Firewall Stamping Automotive: Decoding Factory Inspection Marks

TL;DR

Firewall stamping in the automotive world carries a dual meaning: it most often refers to the cryptic quality control (QC) ink markings (like "PTB" or "OK") applied during assembly to verify Paint, Trim, and Body inspections, which are highly prized by restorers for authenticity. Secondarily, it describes the industrial metal stamping process of pressing the structural firewall panel itself from sheet metal. If you are restoring a classic car, those smudged ink stamps are vital clues to its factory origins; if you are looking at manufacturing, the firewall is a critical stamped component for structural rigidity.

For restoration enthusiasts, preserving or replicating these inspection marks—often found hidden behind heater boxes or master cylinders—adds "concours" value. However, distinguishing these cosmetic ink stamps from the legally protected, permanent VIN metal stampings is crucial to avoid felony tampering issues.

Decoding the Mystery: PTB and Inspection Marks

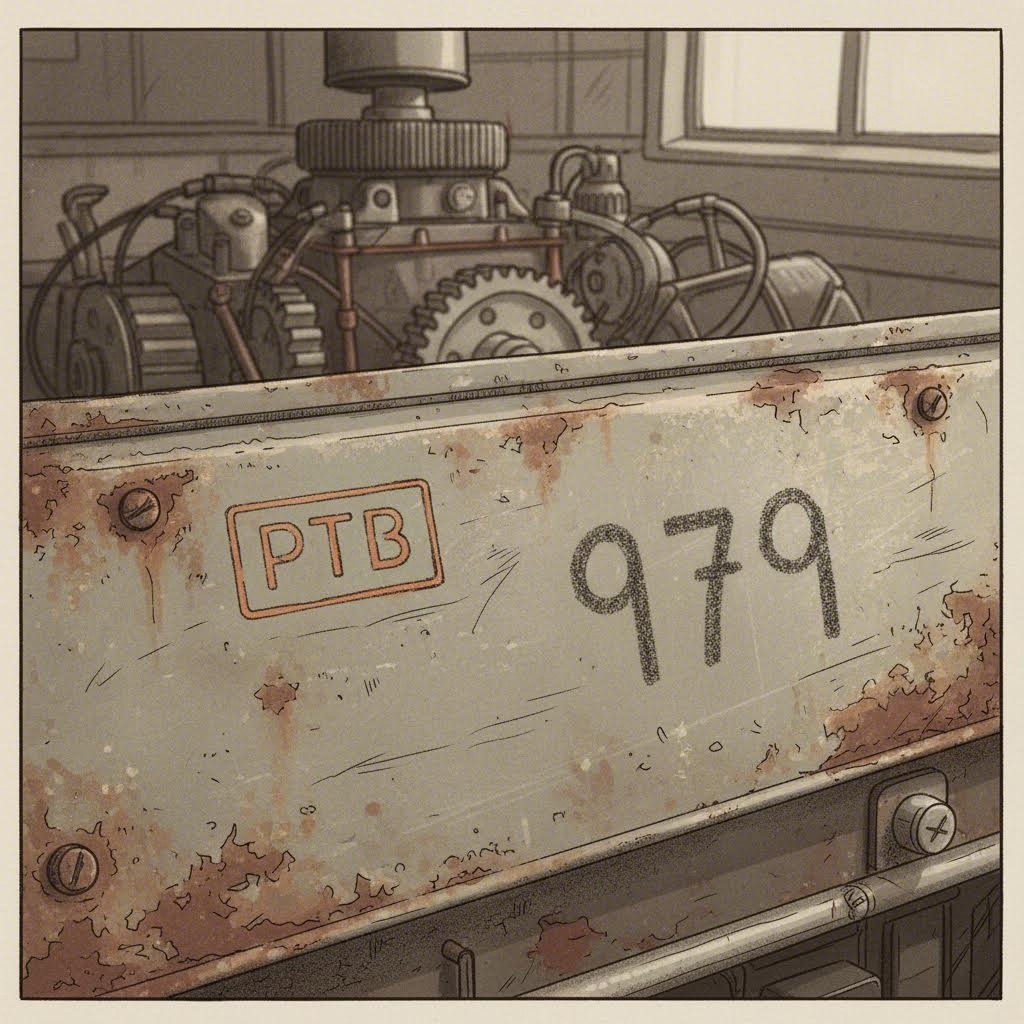

For the classic car detective, nothing beats the thrill of finding a survivor firewall with its original ink stamps intact. These markings were not meant for the customer; they were factory shorthand used by Fisher Body and assembly line inspectors to sign off on specific stages of the build. The most legendary among these is the "PTB" system found on many GM muscle cars (Camaros, Chevelles, GTOs) from the late 1960s and early 1970s.

The code breaks down simple assembly checkpoints:

- P (Paint): Verified that the body paint finish met factory standards and coverage was complete.

- T (Trim): Confirmed that moldings, chrome, and interior soft trim were installed correctly without damage.

- B (Body): The final check for sheet metal fitment, door gaps, and structural welding quality.

The Color of the Shift

The color of the ink was rarely a random choice. Factory consensus suggests that colors were often used to identify specific work shifts to trace accountability. For example, an orange stamp typically indicated the Day Shift, while a green stamp often denoted the Night Shift. However, anomalies exist—inspectors would sometimes grab whatever grease pencil or rubber stamp was available, leading to yellow, white, or blue markings on "survivor" cars. Finding a yellow "OK" or a blue "Z" is less about a secret code and more about who was working the line that Tuesday in 1969.

Grease Pencil Scribbles vs. Rubber Stamps

Not all firewall markings are created equal. You will often see two distinct types of writing on an original firewall, and understanding the difference is key to an authentic restoration.

Rubber Stamps (The Official QC): These are the formal "P-T-B," "Inspected," or "Approved" marks. They were applied with a rubber die and permanent ink. They are usually located in consistent general areas—like the flat surface near the heater box or behind the brake booster—but the angle and clarity vary wildly. It was a human process, often done quickly as the chassis moved down the line.

Grease Pencil (The Assembly Aid): These look like crude, hand-written scribbles. They were visual aids for assembly workers, not quality checks. A large "979" scrawled in yellow grease pencil might correspond to the code for a Sienna Brown interior, telling the line worker which seats to grab before the trim tag was easily readable. A "59" might indicate the paint code. These marks are often much larger and messier than the inspection stamps.

Restoration Guide: Applying Reproduction Stamps

One of the biggest debates in the restoration community is whether to reapply these stamps after repainting a firewall. If you choose to add them, the goal is imperfection. A common mistake in "over-restoration" is placing the stamps perfectly straight and centered. Factory workers were stamping hundreds of cars a shift, often leaning over a fender; they rarely aimed for geometric perfection.

Techniques for the "Factory" Look:

- The Stencil Method: Vinyl stencils are popular, but they can leave hard, unnatural edges. To soften the look, mist the paint lightly rather than flooding the stencil.

- The "Potato" Trick: Old-school restorers sometimes carve a potato into a stamp for grease-style markings. The texture of the potato mimics the uneven transfer of a worn rubber stamp better than a crisp vinyl sticker.

- Placement Strategy: Don't guess. Look for "shadows" of the original ink during sanding. If your car has lost all traces, check survivor forums for your specific assembly plant (e.g., Norwood vs. Van Nuys for Camaros). Placing a stamp where it never existed is a dead giveaway of a non-authentic restoration.

CRITICAL: VIN Stamping vs. Ink Stamps

It is vital to distinguish between cosmetic ink stamps and VIN (Vehicle Identification Number) metal stampings. While you are free to scrub, paint over, or reapply ink stamps, tampering with the stamped metal VIN numbers is a federal felony.

Hidden VINs (Con Numbers):

Beyond the dashboard VIN plate, manufacturers often stamped a "partial VIN" or "hidden VIN" directly into the sheet metal of the firewall, usually hidden by the heater box or blower motor. These were anti-theft measures designed to help law enforcement identify stolen vehicles. Never fill, grind, or alter these metal stampings during bodywork. If you are blasting the firewall, tape over these numbers to preserve them. They are the ultimate proof of your car's identity.

Automotive Sheet Metal Stamping: The Industrial Side

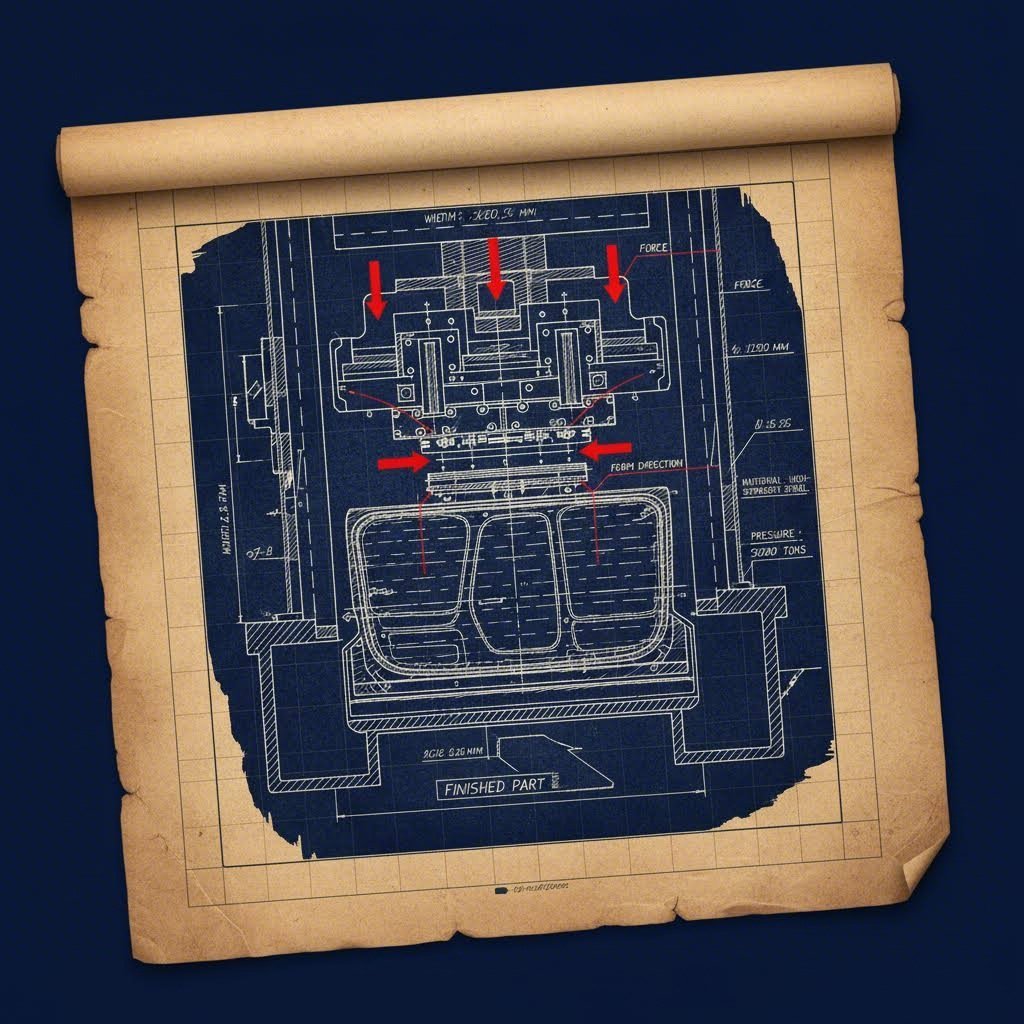

While restorers focus on the ink, the firewall itself is a marvel of the other definition of "stamping": the metalworking process. The firewall (or bulkhead) is a complex panel formed by pressing flat sheet metal between massive steel dies under hundreds of tons of pressure. This process, known as deep drawing, creates the complex curves and recesses needed to mount the engine, steering column, and pedals while providing rigid structural protection for the cabin.

From Classic to Modern Stamping

In the 1960s, firewall stamping was a brute-force operation often requiring multiple hits to form the shape. Today, the technology has evolved into precision engineering. Modern automotive production demands tight tolerances for robotic assembly. For manufacturers looking to bridge the gap between prototyping and mass production, companies like Shaoyi Metal Technology offer comprehensive stamping solutions. Leveraging IATF 16949-certified precision and press capabilities up to 600 tons, they deliver critical components—from structural subframes to intricate brackets—bridging the gap whether you need 50 prototypes or millions of mass-produced parts.

Frequently Asked Questions

1. What is a firewall in automotive terms?

In automotive design, the firewall (also called the bulkhead) is the metal panel that separates the engine compartment from the passenger cabin. Its primary functions are to provide structural rigidity, mount essential components like the steering column and master cylinder, and protect passengers from engine noise, heat, and potential fires.

2. Where are firewall inspection stamps usually hidden?

Inspection stamps are frequently found in areas that were accessible during early assembly but covered later. Common hiding spots include the area behind the heater or air conditioning box, behind the brake booster/master cylinder, or near the windshield wiper motor. On many "survivor" cars, these stamps are only discovered when components are removed for restoration.

3. What is the best firewall insulation for restoration?

For authentic restoration, many owners use reproduction jute padding or asphalt-based mats that mimic the factory look. However, for modern performance, butyl-based sound deadeners (like Dynamat) paired with a closed-cell foam liner offer superior heat and noise rejection. If you want the stock look with modern performance, some restorers place modern insulation under the factory-style rubber mat.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —