Metal Stamping Engine Brackets: Manufacturing, Materials & Sourcing

TL;DR

Metal stamping engine brackets are critical automotive components engineered to secure powertrains, dampen vibration, and maintain structural integrity under high-stress conditions. Manufactured primarily through progressive die stamping for high-volume efficiency, these parts typically utilize High-Strength Low-Alloy (HSLA) steel or aluminum to balance durability with weight reduction. For procurement officers and automotive engineers, the key to successful sourcing lies in selecting manufacturers with IATF 16949 certification and the capability to hold tight tolerances (often down to +/- 0.001″). This guide explores the manufacturing technologies, material selection criteria, and design standards essential for producing reliable stamped engine brackets.

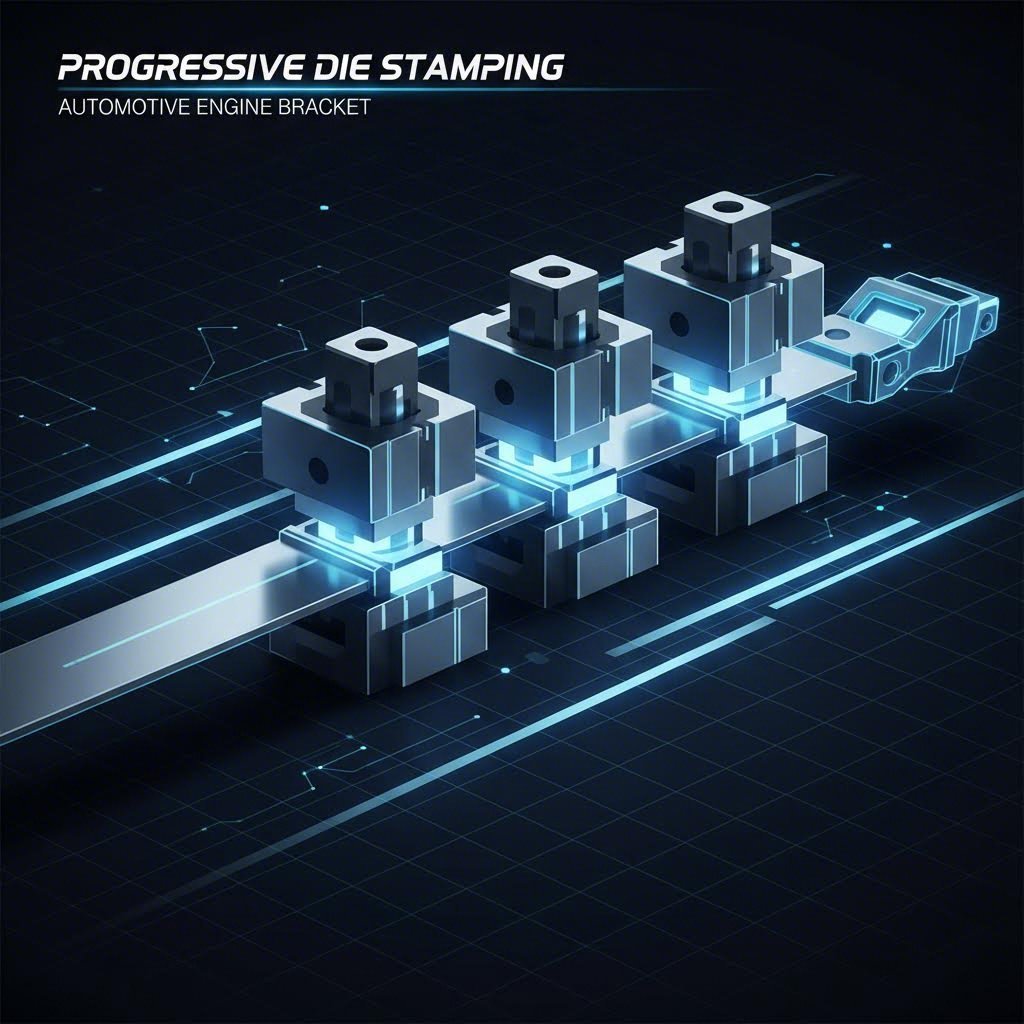

Engine Bracket Manufacturing: Process & Technologies

The manufacturing of engine brackets is a discipline that demands a precise balance between speed, volume, and geometric complexity. Unlike simple bent clips, engine brackets must withstand dynamic loads and fatigue while maintaining strict dimensional accuracy to ensure proper engine alignment.

Progressive Die Stamping is the dominant technology for producing these components at scale. In this process, a metal coil is fed through a series of stations in a single die set. Each station performs a specific operation—cutting, bending, punching, or coining—as the strip moves forward. This method is ideal for high-volume production (50,000+ units) because it minimizes handling and maximizes speed. Top-tier manufacturers utilize presses with high tonnage capacities (often 300 to 600 tons) to stamp thick-gauge materials required for engine support. For simpler geometries or lower volumes, transfer die stamping may be used, where mechanical fingers move the part between separate die stations.

A critical advantage of stamping over casting or machining is the ability to improve the material's grain structure through work hardening. While casting offers design freedom for complex 3D shapes, stamped brackets are generally lighter and have better strength-to-weight ratios. Zetwerk highlights that precision stamped brackets not only provide structural support but also play a pivotal role in vibration dampening, a key factor in passenger comfort and vehicle longevity.

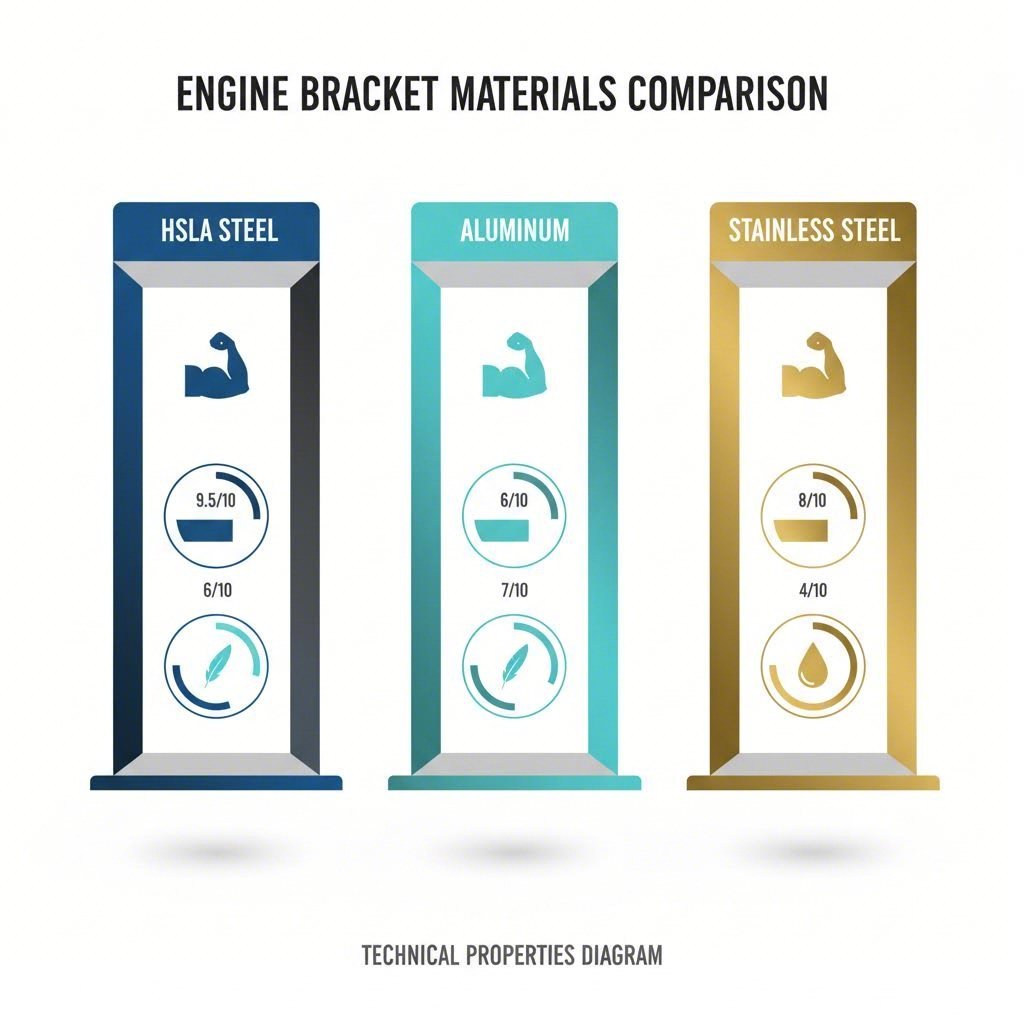

Material Selection for Automotive Brackets

Choosing the right material is a trade-off between tensile strength, fatigue resistance, weight, and cost. Engineers must select a grade that can endure the heat of the engine bay and the constant cyclic loading of road vibrations without failing.

- High-Strength Low-Alloy (HSLA) Steel: The industry standard for load-bearing brackets. Grades like Grade 50 or Grade 80 offer superior strength compared to mild steel without a significant weight penalty. HSLA is preferred where structural integrity is non-negotiable.

- Aluminum Alloys (e.g., 6061-T6, 5052): Increasingly popular for electric vehicles (EVs) and lightweighting initiatives. Aluminum brackets reduce overall vehicle mass, improving range and fuel efficiency. However, they require careful design to manage fatigue limits compared to steel.

- Stainless Steel (304, 316): Used selectively where corrosion resistance is the primary concern, such as in marine or exhaust-adjacent applications. While heavier and more expensive, it eliminates the need for secondary plating.

| Material Type | Key Benefit | Typical Application | Relative Cost |

|---|---|---|---|

| HSLA Steel | High strength-to-weight ratio | Main engine mounts, transmission brackets | Medium |

| Carbon Steel | Cost-effectiveness | Auxiliary brackets, support struts | Low |

| Aluminum | Weight reduction | EV motor mounts, subframe components | High |

| Stainless Steel | Corrosion resistance | Exhaust hangers, marine engines | High |

Surface treatments are equally critical. Most steel brackets require E-coating (electrophoretic painting) or zinc-nickel plating to pass automotive salt-spray tests (often 500+ hours). LCS Company notes that brackets can be finished with various coatings like galvanization or powder coating to ensure longevity in harsh environments.

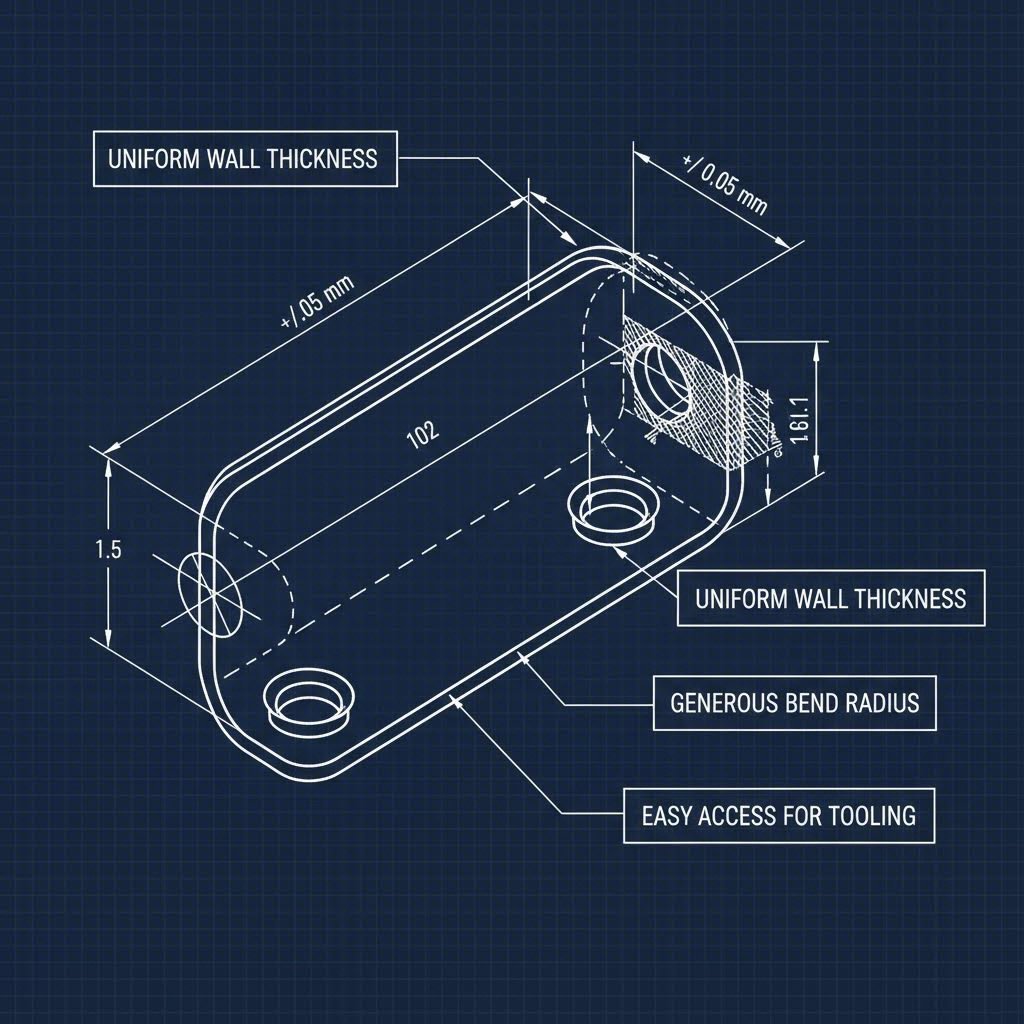

Design for Manufacturability (DFM) Standards

To ensure cost-efficiency and quality, engine brackets must be designed with the stamping process in mind. Ignoring DFM principles often leads to defects like springback, tearing, or excessive tool wear.

Bend Radii and Material Thickness: A general rule of thumb is to maintain an inside bend radius of at least 1.5 to 2 times the material thickness. Tighter radii risk cracking the outer surface of the bend, especially in high-strength grades. Designers should also avoid placing holes too close to a bend; a safe distance is typically 2 to 3 times the material thickness from the bend line to preventing hole distortion.

Tolerance Management: Precision is paramount. Leading stampers can achieve tolerances as tight as +/- 0.001 inches for critical features like mounting holes. However, specifying tighter tolerances than necessary drives up tooling costs. It is crucial to define "critical-to-quality" (CTQ) dimensions that affect fit and function, while allowing looser tolerances for non-mating surfaces.

Defect Prevention: Springback—the tendency of metal to return to its original shape after bending—is a major challenge with HSLA steel. Experienced manufacturers use simulation software during the design phase to predict and compensate for springback in the die design. This predictive engineering prevents costly iterations during production.

Quality Control & Automotive Certifications

In the automotive sector, quality is not just a goal; it is a regulatory requirement. A supplier lacking IATF 16949 certification is rarely eligible for Tier 1 or OEM contracts. This standard goes beyond ISO 9001 by emphasizing defect prevention, supply chain variation reduction, and continuous improvement.

Modern quality control relies heavily on technology. Wiegel employs in-die sensor technology and camera vision systems to inspect 100% of parts during the stamping process. These systems check for critical dimensions, hole presence, and part flatness at production speeds, ensuring that zero defects reach the assembly line.

Key quality documents procurement teams should request include:

- PPAP (Production Part Approval Process): Verifies that the production process can consistently meet requirements.

- FMEA (Failure Mode and Effects Analysis): Identifies potential failure points in the design or process.

- Material Certifications: Traces the raw material back to the mill to ensure chemical and mechanical properties meet specifications.

Sourcing Strategy: Choosing a Manufacturer

Selecting a partner for metal stamping engine brackets requires evaluating both technical capability and production capacity. You need a manufacturer that can scale from prototyping to mass production without compromising quality.

Capacity and Tonnage: Ensure the manufacturer has press capabilities that match your part's requirements. For heavy-duty engine brackets, presses up to 600 tons are often necessary to form thick high-strength steel. Shaoyi Metal Technology is a notable example of a manufacturer that bridges this gap, offering comprehensive stamping solutions from rapid prototyping to high-volume manufacturing. With IATF 16949 certification and press capabilities up to 600 tons, they can deliver critical components like control arms and subframes with strict adherence to global OEM standards.

Value-Added Services: The best suppliers do more than just stamp. Look for partners offering secondary operations like welding (MIG/TIG/Spot), assembly (inserting bushings or fasteners), and surface finishing. Integrated services reduce logistics costs and lead times. G&M Manufacturing emphasizes that in-house tooling maintenance is another critical factor, as it allows for faster reaction times if repairs or engineering changes are needed during a production run.

Conclusion

Sourcing metal stamping engine brackets is a strategic decision that impacts the safety and performance of the final vehicle. By prioritizing IATF 16949 certified suppliers, understanding the nuances of progressive die technology, and selecting appropriate materials like HSLA steel, procurement teams can ensure a robust supply chain. The ideal partner offers not just manufacturing capacity, but engineering support to optimize designs for manufacturability, ultimately delivering a component that meets the rigorous demands of the automotive industry.

Frequently Asked Questions

1. What is the difference between progressive die and transfer die stamping for brackets?

Progressive die stamping uses a continuous strip of metal fed through multiple stations, making it faster and more cost-effective for high-volume, smaller to medium-sized brackets. Transfer die stamping involves moving individual parts between stations, which is better suited for larger, more complex brackets or those requiring deep drawing operations that cannot be done on a continuous strip.

2. Why is IATF 16949 certification important for engine bracket manufacturers?

IATF 16949 is the global technical specification for quality management in the automotive industry. It ensures that the manufacturer has rigorous processes for defect prevention, risk management, and continuous improvement. For critical safety components like engine brackets, this certification provides assurance that the parts will perform reliably under stress.

3. Can stamped brackets replace cast or machined brackets?

Yes, in many cases. Stamped brackets are often lighter and cheaper to produce in high volumes than cast or machined alternatives. Through work hardening and smart geometric design (adding ribs and gussets), stamped parts can achieve comparable structural rigidity. However, extremely complex 3D shapes or low-volume heavy-duty applications might still favor casting.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —