Sheet Metal Products Decoded: From Raw Material To Your Factory Floor

What Are Sheet Metal Products and Why They Matter

When you look around a factory floor, an automotive assembly line, or even your own kitchen, you're surrounded by sheet metal products. But what exactly sets these components apart from other metal goods? Understanding this distinction is essential for buyers, engineers, and manufacturers who need to make informed decisions about materials and fabrication processes.

Defining Sheet Metal Products and Their Core Characteristics

Sheet metal products are components manufactured from thin, flat pieces of metal that have been formed, cut, or shaped through industrial processes. Unlike cast or forged metal goods, these products begin as flat metal sheets that undergo various fabrication techniques to achieve their final geometry. The defining characteristic? Their remarkable combination of structural integrity and formability.

What makes sheet metal fabrication so valuable is the material's plasticity. This allows manufacturers to deform metal sheets into complex shapes while maintaining structural integrity. Whether you're producing car doors, HVAC ductwork, or precision electronic enclosures, the process relies on the same fundamental principle: reshaping without adding or removing material.

- Thickness range: Typically between 0.5 mm and 6 mm, though applications extend from ultra-thin foils to thicker plates

- Formability: High malleability enables bending, stretching, and pressing into diverse shapes

- Material options: Steel, aluminum, copper, brass, and specialty alloys offer application-specific properties

- Manufacturing versatility: Compatible with cutting, forming, joining, and finishing processes for endless design possibilities

How Sheet Metal Differs From Other Metal Forms

Imagine you need a metal component for your next project. You could choose cast metal, forged metal, or machined parts from solid stock. So why do manufacturers consistently turn to metal sheets instead?

The answer lies in efficiency and adaptability. Cast metal requires molds and works best for complex three-dimensional shapes produced in high volumes. Forged components excel in applications demanding extreme strength but involve significant tooling costs. Machined parts offer precision but generate substantial material waste as metal is cut away.

Sheet metal products occupy a unique middle ground. The metal fabrication process preserves nearly all the original material while enabling rapid production of both simple brackets and intricate assemblies. This efficiency translates directly to cost savings, particularly for medium-to-high production volumes.

The Thickness Spectrum From Foil to Plate

Not all flat metal products qualify as sheet metal. The industry recognizes three distinct categories based on thickness, according to Birmingham Metal:

- Foil: Less than 0.2 mm thick. Highly flexible and lightweight, used in electronics, packaging, and research applications

- Sheet: Between 0.5 mm and 6 mm thick. The versatile workhorse used across aerospace, automotive, construction, and medical sectors

- Steel plate: Greater than 6 mm thick. Reserved for heavy-duty applications requiring exceptional strength and durability

This thickness spectrum matters because it determines which fabrication processes are suitable and what applications the final product can serve. Thinner metal sheets are easier to form but more prone to distortion, while thicker materials require greater forming forces and specialized equipment.

Throughout this article, you'll discover how different materials, manufacturing processes, and quality standards come together to produce the sheet metals powering modern industry. Whether you're sourcing components for automotive production, specifying materials for construction projects, or engineering custom solutions, understanding these fundamentals will help you make smarter decisions at every stage.

Sheet Metal Materials and Their Unique Properties

Choosing the right material can make or break your sheet metal project. Each metal brings its own personality to the table—some resist corrosion like champions, others bend effortlessly into complex shapes, and a few deliver that perfect balance of strength and affordability. Let's explore what sets each option apart so you can match material properties to your exact application needs.

Steel and Stainless Steel Options for Durability

When durability and cost-effectiveness top your priority list, steel remains the go-to choice for countless manufacturing applications. But which type fits your project best?

Carbon steel offers excellent strength at competitive pricing. It machines well, welds easily, and provides reliable structural performance. The trade-off? It requires protective coatings or finishes to prevent rust in moisture-prone environments.

Galvanized steel solves this corrosion challenge by applying a zinc coating to carbon steel. This protective layer sacrifices itself to protect the underlying metal, making galvanized sheet metal ideal for outdoor construction, HVAC ductwork, and agricultural equipment.

For applications demanding superior corrosion resistance, stainless steel sheet options deliver exceptional performance. The two most popular grades—304 and 316 stainless steel—serve distinct purposes:

- 304 stainless steel: Contains approximately 18% chromium and 8% nickel. This composition provides excellent corrosion resistance for indoor and mildly corrosive environments. It's the workhorse grade for kitchen equipment, architectural trim, and general hardware applications.

- 316 stainless steel: Adds 2-3% molybdenum to the mix, dramatically improving resistance against chlorides and acidic conditions. According to Ryerson's comparison data, 316 costs about 10-15% more than 304 but delivers longer service life in marine, pharmaceutical, and chemical processing applications.

So is aluminum a metal that competes with steel? Absolutely—but in different arenas, as you'll discover next.

Aluminum Sheet Metal for Lightweight Applications

When weight matters as much as strength, aluminum sheet metal emerges as the clear winner. Weighing roughly one-third as much as steel, aluminum alloys enable fuel-efficient vehicles, aircraft components, and portable equipment that would be impractical with heavier metals.

Metals aluminium alloys come in various grades, each engineered for specific performance characteristics:

- 1100 aluminum: Highly formable with excellent corrosion resistance. Perfect for chemical equipment, decorative trim, and food processing applications.

- 3003 aluminum: The most widely used alloy, offering good workability and moderate strength. Ideal for general sheet metal work, heat exchangers, and storage tanks.

- 5052 aluminum: Provides higher strength and exceptional saltwater corrosion resistance. Common in marine components, fuel tanks, and pressure vessels.

- 6061 aluminum: A heat-treatable alloy with excellent machinability and weldability. Preferred for structural applications requiring both strength and corrosion resistance.

An aluminum sheet naturally forms a protective oxide layer when exposed to air, delivering inherent corrosion resistance without additional coatings. This self-protecting quality makes aluminum especially attractive for outdoor architectural applications and transportation equipment.

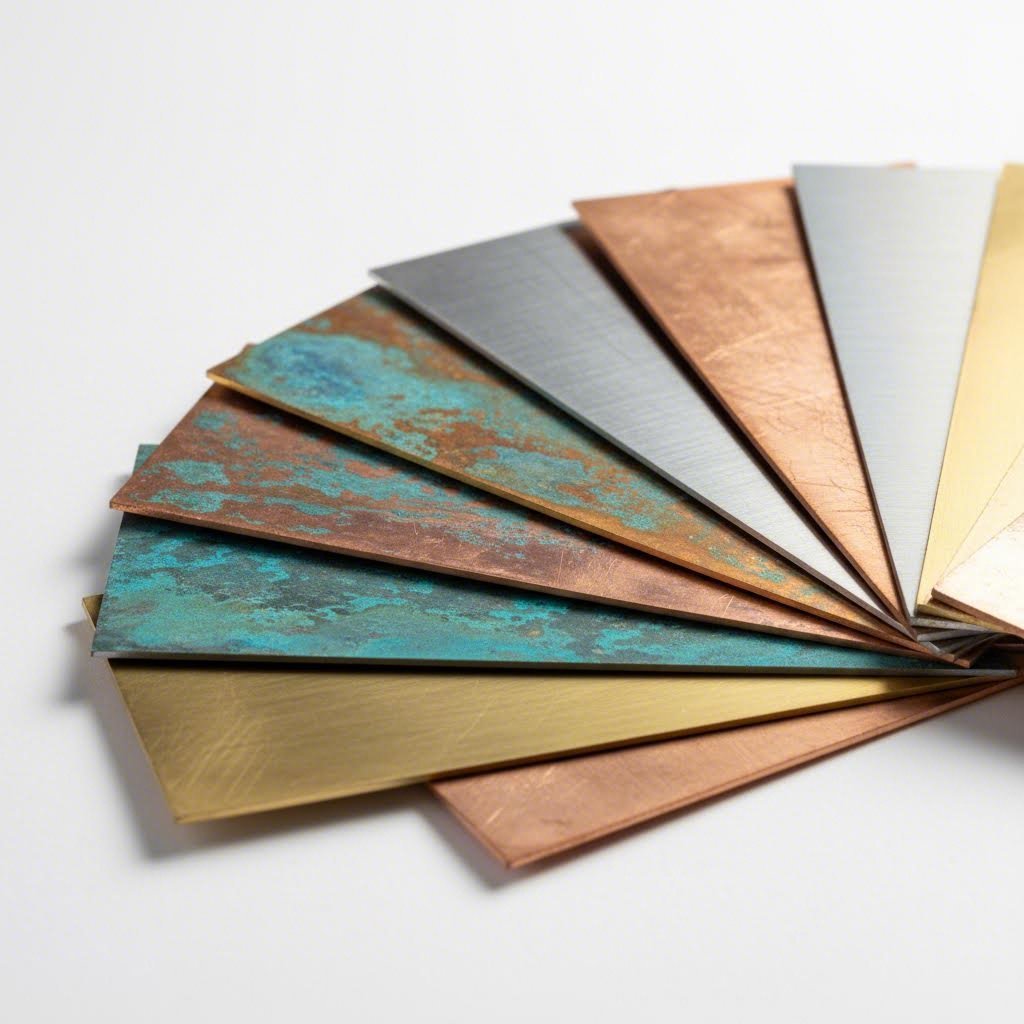

Specialty Metals Including Copper and Brass

Beyond steel and aluminum, specialty metals serve applications where electrical conductivity, thermal performance, or aesthetics take priority.

Copper delivers unmatched electrical and thermal conductivity, making it essential for electrical bus bars, heat exchangers, and roofing systems. Over time, copper develops a distinctive green patina that many architects prize for its visual appeal. However, copper commands premium pricing and requires careful handling to prevent work hardening during fabrication.

Brass offers an attractive alternative when you need good corrosion resistance, excellent machinability, and a warm golden appearance. But what is brass made of exactly? It's an alloy of copper and zinc, with varying proportions that affect its properties. Free-cutting brass alloys typically achieve tensile strengths between 360 and 500 MPa—significantly higher than pure copper's 210 to 370 MPa range.

When comparing brass vs bronze, remember that bronze contains tin rather than zinc, offering superior wear resistance but at higher cost. Brass remains the practical choice for decorative hardware, marine fittings, and precision machined components.

| Material Type | Key Properties | Common Applications | Relative Cost | Best Use Cases |

|---|---|---|---|---|

| Carbon Steel | High strength, excellent weldability, requires coating for corrosion protection | Structural components, machinery, enclosures | Low | Indoor applications where cost matters most |

| Galvanized Steel | Corrosion-resistant zinc coating, good durability | HVAC ductwork, roofing, outdoor equipment | Low-Medium | Outdoor and moisture-exposed applications |

| 304 Stainless Steel | 18% chromium, 8% nickel, excellent formability | Kitchen equipment, architectural trim, fasteners | Medium | General-purpose corrosion resistance |

| 316 Stainless Steel | Added molybdenum, superior chloride resistance | Marine hardware, chemical processing, pharmaceuticals | Medium-High | Harsh chemical or saltwater environments |

| Aluminum (3003/5052) | Lightweight, naturally corrosion-resistant, highly formable | Aerospace, transportation, heat exchangers | Medium | Weight-sensitive applications |

| Copper | Highest electrical/thermal conductivity, antimicrobial | Electrical components, roofing, heat sinks | High | Electrical and thermal management |

| Brass | Excellent machinability, decorative appeal, good wear resistance | Hardware, marine fittings, decorative panels | Medium-High | Decorative and precision-machined parts |

Understanding gauge thickness standards helps you communicate specifications accurately across different materials. A gauge size chart translates standardized numbers into actual thicknesses—but here's the catch: gauge numbers mean different things for different metals. A 14-gauge steel sheet measures approximately 1.9 mm, while 14-gauge aluminum comes in at about 1.6 mm. Always confirm actual thickness measurements when specifying materials across your supply chain.

With material selection clarified, you're ready to explore how these raw metals transform into finished products through cutting, forming, and joining processes.

How Sheet Metal Products Are Manufactured

Now that you understand which materials suit your application, the next question becomes: how do flat metal sheets transform into functional components? The answer involves three fundamental process categories—cutting, forming, and joining—each with multiple techniques that impact precision, edge quality, and overall product performance.

Cutting Technologies From Laser to Waterjet

Every sheet metal product starts with cutting raw material to size and shape. Your choice of cutting method determines not only production speed but also edge quality, dimensional accuracy, and material compatibility.

Laser cutting uses a focused beam of high-intensity light to melt, burn, and vaporize material along a programmed path. A laser cutter excels at producing intricate geometries with exceptional precision on metals less than half an inch thick. According to JR Metal Works, laser cutting can operate 5 to 10 times faster than waterjet methods on thin materials, making it ideal for high-volume production runs.

- Advantages: Unrivaled precision for tight geometries, narrow cutting path conserves material, versatile for cutting, engraving, and perforating

- Limitations: Reflective metals can cause beam deflection, heat-affected zones may alter material properties, limited effectiveness on thicker materials

Waterjet cutting forces water mixed with abrasives like garnet through a high-pressure nozzle to erode material. This cold cutting process eliminates heat-affected zones entirely, preserving the original material properties throughout the cut edge.

- Advantages: Cuts materials up to 15 inches thick, no thermal distortion, handles virtually any material including heat-sensitive composites

- Limitations: Slower than laser on thin materials, higher operating costs due to abrasive consumption, wider cutting path

Shearing and CNC routing offer additional options depending on your requirements. Shearing provides fast, straight cuts for basic shapes, while CNC routing delivers flexibility for non-metallic or composite materials.

One critical concept when specifying precision cuts is kerf—the width of material removed during the cutting process. A laser cutter typically produces kerf widths between 0.1 and 0.3 mm, while waterjet kerf ranges from 0.5 to 1.5 mm. Understanding kerf matters because it affects how tightly you can nest parts and whether your finished dimensions meet tolerance requirements.

Forming and Bending Processes Explained

Once cut to shape, flat blanks undergo forming operations that create three-dimensional geometry without adding or removing material. These processes leverage the inherent malleability of sheet metals to achieve complex shapes efficiently.

Bending remains the most common forming operation. Press brakes apply force along a linear axis to create angles, channels, and enclosures. Modern CNC press brakes can achieve bend tolerances within ±0.5 degrees, enabling precise assembly of multi-bend components.

- Advantages: Relatively low tooling cost, suitable for short and long production runs, highly repeatable results

- Limitations: Limited to linear bends, springback compensation requires experienced programming, material thickness affects minimum bend radius

Stamping uses matched dies to form sheet metal under high pressure. A die cut machine can produce complex shapes including embosses, ribs, and integrated features in a single press stroke. For high-volume applications, progressive stamping moves material through multiple stations, completing several operations before ejecting a finished part.

Roll forming passes sheet metal through successive roller stations that gradually shape the material into continuous profiles. This process excels for producing long, consistent cross-sections like structural channels, roof panels, and door frames.

According to Xometry, sheet metal forming typically handles materials between 0.6 mm and 6.35 mm thick, though specific designs and metal types may extend this range in either direction.

Joining Methods for Sheet Metal Assembly

Most finished products require joining multiple formed components into functional assemblies. Your joining method affects structural integrity, appearance, and production costs.

Welding creates permanent metallurgical bonds between components. When comparing mig vs tig welding, consider that MIG welding offers faster travel speeds and easier learning curves, while TIG welding delivers superior control and cleaner welds for visible joints and thinner materials. Aluminum welding presents additional challenges due to the material's thermal conductivity and oxide layer—TIG welding with AC current or specialized MIG settings typically yields the best results.

- Advantages: Creates strong, permanent joints, can be automated for high production volumes, minimal added weight

- Limitations: Heat-affected zones may require post-processing, skilled operators needed for quality results, some materials require specialized equipment

Mechanical fastening using rivets, screws, or clinch joints provides alternatives when welding isn't practical. Rivets create permanent connections without heat, making them ideal for joining dissimilar metals or heat-sensitive assemblies. Self-clinching fasteners install flush with the surface for clean aesthetics.

Adhesive bonding distributes stress across larger areas and works well for joining thin materials that might distort under welding heat. Modern structural adhesives achieve impressive strength while adding vibration damping properties.

The fabrication processes you select directly influence your product's performance, appearance, and cost. Understanding these manufacturing fundamentals prepares you to evaluate how different industries leverage sheet metal capabilities for their specific applications.

Industry Applications From HVAC to Automotive

Where do all these fabrication techniques and material options actually end up? From the air conditioning keeping your office comfortable to the vehicle in your driveway, sheet metal products serve critical functions across virtually every major industry. Understanding sector-specific requirements helps you specify the right materials, finishes, and tolerances for your particular application.

HVAC and Air Distribution Sheet Metal Products

Walk into any commercial building and you'll find miles of sheet metal ductwork quietly distributing conditioned air. HVAC systems represent one of the largest markets for sheet metal fabrication, with ductwork serving as the literal arteries of modern building infrastructure.

What makes sheet metal ideal for air distribution? The combination of structural rigidity, airtight construction, and long-term durability. According to BESA's DW/144 specification, sheet metal ductwork maintains shape and integrity under varying pressure and temperature conditions while delivering predictable airflow—performance characteristics that alternative materials like fabric or plastic struggle to replicate, particularly in high-pressure systems.

Galvanized steel dominates HVAC applications because it balances corrosion resistance with affordability. The zinc coating protects against moisture accumulation inside ducts, extending service life across decades of operation. For specialized environments like cleanrooms, laboratories, and healthcare facilities, stainless steel sheet metal provides the enhanced hygiene and chemical resistance these demanding applications require.

- Rectangular ductwork: Popular in commercial installations where space constraints and design flexibility matter most

- Circular ductwork: Offers superior aerodynamic efficiency and lower material usage per cubic foot of air moved

- Flat oval configurations: Combine circular efficiency with rectangular space adaptability

- Access panels and dampers: Enable maintenance, inspection, and airflow control throughout the system

Powder coating services add both aesthetic appeal and additional corrosion protection for exposed ductwork in architectural applications. When ducts remain visible as design elements—think industrial-chic restaurants or converted warehouse spaces—the right finish transforms functional infrastructure into visual features.

Construction and Architectural Applications

Look at any modern building envelope and you'll spot sheet metal products everywhere: roofing panels catching sunlight, siding defining facades, and flashing protecting vulnerable joints from water infiltration. Construction applications demand materials that withstand decades of weather exposure while maintaining structural integrity and visual appeal.

Corrugated metal panels remain a construction staple because their wave-like profile dramatically increases rigidity without adding weight. This geometry allows thinner gauge materials to span greater distances between supports, reducing both material costs and structural requirements. You'll find corrugated metal covering agricultural buildings, industrial facilities, and increasingly, residential projects seeking that modern aesthetic.

Architectural applications often prioritize appearance alongside performance. Anodizing aluminum creates a hard, integral oxide layer that resists scratching and fading while accepting vibrant color dyes. Unlike paint that sits on the surface, anodizing becomes part of the metal itself—producing finishes that maintain their appearance for decades without peeling or chipping.

- Standing seam roofing: Concealed fasteners eliminate leak points while creating clean, contemporary lines

- Metal siding systems: Available in countless profiles, colors, and textures for design flexibility

- Flashing and trim: Critical waterproofing components that protect roof penetrations, wall transitions, and window openings

- Custom metal signs: Combine durability with precision fabrication for branded architectural elements

Steel fabrication for construction typically prioritizes corrosion resistance and structural performance over weight savings. Galvanized coatings, factory-applied finishes, and proper flashing details ensure building components perform reliably across their intended service life.

Automotive and Transportation Components

Few industries push sheet metal capabilities harder than automotive manufacturing. Every vehicle on the road contains hundreds of stamped, formed, and welded sheet metal components—from visible body panels to hidden structural reinforcements engineered to protect passengers during collisions.

According to Kloeckner Metals, automotive sheet metal applications span three primary categories:

- Body-in-White (BIW) and frames: The structural skeleton providing rigidity and crash protection

- Closure panels: Doors, hoods, fenders, and liftgates that define vehicle appearance

- Structural reinforcements: Pillars, roof rails, and intrusion beams engineered for occupant safety

Material selection in automotive applications reflects an ongoing balance between strength, weight, and cost. Advanced high-strength steels like dual-phase (DP) and martensitic grades deliver exceptional crash performance in safety-critical areas. DP1270 steel, for example, protects passenger compartments in rockers, A/B pillars, and roof rails where deformation resistance saves lives.

Meanwhile, aluminum alloys increasingly replace steel in closure panels and structural components where weight reduction improves fuel efficiency. Alloys like 6016 and 6022 provide adequate yield strength and dent resistance for exterior panels, while 5182 offers the high strength and galvanic corrosion resistance needed for structural applications.

Aerospace takes weight sensitivity even further, specifying exotic aluminum alloys and advanced composites wherever possible. Aircraft skin panels, structural members, and interior components demand materials that minimize weight while meeting stringent safety certifications.

Electronics and Industrial Equipment

Open any electronic device or industrial control panel and you'll find sheet metal enclosures protecting sensitive components from environmental hazards, electromagnetic interference, and physical damage. These applications demand tight tolerances, clean finishes, and precise cutouts for displays, connectors, and ventilation.

Heat sinks represent another critical electronics application where material selection directly impacts performance. Aluminum's excellent thermal conductivity makes it the preferred choice for dissipating heat from processors, power supplies, and LED lighting systems. The metal's light weight and ease of machining allow complex fin geometries that maximize surface area for convective cooling.

| Industry | Common Products | Typical Materials | Key Performance Requirements |

|---|---|---|---|

| HVAC | Ductwork, plenums, diffusers, dampers | Galvanized steel, aluminum, stainless steel | Airtight construction, pressure resistance, cleanability |

| Construction | Roofing, siding, flashing, gutters, custom metal signs | Galvanized steel, aluminum, copper | Weather resistance, structural span, aesthetic appeal |

| Automotive | Body panels, chassis components, structural reinforcements | Advanced high-strength steel, aluminum alloys | Crash performance, weight reduction, formability |

| Electronics | Enclosures, chassis, heat sinks, brackets | Aluminum, steel, stainless steel | EMI shielding, thermal management, precision tolerances |

| Aerospace | Skin panels, structural members, interior components | Aerospace aluminum alloys, titanium | Minimum weight, fatigue resistance, certification compliance |

Each industry prioritizes different performance factors based on application demands. HVAC systems emphasize airtightness and cleanability. Construction focuses on weather resistance and longevity. Automotive balances crash safety with weight reduction. Understanding these sector-specific priorities helps you communicate effectively with fabricators and specify products that meet real-world performance requirements.

With industry applications clarified, you're ready to explore how custom sheet metal products move from initial concept through prototyping to full-scale production.

The Product Development Lifecycle for Custom Sheet Metal

You've identified the perfect material and understand how fabrication processes work. Now comes the real challenge: transforming your concept into production-ready components. Whether you're developing a single prototype or preparing for thousands of units, the journey from idea to factory floor follows a predictable path—one that rewards careful planning at every stage.

From Concept Design to Engineering Specifications

Every successful sheet metal product starts with a clear design intent. But here's what separates good designs from great ones: considering manufacturability from day one. Design for Manufacturability (DFM) principles help engineers create parts that not only function as intended but also fabricate efficiently and cost-effectively.

What does DFM look like in practice? According to Approved Sheet Metal's DFM guidelines, three fundamental considerations shape successful designs:

- Uniform wall thickness: Your fabricator will produce parts from single sheets with consistent thickness (typically 0.010" to 0.25" thick). Complex designs requiring variable thickness need alternative approaches like machining or multi-component assemblies.

- Proper notch and tab dimensions: Notches should measure at least the material thickness or 0.04" (whichever is greater) and extend no longer than 5x the material width. Tabs require at least 2x material thickness or 0.126" minimum.

- Appropriate bend radii and hole sizes: Standard tooling produces specific bend radii and hole diameters. Designing within these parameters avoids costly custom tooling.

Why invest time in DFM early? Because design flaws discovered during prototyping cost far less to fix than those found in production. Features that seem minor—tight tolerances, deep bends, or intricate cutouts—can dramatically increase per-unit costs and slow down manufacturing if not optimized beforehand.

Steel fabricators and metal fab shops appreciate receiving designs that account for real-world manufacturing constraints. When you specify standard bend radii, hole sizes, and material thicknesses, your parts can be produced using automated processes like CNC press brakes and turret punching—maintaining quality while reducing variability.

Rapid Prototyping for Sheet Metal Products

Once your design is ready, prototyping transforms digital models into physical parts you can hold, test, and refine. This stage serves multiple critical functions: validating fit and function, testing aesthetic appearance, and gathering market feedback before committing to production tooling.

How quickly can you get prototypes in hand? Speed varies dramatically between suppliers. Some fabrication shops near me might quote weeks for simple parts, while specialized metal fabricators near me deliver precision prototypes in days. According to Approved Sheet Metal, shops with in-stock materials and efficient operations can expedite prototypes in as few as 2-5 days for standard gauges of steel, stainless, galvanized, and aluminum.

What enables such rapid turnaround? Several factors combine:

- Material availability: Shops maintaining inventory of popular gauges eliminate sourcing delays

- Advanced equipment: Fiber lasers cutting at 866 inches per minute versus traditional CO2 lasers at 60 inches per minute

- Integrated capabilities: In-house welding, finishing, and assembly prevent handoff delays between vendors

- Responsive communication: Quote turnaround within 4 hours accelerates project initiation

Prototype quantities typically range from 1-25 units. At this stage, you might discover you've overengineered certain features or specified tolerances tighter than necessary. Good fabrication partners help identify these optimization opportunities—potentially saving significant costs when you scale to production volumes.

Services like send cut send and similar online platforms have democratized access to rapid prototyping, allowing engineers to upload designs and receive quotes almost instantly. However, for complex assemblies or projects requiring DFM guidance, working directly with experienced metal fabricators often yields better results.

Scaling From Prototype to Mass Production

Your prototype works perfectly. Customer feedback confirms market demand. Now what? Scaling from prototype to mass production requires rethinking nearly every aspect of your manufacturing approach.

The sequential steps in product development follow this progression:

- Design and engineering: Create initial concepts incorporating DFM principles and material specifications

- Prototype fabrication: Produce 1-25 units for testing form, fit, function, and market validation

- Design optimization: Refine based on prototype feedback, eliminating features that complicate manufacturing

- Batch production: Manufacture quantities from 25 to several thousand units, validating process consistency

- Mass production: Scale to thousands or higher with dedicated tooling and automation

Each transition brings new considerations. During batch production (quantities from 25 to thousands), the attention paid to DFM in prototyping begins paying dividends. According to Approved Sheet Metal's manufacturing insights, custom tooling costs become significant at this stage—strategically designed prototypes using standard tooling avoid this expense entirely.

Mass production represents an entirely different manufacturing mindset. High-quality tooling and automation capabilities become essential. A metal fab shop specializing in mass production might dedicate entire lines and tooling sets to single projects, accommodating the volume requirements efficiently.

Surface finishing decisions made during prototyping directly impact production scaling. Account for coating thickness in hole sizes and clearances, specify masking requirements for mating surfaces, and consider pre-finished materials to reduce post-processing time.

Not every fabrication shop handles all production stages equally well. Some excel at prototyping and batch production but lack the automation for mass volumes. Others focus exclusively on high-volume runs and won't accept small prototype orders. Understanding where your project falls in this lifecycle helps you identify the right manufacturing partners from the start.

With product development fundamentals established, you're equipped to tackle the practical decisions that determine project success: selecting the right materials, gauges, and finishes for your specific application requirements.

How to Choose the Right Sheet Metal Product

You've explored materials, manufacturing processes, and industry applications. Now comes the moment of truth: specifying exactly what you need. Choosing the right sheet metal product involves balancing multiple factors—material properties, thickness requirements, surface finishes, and environmental conditions—to arrive at a specification that performs reliably without overengineering costs into your project.

Before requesting quotes or contacting suppliers, work through this checklist of essential questions:

- What mechanical loads will the part experience during use?

- Will the component face outdoor exposure, moisture, or chemical contact?

- What temperature range must the product withstand?

- Are there weight restrictions driving material selection?

- What surface appearance does the application require?

- How tight must dimensional tolerances be for proper fit and function?

- What production volumes do you anticipate over the product lifecycle?

Answering these questions upfront prevents costly mid-project changes and ensures your specifications align with real-world performance demands.

Matching Material Properties to Application Needs

Sounds complex? It doesn't have to be. Start by identifying your primary performance requirement, then narrow options from there.

When corrosion resistance tops your priority list, environmental exposure dictates material choice. Indoor applications with minimal humidity might get by with carbon steel and a simple powder coat finish. Outdoor installations demand galvanized steel, aluminum, or stainless steel depending on severity. Marine or chemical processing environments typically require 316 stainless steel or anodized aluminum to withstand salt spray and acidic compounds.

If weight reduction drives your decision, aluminum alloys deliver approximately one-third the weight of equivalent steel components. This advantage compounds in transportation applications where every pound affects fuel efficiency. However, aluminum costs more per pound than steel—run the numbers to confirm weight savings justify the material premium.

For high-strength applications, advanced high-strength steels provide exceptional performance in safety-critical components. Automotive chassis parts, structural reinforcements, and impact-resistant enclosures benefit from materials engineered specifically for demanding mechanical loads.

Thermal considerations also influence selection. Aluminum's excellent thermal conductivity makes it ideal for heat sinks and heat exchangers. Conversely, applications requiring thermal insulation might benefit from steel's lower conductivity or the addition of insulating barriers.

Understanding Gauge Selection and Thickness Requirements

Here's where many buyers stumble: gauge sizes don't translate directly to inches or millimeters, and the relationship varies between materials. According to Ryerson's steel gauge chart guide, gauge numbers originated in the 19th century British wire industry—and the system stuck despite attempts to replace it with metric measurements.

The fundamental rule? Higher gauge numbers indicate thinner material. But the decimal equivalents differ based on metal type:

- 14 gauge steel thickness: Approximately 0.0747 inches (1.90 mm)

- 14 gauge stainless steel: Approximately 0.0751 inches (1.91 mm)

- 14 gauge aluminum: Approximately 0.0641 inches (1.63 mm)

This variation matters enormously when specifying parts. A sheet metal gauge chart for your specific material ensures accurate communication with fabricators. Never assume gauge equivalency across different metals.

What about 11 gauge steel thickness? At approximately 0.1196 inches (3.04 mm), 11 gauge represents a substantial step up in rigidity and weight compared to thinner options. You'll find this heavier gauge in structural applications, heavy equipment enclosures, and components requiring exceptional durability.

When selecting gauge, balance these competing factors:

- Structural requirements: Thicker gauges resist deflection under load but add weight and cost

- Formability: Thinner materials bend more easily with tighter radii; thick stock requires larger bend allowances

- Fabrication limitations: Your fabricator's equipment has maximum thickness capabilities for cutting and forming

- Cost implications: Material costs scale directly with thickness; doubling gauge roughly doubles material expense

Consulting a gauge size chart early in design prevents specifying thicknesses that complicate fabrication or exceed equipment capabilities.

Surface Finish and Coating Considerations

Your application environment determines which surface treatments provide adequate protection—and which represent unnecessary expense. Indoor components in climate-controlled settings might need nothing more than a basic painted finish. Outdoor installations demand more robust protection.

Powder coat finishes have become the default choice for many applications. The electrostatically applied powder melts and cures into a durable, uniform coating that resists chipping, scratching, and fading. Unlike liquid paint, powder coating produces no volatile organic compounds during application—an environmental advantage that also simplifies regulatory compliance.

According to SAF's coating comparison, powder coatings made from the same resin and pigment as liquid coatings deliver practically identical performance characteristics. The primary difference lies in application technique and batch size requirements—powder typically requires larger minimum orders than custom-mixed liquid paints.

For aluminum applications, anodized finishes offer unique advantages. Unlike coatings that sit on the surface, anodizing creates an integral oxide layer that cannot peel or flake. This electrochemical process produces finishes proportionally durable to their thickness—Class I anodizing (0.7 mils) lasts roughly twice as long as Class II (0.4 mils) in exterior applications.

What makes anodizing particularly appealing? Its renewability. When anodized surfaces appear to have failed after years of exposure, cleaning often restores their original appearance—something impossible with organic coatings that must be completely stripped and reapplied.

However, anodizing has limitations. Its Achilles heel is chemical resistance; acidic pollutants in urban environments eventually degrade even thick anodic coatings. For applications facing harsh chemical exposure, PVDF (polyvinylidene fluoride) coatings deliver superior chemical resistance and color consistency across the widest range of hues.

Match your finish selection to real environmental demands:

- Indoor, low-wear applications: Standard paint or light powder coat provides adequate protection at minimal cost

- Outdoor, moderate exposure: Quality powder coat or Class II anodizing delivers years of reliable service

- High-abrasion areas: Anodizing's superior hardness outlasts organic coatings on door frames, kick plates, and frequently touched surfaces

- Coastal or industrial environments: Class I anodizing, PVDF coatings, or marine-grade stainless steel withstand aggressive conditions

- Chemical exposure: PVDF coatings or appropriate stainless steel grades resist degradation from acids and chlorides

Remember that surface finish decisions made during prototyping carry through to production. Account for coating thickness in hole clearances, specify masking for mating surfaces, and verify that your chosen finish meets applicable industry standards for your market sector.

With material, gauge, and finish decisions clarified, you're prepared to evaluate suppliers based on their quality certifications and manufacturing capabilities.

Quality Standards and Certifications to Look For

You've selected the right material, specified the correct gauge, and chosen an appropriate finish. But how do you know the fabricator you're considering can actually deliver parts that meet your specifications? The answer lies in understanding quality standards, certifications, and the inspection processes that separate reliable suppliers from those cutting corners.

Quality in sheet metal manufacturing isn't subjective—it's documented, audited, and certified. When evaluating potential suppliers, look beyond marketing claims to the certifications hanging on their walls and the systems driving their operations.

Industry Certifications That Signal Quality

Not all certifications carry equal weight. Some represent baseline competency while others indicate world-class quality management systems. Understanding what each certification actually means helps you match supplier capabilities to your application requirements.

- ISO 9001: The foundational quality management standard applicable across industries. Certification demonstrates documented processes, consistent procedures, and commitment to continuous improvement. Consider this the minimum expectation for professional fabricators.

- ISO 14001: Focuses on environmental management systems. Relevant when your organization requires suppliers to demonstrate environmental responsibility and sustainable manufacturing practices.

- AS9100: The aerospace industry's quality standard building on ISO 9001 with additional requirements for traceability, configuration management, and risk mitigation. Essential for any components destined for aircraft or aerospace applications.

- IATF 16949: The automotive industry's gold standard for quality management, representing the most rigorous certification for sheet metal suppliers serving the transportation sector.

Why does IATF 16949 matter so much? According to Xometry's certification guide, this standard was developed by the International Automotive Task Force specifically for automotive manufacturers and suppliers. Unlike general quality standards, IATF 16949 doubles down on creating consistency, safety, and quality across automotive products—from steel plates used in chassis construction to precision-stamped stainless steel sheet metal components in brake assemblies.

The certification process itself indicates supplier commitment. Organizations pursuing IATF 16949 undergo both internal audits and rigorous external assessments. The audit criteria span seven detailed sections covering everything from leadership and planning to performance evaluation and continuous improvement. Certification is binary—a company either meets all requirements or doesn't receive the credential.

What does this mean practically? When you source from an IATF 16949-certified supplier, you're working with an organization that has proven its ability to limit defects, reduce waste, and maintain consistent quality across production runs. For automotive chassis, suspension, and structural components, this certification isn't optional—it's the entry ticket to serious consideration.

Understanding Tolerance and Precision Standards

Certifications tell you about systems and processes. Tolerance specifications tell you about actual part performance. Every sheet metal product carries dimensional requirements—and understanding tolerance classes helps you specify what you actually need without overengineering costs into your project.

Tolerances in sheet metal fabrication fall into several categories:

- Dimensional tolerances: How closely finished dimensions match specified values. Tighter tolerances require more precise equipment, slower processing, and additional inspection—all adding cost.

- Flatness tolerances: Acceptable deviation from a perfectly flat plane. Critical for mating surfaces and assembly applications.

- Angular tolerances: Permissible variation in bend angles. Standard press brake operations typically achieve ±0.5 degrees; tighter requirements demand specialized equipment.

- Hole location tolerances: Positional accuracy for punched or laser-cut features. Modern CNC equipment routinely achieves ±0.005" positioning.

The key insight? Specify only the tolerances your application actually requires. Calling out ±0.001" when ±0.010" would function perfectly adds inspection burden and rejects parts that would perform identically in your assembly. Review your fit and function requirements carefully before specifying precision levels.

For galvanized sheet metal and other coated materials, remember that coating thickness affects final dimensions. A heavy powder coat or zinc galvanizing layer can add several thousandths of an inch to finished surfaces—tolerance specifications should account for these additions when tight fits matter.

Quality Control in Sheet Metal Manufacturing

Certifications and tolerance specifications mean nothing without robust quality control processes backing them up. According to All Precision Metals, quality control in sheet metal fabrication begins long before any cutting or forming occurs—it starts with incoming material inspection.

A comprehensive quality control program addresses multiple checkpoints:

- Material verification: Confirming incoming metal matches specifications for alloy composition, temper, and thickness. Reputable suppliers provide mill certifications documenting material properties including tensile strength, yield strength, and chemical composition.

- In-process inspection: Checking critical dimensions during production rather than waiting until completion. This approach catches deviations before they propagate through subsequent operations.

- Visual inspection: Trained inspectors examining surface condition, edge quality, and overall workmanship. Some defects only reveal themselves under proper lighting and close examination.

- Performance testing: For critical applications, physical testing verifies that finished components meet mechanical requirements. Testing may include tensile strength measurements, hardness testing, and evaluation of temperature influence on material properties.

- Final dimensional verification: Comparing finished parts against specifications using calibrated measurement equipment. Coordinate measuring machines (CMMs) provide precise three-dimensional verification for complex geometries.

When evaluating suppliers, ask about their inspection capabilities and frequencies. Do they sample inspect or verify every part? What measurement equipment do they maintain, and how often is it calibrated? How do they handle non-conforming material?

For anodized aluminum components, quality control extends to coating verification. Thickness measurements, adhesion testing, and colorfastness evaluation ensure that surface treatments meet specifications and will perform as expected in service.

The best fabricators view quality control not as a cost center but as an investment in customer relationships and operational efficiency. Catching defects early costs far less than shipping non-conforming parts that require rework, replacement, or—worst case—fail in the field.

With quality standards understood, you're ready to evaluate where and how to source sheet metal products that meet your specific requirements.

Sourcing Sheet Metal Products Effectively

You've identified the right material, specified tolerances, and verified quality requirements. Now comes the practical question: where should you actually buy sheet metal products? The answer depends on your project's unique combination of volume, complexity, timeline, and technical support needs. Whether you're searching for sheet metal near me or evaluating global manufacturing partners, understanding your sourcing options prevents costly mismatches between supplier capabilities and project requirements.

Local Suppliers Versus Specialized Manufacturers

When you type "sheet metal companies near me" into a search engine, you'll find everything from small job shops to regional distributors. Local suppliers offer distinct advantages—but they're not always the right fit for every project.

According to Zetwerk's fabrication partner analysis, local metal fabrication shops excel at communication, accessibility, and quick-turnaround projects. You can visit facilities in person, inspect quality firsthand, and resolve issues through face-to-face conversations. When last-minute design changes arise, proximity means faster revisions and shorter delivery times.

However, local options may have limitations. Smaller shops might lack specialized equipment for complex geometries or advanced materials. Their capacity may not support high-volume production runs. And while you avoid international shipping complications, you might pay premium rates compared to larger-scale manufacturers.

Specialized manufacturers occupy the opposite end of the spectrum. These facilities invest in advanced equipment, maintain rigorous certifications, and build expertise in specific industries or processes. For automotive applications, a specialized partner like Shaoyi (Ningbo) Metal Technology delivers IATF 16949-certified quality with 5-day rapid prototyping, comprehensive DFM support, and 12-hour quote turnaround—capabilities that general-purpose shops simply cannot match.

How do you decide between local and specialized? Consider these factors:

- Project complexity: Simple brackets and enclosures work well with local fabricators; precision automotive stamping demands specialized expertise

- Volume requirements: Prototype and small-batch work suits local shops; mass production benefits from automation and dedicated tooling

- Industry certifications: Automotive, aerospace, and medical applications require specific certifications that not every shop maintains

- Technical support needs: Complex projects benefit from engineering partnerships; straightforward orders just need reliable execution

Evaluating Lead Times and Production Capacity

Lead time can make or break your project timeline. According to Fry Steel's supplier comparison guide, longer-than-anticipated lead times create massive bottlenecks, contributing to greater downtime and production delays.

When comparing metal fabrication near me options, investigate what actually drives their quoted timelines:

- Material availability: Does the supplier stock common gauges and alloys, or must they order metal plate and sheet metal for sale from distributors? In-stock inventory can shave days or weeks off delivery.

- Equipment capacity: Busy shops queue orders based on machine availability. Ask about current backlog and typical wait times before production begins.

- Value-added services: Suppliers offering in-house finishing, welding, and assembly eliminate handoffs between vendors—each transition adds delay risk.

- Geographic location: Distant suppliers add shipping transit time. However, a specialized manufacturer with faster production may still beat a local shop with longer processing queues.

Production capacity matters equally. As Howard Precision Metals emphasizes, if you end up working with a supplier unable to accommodate your order requests or do so within expected timelines, this can negatively impact both production and profits.

Develop a realistic project timeline before contacting suppliers. Share your volume projections, delivery milestones, and any flexibility in scheduling. This transparency helps potential partners evaluate whether they can genuinely meet your needs—and helps you identify mismatches before they become problems.

Getting Quotes and Comparing Suppliers

Requesting quotes seems straightforward, but the process reveals significant differences between suppliers. How quickly do they respond? How thoroughly do they review your specifications? Do they ask clarifying questions or simply quote whatever you submitted?

According to Howard Precision Metals' evaluation criteria, it can be challenging to obtain accurate quotes without understanding your own budget and requirements first. Before reaching out to potential sheet metal suppliers, clarify:

- Complete part specifications including material, gauge, tolerances, and finish requirements

- Anticipated quantities for initial orders and ongoing production

- Required certifications and quality documentation

- Delivery timeline and any critical milestones

- Budget constraints and flexibility for value engineering

Quality metal products deserve quality evaluation. When quotes arrive, look beyond unit price to understand total cost of ownership. Consider shipping costs, packaging requirements, inspection documentation, and payment terms. A slightly higher per-piece price from a reliable supplier often costs less than chasing delays, managing defects, or expediting replacement orders from a cheaper but less capable source.

Pay attention to responsiveness during the quoting process—it signals how communication will flow throughout your relationship. Suppliers who take days to return calls or weeks to provide quotes rarely improve after you've placed orders.

| Source Type | Best For | Typical Lead Time | Technical Support Level | Volume Suitability |

|---|---|---|---|---|

| Specialized Automotive Manufacturer (e.g., Shaoyi) | Precision automotive stamping, chassis and suspension components requiring IATF 16949 certification | 5-day rapid prototyping; 12-hour quote turnaround | Comprehensive DFM support, engineering collaboration | Prototype through automated mass production |

| Local Job Shop | Simple parts, quick turnaround projects, prototype iterations | 1-3 weeks typical | Basic fabrication guidance | Prototype to low-volume batch production |

| Regional Fabricator | Medium-complexity parts, moderate volumes, regional delivery | 2-4 weeks typical | Moderate; depends on shop expertise | Low to medium volume production |

| Metal Distributor | Raw sheet metal for sale, standard shapes and sizes | Days to 2 weeks depending on stock | Material selection assistance only | Any volume; no fabrication services |

| Online Fabrication Platform | Standard parts, price transparency, digital workflow | 1-3 weeks depending on complexity | Automated DFM feedback; limited engineering support | Prototype to medium volume |

The right sourcing strategy often combines multiple supplier relationships. You might use a local shop for rapid prototyping and design iterations, then transition to a specialized manufacturer for production volumes. Or you might source raw metal plate from a distributor while partnering with a certified fabricator for value-added processing.

Whatever approach you choose, remember that supplier relationships extend beyond individual transactions. According to Howard Precision Metals, one major key to developing an enduring relationship is the attentive customer service your supplier provides. Take note of how they communicate, whether you have consistent points of contact, and how quickly they respond to inquiries.

When you find suppliers who understand your industry, maintain appropriate certifications, and communicate responsively, you've found partners worth keeping—even if their prices aren't always the absolute lowest. The cost of switching suppliers, requalifying parts, and managing learning curves often exceeds modest price differences between capable vendors.

Armed with this sourcing knowledge, you're prepared to transform sheet metal specifications into finished products that meet your quality, timeline, and budget requirements. The journey from raw material to your factory floor involves many decisions—but with the right partners, each step becomes more manageable and more predictable.

Frequently Asked Questions About Sheet Metal Products

1. What products are made from sheet metal?

Sheet metal products span virtually every industry. Common examples include HVAC ductwork, automotive body panels and chassis components, roofing and siding for construction, electronic enclosures and heat sinks, aircraft skin panels, kitchen equipment, and custom brackets. The material's formability allows manufacturers to create everything from simple flat panels to complex three-dimensional assemblies for automobiles, appliances, furniture, and industrial equipment.

2. What are the 5 sheet metal operations?

The five primary sheet metal operations are shearing (straight cuts using opposing blades), blanking (cutting flat shapes from sheet stock), punching (creating holes or openings), bending (forming angles using press brakes), and drawing (stretching material into three-dimensional shapes). Additional operations include stamping, roll forming, embossing, and various joining techniques like welding and riveting that complete the fabrication process.

3. How do I choose the right sheet metal material for my project?

Material selection depends on your application's primary requirements. For corrosion resistance, choose galvanized steel for outdoor use, 304 stainless for general applications, or 316 stainless for marine environments. When weight matters, aluminum alloys offer one-third the weight of steel. For high-strength applications, advanced high-strength steels excel. Consider also thermal conductivity, cost constraints, and required surface finishes when making your final selection.

4. What certifications should I look for in a sheet metal supplier?

ISO 9001 represents the baseline quality management standard for professional fabricators. For automotive applications, IATF 16949 certification is essential—it indicates rigorous quality systems specifically designed for transportation components. Aerospace projects require AS9100 certification. Additionally, verify suppliers maintain calibrated inspection equipment, documented quality control processes, and can provide mill certifications for material traceability.

5. What is the difference between sheet metal gauge sizes?

Gauge numbers indicate material thickness, with higher numbers representing thinner material. However, gauge equivalents vary by metal type—14 gauge steel measures approximately 1.90 mm while 14 gauge aluminum is only 1.63 mm. Common gauges range from 30 gauge (very thin) to 7 gauge (thick structural applications). Always confirm actual thickness measurements in millimeters or inches when specifying materials, as gauge standards differ between steel, stainless steel, and aluminum.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —