification basically states that the parts meet the requirements of safety, quality, and high standards posed by the aviation industry.

What makes AS9100 different from general quality standards? The aerospace certification adds requirements for:

- Configuration management ensuring every component version is tracked and controlled

- Risk assessment protocols identifying potential failure modes before production

- Product safety verification at multiple production stages

- Complete traceability from raw material through finished component

- First Article Inspection (FAI) documentation for new parts

- Special process controls for operations like heat treatment and welding

The specificity exists because of how highly technical everything needs to be for safety and compliance in aviation. A fabricator achieving AS9100 certification has demonstrated capabilities that general metalworking operations simply don't possess.

ISO 13485 for Medical Devices

Medical device manufacturing operates under equally demanding—but distinctly different—requirements. ISO 13485 ensures that all medical devices are designed and manufactured with safety in mind, with rigorous inspections forming an important part of the certification.

This certification specifically addresses the unique requirements of the medical industry, prioritizing high-quality components. Patient safety and well-being are paramount, making ISO 13485 essential in reducing risks and protecting lives. Key requirements include:

- Design controls documenting how devices meet intended use requirements

- Process validation proving manufacturing methods produce consistent results

- Sterility and biocompatibility verification for patient-contacting components

- Complete device history records enabling lot-specific tracking

- Complaint handling and adverse event reporting systems

- Supplier qualification programs for critical material sources

ISO 9001: The Foundation Everything Builds Upon

Before understanding specialized certifications, recognize that ISO 9001 serves as the baseline. According to ISO certification experts, ISO 9001 is regarded as the most universal form of manufacturing certification, holding applicability across industries of all scales.

This foundational certification delineates the prerequisites for a robust quality management system. By obtaining this certification, an organization affirms that its products or services comply with customer expectations and regulatory mandates. Core ISO 9001 elements include:

- Documented quality management system with defined processes

- Management commitment to quality objectives

- Customer focus throughout operations

- Continuous improvement mechanisms

- Evidence-based decision making

- Internal audit programs verifying compliance

For precision metal fabrication, ISO 9001 certification indicates basic quality consciousness—but it's often insufficient for regulated industries. Think of it as the entry ticket: necessary but not sufficient for aerospace, automotive, or medical applications.

Environmental and Safety Certifications

Beyond quality management, responsible fabricators increasingly pursue environmental and safety certifications that demonstrate operational excellence.

ISO 14001 focuses on environmental management systems, offering organizations a structured framework to fulfill their environmental responsibilities. According to certification specialists, the primary aim of this standard is to mitigate adverse environmental actions, including air emissions, waste management, and resource utilization.

ISO 45001 addresses occupational health and safety management—particularly relevant in metal fabrication where hazardous processes require systematic risk management. This certification helps organizations establish approaches to managing health and safety risks that protect workers while improving operational efficiency.

For buyers, these certifications signal fabricators committed to sustainable operations and worker welfare—factors increasingly important for supply chain qualification and corporate responsibility initiatives.

What Certifications Mean for Your Buying Decision

How should you apply this certification knowledge during supplier evaluation? Match certification requirements to your application:

| Your Industry | Required Certifications | Why It Matters |

|---|---|---|

| Automotive OEM or Tier 1 | IATF 16949 (mandatory), ISO 14001 (often required) | Most automakers won't qualify suppliers without automotive-specific certification |

| Commercial Aerospace | AS9100 (mandatory), Nadcap for special processes | FAA/EASA compliance requires documented quality systems |

| Medical Devices | ISO 13485 (mandatory), FDA registration | Regulatory submission requires certified manufacturing |

| General Industrial | ISO 9001 (recommended) | Demonstrates basic quality commitment without sector-specific requirements |

| Defense/Government | AS9100 or ITAR registration depending on application | Government contracts often specify certification requirements |

Remember: certifications require ongoing compliance, not one-time achievement. Ask potential suppliers about their most recent audit dates, any nonconformities identified, and corrective actions implemented. Active certification maintenance demonstrates genuine commitment rather than paper credentials.

Understanding certification requirements positions you to make informed supplier selections—but translating this knowledge into action requires connecting with fabricators whose capabilities match your specific needs.

Getting Started with Precision Metal Fabrication

You've now explored the insider knowledge that separates informed buyers from those who learn expensive lessons through trial and error. Whether you're sourcing components for a critical aerospace application, evaluating automotive suppliers, or considering a career path in advanced manufacturing, the fundamentals remain consistent: precision metal fabrication demands specialized capabilities, documented quality systems, and collaborative partnerships that extend far beyond transactional purchasing.

Here's what the most successful procurement professionals and career seekers understand: the fabrication partner you select—or the employer you join—shapes outcomes for years to come. A fabricator lacking appropriate certifications, engineering depth, or communication discipline creates problems that compound over time. Conversely, the right partnership accelerates development timelines, reduces total costs, and delivers components that perform exactly as designed.

The true value of working with experienced precision metal fabricators lies not in the metal they cut, but in the engineering expertise, quality systems, and collaborative problem-solving they contribute throughout your project lifecycle.

Taking the Next Step in Your Fabrication Journey

Ready to apply what you've learned? Your path forward depends on whether you're sourcing components or building a career.

For B2B Buyers and Engineers:

- Define your tolerance requirements before requesting quotes—precision fabrication costs vary significantly based on dimensional specifications

- Verify certifications match your industry: IATF 16949 for automotive, AS9100 for aerospace, ISO 13485 for medical devices

- Evaluate in-house capabilities to minimize supply chain complexity and communication gaps

- Request DFM consultation early—engineering collaboration prevents costly redesigns later

- Assess scalability from prototype quantities through production volumes

- Confirm lead time commitments and communication protocols before committing

For Career Seekers:

- Explore structured apprenticeship programs offering 4,000 hours of on-the-job training with classroom instruction

- Target employers partnered with registered apprenticeship organizations for tuition assistance and wage progression

- Develop foundational skills in blueprint reading, precision measurement, and CNC operations

- Pursue journey-level certification to unlock advancement into machinist, quality inspector, or supervisory roles

- Consider specialized credentials aligned with high-demand sectors like aerospace or medical manufacturing

Connecting with the Right Precision Fabricator

For companies seeking precision fabrication services, the evaluation framework you've learned applies immediately. Start by identifying fabricators whose certifications, capabilities, and industry experience align with your application requirements. Request detailed quotes that include engineering review—fabricators who quote without understanding your drawings often deliver surprises later.

Modern fabricators differentiate themselves through responsiveness and comprehensive support. Look for partners offering rapid prototyping capabilities that compress development cycles—some manufacturers deliver functional prototypes within five days, enabling faster design iteration. Quote turnaround times matter equally: fabricators like Shaoyi (Ningbo) Metal Technology provide 12-hour quote responses with comprehensive DFM support, demonstrating the engineering capacity and customer focus that distinguish premium suppliers from commodity operations.

For automotive applications specifically, prioritize IATF 16949-certified manufacturers with documented experience in chassis, suspension, and structural components. The combination of certified quality systems, rapid prototyping capabilities, and automated mass production capacity positions your supply chain for both development agility and production scale.

Whether you're launching a new product, optimizing an existing supply chain, or building a career in advanced manufacturing, precision metal fabrication offers opportunities for those who invest in understanding its requirements. The secrets revealed throughout this guide—tolerance fundamentals, process capabilities, material selection, certification requirements, and evaluation criteria—equip you to make decisions that drive success rather than learning through costly mistakes.

Your next step? Apply this knowledge. Evaluate your current suppliers against the criteria outlined here. Explore apprenticeship programs if career development is your goal. And remember: in precision fabrication, the partners who understand your requirements before production begins are the ones who deliver results that exceed expectations.

Frequently Asked Questions About Precision Metal Fabricators

1. What is precision metal fabrication?

Precision metal fabrication is a specialized manufacturing approach that achieves dimensional tolerances between ±0.001 to ±0.010 inches using advanced CNC equipment, rigorous quality systems, and engineered consistency. Unlike standard fabrication with tolerances of ±0.030 inches or more, precision fabrication produces components where microscopic deviations determine product success—critical for aerospace, medical, and automotive applications requiring exact specifications.

2. How much does metal fabrication cost per hour?

Metal fabrication costs typically range from $70 to $130 per hour for local welders and fabricators performing custom sheet metal work. However, precision metal fabrication often commands premium rates due to specialized equipment, tighter tolerances, and quality certification requirements. Factors like IATF 16949 or AS9100 certification, material complexity, and tolerance specifications significantly influence final pricing beyond standard hourly rates.

3. What certifications should precision metal fabricators have?

Required certifications depend on your industry: IATF 16949 for automotive applications, AS9100 for aerospace components, and ISO 13485 for medical devices. ISO 9001 serves as the baseline quality management standard. These certifications demonstrate documented quality systems, not just one-time achievements—look for recent audit dates and ongoing compliance when evaluating potential fabrication partners.

4. What materials do precision metal fabricators commonly work with?

Precision fabricators commonly process stainless steel (304/316 grades), aluminum alloys (6061/7075), carbon steel, cold-rolled steel, copper, brass, and titanium. Material selection depends on application requirements including tensile strength, corrosion resistance, conductivity, and tolerance achievability. Each material behaves differently during cutting, forming, and welding—experienced fabricators guide selection based on your specific performance needs.

5. How do I evaluate and select a precision metal fabricator?

Evaluate fabricators across five critical factors: quality certifications matching your industry, in-house capabilities from cutting through finishing, engineering and DFM support, documented industry experience, and scalability with clear communication protocols. Request detailed quotes including engineering review, verify certification currency through recent audit dates, and assess lead time performance—some premium fabricators offer 5-day rapid prototyping and 12-hour quote turnarounds.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —