Selecting Steel Grades for Automotive Stamping: Engineering Criteria

TL;DR

Selecting the optimal steel grades for automotive stamping requires a precise balance between three competing variables: formability (ductility), mechanical strength (yield/tensile), and production cost. While low carbon steels like SAE 1008 remain the standard for visible body panels due to their superior surface finish, modern safety requirements have shifted the industry toward High-Strength Low-Alloy (HSLA) and Advanced High-Strength Steels (AHSS) for structural integrity. Successful material selection hinges on understanding the trade-offs between a metal's ability to stretch without splitting and its capacity to absorb crash energy.

Critical Selection Factors: Engineering Criteria

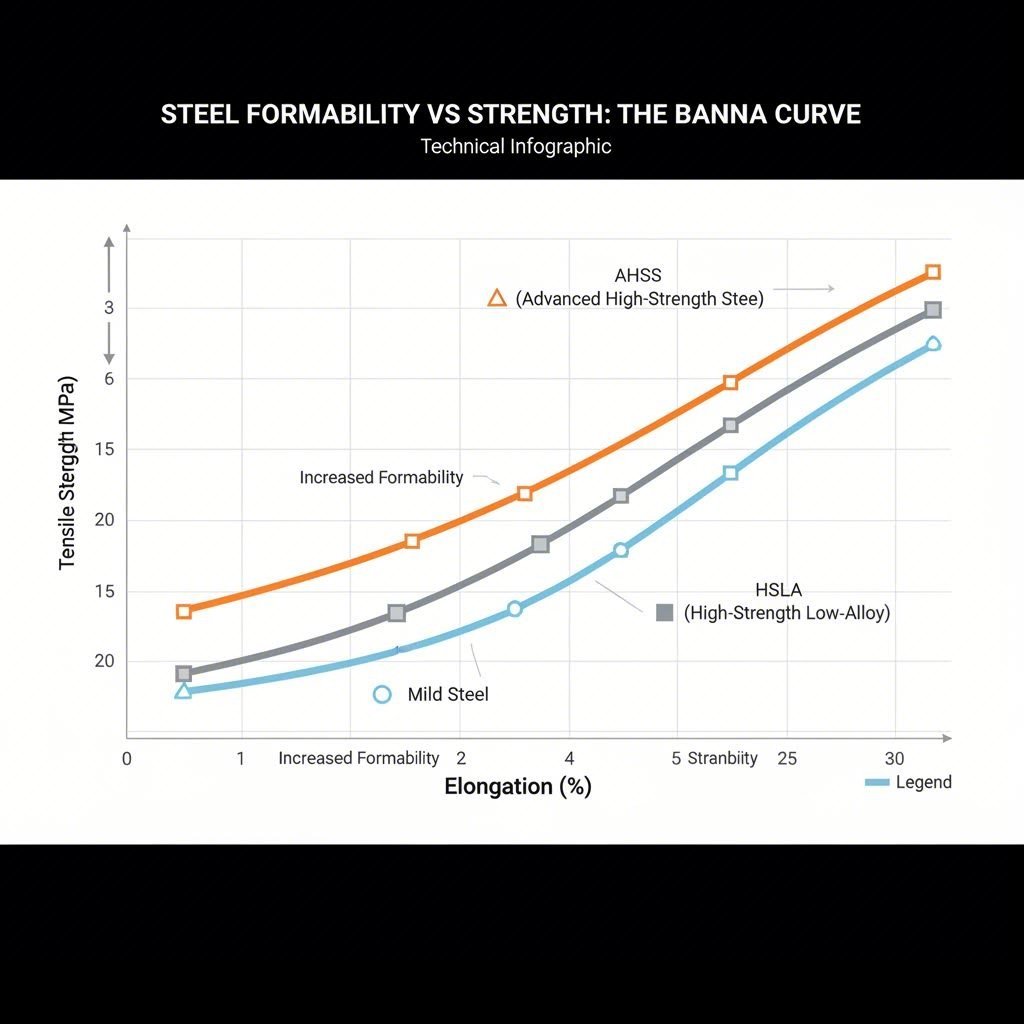

Before specifying a grade, engineers must evaluate the material's mechanical properties against the part's geometry and function. The primary trade-off in automotive stamping is universally recognized: as strength increases, formability generally decreases. This inverse relationship dictates that materials selected for deep-drawn parts must prioritize elongation, while safety-critical components prioritize tensile strength.

Key performance indicators for stamped materials include:

- Yield Strength vs. Tensile Strength: Yield strength determines the limit of elastic deformation, while tensile strength defines the point of fracture. For structural parts, a high yield point is critical to prevent permanent deformation under load.

- Elongation (n-value): The work-hardening exponent (n-value) indicates how well the steel distributes strain. Higher n-values allow for more complex shapes without localized thinning or tearing.

- Anisotropy (r-value): This measures the material's resistance to thinning. A high r-value is essential for deep-drawing applications like oil pans or gas tanks.

Cost efficiency also plays a pivotal role. While advanced grades offer weight reduction, they often require higher tonnage presses and more expensive tooling coatings to manage increased wear. According to Worthy Hardware, understanding these parameters is the first step in avoiding costly production failures such as splitting or excessive springback.

Standard Carbon Steel Grades (The Workhorses)

Carbon steels remain the backbone of automotive manufacturing, accounting for a significant percentage of total vehicle weight. These grades are classified by their carbon content, which directly influences their hardness and ductility.

Low Carbon and Mild Steel (SAE 1008, 1010)

Low carbon steels, often referred to as mild steels, typically contain less than 0.25% carbon. Grades like SAE 1008 and SAE 1010 are the industry standard for visible "Class A" surface parts, such as fenders, hoods, and door panels. Their high ductility allows them to be stamped into complex, sweeping curves without cracking. Additionally, they are easily welded and paintable, making them ideal for the Body-in-White (BIW) assembly.

Medium and High Carbon Steel (SAE 1045, 1095)

As carbon content increases, the steel becomes harder and stronger but significantly less formable. Medium carbon grades like SAE 1045 are utilized for parts requiring higher wear resistance, such as gears or brackets. High carbon steels, such as SAE 1095, function best in applications demanding extreme hardness and shape retention, like springs or clips. Talan Products notes that while these grades offer superior durability, they challenge the stamping process, often requiring multiple forming stages or heat treatment.

| Grade Category | Common SAE Grades | Typical Automotive Application | Key Characteristic |

|---|---|---|---|

| Low Carbon | SAE 1008, 1010, A36 | Body panels, chassis covers | High formability, excellent surface finish |

| Medium Carbon | SAE 1045, 1050 | Gears, axles, brackets | Balanced strength and wear resistance |

| High Carbon | SAE 1080, 1095 | Springs, washers, clips | High hardness, brittle forming behavior |

High-Strength & Advanced Steels (HSLA & AHSS)

To meet tightening fuel economy standards and crash safety regulations, automotive engineers increasingly turn to High-Strength Low-Alloy (HSLA) and Advanced High-Strength Steels (AHSS). These materials allow manufacturers to use thinner gauges (downgauging) to reduce weight without sacrificing structural integrity.

HSLA steels achieve their strength through micro-alloying with elements like vanadium or niobium. They are widely used for chassis components, suspension arms, and reinforcements. AHSS, including Dual Phase (DP) and Transformation Induced Plasticity (TRIP) steels, offer an even more aggressive strength-to-weight ratio, with tensile strengths often exceeding 800 MPa.

Processing these materials requires specialized capabilities. The higher strength results in significant "springback"—the tendency of the metal to return to its original shape after stamping. Addressing this requires advanced die design and heavy-duty press lines. For complex structural components like control arms or subframes, partnering with a manufacturer capable of handling high-tonnage requirements is essential. Companies like Shaoyi Metal Technology leverage IATF 16949-certified precision and press capabilities up to 600 tons to deliver these critical safety components effectively.

Corrosion-Resistant & Stainless Options

For components exposed to harsh environments, such as exhaust systems or exterior trim, corrosion resistance becomes the deciding factor. While galvanizing (zinc coating) protects carbon steel body panels, specific applications demand the inherent properties of stainless steel.

Ferritic Stainless Steel (400 Series): Grade 409 is the go-to choice for automotive exhaust systems. It offers adequate corrosion resistance at a lower cost than the 300 series and resists oxidation at high temperatures. It is magnetic and has moderate formability.

Austenitic Stainless Steel (300 Series): Grade 304 provides superior corrosion resistance and a non-magnetic, aesthetically pleasing finish. According to Larson Tool and Stamping, this grade is preferred for decorative trim, wheel covers, and parts where rust is unacceptable. However, it is more expensive and susceptible to work hardening, which can complicate the stamping process.

Application Mapping: Which Grade for Which Part?

Choosing the right material is ultimately a function of the part's location and purpose within the vehicle architecture. This decision matrix helps streamline the selection process:

- Visible Exterior (Skin Panels): Priority is surface quality and formability. Use: Low Carbon / IF Steels / Bake Hardenable Steel.

- Safety Cage (Pillars, Roof Rails): Priority is energy absorption and crash protection. Use: Dual Phase (DP) or Boron Steel (Hot Stamped).

- Chassis & Suspension: Priority is fatigue strength and durability. Use: HSLA 350/420.

- Exhaust & Heat Shields: Priority is heat and corrosion resistance. Use: Stainless 409 or Aluminized Steel.

By mapping the material properties to the specific stress and environmental conditions of the application, engineers can ensure longevity and performance while controlling manufacturing costs.

Summary of Steel Selection Strategies

The transition from simple mild steels to complex multiphase alloys represents the evolution of modern automotive engineering. Successful stamping projects rely not just on picking a grade from a chart, but on analyzing the entire lifecycle of the component—from the press line to the crash test lab. Whether optimizing for the lightweight demands of electric vehicles or the rugged durability of commercial trucks, the correct steel grade serves as the foundation of automotive safety and efficiency.

Frequently Asked Questions

1. What is the difference between HSLA and mild steel in stamping?

HSLA (High-Strength Low-Alloy) steel is significantly stronger than mild steel due to the addition of alloying elements, allowing for thinner, lighter parts. However, HSLA is less formable and has higher springback, requiring more force and precise die compensation compared to the soft, ductile mild steel used for deep-drawn body panels.

2. Why is SAE 1008 preferred for automotive body panels?

SAE 1008 is preferred because of its excellent formability and surface finish quality. Its low carbon content allows it to be drawn into complex, smooth shapes without splitting, and it provides a consistent surface for painting, which is critical for the visual appeal of a vehicle's exterior.

3. Can stainless steel be used for structural automotive parts?

While stainless steel is incredibly strong and corrosion-resistant, it is generally too expensive for widespread use in the structural safety cage compared to AHSS or HSLA. It is primarily reserved for exhaust systems (high heat resistance) and decorative trim (corrosion resistance), though some specialized high-performance applications may use it for structure.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —