Automotive Seat Frame Stamping: Manufacturing Technologies & Lightweighting Trends

TL;DR

Automotive seat frame stamping is a precision manufacturing process that utilizes high-tonnage progressive and transfer die technologies (typically 100–1,200+ tons) to fabricate structural vehicle components from high-strength materials. As the automotive industry shifts toward electric vehicles (EVs), the primary focus has moved to lightweighting—replacing traditional steel with Advanced High-Strength Steel (AHSS), aluminum, and magnesium alloys to extend battery range without compromising safety.

Modern seat frame production is no longer just about metal forming; it requires the integration of wire bending, tube fabrication, and complex assembly methods like laser welding. For OEMs and Tier 1 suppliers, success depends on selecting the right manufacturing process—balancing the speed of progressive stamping with the material efficiency of transfer systems—while navigating strict safety standards like FMVSS and IATF 16949.

The Core Technologies: Progressive vs. Transfer Stamping

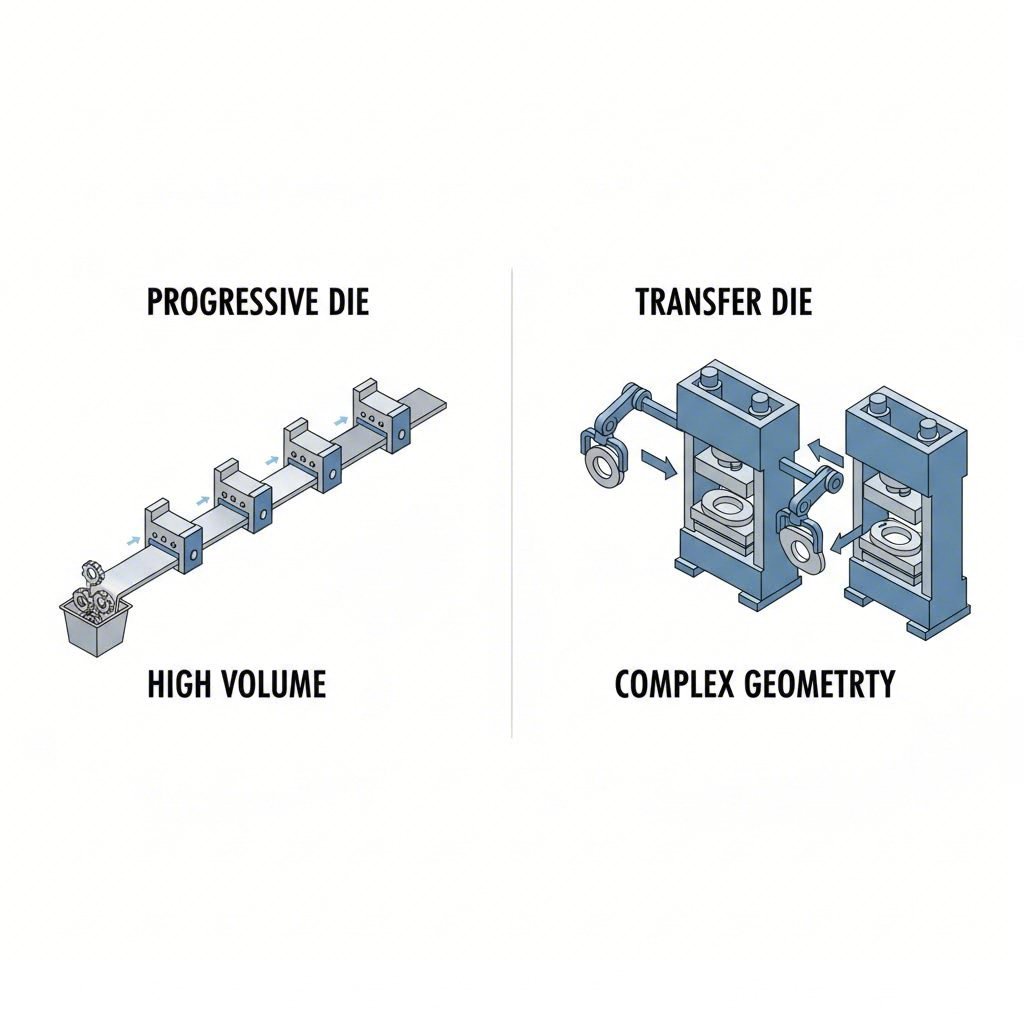

The decision between progressive die and transfer die stamping is the fundamental engineering choice in seat frame production. This decision dictates tooling costs, production speed, and part complexity.

Progressive Die Stamping is the industry standard for high-volume, smaller components. In this process, a continuous strip of metal is fed through a series of stations within a single die. Each stroke of the press performs a different operation—cutting, bending, coining—until the finished part is severed from the strip at the final station. This method is ideal for producing components like recliner rings, guide rails, and connecting brackets where speed is paramount.

Transfer Die Stamping, by contrast, is necessary for larger, deeper, or more complex parts that cannot remain attached to a carrier strip. Here, mechanical fingers or robotic arms transfer individual part blanks between varying die stations. This method is typically used for substantial structural elements like deep-drawn seat pans, side frames, and heavy-gauge risers. While slower than progressive stamping, it offers greater freedom for complex geometries and reduces material waste—a critical factor when working with expensive lightweight alloys.

| Feature | Progressive Die Stamping | Transfer Die Stamping |

|---|---|---|

| Best For | Small to medium parts (Brackets, Rails, Rings) | Large structural parts (Seat Pans, Side Frames) |

| Speed | High (Continuous feed) | Moderate (Part manipulation required) |

| Material Waste | Higher (Requires carrier strip) | Lower (Optimized nesting) |

| Tooling Cost | High initial investment | Generally lower, but press cost is higher |

| Complexity | Limited by strip attachment | High geometric flexibility |

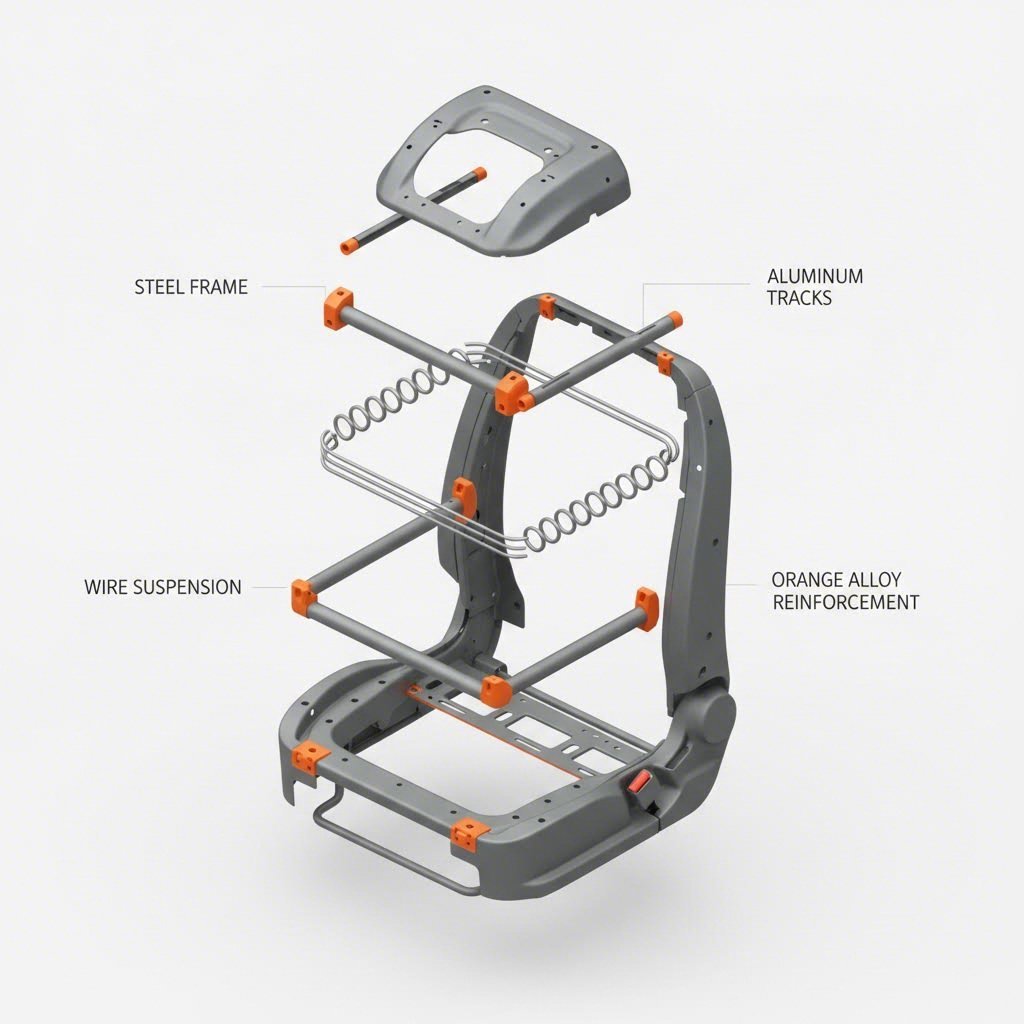

Material Innovation: The Drive for Lightweighting

The mandate to increase EV range and reduce CO2 emissions has revolutionized material selection for seat structures. Manufacturers are moving away from mild steels toward materials that offer higher strength-to-weight ratios.

Advanced High-Strength Steels (AHSS) and UHSS are now dominant. Grades like Dual-Phase (DP) and Transformation-Induced Plasticity (TRIP) steels allow engineers to use thinner gauges without sacrificing crashworthiness. Leading manufacturers like Proma Group utilize patented single-stroke stamping processes to form these difficult materials into robust seat cushion and back frame structures.

Aluminum and Magnesium Alloys represent the next frontier. Aluminum frames can offer weight savings of approximately 28% compared to steel, while magnesium can yield savings up to 35%. However, these materials introduce manufacturing challenges, such as increased springback and the need for specialized lubrication. Addressing these challenges often requires servo-drive presses that can programmatically adjust ram speed during the drawing phase to prevent cracking.

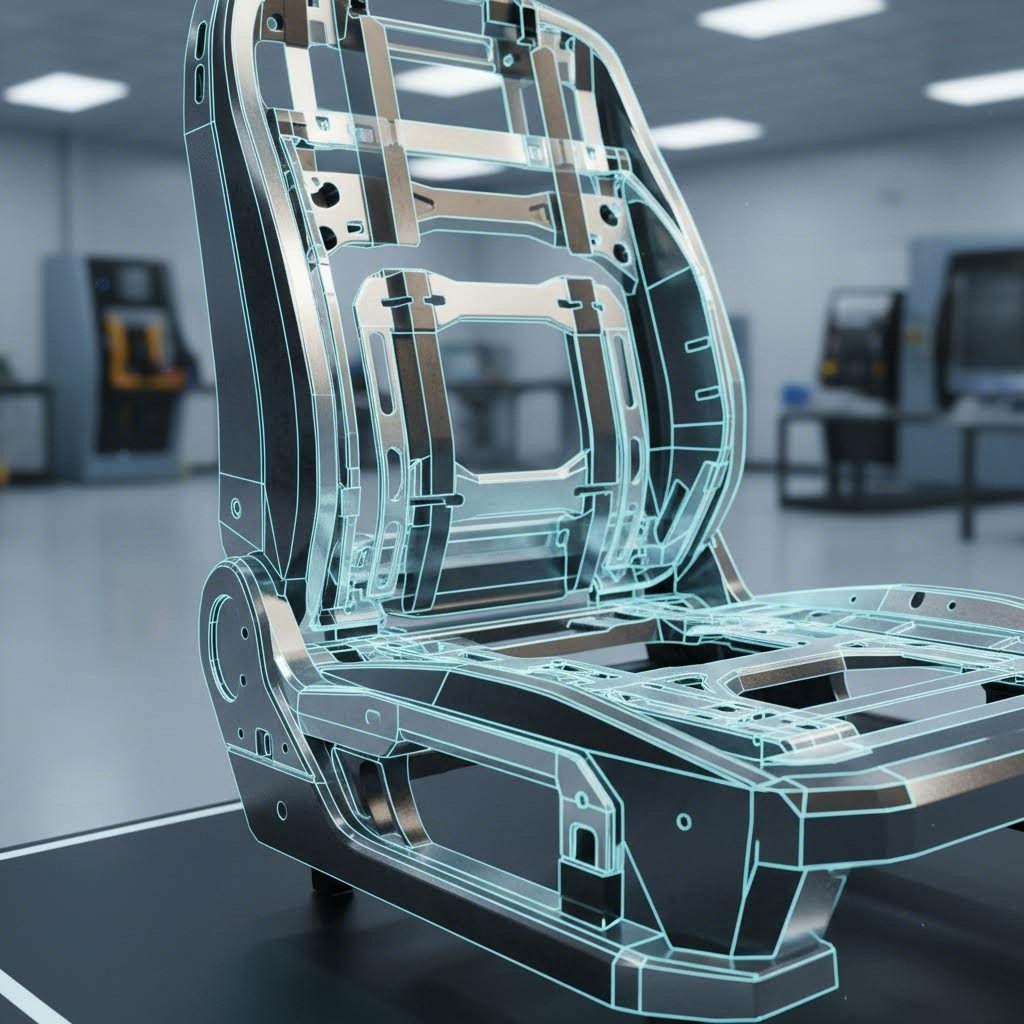

Beyond Stamping: Assembly and Component Integration

A stamped metal part is rarely the final product. Modern automotive seating requires the delivery of fully integrated assemblies. Suppliers like Guelph Manufacturing and Hatch Stamping have evolved into system integrators, combining stamped components with wire forms and tubular structures.

- Tube Bending & Wire Forming: Seat structures often rely on bent tube frames for backrests and wire forms for suspension mats. These processes must be synchronized with stamping operations to ensure fitment.

- Joining Technologies: The shift to mixed materials (e.g., joining steel rails to aluminum pans) has made traditional spot welding insufficient in some applications. Manufacturers are increasingly adopting MIG welding, laser welding, and mechanical fastening to ensure structural integrity across dissimilar metals.

- Mechanism Integration: The frame must house complex electromechanical systems, including lifter brakes, manual and power seat tracks, and recliner mechanisms. Precision stamping is critical here; even micron-level deviations in a seat track can lead to noise, vibration, and harshness (NVH) issues in the final vehicle.

Quality Control and Process Optimization

In safety-critical applications like automotive seating, defect prevention is non-negotiable. Quality starts before the press hits the metal. Precision decoiler machines, such as those detailed by Henli Machine, play a vital role. Features like pneumatic pressure arms and guide arm systems prevent material spread and protect the coil surface from scratches—defects that could lead to cosmetic rejection or structural fatigue.

Finite Element Analysis (FEA) is another essential tool used by top-tier suppliers to simulate the stamping process before tooling is built. FEA helps engineers predict thinning, wrinkling, and springback, allowing for die compensation during the design phase rather than costly trial-and-error on the shop floor.

When selecting a manufacturing partner, certification is the baseline. Look for suppliers holding IATF 16949 certification, which guarantees adherence to strict automotive quality management standards. Furthermore, the ability to bridge the gap between development and production is crucial. For OEMs needing agility, Shaoyi Metal Technology offers comprehensive stamping solutions that scale from rapid prototyping (delivering 50+ parts in as little as five days) to high-volume mass production on 600-ton presses, ensuring design feasibility is validated early in the program.

Engineering the Future of Seating

The automotive seat frame market is evolving from simple metal bending to high-tech structural engineering. As vehicles become autonomous and electric, the seat becomes the center of the passenger experience, demanding lighter weight, higher safety, and greater functionality. For engineers and procurement leaders, the goal is to partner with manufacturers who offer not just press capacity, but a holistic understanding of material science, joining technologies, and precision quality control.

Frequently Asked Questions

1. What is the difference between progressive and transfer die stamping for seat frames?

Progressive die stamping feeds a continuous strip of metal through multiple stations, making it faster and ideal for smaller parts like brackets and connectors. Transfer die stamping moves individual cut blanks between stations, which is better suited for large, deep-drawn parts like seat pans and side frames that require complex forming operations.

2. Why is magnesium used in automotive seat frames?

Magnesium is used primarily for its exceptional strength-to-weight ratio. It is approximately 33% lighter than aluminum and 75% lighter than steel, making it ideal for extending the range of electric vehicles. However, it requires specialized die casting or stamping processes due to its unique material properties.

3. Who are the major global manufacturers of automotive seat structures?

Major players in the automotive seating industry include Lear Corporation, Adient, Faurecia (Forvia), Toyota Boshoku, Tachi-S, and Magna International. These companies typically function as Tier 1 suppliers, delivering complete seating systems to OEMs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —