Stainless Steel Car Parts Stamping: The Engineering Guide to Grades & Process

TL;DR

Stainless steel car parts stamping is a precision manufacturing process that delivers high-volume, corrosion-resistant components essential for modern automotive engineering. From the ferritic 409 grade used in exhaust systems to the austenitic 304 grade favored for decorative trim and safety hardware, stainless steel offers a superior strength-to-weight ratio and heat resistance compared to mild steel. The process primarily utilizes progressive die stamping to manage complex geometries and tight tolerances required by OEMs. For procurement officers and engineers, success lies in selecting the appropriate alloy grade to balance cost with environmental performance while managing technical challenges like work hardening and springback.

Material Science: Selecting the Right Grade for Auto Parts

In automotive manufacturing, the choice of stainless steel grade is not merely about corrosion resistance; it is a strategic decision balancing formability, thermal endurance, and cost. The two primary families used in stamped car parts are Austenitic (300 series) and Ferritic (400 series), each serving distinct roles in the vehicle assembly.

Austenitic Stainless Steel (300 Series) is the industry standard for components requiring deep draw capability and superior corrosion resistance. Grade 304 is the most widely used alloy in this category, valued for its excellent formability and non-magnetic properties. It is frequently employed in structural components, airbag containers, and decorative trim where aesthetic appeal matches functional durability. For applications demanding higher tensile strength, such as chassis stiffeners or complex brackets, Grade 301 is often selected due to its high work-hardening rate, which allows it to absorb significant energy during a crash event.

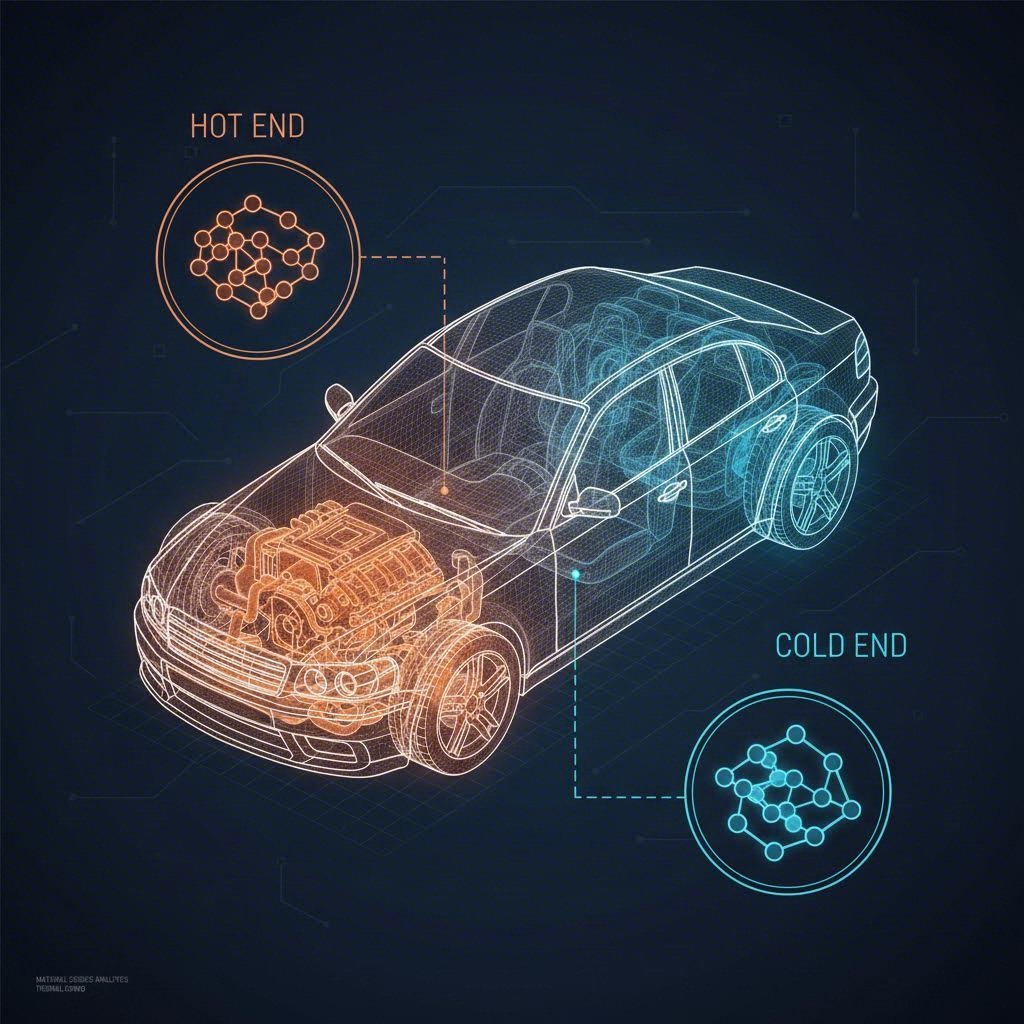

Ferritic Stainless Steel (400 Series), particularly Grade 409 and 430, dominates the "hot end" of the vehicle. Grade 409 was specifically developed for automotive exhaust systems; while it may develop surface rust, it maintains structural integrity under extreme thermal cycling and is significantly cheaper than nickel-rich 300 series alloys. Grade 430 offers better corrosion resistance and is often used for bright trim and interior panels where magnetic properties are not a hindrance. Engineers must note that ferritic grades generally have lower ductility than austenitic grades, limiting their use in deep-drawn parts.

| Grade Family | Key Alloys | Primary Properties | Typical Auto Application |

|---|---|---|---|

| Austenitic | 304, 304L, 301 | High formability, non-magnetic, superior corrosion resistance | Fuel systems, seat belt buckles, decorative trim, airbag housings |

| Ferritic | 409, 430, 439 | Magnetic, heat resistant, cost-effective, lower nickel content | Exhaust manifolds, catalytic converter shells, mufflers, heat shields |

| Specialty | 321, 316 | Titanium stabilized (321), Molybdenum added (316) | High-heat engine components, sensors exposed to road salts |

Critical Applications: From Exhausts to Safety Systems

Stamped stainless steel components are ubiquitous in modern vehicles, often hidden within critical subsystems. The material's ability to withstand harsh operating environments without degrading makes it indispensable for both internal combustion and electric vehicle (EV) architectures.

Exhaust and Emissions Systems represent the largest volume use of stamped stainless steel. The "hot end" components, such as exhaust manifolds and catalytic converter shells, rely on grades like 409 and 321 to resist temperatures exceeding 1500°F (815°C) while enduring constant vibration. Stamped heat shields are another vital application, protecting temperature-sensitive electronics and cabin interiors from engine heat. These parts often feature intricate geometries to maximize rigidity while minimizing mass.

Safety and Structural Components demand the predictable deformation properties of stainless steel. Seat belt buckles, retractor mechanisms, and brake backing plates are commonly stamped from high-strength grades to ensure failure-proof performance over the vehicle's life. In the EV sector, stainless steel stamping is gaining traction for battery enclosure reinforcement and busbars, where protection against puncture and corrosion is non-negotiable. The high energy absorption of austenitic grades contributes significantly to crashworthiness, allowing engineers to design thinner, lighter safety cages that meet stringent crash test standards.

The Stamping Process: Engineering Challenges & Solutions

Stamping stainless steel presents technical hurdles distinct from mild steel, primarily due to the material's higher shear strength and tendency to work harden. Work hardening occurs when the material becomes harder and more brittle as it is deformed. While this can be a benefit for structural strength, it wreaks havoc on tooling if not managed correctly. Manufacturers must use high-tonnage presses and specialized lubricants to prevent galling—the adhesion of the workpiece material to the die surface.

Springback is another critical phenomenon where the stamped part attempts to return to its original shape after the die opens. Because stainless steel has a higher yield strength, it exhibits greater springback than carbon steel. Experienced tool and die engineers compensate for this by over-bending the material in the die design phase. Progressive die stamping is the preferred method for high-volume production, performing multiple operations (cutting, bending, coining) in a single pass. For sourcing partners, checking their press capacity is vital; heavy-gauge automotive stainless parts often require press ratings between 400 and 800 tons to form accurately.

To navigate these complexities effectively, partnering with a capable manufacturer is essential. For OEMs looking to bridge the gap between initial design and mass production, Shaoyi Metal Technology offers comprehensive stamping solutions that leverage presses up to 600 tons and IATF 16949-certified precision. Their capability to scale from rapid prototyping of 50 units to millions of mass-produced control arms or subframes ensures that engineering challenges like springback and tolerance control are addressed early in the development cycle, preventing costly delays during full-scale manufacturing.

Commercial & Performance Advantages

Despite the higher raw material cost compared to galvanized or cold-rolled steel, stainless steel offers a compelling "Lifecycle Cost" advantage for automotive OEMs. The primary driver is the "Fit-and-Forget" durability. Components made from stainless steel do not require secondary plating or painting to resist rust, eliminating entire steps in the manufacturing supply chain and reducing the risk of coating failures in the field.

Lightweighting is another significant commercial benefit. Because stainless steel (especially cold-worked 301 or 304) has significantly higher tensile strength than mild steel, engineers can specify thinner gauges to achieve the same structural performance. This weight reduction is critical for improving fuel economy in ICE vehicles and extending the range of electric vehicles. Furthermore, the material is 100% recyclable, which aligns with the automotive industry's increasing focus on sustainability and circular economy principles.

Frequently Asked Questions

1. Can 304 stainless steel be stamped effectively?

Yes, Grade 304 is one of the most stampable stainless alloys due to its high ductility and elongation properties. However, it requires higher tonnage presses and more robust tooling (often carbide dies) compared to mild steel because it work-hardens rapidly. It is excellent for deep-drawn parts like fuel system components and decorative covers.

2. How do manufacturers prevent galling during stamping?

Galling, or the transfer of material to the die, is prevented by using high-performance lubricants specifically formulated for stainless steel, such as chlorinated oils or dry film barriers. Additionally, coating the tooling with Titanium Nitride (TiN) or using carbide die inserts significantly reduces friction and extends tool life.

3. Is stainless steel stamping more expensive than carbon steel?

The upfront material cost of stainless steel is higher, and the tooling maintenance costs can be greater due to faster die wear. However, the elimination of post-process plating (like zinc or e-coat) and the material's longevity often result in a lower total part cost over the vehicle's lifecycle.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —