Sheet Metal Fabrication Manufacturers: 9 Critical Factors Before You Sign

What Is Sheet Metal Fabrication and Why It Matters

Ever looked at a car body panel, an aircraft fuselage, or even your kitchen appliances and wondered how they came to be? The answer lies in sheet metal fabrication - one of the most versatile and widely used manufacturing processes in modern industry. Before you sign a contract with any sheet metal fabrication manufacturers, understanding exactly what this process involves will help you ask the right questions and make informed decisions.

Sheet metal fabrication is the process of transforming flat metal sheets into functional parts, components, and structures through a series of controlled operations. According to industry experts at Geomiq, this manufacturing process encompasses multiple operations where flat metal sheets of various sizes and thicknesses undergo cutting, forming, and assembly to achieve desired shapes and geometries. Think of it as origami with metal - except instead of paper folds, you're using industrial machinery to create everything from simple brackets to complex aerospace components.

From Flat Stock to Finished Parts

The journey from raw material to finished product follows a structured path. It all starts with sheet metal engineering during the design phase, where engineers create detailed 3D models using CAD software. These digital blueprints capture every dimension, tolerance, and surface finish requirement. But here's what makes this step crucial: the design stage generates machine-readable G-code that controls CNC equipment, ensuring highly accurate execution during production.

Once the design is finalized, flat metal sheets enter the fabrication stage. Here, metal fabrication materials like steel, aluminum, or stainless steel sheets get cut, bent, and shaped according to specifications. The workpiece might pass through several machines and operations before emerging as a recognizable component. Finally, post-processing operations like heat treatment and surface finishing bring the part to its final physical state.

The Manufacturing Process Behind Everyday Metal Components

What happens between that flat sheet of metal and the finished part in your hands? Multiple specialized operations work together to create the transformation. Here are the primary fabrication methods you'll encounter when working with manufacturers:

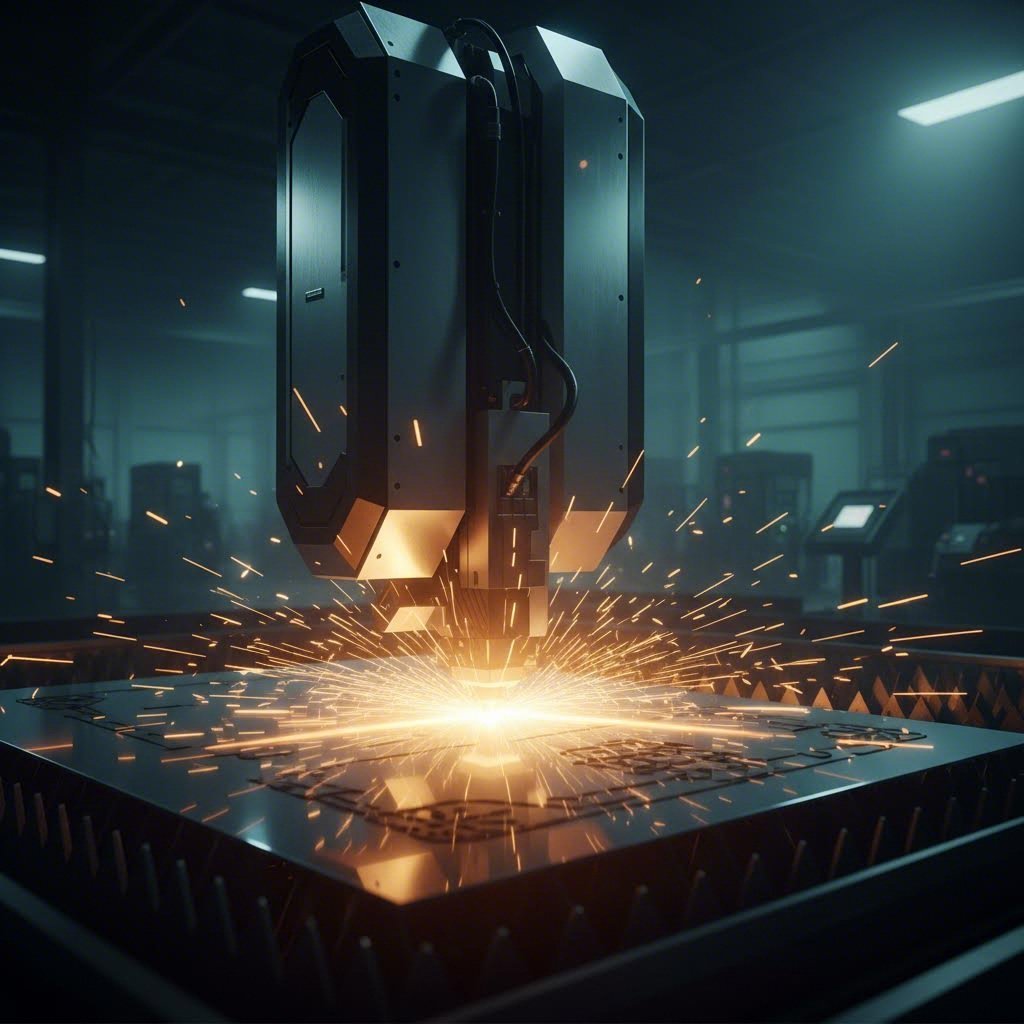

- Laser Cutting: Uses a high-energy laser beam to melt through metal with extreme precision, capable of cutting materials up to 30mm thick with intricate patterns and tight tolerances.

- Punching: Employs a punch and die system to create precise holes or shapes in sheet metal, with the removed material sometimes repurposed as new blanks through a process called blanking.

- Bending: Utilizes brake machines to fold sheet metal into V, U, and channel shapes at angles up to 120 degrees, forming the structural geometry of parts.

- Welding: Joins metal pieces by melting joint edges and allowing them to fuse upon cooling, creating permanent structural connections between components.

- Finishing: Applies surface treatments like powder coating, anodizing, or electroplating to enhance appearance, corrosion resistance, and durability.

Why Sheet Metal Remains the Backbone of Industrial Production

You might wonder why sheet metal fabrication continues to dominate manufacturing when newer technologies like 3D printing exist. The answer comes down to several compelling advantages that matter for real-world production.

First, consider versatility. This process works with hundreds of pure metals, alloys, and super alloys. Whether you need lightweight aluminum for aerospace applications or corrosion-resistant stainless steel for medical devices, sheet metal manufacturing adapts to your requirements. Second, scalability makes it ideal for high-volume production - most processes can be automated or run multiple parts simultaneously.

According to CADDi, sheet metal fabrication offers several benefits over other manufacturing processes: it's lightweight yet strong, produces minimal material wastage, enables fast production cycles, and maintains cost-effectiveness across various production volumes. These qualities explain why over 50% of car parts are manufactured from sheet metal and why industries from aerospace to consumer electronics rely on this process daily.

Understanding these fundamentals positions you to evaluate potential manufacturing partners more effectively. When you know what happens on the shop floor, you can ask better questions about capabilities, quality control, and production timelines - setting the stage for successful fabrication projects.

Material Selection Guide for Sheet Metal Projects

Now that you understand what sheet metal fabrication involves, here's the next critical question: which material should you use? This decision impacts everything from your project's cost to its performance in the field. Yet many buyers rush through material selection, focusing solely on price without considering the long-term implications. Let's change that approach.

When evaluating sheet metal fabrication manufacturers, their material expertise matters just as much as their equipment capabilities. A manufacturer who can guide you through material trade-offs becomes a true partner rather than just a vendor. Here's the comprehensive breakdown you need to make informed decisions.

Steel vs Aluminum vs Stainless Steel Trade-offs

Choosing between these three dominant materials involves balancing competing priorities. Each brings distinct advantages and limitations to your project.

Aluminum sheets metal offer an attractive combination of lightweight construction and natural corrosion resistance. According to Norco Precision, aluminum is easier to form and machine compared to steel alternatives, making it ideal for aerospace, enclosures, signage, and transportation applications. The 5000 and 6000 series alloys dominate sheet metal work, with options like 5052 providing excellent weldability and 6061 offering good mechanical properties through precipitation hardening.

Cold rolled steel delivers the lowest cost option with high strength characteristics. You'll get a very precise surface finish straight from the mill. The trade-off? Poor corrosion resistance unless you add powder coating or other protective finishes. This makes steel best suited for indoor parts, brackets, panels, frames, and structural components where moisture exposure remains minimal.

Stainless steel sheet metal combines exceptional durability with outstanding corrosion resistance. The 300 series austenitic grades like 304 and 316 dominate the market. According to Xometry, 304 stainless contains chromium and nickel that provide excellent corrosion resistance, making it widely used in food and beverage industries. Meanwhile, 316 stainless adds molybdenum for improved resistance against chloric and non-oxidizing acids. Yes, it costs more - but the longevity often justifies the investment for demanding applications.

Understanding Gauge Thickness and Its Impact

Sounds complex? It doesn't have to be. Gauge numbers work inversely to actual thickness - higher gauge means thinner material. A 10-gauge steel sheet measures approximately 3.4mm thick, while 20-gauge comes in at roughly 0.9mm. Here's what this means for your project:

- Thicker gauges (lower numbers): Provide greater structural strength but increase weight, material cost, and processing time. Bending requires more force and larger radius specifications.

- Thinner gauges (higher numbers): Reduce weight and material costs while enabling tighter bend radii. However, they're more susceptible to warping during welding and may not provide adequate rigidity for structural applications.

- Material-specific considerations: Aluminum sheets and stainless sheet metal use different gauge standards than carbon steel, so always confirm actual thickness in millimeters or inches when comparing quotes.

When discussing gauge requirements with manufacturers, specify the actual thickness dimension rather than relying solely on gauge numbers. This prevents miscommunication, especially when working with aluminium fabrication specialists who may reference different standards than steel fabricators.

Matching Material Properties to Application Requirements

The best material choice depends entirely on where and how your part will function. Consider a copper steel sheet for electrical applications requiring conductivity, or bronze sheet for marine environments demanding both strength and corrosion resistance in saltwater exposure.

Here's a comprehensive comparison to guide your selection:

| Material | Tensile Strength | Corrosion Resistance | Weight | Relative Cost | Typical Applications |

|---|---|---|---|---|---|

| Aluminum (5052) | Moderate | Excellent | Light | Medium | Enclosures, signage, aerospace components |

| Aluminum (6061) | Moderate-High | Excellent | Light | Medium | Structural parts, extruded components |

| Cold Rolled Steel | High | Poor (requires coating) | Heavy | Low | Brackets, frames, indoor panels |

| Stainless Steel 304 | Very High | Excellent | Heavy | High | Food equipment, medical devices |

| Stainless Steel 316 | Very High | Superior (chloride resistant) | Heavy | Very High | Marine, chemical processing |

| Copper | Low-Moderate | Good | Heavy | High | Electrical components, decorative elements |

| Bronze | Moderate-High | Excellent (saltwater) | Heavy | High | Marine hardware, bearings, bushings |

When you're evaluating aluminum bars for structural components or considering aluminium sheet for enclosures, remember that material selection directly impacts manufacturability. Some materials weld more readily, others bend without cracking, and certain alloys machine with less tool wear. A knowledgeable manufacturer will help you balance performance requirements against production constraints.

Your material choice also affects downstream costs beyond the initial purchase price. Stainless steel sheet metal may cost more upfront but eliminates ongoing painting and maintenance expenses. Aluminum's lighter weight reduces shipping costs and enables thinner structural members. Think about the total lifecycle cost, not just the per-pound material price.

With your material selection strategy in place, understanding how that material gets transformed into finished parts becomes your next priority. The fabrication processes themselves determine what geometries are achievable and at what cost.

Core Fabrication Processes Explained

You've selected your material - now what happens to that flat sheet of metal? Understanding the core fabrication processes helps you communicate effectively with manufacturers and evaluate whether their capabilities match your project requirements. Let's dive into the technologies that transform raw materials into precision components.

Metal fabrication encompasses several distinct operations, each suited to specific applications. When evaluating sheet metal fabrication manufacturers, knowing which processes your project requires helps you identify partners with the right equipment and expertise. More importantly, understanding process trade-offs enables you to make design decisions that optimize both quality and cost.

Cutting Technologies Compared

Imagine you need to cut intricate patterns into steel plate. Which technology should your manufacturer use? The answer depends on material type, thickness, precision requirements, and production volume. Here's how the three dominant cutting methods stack up:

Laser Cutting uses a focused beam of intense light to melt through metal with surgical precision. According to testing by Wurth Machinery, laser cutting excels with thin sheets requiring fine details, small holes, or intricate shapes. The focused beam creates exceptionally clean edges with minimal post-processing needed.

- Advantages: Superior precision for thin materials, clean edges requiring minimal finishing, excellent for complex geometries and small holes, high repeatability for production runs

- Limitations: Struggles with thicker materials (typically limited to under 25mm depending on power), higher equipment cost, reflective materials like copper can be challenging

- Best for: Electronics enclosures, medical devices, precision sheet metal fabrication, and any application where edge quality matters

Plasma Cutting uses an electrical arc and compressed gas to melt and blast through conductive metals. This technology dominates when working with thick steel plate while keeping costs manageable.

- Advantages: Excellent speed on thick metals (1 inch and above), lower operating costs than laser or waterjet, handles a wide range of conductive materials effectively

- Limitations: Less precise than laser cutting, creates a heat-affected zone that may alter material properties, not suitable for non-conductive materials

- Best for: Structural steel fabrication, heavy equipment manufacturing, shipbuilding, and projects prioritizing speed over precision

Waterjet Cutting uses high-pressure water mixed with abrasive particles to cut through virtually any material without generating heat. This cold-cutting process eliminates warping, hardening, and heat-affected zones entirely.

- Advantages: Cuts any material including non-metals, no heat distortion or material property changes, excellent edge quality, handles very thick materials

- Limitations: Slower cutting speeds than plasma or laser, higher operating costs, requires abrasive material management

- Best for: Aerospace components, heat-sensitive materials, stone and glass, and applications where thermal distortion is unacceptable

When you're sourcing steel sheet fabrication or aluminum fabrication services, ask manufacturers which cutting technologies they operate. A shop with only plasma capability may not deliver the edge quality needed for visible components, while a laser-only operation might struggle with thick structural parts.

Precision Bending and Forming Techniques

Cutting creates flat profiles - bending transforms them into three-dimensional parts. Metal fabrication and bending go hand-in-hand, and understanding the different techniques helps you specify achievable geometries in your designs.

Press Brake Bending remains the workhorse of sheet metal working. According to Nova Fabrication, this process positions metal over a V-shaped die opening while a punch applies force to create the bend. The technique allows angle adjustment by controlling punch depth, making it extremely versatile for custom fabrication.

Steel sheet bending through press brake operations suits most standard applications. However, precision requirements determine which specific technique manufacturers employ:

- Air Bending: The punch doesn't fully press material into the die, allowing angle flexibility. Some spring-back occurs, requiring operator compensation. Most cost-effective for general work.

- Bottoming: Metal presses completely into the die, eliminating spring-back for consistent, repeatable angles. Ideal for aerospace or medical applications demanding tight tolerances.

- Coining: Applies significant force to imprint the die shape onto metal. Creates extremely accurate bends for delicate components where precision is paramount.

Roll Bending handles large-radius curves and cylindrical shapes that press brakes cannot achieve. A set of rollers gradually forms the material into curves, producing components for pipelines, storage tanks, and architectural elements. If your design includes sweeping curves rather than sharp angles, confirm your manufacturer has roll bending capability.

Modern CNC bending machines integrate automation through pre-programmed instructions, ensuring consistency across production runs. For precision sheet metal forming requirements, ask manufacturers about their CNC equipment and the tolerances they can hold on bent features.

Welding Methods for Different Applications

Sheet metal machining and cutting create individual pieces - welding joins them into assemblies. The two dominant methods for sheet metal work are MIG and TIG welding, each suited to different applications.

MIG Welding (Metal Inert Gas) feeds a continuous wire electrode through a welding gun while shielding gas protects the weld pool. According to Metal Works HP, MIG welding offers high production rates and user-friendly operation.

MIG Welding Pros

- Faster welding speeds for higher throughput

- Easier for operators to learn and execute

- Works well on thicker materials

- Lower cost per weld on production runs

MIG Welding Cons

- Less precise control than TIG

- Produces more spatter requiring cleanup

- Not ideal for thin sheet metal or visible welds

TIG Welding (Tungsten Inert Gas) uses a non-consumable tungsten electrode with a separate filler rod added manually. This method delivers precision and clean, aesthetic welds for intricate or specialized applications.

TIG Welding Pros

- Superior precision and control over the weld pool

- Clean, aesthetic welds with minimal spatter

- Excellent for thin materials and visible joints

- Works on a wider variety of metals including aluminum and stainless

TIG Welding Cons

- Slower process requiring more operator time

- Demands higher skill levels from welders

- Higher cost per weld compared to MIG

For metal fabrication projects requiring aesthetic welds on enclosures or thin-gauge assemblies, TIG welding typically delivers better results. Production-focused work with thicker materials often favors MIG for speed and economy. Many manufacturers offer both, selecting the appropriate method based on your specific requirements.

Understanding these core processes positions you to have productive conversations with potential manufacturing partners. You'll know what questions to ask about their capabilities and can better evaluate whether their equipment matches your project needs. The next critical consideration? Ensuring your designs are optimized for these manufacturing processes from the start.

Design for Manufacturability Best Practices

Here's a truth most sheet metal fabrication manufacturers won't tell you upfront: your design determines your costs more than any other factor. A brilliant concept that ignores manufacturing realities leads to rejected parts, expensive tooling changes, and blown budgets. Design for Manufacturability (DFM) bridges the gap between what you envision and what's actually producible - and mastering these principles separates successful projects from costly failures.

Whether you're working with precision sheet metal fabricators for aerospace components or sourcing custom fabrication for industrial enclosures, these guidelines apply universally. Let's explore the design considerations that prevent headaches before they start.

Common Design Mistakes That Increase Costs

Even experienced engineers fall into these traps. According to fabrication experts at JC Metalworks, overlooking DFM principles during design leads to higher costs, production delays, and rejected parts. Here are the critical errors to avoid:

Placing holes too close to bend lines. When you position holes or slots near a bend, the forming operation distorts them into ovals or misaligns fastener locations entirely. The rule? Keep holes at least 2.5 times the material thickness plus the bend radius away from bend lines. Tight on space? Either move the feature, increase the bend radius, or plan for post-bending drilling operations.

Specifying bend radii that are too tight. A small inside radius might look clean in CAD, but it risks cracking or excessive springback in reality. Softer materials tolerate smaller radii while harder alloys often need at least one times the material thickness. Match your radius specifications to both the material and your manufacturer's available tooling.

Ignoring bend relief requirements. When bends intersect without proper relief cuts, the sheet metal tears or buckles at the corner. These small semicircular or rectangular cutouts allow the material to fold cleanly and reduce tooling stress. Always add bend reliefs near sharp corners and cutouts adjacent to bends.

Designing flanges that are too short. Short flanges can't be clamped or formed properly, causing slipping and inconsistent bends. According to EABEL, a common guideline requires flange length to be at least four times the material thickness for proper grip during forming.

Ignoring grain direction. Metal sheets have a grain direction from the rolling process that affects bending behavior. Bending against the grain increases crack risk, especially on sharp radii. Work with your fabricator to align bends parallel to the grain direction whenever possible.

Optimizing Your Design for Production Efficiency

Smart design choices reduce manufacturing complexity and lower your per-part costs. When working with custom sheet metal fab operations, consider these optimization strategies:

- Maintain consistent wall thickness throughout your part. Varying thicknesses complicates production and increases setup time. Uniform material also ensures predictable behavior during forming operations.

- Minimize the number of different gauges in a project. Using multiple thicknesses might seem beneficial for performance, but it significantly increases manufacturing complexity and material handling costs.

- Design parts to fit standard sheet sizes efficiently. Metal sheets come in standard dimensions (4' x 8', 5' x 10'). Parts that nest efficiently within these sizes minimize material waste and reduce raw material expenses.

- Incorporate tabs and slots for self-locating assembly. These interlocking features allow easy alignment without requiring complex fixtures or jigs, streamlining downstream assembly operations.

- Use standard hole sizes whenever possible. Odd hole diameters force custom punches or laser cutting, increasing cycle time and cost. Standardizing keeps production predictable and lowers tooling expenses.

- Plan for secondary operations during initial design. Consider welding distortion, coating thickness, and assembly clearances from the start. These factors change part fit and performance if ignored.

Sheet metal design services from experienced manufacturers often include DFM reviews that catch these issues before production begins. If your supplier offers this consultation, take advantage of it - the upfront investment prevents expensive revisions later.

Critical Dimensions and Tolerance Considerations

Here's where sheet metal prototype development often goes wrong: treating formed parts like machined components. According to Protolabs, precision sheet metal forming has natural variation that differs significantly from machining tolerances.

For precision sheet metal work, understand these achievable specifications:

| Feature Type | Typical Tolerance | Notes |

|---|---|---|

| Hole position (same surface) | ±0.005" to ±0.010" | Laser cutting delivers tightest tolerances |

| Hole position (across bends) | ±0.030" per bend crossed | Tolerance stacks with each bend |

| Bend angle | ±1° per bend | Tighter tolerances require bottoming or coining |

| Linear dimensions | ±0.010" to ±0.020" | Material thickness affects achievable precision |

| Flange height | ±0.015" to ±0.030" | Minimum flange = 4x material thickness |

Notice how tolerances stack across bends? When holes on a box appear on four different surfaces separated by four bends, the stacking angular tolerance reaches 1° per bend. This means hole locations across multiple surfaces are far less tightly controlled than holes on a single flat surface.

What can you do about this? Open holes to allow for misalignment, use floating hardware that accommodates position variation, or combine both approaches. According to Protolabs, these strategies effectively trivialize stacking tolerances and ensure reliable assembly. Specify tight tolerances only where function demands them - everywhere else, use realistic, process-based tolerances that match what precision sheet metal forming can actually deliver.

For sheet metal finishing operations, remember that coatings add thickness. Powder coating typically adds 0.002" to 0.003" per surface. If you're designing interference fits or tight clearances, account for this additional material in your tolerance calculations.

With your designs optimized for manufacturability, the next question becomes: how do you verify that finished parts meet your specifications? Quality control processes and industry certifications provide the answer.

Quality Control and Industry Certifications

You've designed a manufacturable part and selected the right material - but how do you know the finished components actually meet your specifications? Quality control separates reliable sheet metal fabrication manufacturers from those who deliver inconsistent results. Understanding how manufacturers verify part accuracy helps you evaluate partners and set appropriate expectations for your projects.

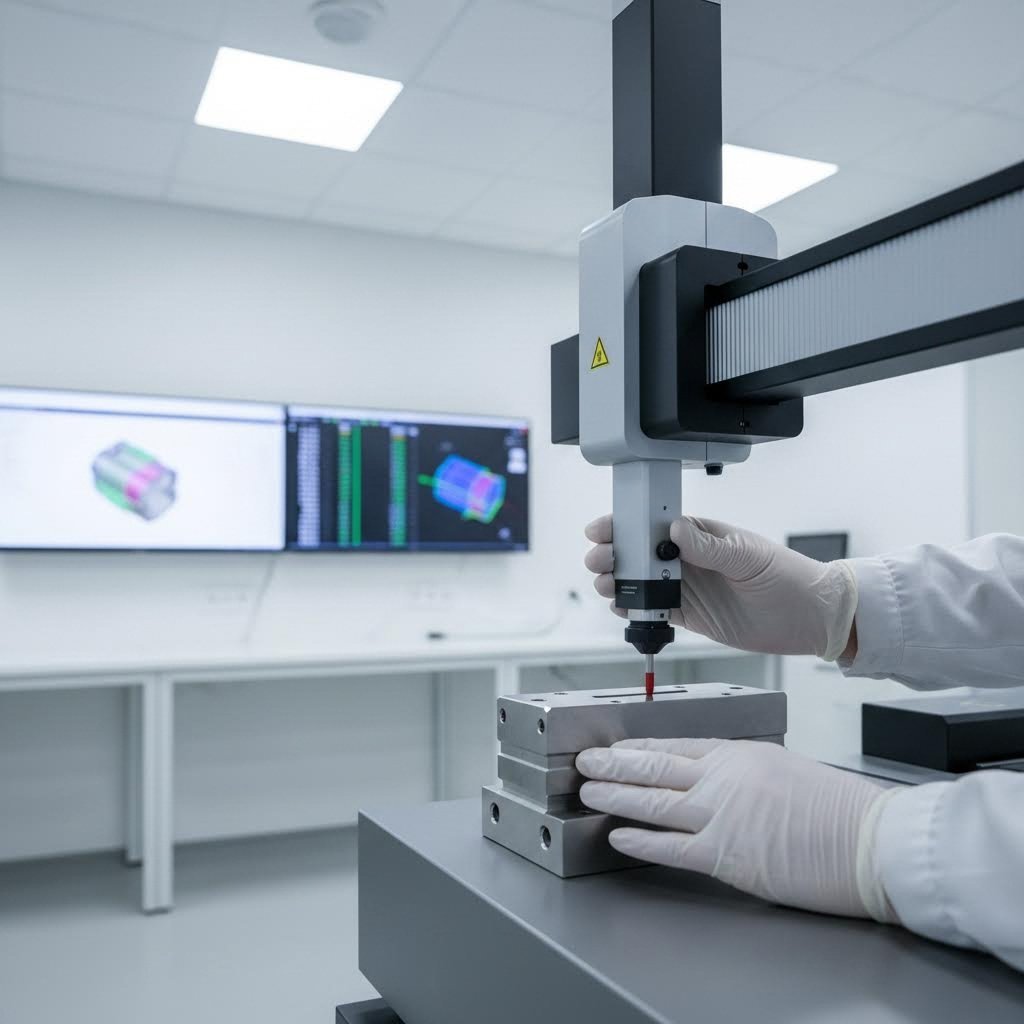

Quality control isn't simply a final inspection before shipping. According to experts at HiTech Digital, it's a methodical process of checks for dimensional accuracy, material integrity, and product craftsmanship spanning from design to delivery. This systematic approach ensures products meet or exceed set standards throughout the entire fabrication process.

Inspection Methods That Ensure Part Accuracy

How do precision metal fabricators verify that metal fabrication parts conform to your drawings? Multiple inspection methods work together at different stages of production. Here's what happens behind the scenes:

- First Article Inspection (FAI): Before full production begins, manufacturers produce and thoroughly measure initial samples against all drawing specifications. This catches design or setup issues before they multiply across hundreds of parts.

- In-Process Inspection: Operators check critical dimensions during production runs, catching drift or variation before defective parts accumulate. Statistical process control charts track trends over time.

- Dimensional Verification: Coordinate measuring machines (CMMs), optical comparators, and calibrated gauges confirm that hole positions, bend angles, and linear dimensions fall within tolerance.

- Surface Finish Verification: Profilometers measure surface roughness while visual inspections check for scratches, dents, and coating defects that affect appearance or function.

- Material Certification: Mill test reports verify that raw materials meet specified alloy compositions, tempers, and mechanical properties before fabrication begins.

- Final Inspection: Completed parts undergo comprehensive checks against all drawing requirements before packaging and shipment.

For stainless steel fabrication or metal fabrication stainless steel projects demanding high accuracy, ask manufacturers about their inspection equipment and procedures. Accurate metal fabricating requires both the right tools and trained personnel who know how to use them effectively.

Understanding Industry Certifications

Certifications provide third-party validation that a manufacturer maintains consistent quality systems. But what do these acronyms actually mean for your project?

ISO 9001 establishes the foundation for quality management systems across all industries. According to Qualityze, ISO 9001 certified organizations demonstrate their ability to deliver high-quality products and services consistently while meeting customer and applicable regulatory requirements. This certification confirms that a manufacturer has documented procedures, trained personnel, and continuous improvement processes in place.

IATF 16949 builds upon ISO 9001 with additional requirements specific to the automotive industry. This certification, specified by The International Automotive Task Force, addresses defect prevention, variation reduction, and waste elimination in the automotive supply chain. If you're sourcing components for OEM metal fabrication in the automotive sector, IATF 16949 certification indicates a manufacturer understands the rigorous demands of that industry.

ITAR (International Traffic in Arms Regulations) governs manufacturers producing defense-related articles. ITAR registration confirms that a company can handle controlled technical data and maintain the security protocols required for defense contracts.

Other relevant certifications include AS9100 for aerospace, ISO 13485 for medical devices, and NADCAP for special processes like welding and heat treatment. Match the certifications to your industry requirements when evaluating potential partners.

Quality Documentation and Traceability

Beyond certifications, examine what documentation manufacturers provide with delivered parts. For industrial fabrication projects, traceability matters when problems surface months or years later.

Comprehensive quality documentation typically includes:

- Inspection reports: Dimensional data confirming parts meet drawing specifications

- Material certifications: Mill test reports tracing raw materials to their source

- Process records: Documentation of heat treatment, welding parameters, or special processes

- Certificates of conformance: Formal statements that parts meet all specified requirements

This documentation creates an audit trail connecting finished parts back to specific material lots, operators, and equipment. When quality issues arise, traceability enables root cause analysis and targeted corrective actions rather than broad recalls or rework.

A strong quality control framework, validated by relevant certifications and supported by thorough documentation, protects both you and your manufacturing partner. With quality systems understood, the next consideration is how requirements vary across different industries and applications.

Industry Applications and Sector Requirements

Ever wonder why the same sheet metal part costs dramatically different amounts depending on whether it goes into a car or a medical device? Industry-specific requirements explain the variation. Each sector brings unique demands for materials, tolerances, certifications, and documentation that directly impact how manufacturers approach your project.

When searching for sheet metal fabricators near me or evaluating metal fabrication companies near me, understanding these sector-specific requirements helps you identify partners with relevant experience. A manufacturer excelling in industrial equipment may lack the certifications or quality systems needed for aerospace work. Let's explore what each major industry demands.

Automotive Component Requirements

The automotive industry pushes sheet metal fabrication manufacturers toward high-volume efficiency without sacrificing quality. Components range from structural brackets and body panels to electronic enclosures and exhaust shields - each with distinct performance requirements.

Material selection in automotive applications balances weight reduction against crash performance. Aluminum sheet metal fabrication dominates where weight savings matter most, while high-strength steel handles structural and safety-critical components. According to Neway Precision, aluminum grades like 6061 offer high dimensional stability in CNC-fabricated parts, making them ideal for enclosures requiring structural rigidity.

Tolerance expectations in automotive work typically fall between ±0.1mm and ±0.3mm depending on the component function. Visible exterior parts demand tighter controls than hidden structural brackets. However, the real differentiator is consistency - automotive OEMs expect identical quality across thousands or millions of parts.

Certification requirements center on IATF 16949, the automotive-specific quality management standard. This certification demonstrates that manufacturers understand production part approval processes (PPAP), statistical process control, and the documentation requirements that automotive supply chains demand.

Aerospace Component Specifications

Aerospace applications represent the most demanding environment for the sheet metal manufacturing industry. Every gram matters, every tolerance is critical, and failure is simply not an option when components fly at 35,000 feet.

According to aerospace fabrication specialists at Neway Precision, precision sheet metal fabrication supports the structural and electronic integrity of aircraft, satellites, and UAV systems. From lightweight brackets to mission-critical enclosures, parts must meet exacting standards in flatness, form accuracy, and surface finish.

Material requirements favor aluminum alloys like 6061 and specialized grades such as AlSi10Mg for their excellent strength-to-weight ratios. Stainless steel sheet metal fabrication enters the picture when superior mechanical strength or fire resistance is required - particularly for structural mounts and pressurized compartment interfaces.

Tolerance expectations tighten considerably, with many aerospace enclosure components requiring geometric tolerances within ±0.05mm or better. CMM inspection is standard for flight-critical enclosures, ensuring each component meets design intent before assembly. Certifications include AS9100 for quality management and NADCAP for special processes like welding and heat treatment.

Medical Device Manufacturing Standards

Medical device fabrication operates under strict regulatory oversight from agencies like the FDA. According to the FDA's guidance on materials in medical devices, manufacturers must submit biocompatibility evaluations demonstrating that materials can be safely used in or on the human body.

Material selection focuses heavily on biocompatibility and corrosion resistance. Stainless steel grades 304 and 316 dominate surgical instruments and implant housings, while titanium serves applications requiring both strength and biological inertness. The FDA specifically evaluates how materials may behave in the body, including potential for wear and corrosion through different mechanisms depending on the intended environment.

What makes medical device fabrication unique? Documentation requirements exceed most other industries. Manufacturers must maintain complete traceability from raw material lots through finished devices. ISO 13485 certification validates quality management systems specific to medical devices, while FDA registration may be required for certain device classifications.

Tolerance expectations vary based on device classification and patient contact. Implantable devices demand the tightest controls, while external housings allow more flexibility. Surface finish requirements often specify electropolishing or passivation to enhance corrosion performance and cleanability.

Electronics Enclosure Specifications

Electronics enclosures protect sensitive components from environmental hazards while managing electromagnetic interference (EMI). These requirements create unique challenges for aluminum fabricators and stainless steel specialists alike.

Material selection depends on shielding requirements and weight constraints. Aluminum provides excellent EMI shielding with low weight for portable devices, while steel offers better magnetic shielding for industrial applications. Bronze sheet metal occasionally appears in specialty RF shielding applications where its conductivity properties offer advantages.

Design considerations include ventilation patterns, cable routing, and access panel integration. According to aerospace fabrication experts, enclosures are often optimized for cable routing, ventilation, and modular access panels, supporting system upgrades without complete disassembly. These same principles apply to commercial and industrial electronics enclosures.

Tolerance requirements focus on consistent mating surfaces for EMI gaskets and proper alignment of internal mounting features. While linear tolerances may be moderate (±0.25mm), flatness requirements for sealing surfaces often specify ±0.1mm or tighter to ensure proper gasket compression.

Industrial Equipment Sector Demands

Industrial fabrication services support equipment ranging from agricultural machinery to factory automation systems. This sector values durability and cost-effectiveness over extreme precision, though requirements vary widely based on application.

Material selection emphasizes corrosion resistance appropriate to the operating environment. Cold rolled steel with powder coating suits indoor applications, while stainless steel or hot-dip galvanized components handle outdoor or washdown environments. Material thickness tends toward heavier gauges for structural integrity and vibration resistance.

Tolerance expectations are typically the most relaxed among these industries, with ±0.5mm acceptable for many applications. However, mounting interfaces and mating surfaces still require reasonable accuracy to ensure proper assembly. Certification requirements vary - ISO 9001 provides a baseline, while specific industry standards may apply for food processing, pharmaceutical, or hazardous environment equipment.

Industry Requirements Comparison

The following table summarizes key differences across sectors to help you match your project requirements with appropriately qualified manufacturers:

| Industry | Typical Materials | Tolerance Range | Common Certifications | Lead Time Expectations |

|---|---|---|---|---|

| Automotive | Aluminum, High-strength steel | ±0.1mm to ±0.3mm | IATF 16949, ISO 9001 | 8-12 weeks for production tooling |

| Aerospace | Aluminum 6061, Stainless steel, Titanium | ±0.05mm or better | AS9100, NADCAP, ITAR | 12-20 weeks including certification |

| Medical Devices | 316 Stainless, Titanium | ±0.05mm to ±0.15mm | ISO 13485, FDA registration | 10-16 weeks with validation |

| Electronics | Aluminum, Cold rolled steel | ±0.1mm to ±0.25mm | ISO 9001, UL certification | 4-8 weeks standard |

| Industrial Equipment | Carbon steel, Stainless steel | ±0.25mm to ±0.5mm | ISO 9001 | 3-6 weeks standard |

When evaluating potential manufacturing partners, match their certifications and experience to your specific sector. A fabricator with deep automotive experience may struggle with aerospace documentation requirements, while an aerospace specialist might be overqualified - and overpriced - for general industrial work.

Understanding these sector-specific requirements positions you to have informed conversations about what your project truly needs. The next critical factor? Understanding what drives costs and lead times so you can budget and plan effectively.

Understanding Costs and Lead Times

Why does the same part cost $5 from one manufacturer and $15 from another? Understanding the economics behind sheet metal production separates informed buyers from those who chase the lowest quote and end up paying more in the long run. Let's break down what actually drives your fabrication costs - and how you can control them.

When evaluating quotes from sheet metal fabrication manufacturers, you're not just comparing prices. You're comparing different approaches to your project, varying quality levels, and distinct capabilities. The cheapest option rarely delivers the best value when you factor in rework, delays, and quality issues.

Key Cost Drivers in Fabrication Projects

Several factors combine to determine your final per-part price. Understanding each one helps you make design and sourcing decisions that optimize your budget without sacrificing quality.

Material Selection often represents the largest cost component. According to Komacut's cost guide, aluminum commands higher prices than mild steel despite offering weight advantages, while stainless steel costs significantly more than both. Beyond base material prices, thickness impacts cost directly - heavier gauges mean more metal materials per part and longer processing times.

Design Complexity drives labor and machine time. Parts with numerous bends, tight tolerances, or intricate cut patterns require more programming, setup adjustments, and operator attention. A simple bracket with two bends costs far less than a complex enclosure with twenty features requiring multiple setups and operations.

Tolerance Requirements affect both processing approach and inspection effort. Requesting ±0.05mm tolerances when ±0.25mm would suffice forces manufacturers toward slower, more precise processes and comprehensive inspection protocols. Every decimal point of precision adds cost.

Finishing Requirements add significant expense beyond base fabrication. Powder coating, anodizing, plating, and specialty finishes each carry setup charges and per-part costs. According to Protolabs, silkscreening and engraving should be delayed until later development stages if appearance isn't critical for prototyping.

Volume Considerations and Price Breaks

Here's where quantity dramatically changes the economics. Every metal fabrication shop invests significant time in setup before cutting the first part - programming CNC equipment, configuring tooling, and verifying first articles. These fixed costs spread across your order quantity.

According to fabrication specialists at Baillie Fabricators, a project's price per part will almost always decrease as quantity increases. One-off parts can be particularly expensive due to setup fees and layout costs. Even modest increases in order quantity can help reduce per-part costs significantly.

Consider this pricing reality for custom metal projects:

- Prototype quantities (1-10 pieces): Highest per-part cost due to setup amortization, but lowest total investment for design validation

- Low-volume production (10-100 pieces): Setup costs spread more efficiently, often 30-50% lower per-part than prototypes

- Medium-volume runs (100-1000 pieces): Significant price breaks as manufacturers optimize processes and material purchasing

- High-volume production (1000+ pieces): Lowest per-part costs through dedicated tooling, optimized nesting, and bulk material purchasing

When you need parts over time, consider ordering larger quantities upfront rather than multiple small orders. Metal fab services often offer blanket orders or scheduled releases that capture volume pricing while managing your inventory and cash flow.

Balancing Speed, Quality, and Budget

Lead times vary dramatically based on project complexity, current shop loading, and your flexibility. Standard sheet metal shops typically quote 3-6 weeks for custom metal shapes in moderate quantities. Expedited service is available but commands premium pricing - sometimes 50-100% above standard rates.

What affects your timeline? Material availability plays a significant role. Common aluminum and steel grades ship quickly, while specialty alloys may require weeks of lead time before fabrication begins. Complex assemblies with multiple operations naturally take longer than simple cut-and-bend parts.

Here are proven strategies to reduce your overall sheet metal fabrication costs without compromising quality:

- Standardize bend radii across your design to minimize tooling changes and setup time

- Use shop-specific K-factors rather than generic values to avoid costly redrafting - many manufacturers provide these charts upon request

- Handle finishing operations in-house when you have the capability - deburring, painting, and polishing can be done internally to reduce outsourcing costs

- Specify standard hole sizes that match common punch tooling rather than custom diameters

- Use self-adjusting fasteners like spring nuts or captive fasteners that accommodate slight variations, reducing the need for tight tolerances

- Consolidate orders to capture volume pricing rather than placing multiple small orders over time

- Request DFM review early to catch expensive design issues before tooling and programming begin

When seeking steel fabrication shops near me or evaluating quotes from distant suppliers, factor in shipping costs and communication overhead. A slightly higher quote from a local partner may deliver better total value through reduced freight, easier communication, and faster problem resolution.

Understanding these cost dynamics positions you to negotiate effectively and make informed trade-offs between price, quality, and speed. With economics understood, the next step is developing a systematic approach to evaluating and selecting the right manufacturing partner for your specific needs.

How to Evaluate and Select Fabrication Partners

You've done the homework - understanding materials, processes, quality systems, and cost drivers. Now comes the decision that matters most: choosing which manufacturer to trust with your project. This isn't a decision to rush. The right fabrication partner becomes an extension of your team, while the wrong one creates headaches that ripple through your entire production schedule.

Whether you're searching for a sheet metal fabricator near me or evaluating manufacturers across the country, a systematic evaluation approach prevents costly mistakes. According to fabrication experts at Thin Metal Parts, finding reliable fabrication companies can be daunting, but asking the right questions makes the process manageable and effective.

Essential Questions for Potential Partners

Before committing to any manufacturer, gather critical information that reveals their true capabilities. These questions separate serious contenders from those who simply tell you what you want to hear:

- Can you build a prototype before production commitment? Quality manufacturers offer prototyping services that let you assess their work before scaling up. Companies like Shaoyi demonstrate this capability with 5-day rapid prototyping turnaround.

- What is your typical quote turnaround time? According to industry guidance, delays in quoting can bottleneck your workflow before the project even starts. Leading manufacturers offer rapid response - some as fast as 12-hour quote turnaround.

- What materials can you process, and at what thicknesses? Confirm they handle your specific material requirements, including any specialty alloys or unusual gauges your project demands.

- What certifications do you hold? Match their certifications to your industry requirements. IATF 16949 matters for automotive, AS9100 for aerospace, ISO 13485 for medical devices.

- Can you provide samples or references from similar projects? Past work indicates future performance. Request examples relevant to your industry and complexity level.

- What is your production capacity and current lead time? Understanding their workload prevents surprises when your project competes for machine time with existing commitments.

- Do you offer in-house engineering and DFM support? According to Seconn Fabrication, partners offering design assistance can optimize your parts for efficient manufacturing, reducing costs and improving quality.

- Who will be my primary point of contact? Clear communication channels streamline the entire production process and prevent information gaps.

Evaluating Technical Capabilities

Questions reveal intentions - capabilities determine outcomes. When evaluating precision sheet metal fabrication near me or distant suppliers, dig into the specifics of their equipment and expertise.

Equipment matters. Ask about their cutting technologies (laser, plasma, waterjet), bending equipment (CNC press brakes, roll forming), and welding capabilities (TIG, MIG, robotic). A manufacturer limited to plasma cutting cannot deliver the edge quality needed for precision enclosures, regardless of their promises.

Precision capability varies. According to fabrication specialists, when working with thin and small parts, differences of microns make a huge quality difference. Ask specifically about achievable tolerances and repeatability across production runs.

Capacity alignment matters. A shop equipped for low-volume prototypes may struggle with 10,000-piece production runs. Conversely, a high-volume operation might not give your 50-piece order the attention it deserves. Match their sweet spot to your needs.

Use this evaluation framework when comparing potential partners:

| Evaluation Criteria | What to Look For | Why It Matters |

|---|---|---|

| DFM Support & Prototyping | Comprehensive design review, rapid prototyping (5-day or faster), engineering consultation | Catches costly design issues early, validates parts before production investment |

| Quote Responsiveness | 12-24 hour turnaround, clear pricing breakdown, proactive communication | Indicates operational efficiency and customer focus |

| Quality Certifications | IATF 16949, AS9100, ISO 13485 relevant to your industry | Third-party validation of quality systems and industry expertise |

| Equipment Capability | Modern CNC equipment, multiple cutting technologies, automated processes | Determines achievable precision, material range, and production efficiency |

| Production Capacity | Volume flexibility, scalability, on-time delivery track record | Ensures partner can grow with your needs without sacrificing quality |

| Communication Practices | Dedicated project contact, proactive updates, responsive problem-solving | Prevents miscommunication and enables rapid issue resolution |

For automotive-focused projects requiring high-volume production with certified quality systems, manufacturers like Shaoyi demonstrate the combination of IATF 16949 certification, rapid prototyping capability, and mass production capacity that demanding applications require.

Red Flags When Vetting Manufacturers

Knowing what to avoid matters as much as knowing what to seek. Watch for these warning signs during your evaluation of metal sheet fabrication near me or any potential partner:

Vague answers about capabilities or capacity. If a manufacturer cannot clearly explain their tolerances, equipment, or production timeline, they likely cannot deliver consistently. Competent fabricators know their capabilities precisely.

No references or reluctance to share samples. According to industry experts, samples are crucial in selecting the right fabricator. Resistance to providing examples suggests quality issues they'd rather hide.

Missing certifications for your industry. A manufacturer claiming automotive expertise without IATF 16949 certification raises immediate questions. Certifications require investment and commitment - their absence signals potential quality gaps.

Unrealistic pricing or timelines. Quotes significantly below competitors often indicate corners being cut somewhere - whether in material quality, inspection processes, or finishing operations. The same applies to impossibly fast lead times.

Poor communication during the quoting process. How a manufacturer handles the pre-order phase predicts how they'll perform during production. Slow responses, missed details, or difficulty reaching decision-makers foreshadow future frustration.

Inconsistent quality across samples. According to fabrication specialists, you won't want products that differ in quality, so inquire about repeatability on the production line. If samples show variation, production runs will show more.

No documentation or traceability systems. For regulated industries, lack of material certifications, inspection records, or process documentation creates compliance risks that extend far beyond fabrication costs.

The cheapest quote rarely delivers the best value. Evaluate total cost of ownership including quality consistency, communication efficiency, and problem resolution - not just per-part pricing.

Taking time to thoroughly evaluate potential partners prevents expensive surprises later. Document your findings, compare options systematically, and trust your assessment of both technical capability and working relationship potential. The right partner makes complex projects manageable, while the wrong choice turns simple parts into ongoing headaches.

With a framework for evaluating manufacturers in hand, the final step is translating all this knowledge into action - moving your fabrication project from planning to production with confidence.

Taking Action on Your Fabrication Project

You've absorbed a lot of information - materials, processes, quality systems, cost drivers, and evaluation criteria. Now what? Knowledge without action is just trivia. Whether you're launching your first fabrication project or optimizing an existing supply chain, the next steps depend entirely on where you stand today. Let's translate everything you've learned into concrete actions that move your project forward.

Your Next Steps Based on Project Stage

Different stages demand different priorities. Here's how to apply what you've learned based on your current situation:

If you're in the concept phase: Focus on Design for Manufacturability before investing in detailed drawings. According to EABEL's design guidance, applying DFM principles early is essential for accurate, repeatable results. Engage potential fabrication partners now - not after your design is locked. Early collaboration with custom metal fabricators catches expensive issues before they multiply into production problems.

If you have completed designs: Request DFM reviews from multiple manufacturers before committing. Quality partners offering sheet metal design services will identify optimization opportunities you might have missed. Order sheet metal prototyping samples to validate fit, finish, and function before scaling to production quantities.

If you're sourcing for production: Evaluate manufacturers systematically using the criteria framework from the previous section. Don't chase the lowest quote - assess total value including quality consistency, communication practices, and long-term partnership potential. For automotive or precision metal projects, manufacturers like Shaoyi offer comprehensive DFM support alongside mass production capabilities worth exploring.

Avoiding Common Project Pitfalls

Even experienced procurement professionals stumble into predictable traps. According to ReNEW Manufacturing Solutions, engaging your partner as early as possible in the process is vital - precision fabricators will offer recommendations early to ensure your vision is achievable with fewer obstacles. Here are the mistakes that derail projects:

- Finalizing designs without manufacturer input: Your CAD model might look perfect but violate basic forming rules. Get feedback before committing to tooling.

- Selecting partners based solely on price: The cheapest quote often hides quality compromises, communication gaps, or capability limitations that cost far more than the initial savings.

- Underestimating lead times: Material procurement, tooling setup, and first article approval take time. Build realistic buffers into your schedule for custom metal parts.

- Neglecting documentation requirements: For regulated industries, incomplete traceability or missing certifications create compliance nightmares that extend far beyond fabrication costs.

- Poor communication cadence: According to Maker's Row, once you establish the best communication method, work out a regular cadence for scheduled updates, news, or milestones to keep projects on track.

Building Long-Term Manufacturing Partnerships

The most successful companies treat fabrication partners as extensions of their teams rather than interchangeable vendors. According to relationship management experts at Maker's Row, discussing your long-term plans with your manufacturer can lead to strategic benefits - suppliers invested in your success may offer better pricing, innovative solutions, and priority service.

Strong manufacturer relationships enhance product quality, improve lead times, and create cost efficiencies that transactional purchasing simply cannot match.

What does partnership look like in practice? Share your roadmap so manufacturers can plan capacity. Provide feedback on both successes and problems. Pay on time and communicate proactively when challenges arise. These practices build trust that pays dividends when you need expedited service or creative problem-solving on complex sheet metal components.

For custom metal work requiring consistent quality across high volumes, invest the time to find partners whose capabilities align with your needs. The evaluation process may feel slow, but the right partnership accelerates every project that follows.

- Action item: Identify 3-5 potential manufacturers matching your industry and volume requirements

- Action item: Request DFM review on your current designs before finalizing

- Action item: Establish clear communication protocols and update schedules with your selected partner

- Action item: Document lessons learned from each project to continuously improve your process

Your fabrication projects succeed or fail based on decisions made before production ever begins. Use the knowledge you've gained here to ask better questions, evaluate partners systematically, and build relationships that deliver value for years to come. The right manufacturer doesn't just make custom metal products - they become a strategic asset that strengthens your entire operation.

Frequently Asked Questions About Sheet Metal Fabrication

1. How much does sheet metal fabrication cost?

Sheet metal fabrication costs range from $4 to $48 per square foot, with an average project costing around $1,581. Key cost drivers include material selection (aluminum costs more than mild steel, stainless steel is most expensive), design complexity, tolerance requirements, finishing operations, and order volume. Per-part costs decrease significantly as quantities increase due to setup cost amortization across more units. Prototypes carry the highest per-part costs, while production runs of 1,000+ pieces achieve the lowest pricing through optimized processes and bulk material purchasing.

2. What materials are commonly used in sheet metal fabrication?

The most common sheet metal fabrication materials include aluminum (5052 and 6061 grades for lightweight corrosion-resistant applications), cold rolled steel (economical option for indoor structural components), stainless steel 304 and 316 (excellent corrosion resistance for food, medical, and marine applications), copper (electrical components and decorative elements), and bronze (marine hardware and bearings). Material selection depends on your application requirements including strength, weight, corrosion resistance, and budget constraints.

3. What certifications should I look for in a sheet metal fabrication manufacturer?

Essential certifications vary by industry. ISO 9001 provides baseline quality management validation for all industries. IATF 16949 is required for automotive supply chain partners and demonstrates defect prevention and variation reduction capabilities. AS9100 certifies aerospace manufacturers, while ISO 13485 validates medical device fabrication quality systems. ITAR registration is necessary for defense-related manufacturing. NADCAP certification covers special processes like welding and heat treatment. Manufacturers like Shaoyi hold IATF 16949 certification, making them qualified for demanding automotive applications.

4. What is the difference between laser cutting, plasma cutting, and waterjet cutting?

Laser cutting uses focused light beams for superior precision on thin materials (under 25mm), producing clean edges ideal for electronics and medical devices. Plasma cutting employs electrical arcs for fast, cost-effective cutting of thick conductive metals (1 inch and above), though with less precision and a heat-affected zone. Waterjet cutting uses high-pressure water with abrasives to cut any material without heat, eliminating warping and material property changes—perfect for aerospace components and heat-sensitive materials, though slower and more expensive to operate.

5. How long does sheet metal fabrication typically take?

Standard lead times range from 3-6 weeks for custom sheet metal parts in moderate quantities. Timelines vary by industry: automotive production tooling takes 8-12 weeks, aerospace projects require 12-20 weeks including certification, medical devices need 10-16 weeks with validation, electronics enclosures take 4-8 weeks, and industrial equipment runs 3-6 weeks. Factors affecting timeline include material availability (specialty alloys may add weeks), design complexity, current shop loading, and finishing requirements. Some manufacturers offer rapid prototyping—Shaoyi delivers 5-day prototype turnaround for urgent projects.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —