Stamping Sensor Brackets: Manufacturing Guide for Precision & Scale

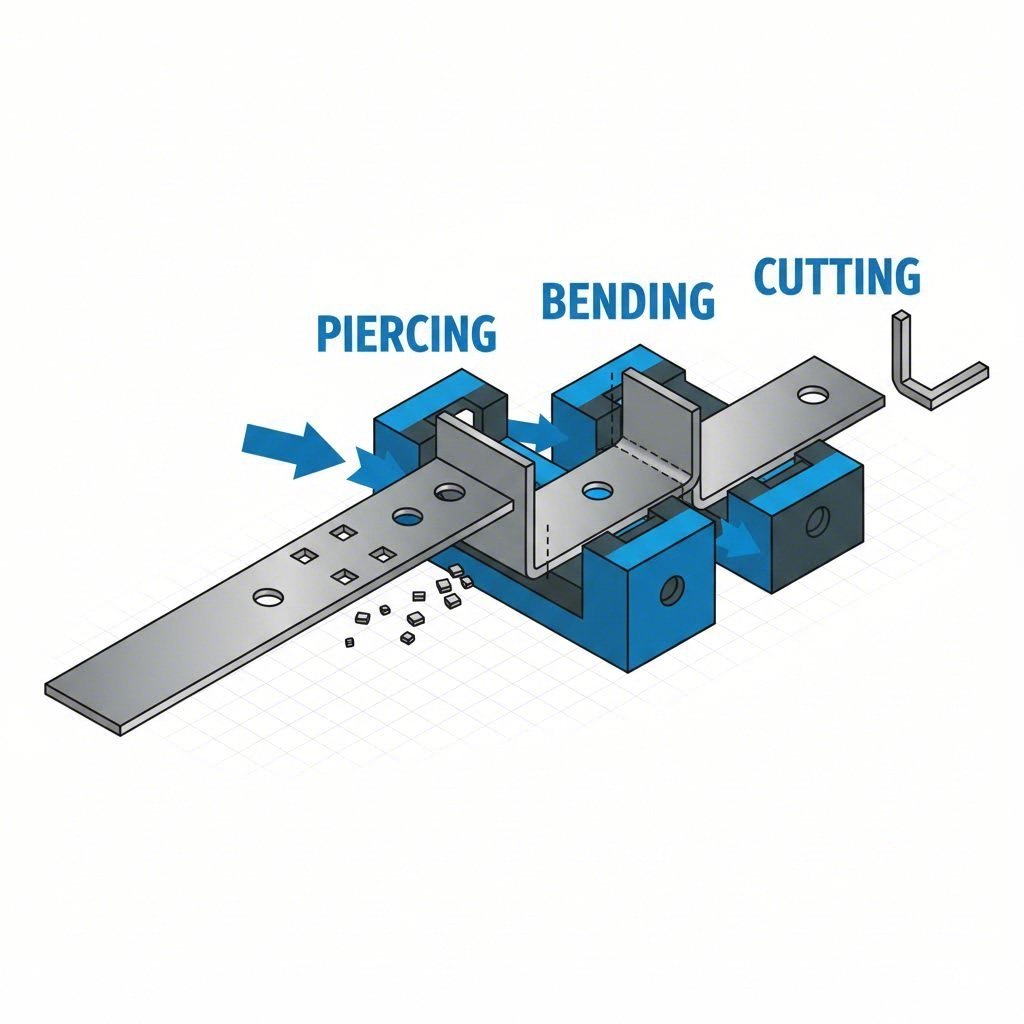

<h2>TL;DR</h2><p>Stamping sensor brackets is a precision manufacturing process designed to produce high-volume, durable mounting components for industrial, automotive, and electronic applications. By utilizing progressive die technology, manufacturers can cut, bend, and form metal sheets into complex geometries with tight tolerances (often within ±0.001 inches) at a fraction of the cost of machining. Common materials include corrosion-resistant 304 stainless steel and lightweight aluminum, ensuring that sensors remain aligned despite heavy vibration or harsh environmental conditions. For engineers and procurement teams, stamped brackets offer the optimal balance of structural rigidity, repeatability, and unit cost efficiency for mass production.</p><h2>Why Choose Metal Stamping for Sensor Brackets?</h2><p>When scaling production from dozens to thousands of units, manufacturing methods must evolve to maintain cost efficiency without sacrificing quality. Metal stamping, specifically progressive die stamping, emerges as the superior choice for sensor brackets compared to CNC machining or casting, primarily due to its speed and consistency.</p><p>The economic advantage of stamping lies in its volume-driven cost structure. While the initial investment in hard tooling (dies) is higher than machining fixtures, the per-unit cost drops precipitously as volume increases. For a run of 50,000 sensor mounts, a stamped part might cost cents versus dollars for a machined equivalent. This efficiency is achieved because the press performs multiple operations—piercing, forming, and cutting—with every stroke, producing a finished part in seconds rather than minutes.</p><p>Beyond cost, stamping delivers the mechanical consistency required for sensitive electronics. Sensors used in automation or automotive systems rely on precise alignment to function correctly. A stamped bracket guarantees that every unit has identical bend angles and hole locations, ensuring the sensor "sees" the same target every time. Furthermore, stamping allows for the integration of complex features directly into the process. Grounding tabs, cable strain relief slots, and stiffening ribs can be formed in the same pass, eliminating the need for expensive secondary operations.</p><h2>Critical Design Considerations for Stamped Brackets</h2><p>Designing a sensor bracket for manufacturability (DFM) requires balancing the sensor's performance needs with the physical limitations of the metal sheet. A primary concern is <strong>vibration resistance</strong>. Sensors mounted on vibrating machinery can yield false readings or fail prematurely if the bracket resonates. To mitigate this, engineers should incorporate stiffening ribs or flanges into the design. These features add structural rigidity without increasing material gauge, keeping the part lightweight yet robust.</p><p>Another critical factor is <strong>feature placement and tolerance</strong>. To ensure secure mounting, consider using cross-thread patterns or extruded holes that provide more thread engagement for screws, preventing them from backing out under vibration. When designing adjustable mounting slots—often necessary for calibrating sensor position—ensure the slot width accommodates standard fastener sizes with enough clearance for adjustment but not so much that the washer deforms the material.</p><p>Material "springback" is an inherent challenge in metal stamping, where the metal tries to return to its original shape after bending. Experienced designers and toolmakers calculate this factor into the die design, over-bending the metal slightly so it relaxes into the correct angle. Specifying generous bend radii (typically 1x material thickness) prevents cracking, especially in harder materials like stainless steel.</p><h2>Material Selection for Sensor Performance</h2><p>The environment where the sensor operates dictates the material choice for its bracket. Selecting the wrong alloy can lead to corrosion, signal interference, or mechanical failure.</p><ul><li><strong>Stainless Steel (304/316):</strong> The gold standard for food processing, pharmaceutical, and outdoor applications. Grade 304 offers excellent general corrosion resistance, while 316 is preferred for marine or chemical environments. Its high tensile strength ensures rigid sensor alignment even with thin gauges.</li><li><strong>Aluminum (5052/6061):</strong> Ideal for robotics and aerospace where weight is a premium. Aluminum creates a non-magnetic mount, which is critical for inductive sensors that might otherwise be triggered by a ferrous bracket. It can be anodized for extra protection and aesthetic color-coding.</li><li><strong>Pre-Plated Carbon Steel:</strong> A cost-effective solution for general industrial indoor use. Materials like galvanized steel or zinc-plated carbon steel provide basic rust protection. However, cut edges will expose the raw steel, so post-stamping plating may be required for complete protection.</li></ul><p>For applications requiring electrical grounding, pre-plated materials or specific raw metals are preferred over painted or powder-coated surfaces, which act as insulators. If a non-conductive mount is needed to isolate the sensor, composite laminates or post-process dielectric coatings can be applied.</p><h2>The Manufacturing Process: From Prototype to Production</h2><p>The journey of a stamped sensor bracket begins long before the press starts running. It typically follows a structured path to ensure the final part meets all specifications.</p><ol><li><strong>Prototyping:</strong> Before committing to hard tooling, designs are validated using laser cutting or soft tooling. This allows engineers to test fitment and sensor alignment in the real world. Adjustments to hole locations or bend angles are easy and cheap at this stage.</li><li><strong>Tool Design & Fabrication:</strong> Once the design is frozen, a progressive die is engineered. This tool consists of a series of stations. As the metal strip feeds through, the die progressively pierces pilot holes, trims the outline, forms bends, and finally cuts the part free.</li><li><strong>Stamping Production:</strong> The coil is loaded into a press (ranging from 30 to 600+ tons depending on part size and material thickness). The press cycles automatically, producing finished brackets at high speeds. Advanced presses can include in-die sensors to detect misfeeds, protecting the expensive tooling.</li><li><strong>Value-Added Operations:</strong> Many sensor brackets require secondary steps. This includes deburring to remove sharp edges that could cut wires, tapping threads for mounting screws, or inserting hardware like PEM nuts. Some advanced dies can perform "in-die tapping" or hardware insertion, further reducing costs.</li></ol><h2>Sourcing Guide: Choosing a Manufacturer</h2><p>Selecting the right manufacturing partner is as critical as the design itself. For general industrial brackets, a shop with standard ISO 9001 certification may suffice. However, for automotive or safety-critical sensor mounts, look for suppliers with <strong>IATF 16949 certification</strong>. This standard ensures rigorous quality management and traceability.</p><p>Evaluate a supplier's capacity to handle your specific volume curve. You need a partner who can support you from the initial sample phase through to full-scale mass production without forcing you to switch vendors. For automotive applications requiring strict adherence to global OEM standards, manufacturers like <a href="https://www.shao-yi.com/auto-stamping-parts/">Shaoyi Metal Technology</a> offer comprehensive stamping solutions. They bridge the gap from rapid prototyping (delivering as few as 50 parts in five days) to high-volume manufacturing using presses up to 600 tons, ensuring critical components meet precise specifications.</p><p>Finally, ask about their quality control equipment. Top-tier suppliers utilize automated vision systems that inspect 100% of the parts as they come off the line, checking for critical dimensions like mounting hole positions. This level of verification is essential for automated assembly lines where a single out-of-spec bracket can cause costly jams or sensor failures.</p><section><h2>Securing Precision for Automation</h2><p>The humble sensor bracket plays a pivotal role in the reliability of modern automation systems. By leveraging the speed and precision of metal stamping, engineers can secure their sensors against vibration and misalignment while keeping project costs in check. Whether utilizing robust stainless steel for harsh environments or lightweight aluminum for dynamic robotics, the key to success lies in early DFM collaboration and selecting a manufacturing partner capable of delivering consistent quality at scale. As industries continue to automate, the demand for these precision-stamped backbones will only grow, making their design and sourcing a critical skill for today's engineers.</p></section><section><h2>Frequently Asked Questions</h2><h3>1. What is the difference between progressive die stamping and laser cutting for brackets?</h3><p>Laser cutting is ideal for low-volume prototyping because it requires no hard tooling, but it is slower and more expensive per unit. Progressive die stamping requires an upfront tooling investment but offers significantly lower per-unit costs and higher speeds for large production runs (typically over 5,000 units). Stamping also ensures higher repeatability for complex bent geometries.</p><h3>2. Can stamped brackets include grounding features for sensors?</h3><p>Yes, stamped brackets can easily integrate grounding features. During the stamping process, specific areas can be coined or pierced to create sharp contact points that bite into the mating surface, ensuring electrical conductivity. Additionally, using pre-plated materials or selective masking during finishing can maintain a conductive path for grounding requirements.</p><h3>3. What are typical tolerances for stamped metal sensor mounts?</h3><p>Precision metal stamping typically achieves tolerances of ±0.005 inches (0.127 mm) for general features. However, with high-precision tooling and quality control, critical dimensions like sensor mounting hole locations can be held to tighter tolerances of ±0.001 inches (0.025 mm) to ensure accurate sensor alignment.</p></section>

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —