Industrial Sheet Metal Decoded: From Raw Gauge to Finished Part

Understanding Industrial Sheet Metal and Its Critical Role in Manufacturing

When you hear "sheet metal," you might picture the shiny ductwork snaking through your home's HVAC system. But industrial sheet metal operates in an entirely different league. It forms the backbone of critical infrastructure—from oil refinery components to medical device housings and semiconductor equipment frames. Understanding what separates industrial-grade materials from their commercial counterparts is essential for engineers, procurement specialists, and manufacturers seeking reliable performance in demanding environments.

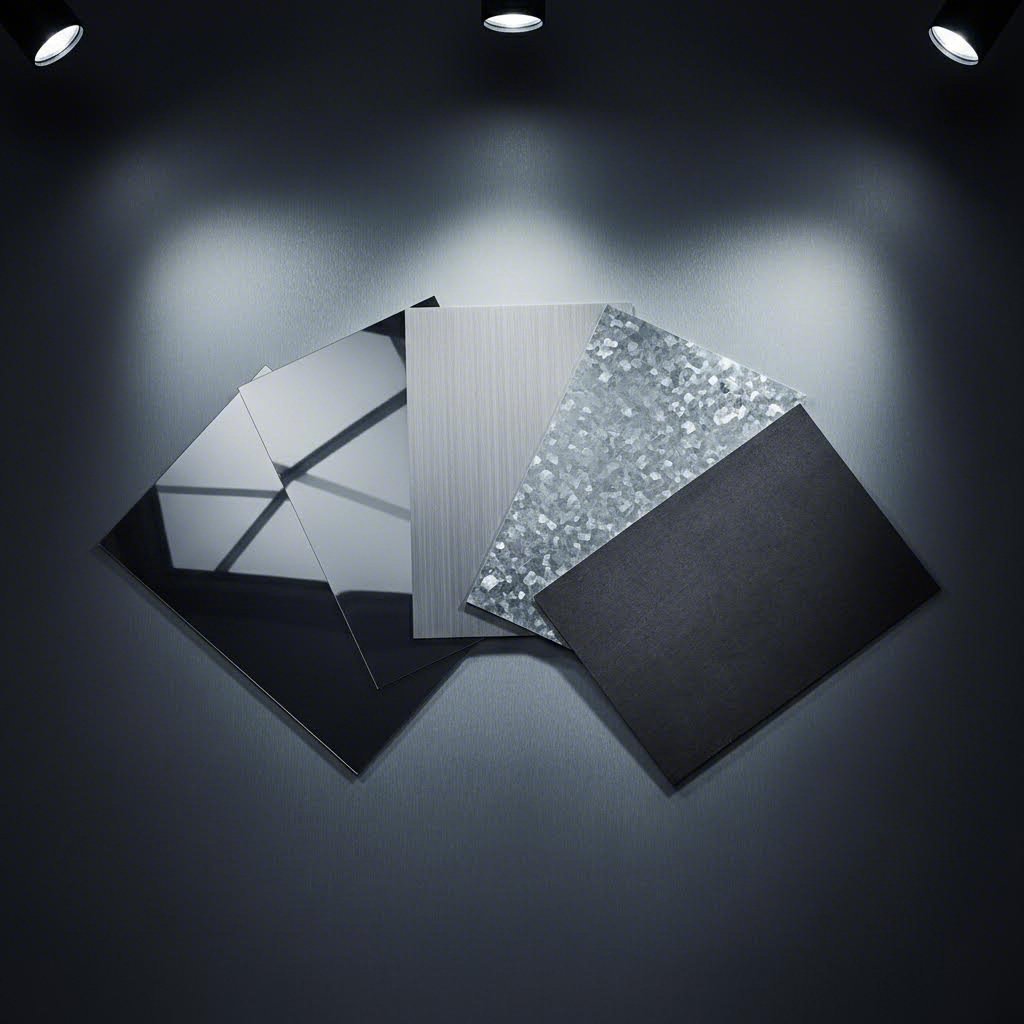

What Sets Industrial Sheet Metal Apart from Standard Materials

So what exactly qualifies as industrial sheet metal? The distinction comes down to three core factors: thickness specifications, material certifications, and manufacturing standards designed for high-performance applications.

According to industry standards, sheet metal encompasses any metal with a thickness between 0.5mm and 6mm. Anything thinner falls into foil territory, while thicker materials become plates. Industrial applications typically demand the mid-to-upper range of this spectrum, where structural integrity and durability take priority over flexibility.

Unlike decorative metal sheets used in architectural accents or commercial signage, industrial-grade materials must meet rigorous certification requirements. These certifications verify tensile strength, corrosion resistance, and dimensional tolerances—specifications that matter when a component failure could halt production lines or compromise safety systems.

Core Characteristics of Industrial-Grade Metal Sheets

What makes a metal sheet truly "industrial grade"? Here are the defining characteristics that separate these materials from standard commercial options:

- Precise thickness tolerances: Industrial applications require consistency. Even variations as small as 0.003 inches (roughly the thickness of a human hair) can impact fabrication processes like forming and welding.

- Certified material composition: Mill certifications document exact alloy compositions, ensuring materials meet ASTM, SAE, or industry-specific standards.

- Controlled surface finish requirements: Surface quality affects everything from coating adhesion to corrosion resistance, making finish specifications critical for end-use performance.

- Documented mechanical properties: Tensile strength, yield strength, and elongation percentages are verified through testing protocols.

- Full traceability: Heat lot numbers and material certificates enable complete tracking from mill to finished component.

Industrial metal fabrication spans remarkably diverse sectors, each with unique demands. The Oil & Gas industry requires materials that withstand extreme pressures and corrosive environments. Medical device manufacturers need biocompatible alloys with impeccable surface finishes. Semiconductor equipment demands ultra-clean materials free from contaminants that could compromise sensitive processes.

Heavy manufacturing, architectural construction, and automotive production each bring their own specifications to the table. This diversity within sheet metal industries drives the need for specialized knowledge—understanding not just what materials exist, but which ones perform optimally in specific applications.

Sheet metal fabrication at the industrial level also differs in production methods. While commercial applications might rely on basic shearing and bending, industrial metal fabrication often incorporates precision laser cutting, CNC-controlled forming, and multi-stage quality inspections. These processes transform raw metal sheets into components that meet exacting tolerances measured in thousandths of an inch.

The journey from raw coil to finished industrial component involves sophisticated processing. Large coils arrive at processing facilities via railcar, then pass through massive leveling machines that flatten, stretch, and cut the material into workable sheets. Common dimensions include four-foot by ten-foot and five-foot by ten-foot sheets, though custom sizes can be produced for specific applications.

Understanding these fundamentals positions you to make informed decisions throughout the specification and procurement process. In the sections ahead, we'll explore specific materials, gauge selections, fabrication methods, and quality standards that define successful industrial sheet metal projects.

Industrial Sheet Metal Materials and Their Performance Properties

Choosing the right material for your industrial sheet metal project isn't just a technical decision—it's a strategic one. The metal you select directly impacts performance, longevity, manufacturing costs, and even your project timeline. Yet many buyers struggle with material comparisons because specifications often read like alphabet soup. Let's break down the primary industrial materials and explain what those numbers actually mean for your application.

Carbon Steel vs Stainless Steel for Industrial Applications

Imagine you're specifying materials for heavy machinery components. Do you reach for carbon steel or stainless steel? The answer depends on your operating environment, budget constraints, and performance requirements.

Carbon steel remains the workhorse of industrial fabrication. It delivers exceptional tensile strength—typically ranging from 400 to 550 MPa—at a fraction of the cost of specialty alloys. This makes it ideal for structural applications, machinery frames, and components where raw strength matters most. However, carbon steel has an Achilles heel: corrosion. Without protective coatings or galvanization, it will rust when exposed to moisture and oxygen.

Stainless steel sheet solves the corrosion problem through chromium content (minimum 10.5%). This creates a passive oxide layer that resists rust and chemical attack. But not all stainless steels perform equally. The 300-series grades dominate industrial applications, with 304 serving general purposes and 316 stainless steel handling more aggressive environments.

What makes 316 stainless steel special? The addition of 2-3% molybdenum significantly improves resistance to chlorides and acids. This explains why you'll find it in marine equipment, chemical processing plants, and medical devices where exposure to harsh substances is unavoidable. The tradeoff? It costs roughly 20-30% more than 304 stainless.

When selecting between carbon steel and stainless steel, consider the total cost of ownership—not just material price. A stainless steel component that lasts 15 years without maintenance may prove more economical than carbon steel requiring regular painting or replacement every 5 years.

When Aluminum Sheet Metal Outperforms Steel Alternatives

Here's a question that sometimes catches engineers off guard: is aluminum a metal? Absolutely—it's a silvery-white, lightweight metallic element (atomic number 13) classified among the post-transition metals. What makes aluminum sheet remarkable for industrial applications is its unique combination of properties that steel simply cannot match.

Aluminum weighs roughly one-third as much as steel while offering excellent strength-to-weight ratios. For transportation, aerospace, and mobile equipment applications, this weight reduction translates directly into fuel savings and improved performance. An aluminum component replacing steel can reduce weight by 50-60% while maintaining adequate structural integrity for many applications.

Corrosion resistance comes naturally to aluminum through its oxide layer—similar to stainless steel but without the chromium cost. For enhanced protection and aesthetic options, anodized aluminum provides a thicker, harder oxide coating that also accepts dyes for color customization. You'll find anodized aluminum panels in architectural applications, electronic enclosures, and consumer products.

The thermal and electrical conductivity of aluminum makes it indispensable for heat exchangers, electrical busbars, and electronic housings. Copper offers higher conductivity, but aluminum provides approximately 60% of copper's conductivity at one-third the weight and significantly lower cost.

Understanding Galvanized Steel and Specialty Alloys

Galvanized steel offers a practical middle ground between raw carbon steel and stainless steel. The zinc coating provides sacrificial corrosion protection—meaning the zinc corrodes preferentially, protecting the underlying steel. Hot-dip galvanizing creates coatings ranging from 1 to 3 mils thick, suitable for outdoor equipment, HVAC components, and agricultural machinery.

Beyond these primary materials, industrial applications sometimes demand specialty alloys. When engineers compare brass vs bronze for specific components, they're weighing distinct property profiles. Brass—an alloy of copper and zinc—offers excellent machinability and corrosion resistance. So what is brass made of exactly? Typically 60-70% copper with 30-40% zinc, though formulations vary. Bronze substitutes tin for zinc, providing superior wear resistance for bearings and marine hardware.

Material Properties Comparison for Industrial Applications

Making informed material decisions requires understanding how properties translate to real-world performance. The following comparison covers the metrics that matter most for industrial sheet metal projects:

| Property | Carbon Steel | 304 Stainless | 316 Stainless Steel | Aluminum (6061) | Galvanized Steel |

|---|---|---|---|---|---|

| Tensile Strength | 400-550 MPa | 505-750 MPa | 515-690 MPa | 290-310 MPa | 400-550 MPa |

| Corrosion Resistance | Poor | Excellent | Superior | Very Good | Good |

| Weight (Relative) | 1.0 (baseline) | 1.0 | 1.0 | 0.35 | 1.0 |

| Relative Cost | $ (lowest) | $$$ | $$$$ | $$ | $-$$ |

| Weldability | Excellent | Good | Good | Requires care | Good |

| Ideal Applications | Structural frames, machinery, indoor equipment | Food processing, general corrosive environments | Marine, chemical, medical devices | Aerospace, transportation, electronics | HVAC, outdoor equipment, agriculture |

How Material Selection Impacts Project Outcomes

Your material choice ripples through every aspect of a project. Consider these downstream effects:

- Fabrication methods: Aluminum requires specialized welding techniques and different cutting parameters than steel. Stainless steel work-hardens during forming, demanding adjusted tooling and processes.

- Surface treatments: Carbon steel needs painting or plating for corrosion protection. Aluminum accepts anodizing for enhanced durability. Stainless steel typically requires only passivation.

- Lead times: Common carbon steel gauges ship quickly from distributor stock. Specialty stainless alloys or unusual aluminum tempers may require mill orders with 8-12 week lead times.

- Secondary operations: Some materials machine more easily than others. 303 stainless offers superior machinability compared to 316, potentially reducing finishing costs.

Industrial sectors each gravitate toward materials matching their unique demands. Automotive manufacturers favor high-strength steel and aluminum for lightweighting initiatives. Chemical processors rely heavily on 316 stainless steel for tank and piping fabrication. Medical device companies require specific stainless grades meeting biocompatibility standards.

Understanding these material fundamentals positions you to have productive conversations with fabricators and make specifications that balance performance requirements with budget realities. But material selection represents only half the equation—thickness specifications determine whether your chosen material will actually perform as needed in your application.

Sheet Metal Gauge Chart and Thickness Selection Guide

You've selected your material—now comes the question that trips up even experienced engineers: what thickness do you actually need? Unlike most measurements in manufacturing, sheet metal thickness follows a counterintuitive numbering system where bigger numbers mean thinner material. This quirk traces back to 19th-century British wire manufacturing, and understanding it remains essential for specifying industrial sheet metal correctly.

Decoding the Sheet Metal Gauge System

Here's the fundamental rule that governs every sheet metal gauge chart: the higher the gauge number, the thinner the metal. A 10-gauge steel sheet is substantially thicker than a 20-gauge sheet. Sounds backward? You're not alone in thinking so.

The gauge system originated during wire drawing processes where metal was progressively pulled through smaller dies. Each pass reduced the wire's diameter and increased its gauge number. According to Ryerson's steel gauge chart guide, the word "gauge" derives from the French "jauge," meaning "result of measurement." Despite attempts to replace it with metric measurements during the 20th century, the gauge system persisted due to its widespread adoption among craftsmen and manufacturers.

What makes gauge sizes particularly tricky? Two critical factors:

- Non-linear increments: Moving between gauge numbers doesn't represent equal changes in thickness. The jump from 14 gauge to 13 gauge differs from the jump between 14 and 15.

- Material-specific values: The same gauge number represents different actual thicknesses depending on the metal type. A 14-gauge stainless steel sheet measures 0.0751 inches, while 14 gauge steel thickness in carbon steel measures 0.0747 inches.

This means you cannot simply specify "14 gauge" without also specifying the material. The decimal equivalent varies based on whether you're working with standard steel, stainless steel, galvanized steel, or aluminum.

Industrial Gauge Size Chart: From Heavy to Light Applications

Industrial applications typically utilize gauge sizes ranging from 6 gauge (heavy structural components) through 22 gauge (lighter enclosures and ductwork). The following table presents the most commonly specified gauges for industrial sheet metal projects, with actual thickness measurements and typical applications:

| Gauge | Standard Steel (inches) | Standard Steel (mm) | Stainless Steel (inches) | Recommended Applications |

|---|---|---|---|---|

| 6 | 0.1943 | 4.94 | 0.2031 | Heavy structural frames, industrial flooring, equipment bases |

| 8 | 0.1644 | 4.18 | 0.1719 | Machinery guards, heavy brackets, structural supports |

| 10 | 0.1345 | 3.42 | 0.1406 | Equipment housings, heavy-duty enclosures, truck bodies |

| 11 | 0.1196 | 3.04 | 0.1250 | Automotive chassis components, industrial shelving, structural brackets |

| 12 | 0.1046 | 2.66 | 0.1094 | Appliance panels, electrical enclosures, machine covers |

| 14 | 0.0747 | 1.90 | 0.0751 | HVAC components, automotive panels, general fabrication |

| 16 | 0.0598 | 1.52 | 0.0595 | Ductwork, light structural components, decorative panels |

| 18 | 0.0478 | 1.21 | 0.0500 | Residential HVAC, light enclosures, formed parts |

| 20 | 0.0359 | 0.91 | 0.0375 | Light ductwork, electronic chassis, decorative trim |

| 22 | 0.0299 | 0.76 | 0.0312 | Flashings, light formed components, shielding |

Notice how 11 gauge steel thickness (0.1196 inches) provides substantial rigidity for structural applications, while 22 gauge steel thickness (0.0299 inches) works best for non-structural components where weight savings and formability matter more than load-bearing capacity.

Selecting the Right Thickness for Structural Integrity

How do you determine which gauge fits your application? Consider three interconnected factors: structural requirements, fabrication methods, and cost implications.

Structural Requirements

The intended load and operating environment largely dictate minimum thickness. A machinery guard protecting workers from rotating equipment needs sufficient rigidity to withstand impact—typically 10 or 12 gauge. Conversely, an electrical enclosure housing lightweight components might perform perfectly well in 16 gauge steel or even 20 gauge sheet metal.

Ask yourself: What forces will this component experience? Static loads differ from dynamic impacts. A bracket supporting a stationary motor faces different stresses than a truck body panel subjected to road vibration and occasional debris strikes.

Fabrication Method Compatibility

Your thickness selection directly affects which fabrication processes work efficiently:

- Bending: Thicker materials require larger bend radii and higher-tonnage press brakes. A tight bend achievable in 20 gauge sheet metal might crack or require multiple operations in 11 gauge.

- Cutting: Laser cutting parameters change dramatically with thickness. A fiber laser cutting 16 gauge steel at 400 inches per minute might slow to 80 inches per minute for 10 gauge—directly impacting production costs.

- Welding: Thinner materials (18 gauge and lighter) demand careful heat control to prevent burn-through. Heavier gauges require more weld passes and higher heat input.

Cost Considerations

Material cost scales roughly with weight—thicker sheets cost more per square foot. But don't optimize solely on material price. A component designed in 20 gauge that requires reinforcing brackets might cost more than the same component in 14 gauge steel thickness without reinforcement.

The sweet spot often lies in matching gauge to application requirements without over-engineering. Specifying 10 gauge where 14 gauge suffices wastes material and increases weight without adding functional value.

For reference, 16 gauge steel at approximately 0.060 inches thick represents a versatile middle ground for many industrial applications—rigid enough for light structural use yet thin enough for efficient forming operations. It's commonly specified for equipment housings, HVAC components, and general fabrication work.

Understanding gauge specifications ensures your material selection translates into components that perform as intended. But raw material is only the starting point—the fabrication processes used to transform flat sheets into precision components determine whether your carefully specified gauge actually delivers the expected results.

Fabrication Processes That Transform Raw Metal into Precision Components

You've selected your material and specified the perfect gauge. Now comes the transformation—turning flat sheets into functional components through cutting, forming, and shaping operations. Yet many buyers receive quotes listing processes like "laser cutting" or "CNC forming" without understanding what these terms actually mean for their parts. This knowledge gap leads to missed optimization opportunities and sometimes costly specification errors.

Industrial sheet metal fabrication relies on two fundamental categories of operations: cutting processes that separate material, and forming processes that reshape it without removal. Each method offers distinct advantages depending on your material type, thickness, tolerance requirements, and production volume. Understanding these distinctions helps you specify parts that balance quality with cost-effectiveness.

Laser Cutting vs Plasma Cutting for Precision Results

When your fabricator mentions thermal cutting, they're typically referring to laser or plasma methods—both using intense heat to sever metal. But the similarities end there. These technologies differ dramatically in precision, speed, material compatibility, and cost structure.

How Laser Cutting Works

A laser cutter concentrates light energy into an incredibly focused beam that melts and vaporizes material along a programmed path. Modern CNC laser cutters achieve positioning accuracy measured in thousandths of an inch, with tolerances as tight as ±0.03 mm. The process involves generating a laser beam through a medium (CO₂ gas or fiber optics), focusing it through precision lenses, and directing it via CNC-controlled movement.

Three laser types dominate industrial applications:

- CO₂ lasers: Excellent for cutting non-metals and thicker steel sections, producing smooth edges on wood, acrylic, and composite materials.

- Fiber lasers: Superior for thin metals, offering faster cutting speeds and lower operating costs than CO₂ systems.

- Nd:YAG crystal lasers: Specialized applications requiring high peak power, often used for precision marking and engraving.

How Plasma Cutting Works

A plasma metal cutter takes a different approach—superheating compressed gas (typically air, nitrogen, or argon) with an electric arc until it becomes plasma, reaching temperatures exceeding 20,000°C. This ionized gas stream melts through conductive metals with impressive speed, particularly on thicker materials. CNC plasma systems guide the torch along programmed paths, though with wider tolerances than laser cutting—typically ±0.1 mm.

Understanding Kerf and Dross

Two technical terms appear frequently in cutting specifications that many buyers don't fully understand:

- Kerf: The width of material removed during cutting—essentially the "slot" left by the cutting process. Laser cutting produces narrower kerf (0.1-0.3 mm) than plasma (1.5-3 mm), directly affecting material utilization and the ability to cut fine details.

- Dross: To define dross simply, it's the resolidified metal that adheres to the cut edge's bottom surface. Proper cutting parameters minimize dross, but plasma cutting typically produces more than laser cutting, requiring additional cleanup operations.

Comparing Laser and Plasma Cutting Performance

| Factor | Laser Cutting | Plasma Cutting |

|---|---|---|

| Tolerance | ±0.025 mm to ±0.1 mm | ±0.1 mm typical |

| Maximum Thickness | Up to 25 mm (varies by material) | Up to 50 mm standard; 100 mm+ possible |

| Edge Quality | Smooth, burr-free, minimal post-processing | Rougher edges, slag present, grinding often required |

| Material Compatibility | Metals, plastics, wood, composites | Conductive metals only |

| Speed (Thin Materials) | Nearly 2x faster than plasma | Slower on materials under 1.25 mm |

| Speed (Thick Materials) | Slower as thickness increases | Excels on thick sections |

| Equipment Cost | $50,000 - $500,000 | $10,000 - $100,000 |

Pros and Cons: Laser Cutting

Advantages:

- Exceptional precision for intricate designs and tight corners

- Clean edges requiring minimal secondary finishing

- Narrow kerf maximizes material utilization

- Works on non-conductive materials including plastics and wood

- Minimal heat-affected zone on thin materials

Limitations:

- Higher equipment and operating costs

- Thickness limitations compared to plasma

- Slower on thick metal sections

- Some reflective materials pose cutting challenges

Pros and Cons: Plasma Cutting

Advantages:

- Lower equipment and operational expenses

- Excellent for cutting thick conductive metals

- Faster processing on heavy-gauge materials

- Simpler maintenance requirements

Limitations:

- Wider kerf wastes more material

- Rougher edge quality with dross formation

- Limited to electrically conductive materials

- Lower precision makes fine detail work impractical

Choose laser cutting when precision, edge quality, or material versatility matters most. Select plasma cutting for thick steel sections where speed and cost outweigh tolerance requirements.

Metal Forming Techniques That Shape Industrial Components

Cutting separates material, but forming transforms flat sheets into three-dimensional components. Unlike cutting processes that remove material, forming operations reshape metal through controlled deformation—no material is wasted. The sheet is stressed beyond its elastic limit but kept below its ultimate strength, creating permanent shape changes.

Bending Operations

Bending represents the most common forming operation in industrial fabrication. A straight sheet transforms into an angled or curved shape through applied force, typically using a press brake with matched punch and die tooling. During bending, the outer surface stretches while the inner surface compresses—understanding this behavior is crucial for accurate part design.

Common bending variations include:

- V-bending: The workpiece is pressed into a V-shaped die, forming angles typically between 30° and 120°.

- Air bending: The punch doesn't fully bottom out in the die, allowing angle adjustment through depth control.

- Bottoming: The punch presses the material completely into the die for precise, repeatable angles.

- Wiping: One edge is clamped while the other is bent over a die, suitable for longer flanges.

A critical factor in bending operations is springback—the tendency of bent metal to partially return toward its original shape after pressure release. Fabricators compensate by overbending slightly, with the exact compensation depending on material type, thickness, and bend radius.

Shearing and Punching

While technically cutting operations, shearing and punching work differently than thermal methods. Shearing uses opposing blades to make straight cuts across sheet metal—imagine an industrial-scale paper cutter. The process involves three stages: initial plastic deformation, crack formation at the blade edges, and final fracture as cracks meet.

Punching removes material by forcing a shaped punch through the sheet into a matching die. This method efficiently creates holes, slots, and simple shapes. A die cut machine can produce thousands of identical features per hour, making punching economical for high-volume production of parts with repetitive features.

Deep Drawing and Forming

When your design requires cup-shaped, box-shaped, or other hollow geometries, deep drawing pulls flat sheet metal into a die cavity using a punch. A blankholder controls material flow to prevent wrinkling, while proper lubrication prevents tearing. You'll find deep-drawn components in cookware, automotive fuel tanks, and beverage cans.

General forming operations reproduce the contour of punch and die surfaces without significant material flow—think door panels, appliance housings, and aircraft body sections. Unlike drawing, forming relies on localized stretching rather than pulling material from surrounding areas.

Selecting the Right Process for Your Application

How do you choose among these options? Four key factors guide the decision:

- Material type: Non-conductive materials eliminate plasma as an option. Highly reflective metals may require specific laser types. Some alloys form more readily than others.

- Thickness requirements: Materials exceeding 25 mm generally favor plasma cutting. Very thin sheets (under 1 mm) benefit from laser precision.

- Tolerance and edge quality: Precision assemblies requiring ±0.1 mm or better demand laser cutting. Parts destined for welding may accept rougher plasma-cut edges.

- Production volume: High-volume production justifies die cut machine tooling investments. Prototypes and small runs favor flexible CNC laser or forming operations.

Process selection directly impacts your project economics. A part laser-cut in 30 seconds might require 2 minutes of grinding if plasma-cut—potentially erasing any initial cost savings. Conversely, overspecifying laser precision on thick structural components wastes money without adding value.

Understanding these fabrication fundamentals positions you to evaluate quotes intelligently and collaborate effectively with your fabrication partner. But even perfect process selection means little without proper quality controls—the certifications and standards that separate reliable industrial components from inconsistent commodity parts.

Quality Standards and Certifications for Industrial Sheet Metal

You've specified the right material, selected the optimal gauge, and chosen appropriate fabrication processes. But here's a question many buyers overlook until problems arise: how do you verify that what you ordered actually meets your specifications? Quality standards and certifications provide the answer—yet this critical topic receives surprisingly little attention in most industrial sheet metal discussions.

For steel fabrication projects serving demanding industries, certifications aren't optional extras. They represent documented proof that materials and processes meet established requirements. Whether you're sourcing stainless steel sheet metal for medical devices or structural components for heavy equipment, understanding these standards helps you specify correctly and evaluate suppliers effectively.

Quality Certifications That Matter for Industrial Projects

Industrial certifications fall into two categories: material certifications that verify what the metal actually is, and process certifications that verify how the fabricator operates. Both matter for ensuring consistent, reliable components.

ASTM Standards: The Foundation of Material Certification

ASTM International develops and publishes technical standards covering materials, products, and testing methods. According to Industrial Metal Supply, ASTM steel standards serve four critical purposes:

- Define material properties: Specify chemical composition, mechanical properties, and metallurgical characteristics for different steel types

- Enable quality control: Help manufacturers produce steel products with consistent, reliable quality

- Ensure compatibility: Provide a common language for global markets, ensuring component interoperability

- Guide testing methods: Outline standardized procedures for evaluating tensile strength, hardness, corrosion resistance, and other properties

Reading ASTM codes becomes straightforward once you understand the structure. Each code begins with a letter indicating the material category—"A" denotes ferrous metals like steel, while "B" covers nonferrous metals. The number following is simply a sequential identifier. For example, ASTM A36 specifies structural carbon steel, while ASTM A240 covers stainless steel plate and sheet.

Steel fabricators working with stainless steel sheet metal commonly reference ASTM A240 for flat products and ASTM A276 for bars and shapes. These standards specify not just composition but also acceptable tolerances, surface finish requirements, and testing protocols.

Mill Test Reports: Your Material's Birth Certificate

Every shipment of industrial-grade metal should arrive with a Mill Test Report (MTR), sometimes called a Mill Certification or Material Test Report. This document traces material from its origin and confirms it meets specified standards. A proper MTR includes:

- Heat or lot number for traceability

- Chemical composition analysis

- Mechanical property test results (tensile strength, yield strength, elongation)

- Applicable ASTM or other standard specifications

- Manufacturer identification and certification signature

Never accept industrial sheet metal for critical applications without reviewing the Mill Test Report. This document provides the only verifiable proof that your material meets specifications—and it's essential for traceability if problems emerge later.

Understanding IATF 16949 and Industry-Specific Standards

Material certifications confirm what you're buying. Process certifications confirm that your fabrication partner operates reliable, consistent systems. Different industries impose different requirements based on their unique risk profiles and performance demands.

Automotive: IATF 16949

The automotive industry requires suppliers to maintain IATF 16949 certification—a quality management standard developed by the International Automotive Task Force. According to Advisera, this standard builds on ISO 9001:2015 while adding automotive-specific requirements around process design, statistical tools, measurement system analysis, and control of nonconforming products.

IATF 16949 emphasizes defect prevention rather than detection. Steel fabricators serving automotive OEMs must demonstrate:

- Advanced Product Quality Planning (APQP) processes

- Production Part Approval Process (PPAP) capability

- Statistical process control implementation

- Error-proofing (poka-yoke) systems

- Documented problem-solving methodologies

Aerospace: AS9100

Aerospace applications demand AS9100 certification, released by the International Aerospace Quality Group. This standard addresses concerns unique to aircraft, space, and defense manufacturing—product safety, configuration management, counterfeit parts prevention, and on-time delivery management.

Metal fab operations serving aerospace customers face additional requirements around human factors, special process controls, and first article inspection. The consequences of failure in aerospace applications drive these stringent protocols.

Medical: Traceability and Biocompatibility

Medical device manufacturing requires different emphases—complete material traceability, validated cleaning processes, and documentation supporting biocompatibility claims. While ISO 13485 provides the quality management framework, individual projects may require specific material certifications depending on patient contact and device classification.

Surface Finish Specifications and Tolerance Requirements

Quality extends beyond material certification to the finished component's physical characteristics. Two critical specifications often cause confusion: surface finish and dimensional tolerances.

Surface Finish Standards

Surface finish affects both appearance and function. Rougher surfaces may trap contaminants in food processing equipment, while certain medical applications require mirror-polished finishes. Common finish designations include:

- Mill finish: The natural surface condition after rolling, suitable for painted or coated applications

- #2B finish: Cold-rolled, annealed, and pickled stainless steel—the most common commercial finish

- #4 finish: Brushed or satin finish achieved through directional polishing, common in architectural applications

- Mirror polish (#8): Highly reflective surface for decorative or sanitary applications

Surface treatments like anodizing (for aluminum) or powder coat finishes add protection and aesthetic options. Anodizing creates a harder, more durable oxide layer that resists scratching and accepts dyes. Powder coat applications provide excellent corrosion protection with extensive color choices, making them popular for equipment housings and architectural panels.

Dimensional Tolerances

Tolerance specifications define acceptable variation from nominal dimensions. Tighter tolerances cost more—both in material (requiring higher-grade stock) and processing (demanding more careful fabrication and inspection). Typical industrial sheet metal tolerances include:

| Feature Type | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Flat dimensions | ±0.5 mm (±0.020") | ±0.1 mm (±0.004") |

| Bend angles | ±1° | ±0.5° |

| Hole locations | ±0.25 mm (±0.010") | ±0.1 mm (±0.004") |

| Overall flatness | 1 mm per 300 mm | 0.5 mm per 300 mm |

Inspection Protocols and Quality Documentation

Reliable steel fabricators implement inspection protocols throughout production—not just at final inspection. Incoming material verification, in-process checks, and final dimensional inspection create multiple opportunities to catch deviations before shipping.

Documentation requirements vary by industry and application criticality. At minimum, expect:

- Material traceability records linking finished parts to source material lot numbers

- Dimensional inspection reports for critical features

- Process records for any special operations (heat treatment, welding, surface finishing)

- Certificates of conformance stating parts meet drawing and specification requirements

For aerospace, automotive, and medical applications, additional documentation may include first article inspection reports, capability studies, and validated measurement system analyses.

Understanding these quality standards positions you to write better specifications and ask the right questions when evaluating fabrication partners. But standards represent just one consideration—different industries impose unique requirements that shape material selection, design constraints, and supplier qualifications in ways worth examining more closely.

Industry-Specific Applications and Specialized Requirements

Industrial sheet metal doesn't exist in a vacuum—it serves remarkably diverse sectors, each demanding unique material properties, tolerances, and surface treatments. While competitors often publish simple bullet lists of industries, understanding the actual requirements driving each sector's specifications separates informed buyers from those who underspecify and overspend. Let's examine what each major industry truly demands from its fabricated metal components.

Automotive Sheet Metal Requirements for Chassis and Structural Parts

Think about what your vehicle endures daily: vibration, thermal cycling, road salt exposure, and occasional impacts. Now imagine specifying the materials that must survive these conditions for 10-15 years. Automotive sheet metal requirements reflect this demanding reality.

Chassis and suspension components favor high-strength low-alloy (HSLA) steels and increasingly, aluminum sheet metal for weight reduction. According to Machining Custom, automotive sheet metal typically ranges from 0.5 mm to 2.0 mm thickness—thinner sheets for body panels and thicker material for structural reinforcements.

What makes automotive fabrication distinctive?

- Tight dimensional tolerances: Components must fit precisely during high-speed assembly line operations. Even 0.5 mm variation can cause fitment issues.

- Galvanized sheet metal dominance: Zinc-coated steel plates provide sacrificial corrosion protection essential for underbody components exposed to road salt and moisture.

- High-volume stamping: Progressive dies produce thousands of identical parts per hour, demanding consistent material properties across production runs.

- Weld compatibility: Resistance spot welding remains the primary joining method, requiring materials with predictable electrical and thermal characteristics.

- Weight optimization: Every kilogram saved improves fuel efficiency, driving adoption of advanced high-strength steels and aluminum alternatives.

Corrugated metal and steel plate find applications in truck beds and commercial vehicle bodies where load-bearing capacity outweighs weight concerns. These applications accept wider tolerances than passenger vehicle components but demand superior fatigue resistance.

Architectural and Construction Applications

Walk through any modern commercial building and you're surrounded by fabricated sheet metal—from exterior cladding to interior partition systems. Architectural applications prioritize aesthetics alongside durability, creating unique specification challenges.

Decorative metal panels demand consistent surface appearance across large installations. A single discolored panel in a building facade becomes immediately visible, making material lot consistency critical. Common architectural materials include:

- Aluminum sheet metal: Lightweight, corrosion-resistant, and accepts anodized or painted finishes. Standard thicknesses range from 0.040" to 0.125" for facade panels.

- Stainless steel: Mirror or brushed finishes for entranceways, elevator interiors, and accent features. The 304 grade handles most architectural environments.

- Perforated metal: Punched patterns provide visual interest, acoustic control, and ventilation in ceilings, screens, and sunshades.

- Weathering steel: Develops a protective rust patina for intentionally aged aesthetic effects.

Architectural tolerances differ from industrial norms—visual alignment matters more than decimal precision. A slight bow in a 10-foot decorative metal panel becomes obvious to observers, while the same deviation in a hidden structural member goes unnoticed.

Oil & Gas Equipment Fabrication

Few industries subject sheet metal to harsher conditions than oil and gas operations. Components face extreme pressures, corrosive chemicals, explosive atmospheres, and temperature swings from arctic cold to desert heat—sometimes within the same installation.

Material selection reflects these challenges:

- 316L stainless steel: The "L" designation indicates low carbon content, improving weldability and corrosion resistance in chloride-rich environments like offshore platforms.

- Duplex stainless steels: Combine austenitic and ferritic structures for superior strength and corrosion resistance in demanding process equipment.

- Carbon steel plate: Heavy steel plates (often 1/4" to 1" thick) form pressure vessel shells and structural supports where corrosion-resistant coatings protect base material.

- Nickel alloys: Handle highly corrosive hydrogen sulfide (sour gas) environments that destroy conventional stainless steels.

Certification requirements intensify in this sector. Components may require NACE (National Association of Corrosion Engineers) compliance, pressure vessel certifications, and witnessed material testing. Traceability documentation follows parts throughout their service life—sometimes spanning decades.

Specialized Applications Across Industrial Sectors

Medical Device Housings

Medical applications demand more than just biocompatibility—they require complete material traceability, validated cleaning processes, and surfaces that resist bacterial colonization. According to Prototek's medical fabrication guide, common materials include 316L stainless steel for surgical instruments, aluminum for portable equipment housings, and titanium for implantable devices.

Key medical fabrication requirements include:

- Surface finish specifications: Ra values (roughness average) typically under 0.8 μm for surfaces requiring frequent sanitization.

- Passivation treatments: Chemical treatments remove surface iron contamination from stainless steel, maximizing corrosion resistance.

- Lot-level traceability: Every component must trace back to specific material lots for recall capability.

- Validated processes: Fabrication methods require documented validation proving consistent, repeatable results.

Semiconductor Manufacturing Equipment

Semiconductor fabrication equipment operates in ultra-clean environments where microscopic contamination destroys billion-dollar production runs. The sheet metal forming these tool enclosures must meet exacting cleanliness standards:

- Electropolished stainless steel: Mirror-smooth surfaces minimize particle trapping and simplify cleaning.

- Outgassing requirements: Materials must not release volatile compounds that could contaminate wafer processing.

- Precision tolerances: Tool assemblies require exceptional dimensional control for proper sealing and alignment.

- Specialized coatings: Some applications require nickel plating, specialized paints, or other treatments to control electrostatic discharge or chemical resistance.

Matching Fabrication Capabilities to Industry Needs

Different industries require different production approaches. Understanding this alignment helps you select appropriate fabrication partners:

| Industry | Typical Volume | Critical Requirements | Preferred Materials |

|---|---|---|---|

| Automotive | High volume (10,000+) | IATF 16949, PPAP, tight tolerances | HSLA steel, galvanized sheet metal, aluminum |

| Architectural | Low-medium volume | Visual consistency, custom finishes | Aluminum, stainless steel, decorative metal panels |

| Oil & Gas | Low volume, high mix | NACE compliance, pressure ratings | 316L SS, duplex SS, steel plate |

| Medical | Low-medium volume | ISO 13485, traceability, validated processes | 316L SS, aluminum, titanium |

| Semiconductor | Low volume, high precision | Cleanliness, outgassing control | Electropolished SS, specialized coatings |

Rapid prototyping serves industries differently. Automotive programs may produce 50-100 prototype parts for validation testing before committing to production tooling. Medical device developers iterate through multiple design revisions during regulatory approval processes. Semiconductor equipment builders often need single prototype units for tool qualification.

Conversely, mass production capabilities matter most for automotive and consumer electronics applications where volumes justify dedicated tooling investments. A progressive stamping die costing $50,000 makes sense when producing 100,000 parts—but represents pure overhead for a 500-piece medical device run.

Understanding your industry's specific requirements enables smarter conversations with fabrication partners. But even perfect specifications mean little without understanding the cost factors that translate those specifications into actual quotes and project timelines.

Cost Factors and Procurement Considerations for Industrial Projects

You've defined your material, specified the gauge, and identified the fabrication processes your project requires. Now comes the question that keeps procurement teams awake at night: what will this actually cost, and when can we expect delivery? Surprisingly, these fundamental concerns remain largely unaddressed in most industrial sheet metal discussions—leaving buyers to navigate pricing conversations without clear benchmarks.

Whether you're searching for metal fabrication near me or evaluating fabrication shops near me for a multi-state project, understanding the factors that drive quotes helps you budget accurately and avoid unwelcome surprises. Let's break down what actually influences your project costs and timelines.

Key Cost Drivers in Industrial Sheet Metal Projects

Think of your project quote as a layered calculation. Each layer adds cost based on specific decisions you've made—or haven't yet finalized. Understanding these layers helps you identify optimization opportunities before committing to specifications.

Material Costs: The Foundation of Every Quote

Raw material typically represents 30-50% of total project cost, making material selection your most significant cost lever. According to Komacut's fabrication cost guide, material pricing varies dramatically based on type, grade, and market conditions.

Consider the relative cost differences:

- Mild steel: The most economical option for non-corrosive environments—often the baseline for cost comparisons

- Stainless steel: Commands a significant premium over mild steel, with 316 grades costing 20-30% more than 304

- Aluminum: Higher cost per kilogram than steel, though weight savings may offset material expense in transportation-sensitive applications

Material thickness directly impacts cost—thicker gauges mean more material per square foot and higher raw material expense. However, the relationship isn't always straightforward. Specifying lighter gauges may reduce material cost while increasing labor expense if additional reinforcement or forming operations become necessary.

Fabrication Complexity: Where Labor Meets Equipment

Simple parts with straight cuts and single bends cost far less than intricate components requiring multiple operations. Complexity drivers include:

- Number of features: Each hole, slot, bend, and formed feature adds setup time and processing steps

- Tolerance requirements: Tighter tolerances demand slower processing speeds, more careful inspection, and sometimes specialized equipment

- Material handling: Large or heavy parts require additional equipment and labor for safe manipulation

- Secondary operations: Deburring, tapping, hardware insertion, and assembly steps each add labor content

Volume Considerations: The Power of Scale

Production volume dramatically affects per-unit pricing. Setup costs—programming, tooling installation, first-piece inspection—spread across more units as quantities increase. According to LTJ Industrial's fabrication quote guide, prototypes carry higher per-unit costs due to setup and programming efforts, while large production runs benefit from economies of scale.

| Order Quantity | Setup Cost Impact | Per-Unit Price Trend |

|---|---|---|

| 1-10 pieces (prototype) | 100% of setup absorbed | Highest per-unit cost |

| 11-100 pieces | Setup distributed across batch | Moderate reduction |

| 101-1,000 pieces | Setup becomes minor factor | Significant reduction |

| 1,000+ pieces | Setup negligible per unit | Lowest per-unit cost |

Finishing Requirements and Certifications

Surface treatments add both time and cost. Powder coating services, anodizing, plating, and specialized finishes each require additional processing steps—and sometimes third-party vendor coordination. Certification requirements for regulated industries (automotive, aerospace, medical) add documentation, inspection, and quality system overhead that factors into pricing.

Lead Time Factors That Impact Your Production Schedule

Delivery timing often matters as much as price. Understanding what affects lead times helps you plan realistic schedules and identify opportunities for acceleration.

Material Availability

Common materials in standard gauges typically ship from distributor stock within days. Specialty alloys, unusual thicknesses, or large quantity requirements may require mill orders with 8-12 week lead times. Regional factors also play a role—metal fabricators near me may have different stock availability than suppliers in major manufacturing regions like steel fabrication Kansas City or wholesale sheet metal Kansas City distributors.

Production Scheduling

Your project enters a queue alongside other customer orders. Lead times extend during peak seasons and contract when capacity opens. Expedite options typically exist but carry premium charges—often 25-50% above standard pricing for significantly accelerated delivery.

Finishing and Secondary Operations

Complex finishing requirements can double lead times. Powder coating, heat treatment, or plating often involve external vendors with their own scheduling constraints. Plan accordingly when specifying multiple finishing steps.

How Design for Manufacturing Support Reduces Costs

Want to cut project costs without compromising quality? Design for Manufacturing (DFM) reviews identify opportunities before production begins. According to Fictiv's DFM guide, design choices impact approximately 80% of manufacturing cost—making early optimization far more effective than negotiating unit prices after specifications are locked.

Effective DFM analysis addresses:

- Material optimization: Selecting readily available, cost-effective materials that meet performance requirements

- Tolerance rationalization: Applying tight tolerances only where functionally necessary, reducing inspection and rejection costs

- Feature simplification: Eliminating unnecessary complexity that adds processing time without functional benefit

- Nesting efficiency: Arranging parts on sheet stock to minimize material waste

- Process alignment: Designing features compatible with available equipment capabilities

Rapid prototyping enables DFM validation before mass production commitment. Producing 5-10 prototype parts reveals fit, function, and manufacturability issues that drawings alone cannot predict. This validation step often pays for itself by preventing costly mid-production changes.

Preparing for Accurate Quotes

The information you provide directly affects quote accuracy and turnaround time. Incomplete requests generate questions and delays; thorough packages receive faster, more precise pricing.

What fabricators need for accurate quoting:

- Complete CAD files: 3D models (STEP, IGES) and 2D drawings with dimensions and tolerances

- Material specifications: Alloy, grade, and any certification requirements

- Quantity requirements: Initial order size plus estimated annual volumes

- Finish specifications: Surface treatment, coating, and any appearance requirements

- Delivery timeline: Required delivery date and any flexibility in scheduling

- Quality documentation: Inspection requirements, certifications needed, and traceability expectations

Quote turnaround varies by fabricator and project complexity. Simple parts may receive same-day pricing, while complex assemblies requiring engineering review might take a week. Establishing a relationship with reliable fabrication partners often accelerates this process—repeat customers receive priority attention and benefit from established pricing frameworks.

Understanding these cost and timeline factors positions you to budget accurately, set realistic expectations, and identify optimization opportunities. But even perfect project planning requires finding the right fabrication partner—a decision that deserves careful evaluation against specific capability and quality criteria.

Selecting the Right Industrial Sheet Metal Partner for Your Manufacturing Needs

You've mastered material specifications, gauge selections, and fabrication processes. You understand quality standards and cost drivers. But here's the critical question that determines whether all that knowledge translates into successful projects: how do you find a fabrication partner capable of delivering on your specifications? Searching for sheet metal near me returns hundreds of results—but capability claims are easy to make and difficult to verify.

The gap between an average supplier and a true manufacturing partner shows up in missed deadlines, quality rejections, and communication breakdowns. According to industry research, many custom fabrication projects experience delays, often stemming from poor partner selection rather than technical complexity. Choosing the right industrial sheet metal fabrication partner requires systematic evaluation across multiple dimensions.

Evaluating Fabrication Partners for Quality and Reliability

What separates reliable partners from problematic suppliers? Start by examining their track record and operational systems rather than just their equipment lists.

Certifications as Quality Indicators

Certifications provide external validation that a fabricator operates reliable, consistent systems. While ISO 9001:2015 represents the baseline quality management standard, industry-specific certifications signal advanced capabilities:

- IATF 16949: The automotive industry's rigorous quality standard. Fabricators holding this certification operate at an elite level of process control, defect prevention, and traceability—regardless of whether you're in the automotive sector.

- AS9100: Required for aerospace applications, demonstrating capability in configuration management, counterfeit parts prevention, and special process controls.

- ISO 13485: Medical device quality management certification indicating validated processes and full traceability.

- ISO 14001 and ISO 45001: Environmental and safety management certifications signaling responsible, stable operations.

Choosing a fabricator with IATF 16949 certification helps ensure your project meets the highest possible quality standards, regardless of your industry.

Supplier Reliability and Reputation

Certifications verify systems—but reputation reveals execution. According to EOXS, evaluating supplier reliability should include:

- Track record: Research the supplier's history. A company with longstanding relationships with industry leaders has already passed rigorous audits.

- Reference checks: Talk to past customers about on-time delivery, quality consistency, and problem resolution.

- Supply chain management: Inquire about inventory management and logistics capabilities that ensure consistent material availability.

- Customer service responsiveness: Reliable partners provide prompt responses, flexibility in order fulfillment, and strong after-sales support.

What to Look for in an Industrial Sheet Metal Supplier

Beyond certifications and reputation, evaluate specific capabilities that match your project requirements.

Production Capabilities: Prototype to Mass Production

Your fabrication partner should handle your complete production lifecycle. Look for:

- Rapid prototyping capabilities: The ability to produce functional prototypes quickly—ideally within 5-7 days—enables design validation before committing to production tooling.

- Scalable production capacity: Partners with substantial facilities and workforce can confidently handle high-volume production runs without compromising lead times.

- Modern equipment: CNC machining centers, fiber laser cutters, and robotic welding systems work faster and produce consistent results across production runs.

- In-house finishing: One-stop capabilities for powder coating, plating, anodizing, and other surface treatments reduce lead times and ensure consistent quality.

For example, Shaoyi (Ningbo) Metal Technology demonstrates what comprehensive capabilities look like in practice—offering 5-day rapid prototyping alongside automated mass production, all under IATF 16949 certification. Their focus on automotive chassis, suspension, and structural components illustrates how specialized expertise pairs with broad production capabilities.

Engineering Support and DFM

A true partner invests in your project's success through engineering collaboration. Evaluate:

- DFM support availability: Comprehensive Design for Manufacturing analysis identifies cost reduction and manufacturability improvements before production begins.

- CAD/CAM capabilities: Engineering teams that can translate conceptual designs into optimized production files add significant value.

- R&D resources: Partners with dedicated technical personnel and patent portfolios solve problems rather than just cutting metal.

Quote Responsiveness

How quickly can you get accurate pricing? Quote turnaround reveals both capability and customer priority. While complex projects require engineering review, responsive partners provide preliminary quotes within 24-48 hours for standard work. Some leading fabricators—including Shaoyi—offer 12-hour quote turnaround, demonstrating the operational efficiency that translates into faster project timelines.

Welding Expertise

If your project requires welding, evaluate the fabricator's capabilities in appropriate processes. When comparing mig vs tig welding or tig vs mig welding options, understand that MIG offers faster production speeds for thicker materials, while TIG provides superior precision and cleaner welds for thinner gauges and visible joints. Partners with aluminum welding expertise require specialized equipment and trained personnel—not all steel fabricators handle aluminum effectively.

Supplier Evaluation Checklist

Use this systematic checklist when evaluating potential industrial sheet metal fabrication partners:

| Evaluation Category | Key Questions | Verification Method |

|---|---|---|

| Certifications | Are they IATF 16949, AS9100, or ISO 13485 certified as applicable? | Request current certificates; verify through registrar |

| Experience | Do they have documented experience in your industry? | Case studies, customer references, project portfolios |

| Equipment | Is their machinery modern and well-maintained? | Facility tour, equipment list review |

| Capacity | Can they handle your volumes without compromising delivery? | Discuss capacity planning, review on-time delivery metrics |

| Engineering Support | Do they offer DFM analysis and design optimization? | Request sample DFM report, discuss engineering team structure |

| Quality Systems | What inspection protocols and documentation do they provide? | Review QMS documentation, inspection capabilities |

| Responsiveness | How quickly do they respond to quote requests? | Submit test RFQ, evaluate turnaround time and thoroughness |

| Financial Stability | Are they financially sound and investing in growth? | Review available financial information, assess facility investment |

Conducting Due Diligence

Paper qualifications only tell part of the story. Before committing to a fabrication partner, consider these verification steps:

- Facility visits: Tour the facility in person when possible. Look for cleanliness, organization, and well-maintained equipment. Ask to see their quality control lab and inspection processes.

- Reference conversations: Speak directly with current customers. Ask about on-time delivery rates, quality consistency, and how problems get resolved when they occur.

- Trial orders: Start with smaller prototype or pilot orders before committing to large production volumes. This validates actual performance against claims.

- Communication assessment: Evaluate responsiveness during the quoting process. Partners who communicate poorly during sales rarely improve during production.

Finding a sheet metal contractor near me who checks all these boxes requires effort—but the investment pays dividends through reliable delivery, consistent quality, and collaborative problem-solving. Whether you're sourcing components for automotive, medical, semiconductor, or architectural applications, the right industrial sheet metal inc partner transforms your specifications into successful finished parts.

The fabrication partner you select ultimately determines whether your carefully specified materials, gauges, and processes translate into components that perform as intended. Choose based on verified capabilities rather than promises, and you'll build a manufacturing relationship that supports your projects for years to come.

Frequently Asked Questions About Industrial Sheet Metal

1. What is industrial sheet metal?

Industrial sheet metal refers to metal sheets with thickness between 0.5mm and 6mm, manufactured to meet rigorous certification requirements for high-performance applications. Unlike commercial or decorative sheet metal, industrial-grade materials must satisfy precise thickness tolerances, certified material compositions, controlled surface finishes, and documented mechanical properties. These specifications make industrial sheet metal suitable for demanding sectors including Oil & Gas, Medical, Automotive, Aerospace, and Semiconductor manufacturing where component failure could compromise safety or halt production.

2. What materials are commonly used in industrial sheet metal fabrication?

The primary industrial sheet metal materials include carbon steel, stainless steel (304 and 316 grades), aluminum, and galvanized steel. Carbon steel offers exceptional tensile strength at lower cost but requires corrosion protection. Stainless steel provides superior corrosion resistance, with 316 stainless steel handling aggressive chemical environments. Aluminum delivers excellent strength-to-weight ratios at roughly one-third the weight of steel, making it ideal for transportation and aerospace applications. Galvanized steel offers a cost-effective middle ground with zinc coating for corrosion protection in outdoor and HVAC applications.

3. How does the sheet metal gauge system work?

The sheet metal gauge system follows a counterintuitive numbering convention where higher gauge numbers indicate thinner material. A 10-gauge sheet is substantially thicker than 20-gauge sheet metal. This system originated from 19th-century wire manufacturing processes. Importantly, the same gauge number represents different actual thicknesses depending on the metal type—14-gauge stainless steel measures 0.0751 inches while 14-gauge carbon steel measures 0.0747 inches. Industrial applications typically use gauges ranging from 6 gauge (heavy structural) through 22 gauge (light enclosures and ductwork).

4. What certifications matter for industrial sheet metal suppliers?

Key certifications indicate a fabricator's quality management capabilities. ISO 9001:2015 serves as the baseline standard, while industry-specific certifications signal advanced capabilities. IATF 16949 certification is essential for automotive applications, demonstrating rigorous process control and defect prevention. AS9100 is required for aerospace work, covering configuration management and special process controls. ISO 13485 applies to medical device manufacturing with validated processes and traceability requirements. Manufacturers like Shaoyi (Ningbo) Metal Technology maintain IATF 16949 certification, ensuring components meet the highest quality standards across industries.

5. How can I reduce costs on industrial sheet metal projects?

Cost optimization starts with Design for Manufacturing (DFM) analysis before production begins, as design choices impact approximately 80% of manufacturing cost. Key strategies include selecting readily available materials in standard gauges to avoid mill order lead times, applying tight tolerances only where functionally necessary, simplifying features that add processing time without functional benefit, and optimizing part nesting to minimize material waste. Working with fabrication partners offering comprehensive DFM support, rapid prototyping for design validation, and quick quote turnaround—such as the 12-hour quote service from specialized manufacturers—helps identify savings opportunities early in the project lifecycle.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —