Inside A Sheet Metal Factory: From Raw Steel To Finished Parts

What Is a Sheet Metal Factory and Why It Matters

Ever wondered how the metal panels in your car, the enclosures protecting electronic devices, or the structural components in aircraft come to life? The answer lies within a sheet metal factory—a specialized manufacturing facility where flat metal sheets transform into precision-engineered parts through a series of carefully controlled processes.

Understanding what happens inside these facilities can help you make smarter decisions when sourcing components for your next project. Whether you're an engineer, procurement specialist, or business owner, this comprehensive guide will walk you through every aspect of modern sheet metal manufacturing.

Defining the Modern Sheet Metal Factory

A sheet metal factory is a dedicated manufacturing facility that specializes in transforming flat metal sheets—typically less than 6mm thick—into functional components through cutting, bending, forming, and assembly operations. These facilities house specialized equipment, skilled technicians, and quality control systems designed specifically for working with thin-gauge metals.

Think of it as a precision workshop where raw metal for fabrication becomes everything from simple brackets to complex enclosures. The focus is on manipulating sheet materials rather than working with thick plate steel or raw castings. This specialization allows these facilities to achieve tight tolerances and consistent quality across high-volume production runs.

Core Manufacturing Capabilities Explained

What exactly happens once metal enters the facility? A typical sheet metal factory performs several interconnected operations that work together to create finished parts:

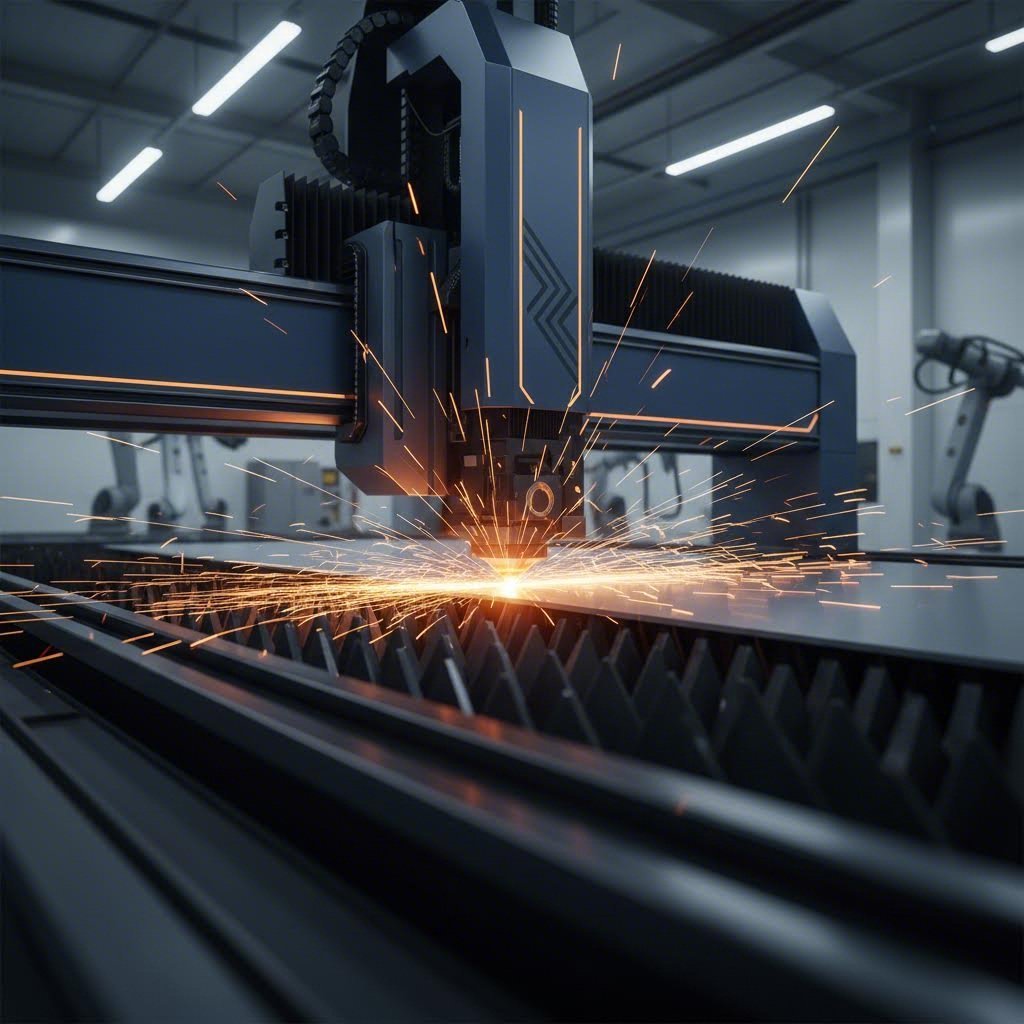

- Laser cutting: Uses focused light beams to slice through metal with exceptional precision, ideal for intricate designs and clean edges

- CNC punching: Employs computer-controlled machines to stamp out holes and shapes with high repeatability

- Press brake forming: Bends metal sheets into angular shapes using powerful hydraulic or electric presses

- Welding: Joins multiple pieces together through MIG, TIG, or spot welding techniques

- Finishing: Applies surface treatments like powder coating, painting, or deburring for protection and aesthetics

These capabilities work in sequence. First, flat sheets are cut to size. Next, holes and features get punched. Then, the material is bent into shape before being welded to other components. Finally, finishing processes prepare the part for its end application.

How Sheet Metal Factories Differ from General Fabricators

Here's where things get interesting. Many people use "sheet metal factory" and "metal fabrication shop" interchangeably, but they're not quite the same thing. Understanding this distinction matters when you're sourcing parts.

General metal fabrication shops work with a broader range of materials and thicknesses. They might handle heavy structural steel, thick plate materials, or even raw castings alongside sheet metal work. Their equipment is often designed for versatility rather than specialization.

In contrast, fabrication sheet metal specialists focus exclusively on thin-gauge materials. Their laser cutters, press brakes, and punching machines are optimized for precision work on sheets rather than heavy plate. This specialization translates to tighter tolerances, faster turnaround times, and greater expertise in handling the unique challenges of thin materials—like preventing warping during welding or achieving consistent bend angles.

When your project demands precision components from materials under 6mm thick, a dedicated sheet metal facility typically delivers better results than a general-purpose shop handling everything from bridge beams to decorative brackets.

Essential Equipment Inside a Sheet Metal Factory

Walk into any professional sheet metal factory and you'll immediately notice the impressive array of machinery humming with purpose. But what separates a capable facility from an average one? It comes down to the equipment—and more importantly, how that equipment works together to deliver precision parts efficiently.

Understanding what's inside these facilities helps you evaluate potential manufacturing partners and set realistic expectations for your projects. Let's explore the technology that makes modern sheet metal manufacturing possible.

Laser Cutting and CNC Technology

The laser cutter has become the workhorse of modern sheet metal operations. These machines focus intense light beams to slice through metal with surgical precision, creating clean edges that often require minimal finishing. When you need intricate shapes, small holes, or complex contours, laser cutting delivers results that other methods simply cannot match.

Modern fiber lasers have pushed capabilities even further. They cut faster, consume less energy, and handle reflective materials like aluminum and copper more effectively than older CO2 systems. For thin sheets requiring fine details, you'll find laser cutting far superior—achieving tolerances of ±0.005 inches isn't unusual.

CNC punch presses complement laser cutting by handling high-volume hole patterns and standard shapes efficiently. While lasers excel at complex profiles, a CNC router or punch machine can stamp out hundreds of identical holes per minute. Many facilities use both technologies strategically—lasers for intricate cuts and punches for repetitive features—maximizing both quality and throughput.

Some operations also employ specialized equipment like a die cut machine for specific applications where consistent, high-speed production of identical parts justifies the tooling investment.

Forming and Bending Equipment Essentials

Cutting is only half the story. Once flat blanks are cut, press brakes transform them into three-dimensional components. These powerful machines use hydraulic or electric force to bend metal along precise angles, creating everything from simple brackets to complex enclosures.

Modern CNC press brakes store thousands of bend programs, allowing operators to switch between part configurations in minutes rather than hours. Backgauges position material automatically, while angle measurement systems verify each bend meets specification. This automation dramatically reduces setup times and ensures consistency across production runs.

Beyond press brakes, you'll find roll forming equipment for curved shapes, stamping presses for high-volume production, and specialized machines for hemming, flanging, and other forming operations. The depth of forming capabilities directly affects what designs a facility can produce—and how efficiently they can produce them.

Cutting Technology Comparison

Choosing the right cutting method depends on your material, thickness, and precision requirements. Here's how the three primary technologies compare:

| Technology | Precision Level | Material Thickness Range | Best Applications |

|---|---|---|---|

| Laser Cutting | ±0.005" (highest) | Up to 1" (steel) | Intricate designs, clean edges, thin sheets, electronics, medical devices |

| Plasma Cutting | ±0.020" (moderate) | Up to 2"+ (conductive metals) | Thick steel plates, structural fabrication, heavy equipment, speed-critical jobs |

| Waterjet Cutting | ±0.005" (highest) | Up to 12"+ at 60,000–90,000 PSI | Heat-sensitive materials, aerospace components, stone, glass, composites |

According to industry testing by Wurth Machinery, plasma cutting 1-inch steel runs about 3-4 times faster than waterjet, with operating costs roughly half as much per foot. However, when heat effects must be avoided—or when cutting non-metals—waterjet becomes the clear choice despite its slower speed.

Many successful facilities incorporate multiple cutting technologies. Services that send cut send parts directly to customers often combine laser precision with plasma efficiency, selecting the optimal method for each job.

Quality Control Instrumentation

Equipment capability means nothing without verification. Professional facilities invest heavily in quality control instrumentation to ensure every part meets specification.

Coordinate Measuring Machines (CMMs) provide the gold standard for dimensional verification. These computer-controlled probes measure complex geometries against CAD models, detecting deviations as small as 0.0001 inches. For critical aerospace or medical components, CMM inspection isn't optional—it's mandatory.

Beyond CMMs, you'll find optical comparators for profile verification, surface roughness testers, hardness testers, and specialized gauging for specific features. Inline inspection systems integrated with CNC equipment can measure parts during production, catching problems before they multiply across an entire batch.

The sophistication of inspection equipment often signals a facility's commitment to quality. A metal cutter without proper measurement tools is like a chef without taste—technically capable but ultimately unreliable.

How do these equipment investments affect your project? Facilities with advanced technology typically deliver tighter tolerances, handle more complex geometries, and maintain faster turnaround times. When evaluating potential partners, understanding their equipment capabilities helps predict whether they can meet your specific requirements—a topic we'll explore in detail when discussing material selection.

Material Selection Guide for Sheet Metal Projects

So you've identified a capable facility with the right equipment—but what material should your parts be made from? This decision affects everything from performance and durability to cost and manufacturability. Choosing the wrong material leads to premature failures, wasted budget, or parts that simply won't form correctly.

Whether you're specifying a stainless steel sheet for corrosion resistance or aluminum sheet metal for weight savings, understanding your options helps you communicate effectively with manufacturers and avoid costly mistakes.

Steel Types and Their Applications

Steel remains the backbone of sheet metal manufacturing. But "steel" isn't a single material—it's a family of alloys with dramatically different properties. Knowing which type fits your application prevents both over-engineering and under-specifying.

Mild Steel (Low Carbon Steel) offers the best combination of affordability and workability. It bends easily, welds cleanly, and costs less than alternatives. You'll find it in structural brackets, enclosures, chassis components, and countless industrial applications. The tradeoff? It rusts without protective coatings. Most mild steel parts receive paint, powder coating, or plating after fabrication.

Stainless Steel solves the corrosion problem by adding chromium, nickel, and other elements to the alloy. According to fabrication specialists at Smith & Arrow, stainless steel provides higher rust and corrosion resistance, greater strength, and a unique attractive appearance—making it ideal for food processing equipment, marine hardware, medical devices, and architectural applications.

Not all stainless grades perform equally. 304 stainless works well for general-purpose applications, while 316 stainless steel (often called marine grade) offers superior resistance to saltwater and harsh chemicals. If your parts will encounter corrosive environments, specifying the right grade matters tremendously.

Galvanized Sheet Metal provides a middle ground—mild steel coated with a protective zinc layer. It costs more than bare steel but less than stainless, while offering decent corrosion resistance for outdoor applications like HVAC ductwork, gutters, and agricultural equipment. The zinc coating does affect welding and finishing, so discuss these considerations with your fabricator.

Aluminum Grades for Sheet Metal Work

When weight matters, aluminum becomes the obvious choice. It weighs roughly one-third as much as steel while offering excellent corrosion resistance and thermal conductivity. But like steel, aluminum comes in various grades with different properties.

3003 Aluminum offers good formability and weldability at reasonable cost. It's the general-purpose workhorse for sheet metal applications—from fuel tanks to heat exchangers.

5052 Aluminum provides higher strength and better corrosion resistance, making it popular for marine applications, pressure vessels, and structural components.

6061 Aluminum delivers excellent machinability and strength, though it's less formable than 3003 or 5052. It often appears in structural frames and components requiring tight tolerances.

Sounds complex? The key is matching the grade to your requirements. Need maximum bendability? Choose 3003. Facing saltwater exposure? Consider 5052. Requiring structural strength with machined features? Look at 6061.

Understanding Gauge Thickness Systems

Here's where many engineers stumble. When a fabricator asks "what gauge?" they're referring to a thickness measurement system that's counterintuitive—lower numbers mean thicker material.

According to Xometry's engineering resources, metal gauges are standard numbers developed by measuring sheet thickness in relation to weight per square foot. A 3-gauge sheet is about 6.07mm (0.2391 inches) thick, while extreme foil gauges like 38-gauge are only 0.15mm (0.0060 inches). Most sheet metal falls between these extremes, with materials over 6mm typically classified as plate rather than sheet.

Why does this matter? Because 14 gauge steel thickness (approximately 1.9mm or 0.0747 inches) works perfectly for medium-duty applications like equipment enclosures, while 11 gauge steel thickness (around 3.0mm or 0.1196 inches) handles heavier structural loads. Specifying the wrong gauge creates parts that are either too flimsy or unnecessarily heavy and expensive.

Common Sheet Metal Gauge Chart

| Gauge Number | Steel Thickness (inches) | Steel Thickness (mm) | Typical Applications |

|---|---|---|---|

| 10 gauge | 0.1345" | 3.42mm | Heavy structural components, industrial equipment |

| 11 gauge | 0.1196" | 3.04mm | Structural brackets, chassis parts |

| 12 gauge | 0.1046" | 2.66mm | Machine guards, heavy enclosures |

| 14 gauge | 0.0747" | 1.90mm | Equipment housings, panels |

| 16 gauge | 0.0598" | 1.52mm | General enclosures, brackets |

| 18 gauge | 0.0478" | 1.21mm | Ductwork, light enclosures |

| 20 gauge | 0.0359" | 0.91mm | Electronic enclosures, covers |

| 22 gauge | 0.0299" | 0.76mm | Light-duty covers, decorative panels |

Note: Aluminum and stainless steel use slightly different gauge-to-thickness conversions. Always confirm thickness in inches or millimeters when precision matters.

Factors Affecting Material Selection

Before finalizing your material choice, consider these critical factors:

- Strength requirements: Will the part bear loads? Withstand impacts? Handle vibration? Higher-strength materials or thicker gauges may be necessary.

- Corrosion resistance: What environment will the part face? Indoor electronics differ dramatically from marine hardware or food processing equipment.

- Weight considerations: Does every gram matter? Aerospace and portable equipment often justify aluminum's premium price for weight savings.

- Cost constraints: Mild steel costs significantly less than stainless or aluminum. If appearance and corrosion aren't concerns, standard steel with proper coatings delivers the best value.

- Formability: Complex bends and deep draws require materials that won't crack. Mild steel and 3003 aluminum form easily; high-strength stainless can be challenging.

Making an informed decision regarding sheet metal thickness and material type reduces waste and production costs. The right combination of material grade and gauge sizes delivers optimal performance without over-engineering—setting the foundation for a successful fabrication workflow.

The Complete Fabrication Workflow Explained

You've selected your material and identified a capable facility. Now what actually happens when you submit a project? Understanding the journey from digital design to physical part helps you prepare better files, anticipate timelines, and communicate effectively with your manufacturing partner.

Whether you're searching for fabrication shops near me or working with steel fabricators across the country, the fundamental workflow remains remarkably consistent. Let's trace a part's journey through a professional sheet metal factory from start to finish.

From CAD File to Finished Part

Every fabrication project begins with a design file. Your CAD model contains the geometric information that machines will translate into physical cuts and bends. But here's something many engineers overlook—not all file formats work equally well for sheet fabrication.

According to Xometry's manufacturing guidelines, choosing the appropriate CAD file format is the cornerstone of a seamless manufacturing process. For sheet metal work specifically, ensure that bend lines and material thickness are clearly defined before sending files to the manufacturer.

The most commonly accepted formats include:

- STEP (.stp, .step): The industry standard for 3D models. STEP files preserve geometric accuracy and transfer cleanly between different CAD systems—making them the preferred choice for most sheet metal fabricators.

- DXF (.dxf): Ideal for flat patterns and 2D cutting operations. Many laser cutting systems import DXF files directly.

- IGES (.igs, .iges): An older but still widely supported format for 3D geometry exchange.

- Parasolid (.x_t): Excellent for complex geometries with high compatibility across manufacturing software.

- Native CAD formats: SolidWorks (.sldprt), Inventor (.ipt), and Fusion 360 files are often accepted, though STEP remains more universal.

Submitting files in proprietary formats can cause translation errors—holes might shift, bend lines may disappear, or critical dimensions could be lost. When precision matters, export to STEP or Parasolid before submission.

The DFM Review Process

Once files arrive, experienced sheet metal fabricators don't simply hit "start" and begin cutting. Instead, they conduct a Design for Manufacturability (DFM) review—examining your design against their equipment capabilities and sheet metal best practices.

What does this review catch? Potential problems that would cause production failures or quality issues:

- Bend radii too tight for the specified material thickness

- Holes positioned too close to bend lines (they'll distort during forming)

- Features that would require costly secondary operations

- Tolerance specifications tighter than equipment can reliably achieve

- Material selections that conflict with forming requirements

Good fabricators don't just identify problems—they suggest solutions. Perhaps relocating a hole by 2mm prevents distortion. Maybe switching from 304 stainless to 316 improves formability for your complex bends. This collaborative feedback loop saves time and money compared to discovering issues during production.

The DFM review typically takes 24-48 hours for standard parts. Complex assemblies or tight-tolerance components may require longer evaluation. When searching for metal fabrication near me, prioritize partners who offer thorough DFM feedback rather than those who simply quote whatever you submit.

Sequential Steps in a Typical Fabrication Project

After design approval, your project moves through a predictable sequence. Understanding these stages helps you anticipate timelines and identify where delays might occur.

- Material procurement: The facility sources sheet stock matching your specifications. Common materials ship within days; specialty alloys may require weeks.

- Nesting and programming: Software optimizes how multiple parts fit onto standard sheet sizes, minimizing waste. CNC programs are generated for each operation.

- Cutting: Laser, punch, or waterjet machines cut flat blanks from raw sheets according to programmed patterns.

- Deburring: Sharp edges from cutting receive grinding or tumbling to remove hazardous burrs.

- Forming: Press brakes bend flat blanks into three-dimensional shapes. Complex parts may require multiple bend sequences.

- Secondary operations: Hardware insertion, tapping, countersinking, and machining of specific features occur at this stage.

- Joining: Welding, riveting, or fastener assembly combines multiple components into assemblies.

- Finishing: Parts receive surface treatments—powder coating, painting, plating, or anodizing—for protection and appearance.

- Quality inspection: Dimensional verification, visual inspection, and functional testing confirm parts meet specifications.

- Packaging and shipping: Finished parts receive protective packaging appropriate for their fragility and destination.

Each stage presents potential bottlenecks. Specialty materials extend procurement times. Complex nesting requires programming expertise. Multiple bend sequences slow forming operations. Understanding this flow helps you fabricate metal components more efficiently by designing parts that move smoothly through each stage.

Prototyping vs Mass Production Workflows

Here's where workflows diverge significantly. Prototyping and production runs may use identical equipment, but they follow fundamentally different approaches.

Prototyping prioritizes speed and flexibility. When you need 1-10 parts quickly, manufacturers skip extensive optimization. Parts might be nested individually rather than in multi-part arrays. Setup time dominates the cost equation, and engineers may make manual adjustments during production. Rapid prototyping techniques enable iterative design refinement before full-scale production, according to fabrication quality experts.

Expect prototype pricing to reflect this reality—per-part costs run substantially higher than production quantities because setup costs distribute across fewer units.

Mass production prioritizes efficiency and consistency. For runs of 100+ parts, manufacturers invest significantly more in optimization. Nesting algorithms maximize material utilization. Custom fixtures speed handling. Quality control systems monitor statistical process variation rather than inspecting every individual part. Programming time increases, but per-part costs drop dramatically.

The transition point varies by complexity. Simple brackets might reach production economics at 50 pieces. Complex enclosures requiring multiple operations may need 500+ units before optimization investments make sense.

Professional sheet metal fabricators communicate openly about these economics. They'll recommend prototyping approaches for small quantities and suggest design modifications that improve production efficiency when volumes justify the effort. This collaborative relationship—built on understanding the complete workflow—sets the stage for successful projects, especially when you apply Design for Manufacturability principles from the very beginning.

Design for Manufacturability in Sheet Metal

You've submitted your design files and received DFM feedback from your fabricator. But what exactly are they looking for? Understanding Design for Manufacturability principles before you design—rather than after—prevents costly revisions and accelerates your project timeline.

Think of DFM as the translation layer between your engineering intent and physical reality. Metal behaves in specific, predictable ways when cut, bent, and formed. Designs that respect these behaviors produce better parts at lower costs. Designs that ignore them create manufacturing friction—higher prices, longer lead times, and increased defect rates.

Bend Radius and Material Thickness Rules

Imagine folding a piece of cardboard. Fold it gently around a pencil, and the outer surface stays smooth. Try to crease it sharply at a 90-degree corner, and the outside cracks or tears. Metal behaves similarly—bend it too tightly, and the outer surface fractures or develops stress cracks.

The fundamental rule? According to Norck's DFM guidelines, the inside bend radius should at least match the material thickness. A 2mm thick sheet needs a minimum 2mm inside radius. Going tighter risks cracking, especially with harder materials like stainless steel.

Here's a practical tip that saves money: use the same bend radius throughout your design whenever possible. According to Protolabs' fabrication specifications, standard bend radii options of 0.030", 0.060", 0.090", and 0.120" are available with faster lead times. Each different radius requires a tool change. Designing all bends with a single radius means the fabricator uses one tool for every fold—reducing setup time and your costs.

Material grain direction also matters. Metal sheets have a "grain" from the rolling process at the mill. Bending perpendicular to the grain produces cleaner results with less risk of cracking. Bending parallel to the grain—especially on tight radii—invites failure. When your design allows flexibility in orientation, communicate with your fabricator about optimal grain alignment.

Hole Placement Best Practices

This is where many designs fail their first DFM review. Holes placed too close to bend lines distort during forming—round holes become ovals, precise locations shift unpredictably, and your assembly no longer fits together.

Why does this happen? When metal bends, material near the bend line stretches on the outside and compresses on the inside. Holes within this deformation zone get caught in the material flow, warping beyond tolerance.

The simple rule: keep holes a minimum of two times the material thickness from any bend line. For a 1.5mm thick sheet, that means 3mm minimum clearance. Many experienced engineers default to 3x material thickness for additional safety margin.

What if your design absolutely requires a hole near a bend? Fabricators can often punch the hole after bending rather than before—but this adds a secondary operation and increases cost. Alternatively, they may suggest a slotted hole that accommodates the stretching, maintaining functional fit despite the deformation.

Hole sizing matters too. When specifying holes for fasteners, consult a drill bit size chart to select standard dimensions. According to manufacturing best practices, using off-the-shelf hole sizes like 5mm, 6mm, or 1/4 inch allows fabricators to punch your order using existing tooling. Custom dimensions like 5.123mm might require procuring specialized tools—adding cost and delay.

Minimum hole diameter? At least equal to the material thickness. For sheets 0.036" or thinner, holes should be at least 0.062" from material edges to prevent distortion.

Tolerance Specifications That Work

Here's a truth many engineers resist: tighter isn't always better. Specifying tolerances beyond what your application actually requires drives up costs without improving function.

Metal is slightly elastic. When a press brake bends sheet to 90 degrees and releases, the material springs back slightly—perhaps to 88 or 89 degrees. Skilled fabricators compensate by over-bending, but achieving exactly 90.000 degrees consistently requires additional inspection time and rejected parts.

Standard sheet metal tolerances from professional facilities typically include:

- Bend angles: ±1 degree (per industry standards)

- Bend-to-edge dimensions: ±0.030" for most materials

- Hole locations: ±0.005" to ±0.010" depending on size

- Overall dimensions: ±0.010" to ±0.030" based on part size

When reviewing a drill chart or gauge size chart for your design, remember that the manufacturing process introduces variability. Designing your assembly to accommodate these standard tolerances—through slotted holes, clearance fits, or adjustable mounting—often proves more practical than demanding aerospace precision for a commercial enclosure.

That said, some applications genuinely require tight tolerances. Medical devices, aerospace components, and precision instruments may justify the additional cost. Just be intentional—specify tight tolerances only where function demands them, and allow standard tolerances elsewhere.

Common DFM Mistakes to Avoid

After reviewing thousands of designs, fabricators see the same problems repeatedly. Avoid these pitfalls to streamline your project:

- Missing bend reliefs: When a bend runs into an edge, metal tries to tear at the corner. Add small notches (rectangular or circular cutouts) at bend line endpoints to prevent cracking.

- Flanges too short: Press brakes need material to grip. Minimum flange length should be at least 4x material thickness. Shorter "illegal" flanges require expensive custom tooling.

- Narrow slots and fingers: Laser cutting generates heat. Very thin features—less than 1.5x material thickness wide—warp and twist during cutting.

- Ignoring kerf: Laser and plasma cutting remove material (the kerf). Designs with tight nesting or interlocking tabs must account for this material loss.

- Over-specifying non-critical features: Demanding ±0.001" on a mounting hole that works fine at ±0.010" wastes inspection resources and your budget.

- Inconsistent bend radii: Using three different radii when one would work requires three tool changes per part—tripling setup time.

How DFM Reduces Costs and Lead Times

Proper DFM isn't just about avoiding failures—it's about optimization. Parts designed with manufacturability in mind move through production faster, require fewer operations, and generate less scrap.

Consider the economics: setup time on a CNC press brake might run $50-100 per tool change. A design requiring five different bend radii adds $250-500 to every production run. Consolidating to a single radius eliminates that cost entirely.

Material utilization improves with DFM-conscious design too. Parts that nest efficiently on standard sheet sizes waste less raw material. Designs with standard hole sizes skip custom tooling. Features positioned away from bend lines eliminate rework from distortion.

Experienced sheet metal factories provide detailed DFM feedback precisely because it benefits everyone. Their suggestions reduce your costs while improving their production efficiency. When a fabricator recommends moving a hole 3mm or adjusting a bend radius, they're sharing expertise that took years to develop. Embrace that collaboration—it's one of the most valuable services a quality manufacturing partner provides.

With solid DFM principles built into your design, the next critical factor becomes ensuring consistent execution through quality standards and certifications.

Quality Standards and Certifications in Sheet Metal Manufacturing

Your design is optimized for manufacturability. But how do you know the finished parts will actually meet specification? The answer lies in quality control systems—the processes, certifications, and documentation that separate professional sheet metal factories from shops that simply hope for the best.

Quality isn't just about catching defects after they occur. It's a systematic approach woven throughout every production stage—from incoming material verification to final inspection. Understanding these systems helps you evaluate potential manufacturing partners and ensures your parts perform as intended.

Industry Certifications That Matter

Walk into any serious sheet metal factory and you'll notice certification plaques on the wall. But what do those acronyms actually mean? More importantly, which ones matter for your specific application?

ISO 9001 serves as the foundation. According to Hartford Technologies' certification guide, ISO 9001 is regarded as the most universal form of manufacturing certification, holding applicability across industries of all scales. It delineates the prerequisites for a robust quality management system—affirming that products or services comply with customer expectations and regulatory mandates. If a facility lacks ISO 9001 certification, consider it a warning sign about their commitment to consistent quality.

IATF 16949 builds on ISO 9001 specifically for automotive applications. Developed by the International Automotive Task Force, this certification encompasses additional requirements for product design, production processes, continuous improvement, and customer-specific standards. For chassis components, suspension parts, or any automotive sheet metal work, IATF 16949 certification isn't optional—major OEMs require it from their supply chain.

AS9100 addresses the unique demands of aerospace manufacturing. Aircraft parts face extreme performance requirements where failure isn't merely inconvenient—it's potentially catastrophic. This certification ensures parts meet the rigorous safety, quality, and documentation standards the aviation industry demands. If your sheet metal components will fly, partner only with AS9100-certified facilities.

ISO 13485 applies specifically to medical device manufacturing. Patient safety requires medical components be designed and manufactured with exceptional care. This certification aligns closely with ISO 9001 while addressing the unique requirements of the medical industry, prioritizing high-quality components and rigorous inspections.

Why do these certifications matter for your project? They demonstrate that a facility has invested in systematic quality processes—not just equipment. Certified manufacturers document their procedures, train their personnel, conduct internal audits, and face regular third-party verification. That infrastructure translates to consistent, reliable parts.

Inspection Methods and Quality Assurance

Certifications establish the framework, but inspection methods execute the quality plan. Professional facilities employ multiple verification techniques throughout production—each suited to different quality requirements.

Coordinate Measuring Machines (CMM) provide the highest precision dimensional verification available. These computer-controlled probe systems measure complex geometries against CAD models, detecting deviations measured in ten-thousandths of an inch. For critical features requiring tight tolerances, CMM inspection delivers definitive verification that simple hand tools cannot match.

Visual inspection catches surface defects that dimensional tools miss. According to quality control specialists at EOXS, routine visual inspection involves checking for surface defects such as cracks, scratches, and improper finishes using magnifying tools or high-resolution cameras. For parts receiving powder coating services or anodizing treatments, visual inspection verifies coating coverage, color consistency, and adhesion quality.

Non-Destructive Testing (NDT) reveals hidden flaws without damaging parts. Ultrasonic testing detects internal voids using sound waves. Magnetic particle inspection identifies surface and near-surface defects in ferromagnetic materials. Radiographic testing uses X-rays to find internal discontinuities. These methods prove essential for structural components where hidden defects could cause catastrophic failure.

Statistical Process Control (SPC) monitors production in real-time rather than inspecting only finished parts. By tracking measurements during production and plotting data on control charts, quality teams identify trends before they result in defects. This proactive approach—catching variation early—prevents entire batches from drifting out of tolerance.

For parts with anodized aluminum finishes or specialized powder coat treatments, additional inspection steps verify coating thickness, hardness, and corrosion resistance. These finishing processes require their own quality protocols beyond dimensional verification.

Material Traceability and Documentation

Imagine a structural component fails in the field. Can you trace exactly which batch of steel it came from? Which operator formed it? What inspection results it passed? For regulated industries, this traceability isn't optional—it's mandatory.

According to Fox Valley Metal-Tech's documentation experts, a Quality Data Package (QDP) is a compilation of reports that documents the traceability of materials, processes, and certifications used to produce each line item in a customer's purchase order. These packages can exceed 1,000 pages for complex projects—documenting everything from raw material certifications to final inspection results.

What does comprehensive traceability include?

- Material certifications: Mill test reports verifying chemical composition and mechanical properties of incoming sheet stock

- Process certifications: Documentation of heat treatments, coating processes, passivation, and other finishing operations

- Weld documentation: Welder certifications, weld procedure specifications, and weld maps for critical joints

- Inspection records: Dimensional reports, visual inspection results, and any testing performed

- First Article Inspection (FAI): Comprehensive verification that initial production parts match specifications before full production proceeds

- Deviation reports: Documentation of any departures from specified requirements and customer approval

For defense applications, materials must often be obtained from qualifying countries in accordance with DFAR regulations. Certificates of Conformance require printed names, signatures, and dates. Even seemingly minor documentation errors can trigger costly delays and rework.

Key Quality Checkpoints Throughout Fabrication

Quality verification doesn't happen only at the end. Professional sheet metal factories build inspection into every production stage:

- Incoming material inspection: Verify sheet thickness, surface condition, and material certifications before production begins

- First-piece verification: Measure initial parts from each setup before running full quantities

- In-process dimensional checks: Monitor critical dimensions during forming operations

- Weld inspection: Visual and/or NDT verification of joint quality

- Pre-finishing inspection: Confirm dimensional accuracy and surface condition before coating

- Post-finishing verification: Check coating thickness, adhesion, and appearance

- Final inspection: Comprehensive dimensional and visual verification against specifications

- Packaging audit: Ensure parts are protected appropriately for shipping

Each checkpoint creates an opportunity to catch problems before they propagate. A dimensional error caught at first-piece verification affects one part. The same error discovered at final inspection might affect hundreds—all requiring rework or scrap.

When evaluating manufacturing partners, ask about their inspection protocols at each stage. Facilities with robust checkpoint systems consistently deliver better quality than those relying solely on final inspection. This systematic approach to quality—combined with appropriate industry certifications—forms the foundation for reliable production, though it also factors into the overall cost equation you'll need to understand.

Understanding Pricing and Cost Factors

Quality systems protect your parts from defects—but what protects your budget? Understanding how sheet metal factories calculate pricing helps you make informed decisions, compare quotes accurately, and identify opportunities to reduce costs without sacrificing quality.

Here's the reality: fabrication costs aren't arbitrary. They follow predictable patterns driven by material consumption, machine time, labor hours, and finishing requirements. Once you understand these drivers, you can design smarter, negotiate better, and avoid surprise charges that derail project budgets.

Key Factors That Drive Fabrication Costs

When a sheet metal factory calculates your quote, they're evaluating several interconnected cost components. According to NW Metal Fabricators, the type of metal used for the fabrication project is a significant factor in determining its cost. Different metals have varying costs, with some being more expensive than others.

Material costs form the foundation of every quote. A metal sheet in stainless steel costs significantly more than the same dimensions in mild steel. Aluminum sheets fall somewhere between, with pricing varying by grade. Specialty alloys like titanium or Inconel command premium prices that can dominate project economics. Beyond the base metal price, thickness matters—heavier gauge metal sheets consume more raw material per part.

Market conditions also affect material pricing. As Metaltech's pricing analysis documents, hot-rolled steel prices fluctuated dramatically during recent supply chain disruptions—from $1,080 per ton in January 2021 to $1,955 per ton by September, before gradually declining. These swings directly impact your project costs, making timing and long-term supplier relationships increasingly valuable.

Labor and machine time typically represent the largest cost component. Every cut, bend, and weld requires skilled operators and expensive equipment. Complex geometries demand more programming time. Tight tolerances require slower machine speeds and additional inspection. The majority of a project's cost is labor, according to industry analysts—encompassing engineers, fabricators, certified welders, and quality inspectors.

Setup charges often surprise first-time buyers. Before cutting your first part, fabricators must program CNC machines, install appropriate tooling, calibrate equipment, and verify first-piece dimensions. These setup costs distribute across your order quantity—making them negligible for large runs but substantial for small batches.

Design complexity compounds costs at every stage. Intricate designs or complex geometric shapes often require more time, expertise, and precision in the fabrication process. Each additional bend requires tool changes. Every unique hole size needs specific punches. Compound curves may demand specialized forming equipment. When evaluating whether a design feature truly adds value, remember that complexity carries a price tag.

Volume Pricing and Batch Economics

Here's where quantity becomes your most powerful cost lever. The economics of sheet metal fabrication favor larger batches—sometimes dramatically.

Why do per-part costs drop with volume? Consider what happens when you order 10 parts versus 1,000:

- Setup costs spread thinner: A $200 programming and setup charge adds $20 per part on a 10-piece order but only $0.20 per part at 1,000 pieces

- Material efficiency improves: Larger orders allow better nesting—fitting more parts per steel plate or aluminum sheet, reducing scrap waste

- Production rhythm develops: Operators become faster as they repeat identical operations, reducing labor time per unit

- Purchasing power increases: Bulk material orders often qualify for volume discounts from steel suppliers

According to fabrication cost specialists, the economies of scale come into play as larger quantities may allow for bulk purchasing of materials and more efficient production processes. This can lead to lower per-unit costs.

Sounds straightforward? The transition points vary by part complexity. Simple brackets might show meaningful savings at 50 pieces. Complex welded assemblies may require 500+ units before production efficiencies fully materialize. Ask potential suppliers where their pricing break points fall for your specific design.

For applications like corrugated metal panels or standardized alu sheets, manufacturers often stock pre-cut sizes at lower costs than custom dimensions. Designing around these standard sizes—when your application allows—can significantly reduce both material costs and lead times.

How Different Factors Impact Project Cost

Understanding the relative weight of each cost driver helps you prioritize optimization efforts. Here's how various factors typically affect total project pricing:

| Cost Factor | Low-Cost Scenario | High-Cost Scenario | Relative Impact |

|---|---|---|---|

| Material Type | Mild steel | 316 stainless or titanium | Can increase costs 3-10x |

| Order Quantity | 1,000+ pieces | 1-10 pieces (prototype) | Per-part cost 5-20x higher for small runs |

| Design Complexity | Simple bracket (2-3 bends) | Complex enclosure (10+ operations) | 2-5x cost difference |

| Finishing | Raw or simple deburr | Multi-step plating or powder coating | Adds 20-100% to base cost |

| Tolerances | Standard (±0.030") | Precision (±0.005") | 15-50% premium for tight tolerances |

| Lead Time | Standard (2-4 weeks) | Rush (3-5 days) | 25-100% expedite premium |

Notice how material choice and quantity exert the strongest influence? Switching from stainless to mild steel—when corrosion requirements permit—often delivers more savings than any other single decision. Similarly, consolidating multiple small orders into fewer larger batches reduces per-part costs significantly.

How to Optimize Your Budget

Armed with understanding of cost drivers, you can make strategic decisions that reduce expenses without compromising quality:

Choose appropriate materials. According to One Precision's economic analysis, understanding the material sustainability and recyclability is an emerging aspect of material pricing. Don't specify 316 stainless when 304 works. Don't use aluminum when painted mild steel meets requirements. Match material properties to actual performance needs.

Simplify designs where possible. Consolidate bend radii to reduce tool changes. Use standard hole sizes that match existing tooling. Eliminate features that add manufacturing complexity without functional benefit. Every operation you remove reduces cost.

Leverage standard thicknesses and sheet sizes. Standard sheet metal gauges and sizes cost less than longer or thicker sheets, as custom dimensions require more labor and specialized handling. Design parts that nest efficiently on common stock sizes—typically 48" x 96" or 48" x 120" sheets.

Plan for volume when feasible. If you anticipate ongoing demand, ordering annual quantities in fewer batches reduces per-part costs substantially. Many facilities offer blanket orders with scheduled releases—locking in pricing while spreading delivery across months.

Accept standard tolerances on non-critical features. Specify tight tolerances only where function demands them. Allowing ±0.030" instead of ±0.010" on mounting holes reduces inspection time and rejection rates.

Getting Accurate Quotes and Comparing Factories

Requesting quotes seems simple, but the information you provide dramatically affects accuracy. Industry experts recommend supplying detailed specifications to help fabricators deliver on-target estimates:

- Updated and detailed drawings with all dimensions

- Material type, grade, and gauge specifications

- Required finishing processes

- Assembly directions if applicable

- Estimated annual volume of production

- Target delivery timeline

When comparing quotes between facilities, look beyond the bottom-line price. Verify that each quote includes identical specifications—material grade, tolerances, finishing, and inspection requirements. A lower quote that excludes powder coating or uses thinner gauge material isn't actually comparable.

Also consider total cost of ownership. A domestic fabricator charging 15% more but delivering in one week may cost less overall than an overseas supplier requiring eight-week lead times when you factor in inventory carrying costs, shipping expenses, and communication overhead.

The most cost-effective manufacturing relationships often develop over time. Fabricators who understand your products can suggest optimizations, flag potential issues early, and prioritize your work during capacity crunches. These partnership benefits don't appear on quotes but significantly impact long-term value—making supplier selection about more than just finding the lowest price.

How to Choose the Right Sheet Metal Factory Partner

You understand the equipment, materials, workflows, and cost factors. Now comes the decision that ties everything together—selecting the manufacturing partner who will transform your designs into reality. This choice impacts quality, cost, timeline, and your ongoing peace of mind.

Finding metal fabricators near me through a quick search returns dozens of options. But how do you distinguish between facilities that merely claim capability and those that consistently deliver? The answer lies in systematic evaluation across multiple dimensions—not just price.

Evaluating Factory Capabilities

Before signing any agreement, verify that a potential partner actually possesses the equipment, expertise, and capacity your project requires. According to fabrication specialists at Swanton Welding, different projects have different requirements, and a shop that works for one project may not work for another.

Start with equipment. Does the facility have laser cutters capable of handling your material thickness? Press brakes with sufficient tonnage for your bend requirements? Welding capabilities matched to your material type? A local fabrication shops tour—virtual or in-person—reveals whether marketing claims match physical reality.

Capacity matters equally. A small metal fabrication shop with excellent equipment but limited floor space may struggle with large orders or tight deadlines. Ask about current utilization rates, typical lead times, and how they handle demand spikes. Facilities running at 95% capacity leave little room for your urgent projects.

Industry-specific experience separates adequate fabricators from excellent partners. According to industry experts, while there are consistent needs for metal fabrication, different industries do have different requirements, and experience is important. A shop producing agricultural equipment may lack the precision culture required for medical devices. Facilities serving aerospace understand documentation requirements that general fabricators might overlook.

How do you assess this experience? Ask for case studies or references from projects similar to yours. Review their portfolio for complexity levels matching your needs. Speak with past clients about both successes and challenges—how a fabricator handles problems reveals more than how they handle easy projects.

Essential Questions to Ask Potential Manufacturing Partners

When evaluating local fabrication shops or precision sheet metal shops, structured questioning reveals capabilities that marketing materials often obscure:

- What certifications do you hold? ISO 9001 demonstrates baseline quality systems. IATF 16949 signals automotive expertise. AS9100 indicates aerospace capability. Match certifications to your industry requirements.

- Can you provide references from similar projects? According to Seconn Fabrication's partner evaluation guide, past work is one of the most accurate indicators of future performance and customer satisfaction.

- What is your typical quote turnaround time? Responsiveness during quoting predicts responsiveness during production. Facilities offering same-day or 12-hour quote turnaround demonstrate operational efficiency and customer focus.

- Do you offer DFM support? Partners who review designs for manufacturability catch problems early, reducing rework and costs. Ask whether engineers are available to suggest improvements.

- What is your on-time delivery rate? According to industry benchmarks, meeting deadlines no matter how tight is essential for ensuring a smooth production process. Top-tier facilities track and report this metric—typically targeting 95%+ performance.

- How do you handle design changes mid-production? Flexibility matters. Understanding their change management process prevents costly surprises when modifications become necessary.

- What secondary operations do you offer in-house? Facilities offering powder coating, hardware insertion, welding, and assembly under one roof streamline production and reduce lead times compared to outsourcing each operation.

- What is your prototyping capability and lead time? Rapid prototyping—5-day turnaround or faster—accelerates development cycles. This capability proves especially valuable during product development phases.

Domestic vs Overseas Manufacturing Options

The domestic versus overseas debate involves more than simple cost comparison. According to Mead Metals' sourcing analysis, making the right decision can feel like a balancing act—weighing reliability and quality against potentially lower costs.

Advantages of Domestic Manufacturing

Speed and reliability: Domestic suppliers ship within days rather than weeks. There's far less risk of delays due to customs, port congestion, or global shipping crises. When your production schedule can't accommodate eight-week ocean freight, domestic sourcing keeps projects on track.

Quality consistency: U.S. suppliers adhere to strict industry standards and certifications. According to sourcing specialists, with local oversight, issues can be addressed swiftly, reducing the chances of receiving subpar products.

Communication clarity: Same time zone, same language, same business culture. Need to make adjustments or have an urgent request? Picking up the phone and resolving things quickly becomes straightforward with a local metal fabrication shop.

Flexibility: Domestic suppliers often adapt quickly—speeding up delivery, customizing orders, or accommodating special requests without the complexity of international logistics.

Overseas Manufacturing Considerations

Cost potential: International suppliers in countries with lower labor costs can sometimes offer lower per-part pricing. For price-sensitive, high-volume projects, this differential may prove significant.

Specialty materials: Certain exotic alloys may only be produced in specific regions abroad. If your project requires rare materials unavailable domestically, overseas sourcing may be necessary.

Hidden costs: What seems like a good deal can quickly add up. According to cost analysts, shipping fees, tariffs, duties, and currency exchange rates can turn that low-cost order into a much pricier endeavor than expected.

Quality variability: Without regular facility inspections, quality can be inconsistent. Compliance issues may arise without the ability to verify materials and processes firsthand.

For most custom sheet metal fabrication near me searches, domestic partners offer compelling advantages—especially for automotive, aerospace, or medical applications where quality documentation and rapid response matter more than marginal cost savings.

Red Flags to Watch For

Experience teaches which warning signs predict future problems. When evaluating potential partners, proceed cautiously if you encounter:

- Reluctance to provide references: Quality fabricators proudly share client success stories. Hesitation suggests dissatisfied customers.

- Missing or outdated certifications: Lapsed ISO certification indicates declining commitment to quality systems.

- Unrealistic pricing: Quotes dramatically below competitors often signal hidden compromises—thinner materials, skipped inspections, or bait-and-switch tactics.

- Poor communication responsiveness: If getting a quote takes two weeks, imagine getting production updates. According to fabrication experts, reliable partners have streamlined workflows and established efficient practices that include prompt communication.

- No DFM feedback: Fabricators who simply quote whatever you submit—without suggesting improvements—lack the engineering depth to optimize your designs.

- Vague capacity claims: Unable to specify equipment models, tonnage ratings, or production capacity? They may be outsourcing your work to unknown third parties.

- No quality metrics: Facilities unable to provide on-time delivery rates, defect percentages, or inspection records likely don't track them—meaning they don't prioritize them.

What Quality Partners Look Like

The best manufacturing relationships combine technical capability with operational excellence. When evaluating precision sheet metal shops, look for partners demonstrating:

Rapid prototyping capability: Facilities offering 5-day or faster prototype turnaround accelerate your development cycles. This capability indicates flexible operations and engineering responsiveness.

Industry-specific certification: For automotive applications, IATF 16949 certification isn't optional—it demonstrates the quality systems major OEMs require. For example, Shaoyi (Ningbo) Metal Technology delivers IATF 16949-certified quality specifically for chassis, suspension, and structural components.

Comprehensive DFM support: Partners who invest engineering resources in reviewing and improving your designs add value beyond basic fabrication. This collaboration reduces costs and improves manufacturability before production begins.

Fast quote turnaround: Facilities offering 12-hour quote response demonstrate operational efficiency and customer focus. This responsiveness continues throughout production—urgent questions get answered quickly, problems get solved promptly.

Scalability: According to partnership specialists, your fabrication partner should scale with you as your business grows. Find out their flexibility in production volumes, capacity for future growth, and ability to support increased demand without sacrificing quality. Partners capable of transitioning from rapid prototyping to automated mass production provide continuity as your volumes grow.

Whether you're searching for a small fabrication shop for prototype quantities or a high-volume production partner, these evaluation criteria help identify facilities positioned to deliver consistent quality. The investment in thorough partner assessment pays dividends throughout your manufacturing relationship—setting the foundation for successful projects from first article through ongoing production.

Getting Started With Your Sheet Metal Project

You've now journeyed through the complete landscape of sheet metal manufacturing—from understanding what happens inside these facilities to evaluating potential partners. But knowledge without action remains theoretical. Whether you're launching a new product, sourcing replacement components, or exploring manufacturing options for the first time, the path forward requires translating what you've learned into concrete steps.

Let's distill the essential insights and outline how to move from planning to production with confidence.

Key Takeaways for Your Next Project

Throughout this guide, several themes emerged repeatedly—each critical to successful sheet metal fabrication outcomes:

Capabilities determine possibilities. Professional facilities invest in specialized equipment—laser cutters, CNC punch presses, precision press brakes—that general shops simply don't possess. When searching for sheet metal near me or custom metal parts fabrication near me, verify that potential partners actually own the machinery your project demands. A tour reveals whether marketing claims match reality.

Material selection drives performance and cost. Stainless steel sheet metal delivers corrosion resistance but costs more than mild steel. Aluminum saves weight but requires different forming techniques. Understanding gauge thickness, material grades, and their trade-offs prevents both over-engineering and under-specifying. Match metal plate thickness and alloy type to your actual performance requirements—not worst-case assumptions.

DFM saves money before production begins. According to sheet metal design specialists, 30% of projects face costly reworks due to design flaws. Applying Design for Manufacturability principles—appropriate bend radii, proper hole placement, realistic tolerances—eliminates these problems upfront. Partner with fabricators who offer comprehensive DFM feedback rather than those who simply quote whatever you submit.

Certifications signal commitment. ISO 9001 establishes baseline quality systems. IATF 16949 demonstrates automotive expertise. AS9100 indicates aerospace capability. These certifications require significant investment in processes, training, and auditing—they're not merely paperwork. For regulated industries, partner only with appropriately certified facilities.

Volume economics reward planning. Setup costs distributed across 1,000 parts cost pennies each; across 10 parts, they dominate pricing. Whenever feasible, consolidate orders, plan for annual volumes, and design parts that nest efficiently on standard sheet sizes.

The best manufacturing partner isn't necessarily the cheapest—it's the one whose capabilities, certifications, and communication style align with your specific project requirements and quality expectations.

Taking the First Step

Ready to move forward? Here's how to translate knowledge into action:

Prepare complete design files. Export CAD models in STEP or DXF format with clearly defined bend lines and material thickness. Include dimensioned drawings specifying tolerances, material grade, and finishing requirements. Complete documentation accelerates quoting and reduces misunderstandings.

Request DFM feedback early. Submit designs for manufacturability review before finalizing specifications. According to DFM specialists at JC Metalworks, following DFM principles early minimizes risks and improves the likelihood of delivering on time and budget. Embrace fabricator suggestions—they're sharing expertise developed across thousands of projects.

Verify certifications match your industry. Don't assume—request current certification documents. For automotive chassis, suspension, or structural components, IATF 16949 certification isn't optional. For aerospace applications, AS9100 is mandatory. For medical devices, look for ISO 13485 compliance.

Compare quotes on equal terms. Ensure each prospective partner quotes identical specifications—same material grade, tolerances, finishing processes, and inspection requirements. A lower quote that excludes powder coating or uses thinner gauge material isn't truly comparable.

Prioritize responsive partners. Quote turnaround time predicts production responsiveness. Facilities offering 12-hour quote turnaround demonstrate operational efficiency that carries through to production communication. When problems arise—and they occasionally do—responsive partners resolve them quickly.

For readers in specific regions like sheet metal fabrication San Jose or other manufacturing hubs, local partners offer advantages in communication, shipping speed, and facility visits. However, don't limit your search geographically if specialized capabilities or certifications aren't available locally.

For automotive and precision applications specifically, consider partners combining rapid prototyping capability with production scalability. Shaoyi (Ningbo) Metal Technology exemplifies this combination—offering 5-day rapid prototyping, IATF 16949-certified quality for chassis and structural components, comprehensive DFM support, and 12-hour quote turnaround. Whether you're developing prototypes or scaling to automated mass production, starting with a quick quote request puts your project in motion today.

Frequently Asked Questions About Sheet Metal Factories

1. What is a sheet metal factory and what do they do?

A sheet metal factory is a specialized manufacturing facility that transforms flat metal sheets—typically less than 6mm thick—into precision-engineered components through cutting, bending, forming, and assembly operations. These facilities house specialized equipment like laser cutters, CNC punch presses, press brakes, and welding stations operated by skilled technicians. They produce everything from simple brackets to complex enclosures for industries including automotive, aerospace, electronics, and medical devices. Unlike general metal fabrication shops that handle various materials and thicknesses, sheet metal factories focus exclusively on thin-gauge materials, achieving tighter tolerances and faster turnaround times.

2. How much does sheet metal fabrication cost?

Sheet metal fabrication costs depend on several factors: material type (mild steel is cheapest, stainless steel and titanium cost 3-10x more), order quantity (per-part costs drop significantly at higher volumes due to distributed setup costs), design complexity (more bends and operations increase price), finishing requirements (powder coating or plating adds 20-100% to base cost), tolerances (precision specs add 15-50% premium), and lead time (rush orders incur 25-100% expedite fees). To optimize your budget, choose appropriate materials for your actual requirements, simplify designs where possible, consolidate orders into larger batches, and accept standard tolerances on non-critical features.

3. What certifications should a quality sheet metal factory have?

Essential certifications vary by industry application. ISO 9001 serves as the baseline quality management certification applicable across all industries—facilities lacking this should raise concerns. For automotive components like chassis and suspension parts, IATF 16949 certification is mandatory as major OEMs require it from suppliers. Aerospace applications demand AS9100 certification to meet rigorous safety and documentation standards. Medical device manufacturing requires ISO 13485 compliance. These certifications demonstrate that facilities have invested in systematic quality processes, documented procedures, trained personnel, and undergo regular third-party audits—translating to consistent, reliable parts.

4. What is the difference between domestic and overseas sheet metal manufacturing?

Domestic manufacturing offers faster shipping (days vs. weeks), consistent quality under strict industry standards, clear communication in the same time zone and language, and flexibility for custom requests. Overseas manufacturing may provide lower per-part pricing due to reduced labor costs and access to specialty materials only produced abroad. However, hidden costs often diminish savings—shipping fees, tariffs, duties, and currency fluctuations can increase expenses significantly. Quality variability and communication challenges also present risks. For automotive, aerospace, or medical applications where quality documentation and rapid response matter, domestic partners typically offer compelling advantages over marginal cost savings.

5. How do I choose the right sheet metal fabrication partner?

Evaluate potential partners across multiple dimensions: verify equipment capabilities match your project requirements through facility tours, confirm industry-specific certifications (IATF 16949 for automotive, AS9100 for aerospace), request references from similar projects, assess quote turnaround time as an indicator of operational efficiency, confirm DFM support availability, and ask about on-time delivery rates (top facilities target 95%+). Watch for red flags including reluctance to provide references, missing certifications, unrealistic pricing, poor communication responsiveness, and inability to specify equipment details. The best partners combine technical capability with rapid prototyping, comprehensive DFM feedback, and scalability from prototypes to mass production.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —