Custom Steel Sheet Specs Decoded: Stop Ordering The Wrong Material

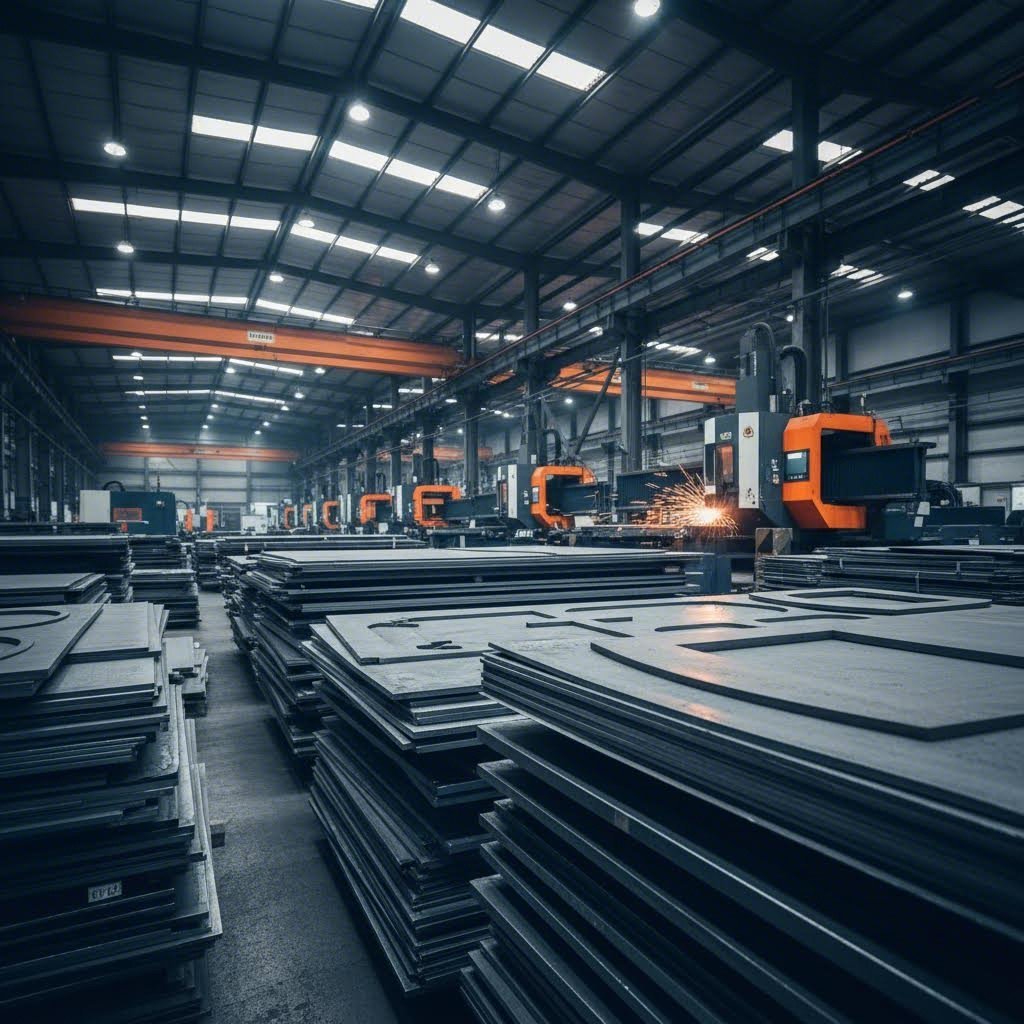

Understanding Custom Steel Sheet and Why Specifications Matter

Ever ordered steel sheet only to discover it doesn't quite fit your application? You're not alone. The difference between a successful fabrication project and a costly mistake often comes down to one critical factor: understanding what makes a custom steel sheet truly custom.

A custom steel sheet is material manufactured or processed to meet your exact specifications rather than pulled from standard inventory. Unlike off-the-shelf options that come in predetermined sizes—typically 4 feet by 8 feet with standard gauge thicknesses—custom orders allow you to specify precise dimensions, exact thickness tolerances, and specific material grades tailored to your project requirements.

What Makes Steel Sheet Custom

When you work with stainless steel sheet metal or carbon steel for sheet metal fabrication, the term "custom" encompasses several key variables:

- Exact dimensions: Length and width cut to your specifications, eliminating waste and secondary processing

- Precise thickness: Material ordered to decimal thickness rather than standard gauge increments

- Specific material grade: Choosing between carbon steel grades like A36 or A572, or selecting stainless sheet options like 304 or 316 based on application needs

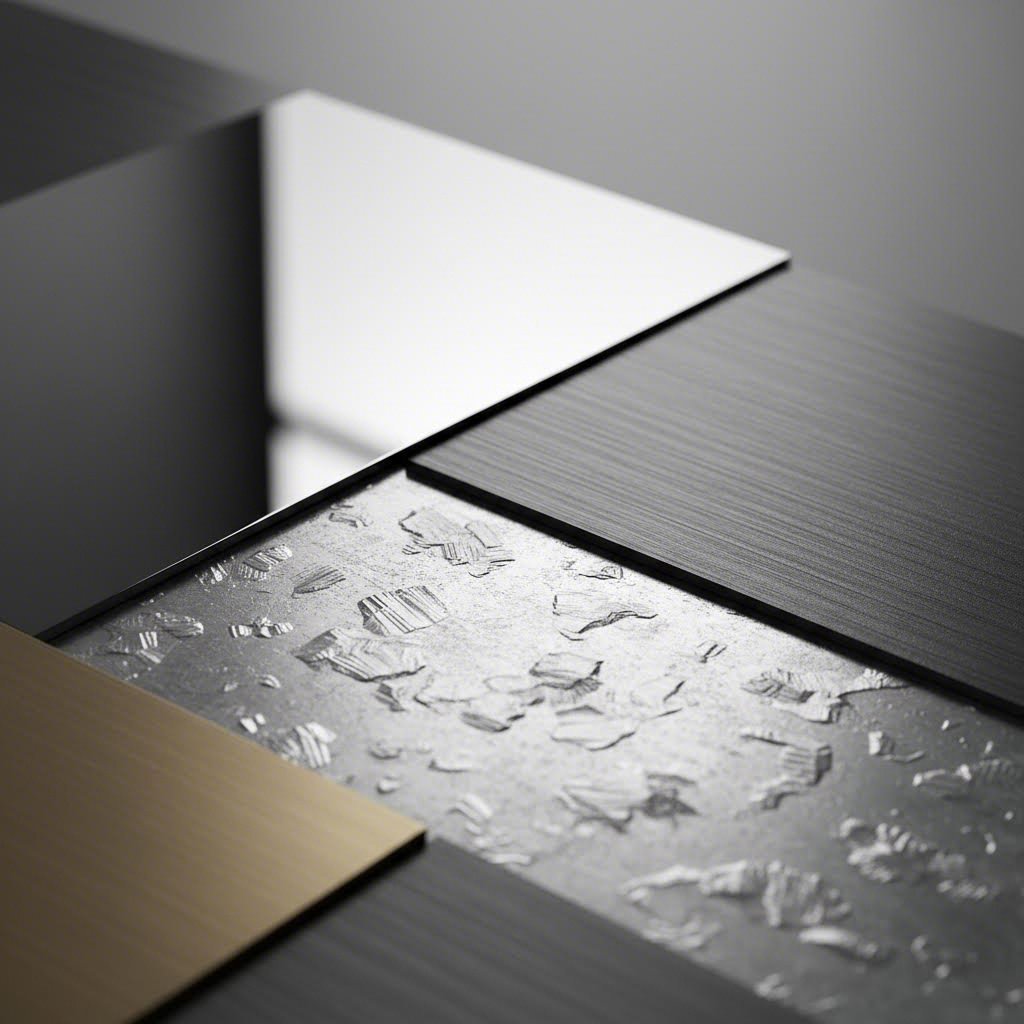

- Surface finish requirements: Hot-rolled, cold-rolled, pickled and oiled, or galvanized finishes matched to your end use

- Edge conditions: Mill edge, sheared edge, or specialty edge preparations

For engineers, fabricators, and procurement professionals, understanding these distinctions isn't optional—it's essential for avoiding rework, reducing scrap, and meeting project timelines.

Standard vs Custom Steel Sheet Specifications

Standard steel sheet comes in pre-defined sizes and thicknesses, making it readily available and generally more affordable for basic applications. According to industry specifications, a typical ss steel sheet might measure 48" x 96" or 48" x 120" in common gauges ranging from 10 gauge (0.1345") to 24 gauge (0.0239"). These standardized options work well for general construction, basic enclosures, or applications where precise fit isn't critical.

Custom steel sheet, however, addresses projects demanding precision. Think automotive components requiring tight tolerances, architectural elements with specific aesthetic requirements, or industrial equipment where every millimeter matters. The fabrication process for custom material involves careful material selection, advanced cutting techniques, and finishing options that standard inventory simply cannot accommodate.

The right custom steel sheet specification eliminates downstream problems—when you get the material grade, thickness, and dimensions correct from the start, you avoid costly rework, reduce scrap rates, and keep production schedules on track.

This guide walks you through everything you need to know about ordering custom steel sheet correctly. You'll learn how to select the right steel grade for your application, decode the gauge system, understand the differences between hot-rolled and cold-rolled material, evaluate cutting methods, and specify your order to get exactly what your project demands. Whether you're sourcing stainless steel sheet for corrosion-resistant applications or carbon steel for structural components, the knowledge ahead will help you stop ordering the wrong material—permanently.

Steel Grades and Material Selection for Custom Projects

Ever wondered why two steel sheets that look identical perform completely differently in the same application? The answer lies in the steel grade—a classification system that determines everything from strength and weldability to corrosion resistance and cost. Understanding these grades transforms you from someone who orders material into someone who specifies exactly the right material for the job.

Steel grades are classified based on chemical composition, mechanical properties, and intended use. Organizations like the American Society for Testing and Materials (ASTM) and the American Iron and Steel Institute (AISI) establish these standards, ensuring consistency across suppliers and applications. When ordering a custom steel sheet, you'll encounter two primary categories: ferrous metals like carbon steel and stainless steel, each with distinct grades suited for specific purposes.

Carbon Steel Grades Explained

Carbon steel remains the workhorse of fabrication and construction due to its excellent strength-to-cost ratio. The carbon content determines hardness and strength, while additional alloying elements fine-tune performance characteristics. Here are the three most common grades you'll encounter when ordering custom sheet:

ASTM A36 Steel: This low-carbon structural steel is the go-to choice for general fabrication, construction, and machinery. With a minimum yield strength of 36,000 psi and excellent weldability, A36 handles most structural applications where corrosion isn't a primary concern. You'll find it in building frames, brackets, and general-purpose components. Its affordability and availability make it the default choice when you don't need specialized properties.

ASTM A572 Steel: When you need higher strength without sacrificing weldability, A572 high-strength low-alloy (HSLA) steel delivers. Available in multiple grades (42, 50, 55, 60, 65), with Grade 50 being most common, this material offers approximately 40% more yield strength than A36. It's preferred for bridges, construction equipment, and structural applications where weight reduction matters. The improved strength-to-weight ratio means you can often use thinner material, reducing overall project weight and cost.

AISI 1018 Steel: This low-carbon steel excels in precision applications requiring machining and forming. With its uniform microstructure and predictable behavior during fabrication, 1018 is ideal for parts needing secondary operations—shafts, pins, and components that will undergo additional machining. Its excellent weldability and case-hardening capability make it versatile for custom projects demanding tight tolerances.

When to Choose Stainless Over Carbon Steel

The decision between carbon steel and stainless steel plate often comes down to one question: what environment will this material face? Stainless steel's chromium content (at least 10.5%) creates a self-repairing oxide layer that prevents rust—making it essential for applications involving moisture, chemicals, or food contact.

When comparing 304 vs 316 stainless steel, the differences matter significantly for custom projects:

304 Stainless Steel: Often called "18-8" stainless (18% chromium, 8% nickel), this grade handles most indoor and mildly corrosive environments with ease. It's the workhorse of the stainless family—excellent corrosion resistance, easy formability, and strong weldability at a reasonable cost. Kitchen equipment, architectural trim, and food-processing surfaces commonly use 304. When you're sourcing material: stainless steel 304 offers the best balance of performance and economy for general applications.

316 Stainless Steel (SS 316): Adding 2-3% molybdenum to the chromium-nickel base dramatically improves resistance to chlorides and acids. Stainless steel ss 316 is the marine-grade choice, excelling in saltwater exposure, chemical processing, and pharmaceutical applications. Yes, it costs 10-15% more than 304—but in harsh environments, that investment prevents premature failure and costly replacements.

Galvanized Steel: When budget constraints conflict with corrosion resistance needs, galvanized steel and zinc-coated carbon steel offer a middle ground. The zinc coating provides sacrificial protection—corroding instead of the underlying steel. It's ideal for outdoor structural applications, HVAC ductwork, and agricultural equipment where appearance is secondary to longevity. However, welding galvanized material requires proper ventilation due to zinc fume hazards.

Selecting among these types of metals isn't about finding the strongest metal for every application—it's about matching properties to requirements. A food-processing facility needs 304 or 316 stainless for its sanitary properties, while a warehouse frame performs perfectly with A36 carbon steel at a fraction of the cost.

| Grade | Tensile Strength (ksi) | Corrosion Resistance | Weldability | Best Applications |

|---|---|---|---|---|

| A36 | 58-80 | Low (requires coating) | Excellent | Structural frames, brackets, general fabrication |

| A572 Grade 50 | 65 min | Low (requires coating) | Excellent | Bridges, heavy equipment, weight-critical structures |

| 1018 | 63.8 | Low (requires coating) | Excellent | Machined parts, pins, shafts, precision components |

| 304 Stainless | 73-90 | High (most environments) | Excellent | Food equipment, architectural, hardware |

| 316 Stainless | 75-95 | Superior (chlorides/acids) | Excellent | Marine, chemical processing, pharmaceuticals |

| Galvanized | Varies by base | Moderate (zinc coating) | Good (with precautions) | Outdoor structures, HVAC, agricultural |

Matching your steel grade to project requirements involves weighing four key factors: mechanical strength needs, environmental exposure, fabrication requirements (especially welding and forming), and budget constraints. Structural applications exposed to weather might justify A572 with hot-dip galvanizing, while a decorative interior panel could use 304 stainless for its clean appearance. Food-grade applications demand 304 or 316 stainless to meet sanitation standards, and chemical exposure typically requires 316 for its superior pitting resistance.

With your steel grade selected, the next critical decision involves thickness—and that's where the gauge system enters the picture. Understanding how gauge numbers translate to actual dimensions prevents ordering material that's either too thin for structural integrity or unnecessarily heavy for your application.

Steel Sheet Gauge and Thickness Reference Guide

Sounds confusing? You're looking at a steel gauge chart and notice that 10 gauge is thicker than 16 gauge—the exact opposite of what logic suggests. Welcome to one of the most counterintuitive measurement systems in manufacturing. Understanding steel gauge thickness is essential for ordering custom steel sheet correctly, yet this 19th-century system trips up even experienced buyers.

According to Ryerson's steel gauge reference, the word "gauge" derives from the French word "jauge," meaning "result of measurement." The system originated in the British iron wire industry when no universal thickness standard existed. Craftsmen found gauge convenient, and the convention stuck—even surviving a 20th-century attempt to replace it with the International System of Units.

Reading the Gauge System Correctly

The fundamental rule is simple: the higher the gauge number, the thinner the material. A 10 gauge steel thickness measures approximately 0.1345 inches, while 16 gauge thickness comes in at just 0.0598 inches—less than half as thick. This inverse relationship catches many first-time buyers off guard.

But here's where it gets tricky. The metal gauge thickness system isn't linear, meaning the difference between gauge numbers varies. Moving from 14 gauge steel thickness (0.0747") to 13 gauge (0.0897") represents a 0.015" increase. However, moving from 14 gauge to 16 gauge steel thickness (0.0598") represents only a 0.0149" decrease. You can't assume equal steps between numbers.

Another critical point: gauge values differ by metal type. A 14-gauge stainless steel sheet has a decimal equivalent of 0.0751", while a 14-gauge carbon steel sheet measures 0.0747". These small differences matter for precision applications, which is why referencing the correct sheet metal gauge chart for your specific material is essential.

| Gauge | Thickness (inches) | Thickness (mm) | Weight (lbs/sq ft) | Common Applications |

|---|---|---|---|---|

| 10 Gauge | 0.1345 | 3.42 | 5.625 | Heavy structural, equipment frames, trailer beds |

| 11 Gauge | 0.1196 | 3.04 | 5.000 | Industrial enclosures, structural brackets, reinforcements |

| 12 Gauge | 0.1046 | 2.66 | 4.375 | Chassis components, machinery guards, heavy brackets |

| 14 Gauge | 0.0747 | 1.90 | 3.125 | Carports, light structural, electrical enclosures |

| 16 Gauge | 0.0598 | 1.52 | 2.500 | HVAC ductwork, decorative panels, light-duty covers |

Thickness Selection for Structural Applications

When does thickness actually matter for your project? The relationship between gauge, weight, and structural capacity directly impacts performance. According to industry guidelines, thicker gauge steel provides better resistance to wind loads, handles snow loads more effectively, and protects against physical impact damage. You'll also generally see longer lifespans from structures using thicker material.

Consider a practical example: a standard residential carport in a mild climate typically performs well with 14 gauge steel thickness. However, if that same structure faces regular harsh weather or needs to support heavier loads, stepping up to 11 gauge steel thickness or 12 gauge provides the additional structural capacity needed. Local building codes often dictate minimum thickness requirements, so always verify permit specifications before ordering.

When should you specify decimal thickness versus gauge? For precision orders—especially those involving tight-tolerance fabrication, CNC machining, or assemblies requiring exact fit—always specify thickness in decimal inches or millimeters. Gauge numbers introduce ambiguity because they vary slightly between manufacturers and metal types. Decimal specifications eliminate interpretation errors and ensure you receive exactly what your design requires.

Several factors should guide your thickness selection decision:

- Load requirements: Higher loads demand thicker material—consider both static weight and dynamic forces like wind or impact

- Forming operations: Thicker material requires more force to bend and may have larger minimum bend radii, affecting design feasibility

- Welding considerations: Material thickness influences welding parameters, heat input requirements, and potential for distortion

- Weight constraints: Every gauge step changes weight per square foot—critical for mobile equipment, lifting assemblies, or shipping cost optimization

- Cost implications: Thicker gauges cost more per square foot; balance structural needs against budget realities

Understanding gauge is just one piece of the specification puzzle. How that steel was produced—whether hot-rolled or cold-rolled—fundamentally affects surface quality, dimensional tolerances, and how the material behaves during fabrication. These manufacturing differences determine whether your custom sheet meets precision requirements or falls short.

Hot-Rolled vs Cold-Rolled Steel Sheet Differences

When you order custom steel sheet, the specification often includes "HR" or "CR"—abbreviations that dramatically affect what arrives at your facility. Hot-rolled and cold-rolled steel look different, behave differently during fabrication, and perform differently in final applications. Understanding these distinctions helps you avoid ordering material that won't meet your project requirements.

The fundamental difference comes down to processing temperature. According to Grob Inc., hot rolling occurs above the steel's recrystallization temperature—typically over 1,700°F—while cold rolling happens at or near room temperature after hot rolling is complete. This temperature difference during forming creates distinct properties of metals that affect everything from surface finish to structural performance.

Hot-Rolled Steel Sheet Characteristics

Imagine steel being shaped while it's still glowing from the furnace. That's hot rolling. The process starts with a billet heated until pliable, then passed through a series of rollers that compress it into the desired thickness. As the material cools naturally, slight dimensional variations occur—the steel essentially relaxes into its final shape.

This cooling process offers a significant advantage: virtually no internal stress. The gradual temperature reduction allows the steel's crystalline structure to normalize, making hot-rolled material stable and predictable for structural applications. You won't experience warping or distortion during subsequent fabrication operations.

Pros of Hot-Rolled Steel

- Lower cost: Less processing means reduced material expense—often 10-15% cheaper than cold-rolled equivalents

- Better workability: The normalized structure makes forming and shaping easier

- Minimal internal stress: Gradual cooling eliminates residual stresses that could cause warping

- Wide availability: Standard hot-rolled sheet is readily stocked in most thicknesses

Cons of Hot-Rolled Steel

- Rough surface finish: A characteristic blue-gray mill scale covers the surface, requiring removal for painting or welding

- Looser dimensional tolerances: Slight shrinkage during cooling creates minor thickness and flatness variations

- Rounded edges and corners: The high-temperature process produces less defined edges compared to cold-rolled material

Hot-rolled steel excels in structural applications where appearance is secondary to performance. Think equipment frames, brackets, trailer beds, and construction components. When your project involves hidden structural members or surfaces that will be coated, primed, or covered, hot-rolled offers the strength you need without paying for unnecessary surface refinement.

Cold-Rolled Advantages for Precision Work

Cold-rolled steel begins its life as hot-rolled material. After cooling, it passes through additional rollers at room temperature—a process requiring significantly more pressure since the metal is no longer pliable. This extra processing step transforms the material's characteristics.

The result? According to Mill Steel, cold-rolled steel can exhibit strength up to 20% greater than hot-rolled equivalents. The room-temperature compression work-hardens the material, increasing tensile strength and hardness. Surface finish improves dramatically—smooth, shiny, and free of scale—allowing the material to be used as-is in visible applications.

Pros of Cold-Rolled Steel

- Superior surface finish: Smooth, bright appearance suitable for visible surfaces without additional processing

- Tighter dimensional tolerances: No shrinkage after forming means precise, predictable dimensions

- Higher strength: Work hardening increases yield and tensile strength by up to 20%

- Better formability for precision bends: Consistent material properties produce predictable bend results

Cons of Cold-Rolled Steel

- Higher cost: Additional processing increases material expense

- Internal stress: The cold-working process introduces residual stresses that may require stress-relief before certain fabrication operations

- Limited thickness range: Cold rolling is typically practical only for thinner gauges

Cold-rolled material dominates applications requiring precision and aesthetics. Enclosures, decorative panels, appliance housings, and automotive components benefit from the tighter tolerances and finished appearance. When your custom steel sheet will be visible in the final product or must meet strict dimensional requirements, cold-rolled is typically the right choice.

Understanding how rolling method affects downstream fabrication helps you plan your project effectively. For bending operations, cold-rolled steel's consistent thickness produces more predictable bend angles—critical for parts that must fit precisely. Hot-rolled material may require test bends to account for slight thickness variations.

Welding considerations differ too. Hot-rolled steel's mill scale must be removed before welding to ensure proper fusion and prevent porosity. Cold-rolled surfaces are generally weld-ready, though both types of metal respond similarly once surface preparation is complete. Neither rolling method changes the base steel's chemistry or its melting point of steel characteristics—both maintain the same steel melting point around 2,500°F depending on the specific alloy.

For finishing operations, cold-rolled steel accepts paint, powder coating, and plating more readily due to its clean surface. Hot-rolled material requires descaling, grinding, or pickling before finishing—adding labor and cost to your fabrication process.

With your material grade, thickness, and rolling method selected, the next critical specification involves how your custom sheet will be cut. The cutting method you choose affects edge quality, tolerances, and even the material's behavior at cut edges—factors that directly impact your downstream fabrication success.

Custom Cutting Methods and Fabrication Considerations

You've selected the perfect steel grade, nailed down the right thickness, and specified hot-rolled or cold-rolled based on your application. Now comes a decision that directly affects edge quality, dimensional accuracy, and fabrication success: how to cut stainless steel or carbon steel sheets to your exact specifications. The cutting method you choose isn't just about getting pieces to size—it determines tolerances, edge conditions, and even the material's behavior during downstream operations.

Each cutting technology offers distinct advantages and limitations. Understanding these trade-offs helps you specify the right process for your custom steel sheet project and set realistic expectations for what you'll receive.

Laser Cutting Precision and Limitations

Laser cutting employs a focused beam of light—typically from a CO2 or fiber laser source—to melt, burn, or vaporize material along a programmed path. According to StarLab CNC, the highly concentrated energy creates extremely precise cuts with minimal heat-affected zones, making this technology ideal for intricate designs and thin materials.

When you need custom laser cut stainless steel for decorative panels, precision brackets, or components with complex geometries, fiber lasers deliver exceptional results. Edge quality rivals machined surfaces on thin material—smooth, square, and virtually burr-free. Tolerances as tight as ±0.005" are achievable on quality equipment, making laser cutting the go-to choice for parts requiring exact fit.

However, laser cutting has practical limitations. Performance degrades significantly as material thickness increases. While fiber lasers dominate thin material cutting at exceptional speeds, cutting rates drop dramatically on materials over 1" thick. The heat generated can also create a heat-affected zone (HAZ) along cut edges—a narrow region where the steel's microstructure changes due to rapid heating and cooling. For most applications, this HAZ is negligible, but heat-sensitive applications may require secondary processing.

The best way to cut stainless steel sheets under 1/4" thick? Laser cutting typically wins on speed, precision, and edge quality. For cutting stainless steel sheets requiring mirror-like edges or intricate patterns, no other technology matches laser's capabilities.

Waterjet Cutting: The Cold-Cutting Advantage

Waterjet cutting uses a high-pressure stream of water—often mixed with abrasive particles—to erode material along a programmed path. Operating at pressures up to 90,000 PSI, waterjet systems can cut virtually any material without generating heat, preserving the material's structural integrity completely.

This cold-cutting advantage matters significantly for specific applications. Heat-sensitive materials, hardened steels, and situations where mechanical properties must remain unchanged at cut edges all benefit from waterjet processing. There's no HAZ, no thermal distortion, and no risk of altering the material's temper or hardness.

Waterjet handles the widest thickness range among cutting technologies—from thin foils to plates 12" thick or more. It's also the most versatile for different types of metals, cutting carbon steel, stainless steel, aluminum, and even non-conductive materials like stone, glass, and composites with equal effectiveness.

The trade-off? Speed. Waterjet systems typically operate at 5-20 inches per minute depending on material thickness and type—significantly slower than plasma or laser. This reduced speed translates to higher per-part costs, especially for high-volume production runs. Edge quality is good but slightly rougher than laser, with a characteristic textured surface from the abrasive particles.

Plasma Cutting for Speed and Versatility

CNC plasma cutting uses an accelerated jet of hot plasma to cut through electrically conductive materials. The plasma arc reaches temperatures up to 45,000°F, instantly melting and blowing away material to create precise cuts. Modern CNC plasma tables combine this powerful cutting technology with computer-controlled precision.

Plasma excels in metal fabrication environments requiring speed and versatility on medium to thick materials. A high-powered plasma system can cut 1/2" mild steel at speeds exceeding 100 inches per minute—making it the fastest option for plate processing. This superior speed translates directly to lower per-part costs for structural components, brackets, and heavy fabrication work.

For stainless steel cutting on thicker gauges, plasma offers a practical balance between cost and quality. Modern high-definition plasma systems achieve near-laser quality on materials over 1/4" thick while cutting significantly faster. The technology handles carbon steel, galvanized steel, and stainless steel effectively, making it versatile for mixed-material shops.

Like laser cutting, plasma creates a heat-affected zone at cut edges. The HAZ is typically larger than laser due to higher heat input, which may affect hardened or heat-sensitive materials. Edge quality, while improved dramatically with high-definition systems, still falls slightly below laser cutting on thin materials.

CNC Shearing: Mechanical Precision for Straight Cuts

Shearing uses a mechanical blade to cut steel sheets in straight lines—think of industrial-scale scissors. The process generates no heat, produces minimal material waste, and operates at high speeds for simple cut-to-size operations.

CNC shearing excels for blanking operations where you need rectangular pieces cut from larger sheets. The entry cost is low compared to thermal cutting technologies, and operating costs are minimal—no consumable gases, abrasives, or laser optics to replace. For pre-processing tasks or short runs requiring straight cuts only, shearing offers excellent economy.

However, shearing has clear limitations. It cannot produce curved cuts, internal cutouts, or complex geometries. Edge quality varies—often showing slight distortion or rollover at cut edges. Thickness capacity is limited compared to thermal processes, and precision decreases as material thickness increases.

Choosing the Right Cutting Method for Your Steel

Selecting the optimal cutting process requires balancing multiple factors. According to Equus, the "best" way to cut steel sheet depends on the balance between cost, quality, and delivery time. Here's how the primary methods compare:

| Method | Best Steel Types | Thickness Range | Edge Quality | Tolerance | Relative Cost |

|---|---|---|---|---|---|

| Laser Cutting | Carbon steel, stainless, aluminum (thin) | Up to 1" (optimal under 1/4") | Excellent—smooth, burr-free | ±0.005" typical | Medium-High |

| Waterjet Cutting | All metals including heat-sensitive | Thin foil to 12"+ | Good—slightly textured | ±0.005" to ±0.010" | High |

| Plasma Cutting | Carbon steel, stainless, galvanized | 0.018" to 2" (optimal) | Good to Very Good (HD systems) | ±0.010" to ±0.030" | Low-Medium |

| CNC Shearing | Carbon steel, stainless (thin) | Up to 1/2" typical | Fair—possible edge rollover | ±0.010" to ±0.020" | Low |

As a general rule: plasma cutting handles thick and structural steel most economically; laser cutting excels when precision and finish are critical on thin sheets; waterjet cutting preserves material properties when you need to avoid HAZ or work with heat-sensitive materials; and shearing provides economical straight cuts for simple blanking operations.

Before placing your custom steel sheet order, ask your supplier these critical questions about cutting capabilities:

- What cutting method will be used for my material type and thickness?

- What tolerances can you guarantee for my specific geometry?

- What edge quality should I expect—will secondary finishing be required?

- How does cutting method affect lead time for my quantity?

- What is the heat-affected zone width for thermal cutting processes?

- Can you provide sample cuts for evaluation before full production?

- How do you handle material with protective film or mill scale during cutting?

Understanding these cutting considerations prepares you to specify your custom steel sheet order correctly. The next step involves translating all your requirements—grade, thickness, rolling method, and cutting specifications—into a complete order that suppliers can quote accurately and fulfill to your expectations.

How to Specify and Order Custom Steel Sheet Correctly

You've done the research—selected the right grade, determined the proper thickness, and identified your cutting method. Now comes the moment that separates successful projects from costly headaches: translating all those decisions into a specification that suppliers can quote accurately and fulfill correctly. Ordering custom cut steel sheet requires more precision than simply stating dimensions. The details you provide—or fail to provide—directly impact pricing, lead times, and whether the material that arrives actually works for your application.

According to industry ordering guidelines, accurate measurements are crucial for a successful order. But measurements are just the starting point. Let's walk through everything you need to specify correctly—and the common mistakes that derail even experienced buyers.

Specifying Dimensions Correctly

When ordering custom cut sheet metal, every dimension requires three pieces of information: the nominal measurement, the acceptable tolerance, and the measurement reference point. Simply stating "24 inches by 36 inches" leaves too much to interpretation. Is that 24.000" ±0.005" or 24" ±1/16"? The difference matters when your parts must fit precisely.

For length and width specifications, always indicate whether measurements are to the edge centerline, inside edge, or outside edge. This distinction becomes critical for parts that nest together or fit into existing assemblies. A steel sheet cut to size for an enclosure door panel requires different edge references than material for a welded frame.

Thickness specifications deserve equal attention. While you've already selected your gauge or decimal thickness, communicate whether you're ordering to nominal thickness or specifying a tolerance band. Standard mill tolerances for hot-rolled steel can vary ±0.006" to ±0.010" depending on thickness—acceptable for structural applications but potentially problematic for precision assemblies requiring consistent material gauge.

Here's what a complete dimensional specification looks like for a custom metal plate order:

- Material: A36 Hot-Rolled Steel, Pickled and Oiled

- Thickness: 0.1875" (3/16") nominal, tolerance ±0.005"

- Length: 48.000" ±0.030"

- Width: 24.000" ±0.030"

- Edge finish: Laser cut, deburred

- Quantity: 50 pieces

- Flatness: 0.125" maximum deviation over 48" length

The difference between custom cut metal that's simply "cut-to-size" and "fabricated parts" affects both pricing and expectations. Cut-to-size means the supplier cuts your material to specified dimensions—straight edges, rectangular shapes, minimal processing. Fabricated parts involve additional operations: hole patterns, notches, bends, welded assemblies, or finishing. When requesting quotes, clearly distinguish between simple blanking and complex fabrication to receive accurate pricing.

Common specification mistakes trip up even experienced procurement professionals. Avoid these pitfalls when ordering sheet metal cut to size:

- Forgetting to specify tolerance: Without explicit tolerances, suppliers apply standard mill tolerances—which may not meet your requirements. Always state acceptable variation for each dimension.

- Unclear edge finish requirements: "Clean edges" means different things to different suppliers. Specify sheared, laser-cut, deburred, ground, or as-cut based on your downstream needs.

- Incorrect grain direction for forming: Steel has a grain direction from rolling. If your parts will be bent, specify whether the bend axis should run parallel or perpendicular to the grain to prevent cracking.

- Missing surface condition requirements: Mill finish, #4 brushed, 2B, or pickled and oiled? Surface condition affects appearance, weldability, and paint adhesion.

- Omitting quantity packaging requirements: How should pieces be separated? Do you need interleaving paper to prevent scratching? Skid packaging for forklift handling?

- Failing to specify inspection criteria: What constitutes an acceptable part? Define surface defect limits, dimensional sampling plans, and certification requirements upfront.

Understanding Lead Times and Order Minimums

Lead time for custom cut steel plate varies dramatically based on material availability, cutting complexity, and supplier workload. According to Ryerson's buyer's guide, standard hot-rolled and cold-rolled materials are typically readily stocked, while specialty grades or unusual thicknesses may require mill orders with extended lead times.

Expect these general timeframes for different order types:

- Standard material, simple cuts: 3-7 business days typical; same-day shipping available from some suppliers for rush orders

- Standard material, complex fabrication: 1-3 weeks depending on operations required

- Specialty grades or non-stock thickness: 4-8 weeks when mill ordering is required

- Large quantity orders: Additional time for production scheduling regardless of complexity

Minimum order quantities (MOQs) vary by supplier and material type. Some suppliers offer true custom cut metal services with no minimums—you can order a single piece if needed. Others require minimum square footage, weight thresholds, or piece counts to justify setup costs. When comparing suppliers, factor MOQ requirements into your total cost analysis. A lower per-piece price means nothing if you're forced to purchase three times what you need.

Complexity directly affects pricing beyond material costs. Each additional operation—deburring, countersinking, beveling, forming—adds labor time and potential scrap risk. When requesting quotes, provide complete specifications including all secondary operations. Suppliers quote more accurately when they understand the full scope upfront, and you avoid costly change orders mid-production.

To receive accurate quotes quickly, provide suppliers with this essential information:

- Complete material specification (grade, thickness, surface condition)

- Dimensional requirements with tolerances

- Cutting method preference (if any) or tolerance/edge quality requirements

- Quantity needed and anticipated reorder frequency

- Required delivery date or acceptable lead time window

- Delivery location for accurate freight calculations

- Any certifications required (mill test reports, compliance documentation)

- Drawing files (DXF or DWG format) for complex geometries

Quality considerations extend beyond dimensional accuracy. When your custom steel sheet arrives, inspect for proper identification and traceability—heat numbers, material certifications, and test reports should accompany orders when specified. Check surface condition for scratches, mill scale consistency, and any handling damage. Verify dimensions on a sampling basis appropriate to your quality requirements. Document any discrepancies immediately and contact your supplier while the delivery is fresh.

For critical applications, discuss inspection criteria during quoting. Some suppliers offer in-process inspection, CMM dimensional verification, or third-party certification. Understanding what quality documentation accompanies your order—and what additional verification costs—helps you make informed sourcing decisions.

With your ordering specifications locked down, the final step is matching all these choices to your specific application. Different industries and end uses demand different combinations of grade, thickness, finish, and fabrication—understanding these requirements ensures your custom steel sheet performs exactly as intended in its final role.

Matching Custom Steel Sheet to Your Application

You've mastered grades, gauges, rolling methods, and cutting techniques—but how do these specifications translate to real-world projects? The steel sheet that performs brilliantly in an architectural façade might fail catastrophically in an automotive chassis. Application-specific knowledge bridges the gap between material science and project success, helping you specify exactly what your end use demands.

Different industries impose unique requirements on custom steel sheet beyond basic mechanical properties. Automotive applications demand certified quality systems and rigorous traceability. Architectural projects prioritize aesthetics and corrosion resistance. Industrial equipment requires durability under harsh operating conditions. Understanding these distinctions ensures your material selection matches your actual performance needs—not just theoretical specifications.

Automotive and Chassis Applications

Automotive components operate under demanding conditions: constant vibration, temperature extremes, exposure to road chemicals, and critical safety requirements. When sourcing stainless steel metal sheet or carbon steel for vehicles, your specifications must account for these harsh realities while meeting stringent industry quality standards.

For chassis, suspension, and structural components, material selection typically favors high-strength low-alloy (HSLA) steels like A572 Grade 50 or dual-phase steels that combine strength with formability. These materials provide the strength-to-weight ratios essential for fuel efficiency without compromising crash protection. Thickness ranges typically fall between 12 gauge (0.1046") for lighter brackets to 10 gauge (0.1345") or thicker for primary structural members.

Recommended specifications for automotive applications include:

- Grade: A572 Grade 50, DP590, or HSLA as specified by engineering requirements

- Thickness range: 10-16 gauge depending on component function and load requirements

- Surface condition: Cold-rolled preferred for tight tolerances; hot-rolled acceptable for non-visible structural members

- Finish: Electrogalvanized or hot-dip galvanized for corrosion protection; e-coat ready surfaces for painting

- Tolerances: Tight dimensional control (±0.005" typical) for components requiring precise fit

Working with manufacturers who hold IATF 16949:2016 certification is essential for automotive steel sheet projects. This internationally recognized quality management standard emphasizes defect prevention, continuous improvement, and waste reduction throughout the supply chain. IATF 16949-certified suppliers understand the documentation, traceability, and process controls that automotive OEMs and Tier 1 suppliers require.

For complex automotive stamping projects, rapid prototyping capabilities accelerate development cycles significantly. When you can move from design concept to physical prototype in days rather than weeks, you validate fit and function before committing to production tooling. This speed becomes invaluable for chassis and suspension components where geometry complexity demands iterative refinement.

Design for Manufacturing (DFM) support transforms good designs into producible reality. Experienced automotive sheet metal fabricators identify potential forming issues, suggest material alternatives, and optimize designs for automated production—all before cutting the first piece. For manufacturers like Shaoyi (Ningbo) Metal Technology, combining 5-day rapid prototyping with comprehensive DFM analysis and 12-hour quote turnaround helps engineering teams accelerate their automotive supply chain from concept through mass production.

Architectural and Decorative Steel Sheet Uses

Architectural applications flip the priority equation—appearance often matters as much as structural performance. Sheet metal stainless steel dominates this space for good reason: its corrosion resistance, aesthetic versatility, and low maintenance make it ideal for building façades, interior features, and decorative elements exposed to public view.

When specifying stainless steel sheet fabrication for architectural projects, finish selection dramatically affects both appearance and cost. A #4 brushed finish provides a subtle, directional grain that hides fingerprints and minor scratches—popular for elevator interiors and wall panels. Mirror-polished (#8) finishes create dramatic visual impact but require more careful handling and show every imperfection. Custom stainless steel products for architecture often feature specialty finishes: bead-blasted, etched, or even colored through physical vapor deposition (PVD) coating.

Recommended specifications for architectural applications include:

- Grade: 304 stainless for most interior and moderate exterior exposure; 316 stainless for coastal or industrial environments

- Thickness range: 16-20 gauge for panels and cladding; heavier gauges for structural trim or high-traffic areas

- Surface finish: #4 brushed, #8 mirror, bead-blasted, or custom finishes as design requires

- Protective film: Essential for handling and installation; specify peel-off protective coating

- Edge condition: Deburred and eased for safety; polished edges for exposed applications

Stainless steel sheet metal fabrication for architectural projects demands precision cutting and forming to achieve the clean lines and tight joints that define quality installations. Laser cutting provides the edge quality these applications require, while CNC press brake forming ensures consistent bend angles across production runs. Specify these fabrication methods when appearance is paramount.

Industrial Equipment and Consumer Products

Industrial equipment presents yet another specification profile. Durability under operational stress, resistance to specific environmental factors, and compatibility with maintenance procedures drive material selection. Custom stainless steel parts for food processing equipment, for example, must meet FDA and USDA sanitation requirements—typically demanding 304 or 316 stainless with specific surface finishes that prevent bacterial harborage.

Recommended specifications for industrial equipment include:

- Grade: A36 or A572 for structural frames; 304/316 stainless for corrosion-critical or sanitary applications

- Thickness range: 10-14 gauge for equipment frames and guards; lighter gauges for enclosures and covers

- Surface condition: Hot-rolled acceptable for painted structural members; cold-rolled or stainless for exposed surfaces

- Finish: Primed or powder-coated for corrosion protection; 2B or #4 finish for stainless applications

- Tolerances: Standard mill tolerances often acceptable; tighter control for mating components

Consumer products span a wide specification range depending on the item. Small appliance housings typically use cold-rolled steel in 18-22 gauge with pre-painted or post-painted finishes. Furniture components might use 16-gauge cold-rolled steel for structural frames with powder-coated finishes for durability and appearance. The common thread: surface quality and finish consistency matter because end users see and touch the final product.

Stainless steel shapes and flat sheet find extensive use in consumer goods requiring corrosion resistance and aesthetic appeal—kitchen appliances, bathroom fixtures, and outdoor furniture all benefit from stainless steel's combination of durability and appearance. When specifying for these applications, pay particular attention to surface finish consistency across production lots to maintain product uniformity.

With application requirements clearly defined, the final step involves synthesizing all your specification decisions into a coherent framework—and understanding when to leverage expert manufacturing partners for complex custom steel sheet requirements that demand specialized capabilities.

Making the Right Custom Steel Sheet Decision

You've journeyed through grades, gauges, rolling methods, cutting technologies, and application requirements. Now it's time to pull everything together into a decision framework that transforms specification knowledge into confident ordering. The relationship between material grade, thickness, cutting method, and end use isn't linear—it's interconnected, with each choice influencing the others.

Your Custom Steel Sheet Decision Framework

Successful custom steel sheet selection follows a logical sequence. Start with application requirements—what environment will the material face, what loads must it handle, and what appearance standards apply? These answers narrow your grade options immediately. Structural outdoor applications point toward galvanized or HSLA grades; food contact demands 304 or 316 stainless steel sheets; precision visible components require cold-rolled material with appropriate finishes.

Thickness selection flows directly from structural analysis and forming requirements. Heavier gauges provide strength but add weight and cost. Lighter gauges reduce material expense but may compromise performance. The sweet spot balances structural adequacy with practical constraints—and when you're sourcing custom stainless or carbon steel, that balance point varies by application.

Cutting method selection depends on your tolerance requirements, edge quality expectations, and budget. Laser cutting delivers precision for stainless steel custom projects requiring tight fits; plasma cutting provides economy for structural work; waterjet preserves material properties when heat-affected zones matter. Match the process to your actual needs—not the most impressive capability.

The most expensive custom steel sheet specification isn't always the best one. The right specification balances material properties, dimensional requirements, surface quality, and fabrication constraints against your budget and timeline—delivering exactly the performance you need without paying for capabilities you won't use.

Next Steps for Your Project

Ready to move from planning to procurement? Follow these actionable steps to ensure your custom cut stainless steel or carbon steel order succeeds:

- Gather complete project requirements: Document material grade, thickness, dimensions with tolerances, surface finish, and any certifications needed before contacting suppliers

- Request samples when appropriate: For new applications or critical aesthetic requirements, evaluate physical samples before committing to production quantities

- Evaluate supplier capabilities honestly: Match your project complexity to supplier expertise—simple cut-to-size orders suit distributors; complex fabrication demands specialized manufacturers

- Verify quality certifications: For automotive, aerospace, or food-grade applications, confirm suppliers hold relevant certifications (IATF 16949, AS9100, FDA compliance)

- Compare total cost, not just material price: Factor in lead time, shipping, secondary processing, and potential scrap when evaluating quotes

When your project involves precision metal stamping, complex assemblies, or automotive-grade requirements, supplier selection becomes even more critical. Look for manufacturing partners offering comprehensive DFM support that identifies potential issues before production begins. Rapid quote turnaround—ideally within hours rather than days—indicates suppliers with streamlined processes and responsive engineering teams.

For automotive chassis, suspension, and structural components specifically, working with IATF 16949-certified manufacturers ensures the quality systems and traceability your supply chain demands. Capabilities like 5-day rapid prototyping accelerate development timelines, while automated mass production delivers consistency at scale. Partners like Shaoyi (Ningbo) Metal Technology combine these capabilities with 12-hour quote turnaround, helping engineering teams optimize manufacturing from concept through production.

Whether you're looking for stainless steel sheets for sale for a one-time project or establishing ongoing supply relationships, the knowledge you've gained positions you to buy stainless steel sheet—or any custom steel material—with confidence. You understand what specifications matter, why they matter, and how to communicate requirements clearly to suppliers.

Wondering where to buy stainless steel sheets or custom carbon steel for your next project? Start with suppliers who ask the right questions about your application, offer technical guidance on material selection, and provide clear documentation of their quality processes. The best manufacturing relationships begin with mutual understanding of requirements and capabilities—and now you have the specification knowledge to build those relationships successfully.

Frequently Asked Questions About Custom Steel Sheet

1. What is the difference between custom steel sheet and standard stock sizes?

Custom steel sheet is manufactured or processed to meet your exact specifications—precise dimensions, specific thickness tolerances, and particular material grades tailored to your project. Standard stock sizes come in predetermined dimensions like 4x8 feet with standard gauge thicknesses. Custom orders eliminate waste, reduce secondary processing, and ensure material matches application requirements exactly. This is especially critical for automotive components, architectural elements, and precision assemblies where tight tolerances matter.

2. How do I choose between 304 and 316 stainless steel for custom sheet orders?

Choose 304 stainless steel for most indoor applications and mildly corrosive environments—it offers excellent corrosion resistance, easy formability, and strong weldability at a reasonable cost. Select 316 stainless steel when your project involves chloride exposure, saltwater, chemical processing, or pharmaceutical applications. The added molybdenum in 316 provides superior resistance to pitting and acids. While 316 costs 10-15% more than 304, the investment prevents premature failure in harsh environments.

3. What cutting method is best for custom steel sheet fabrication?

The best cutting method depends on material type, thickness, and quality requirements. Laser cutting excels for thin materials under 1/4 inch requiring precision and smooth edges. Plasma cutting offers the best speed and economy for thicker structural steel. Waterjet cutting preserves material properties with zero heat-affected zone—ideal for heat-sensitive applications. CNC shearing provides economical straight cuts for simple blanking operations. Match the process to your tolerance requirements, edge quality expectations, and budget constraints.

4. Why does the steel gauge number work inversely with thickness?

The gauge system originated in the 19th-century British iron wire industry before universal thickness standards existed. Higher gauge numbers indicate thinner material—10 gauge measures approximately 0.1345 inches while 16 gauge is just 0.0598 inches. The system isn't linear, meaning steps between gauge numbers vary. For precision orders, specify thickness in decimal inches or millimeters rather than gauge to eliminate interpretation errors and ensure you receive exactly what your design requires.

5. What information do suppliers need for accurate custom steel sheet quotes?

Provide complete material specification including grade, thickness, and surface condition. Include dimensional requirements with explicit tolerances, cutting method preferences, quantity needed, required delivery date, and delivery location. For complex geometries, submit DXF or DWG drawing files. Specify any certifications required like mill test reports or IATF 16949 compliance for automotive applications. The more complete your specification, the more accurate your quote—and the fewer costly change orders during production.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —