4032 vs 2618 Forged Piston Material: Which Alloy Survives Your Build?

The Piston Alloy Decision That Defines Your Build

Every performance engine build eventually arrives at the same crossroads: which forged piston material will survive your specific application? The choice between 4032 vs 2618 pistons isn't just a technical specification—it's a decision that directly shapes your engine's longevity, maximum power ceiling, and long-term maintenance requirements. Get it right, and your build performs flawlessly for years. Get it wrong, and you're looking at premature wear, costly rebuilds, or worse.

Why Your Piston Alloy Choice Matters More Than You Think

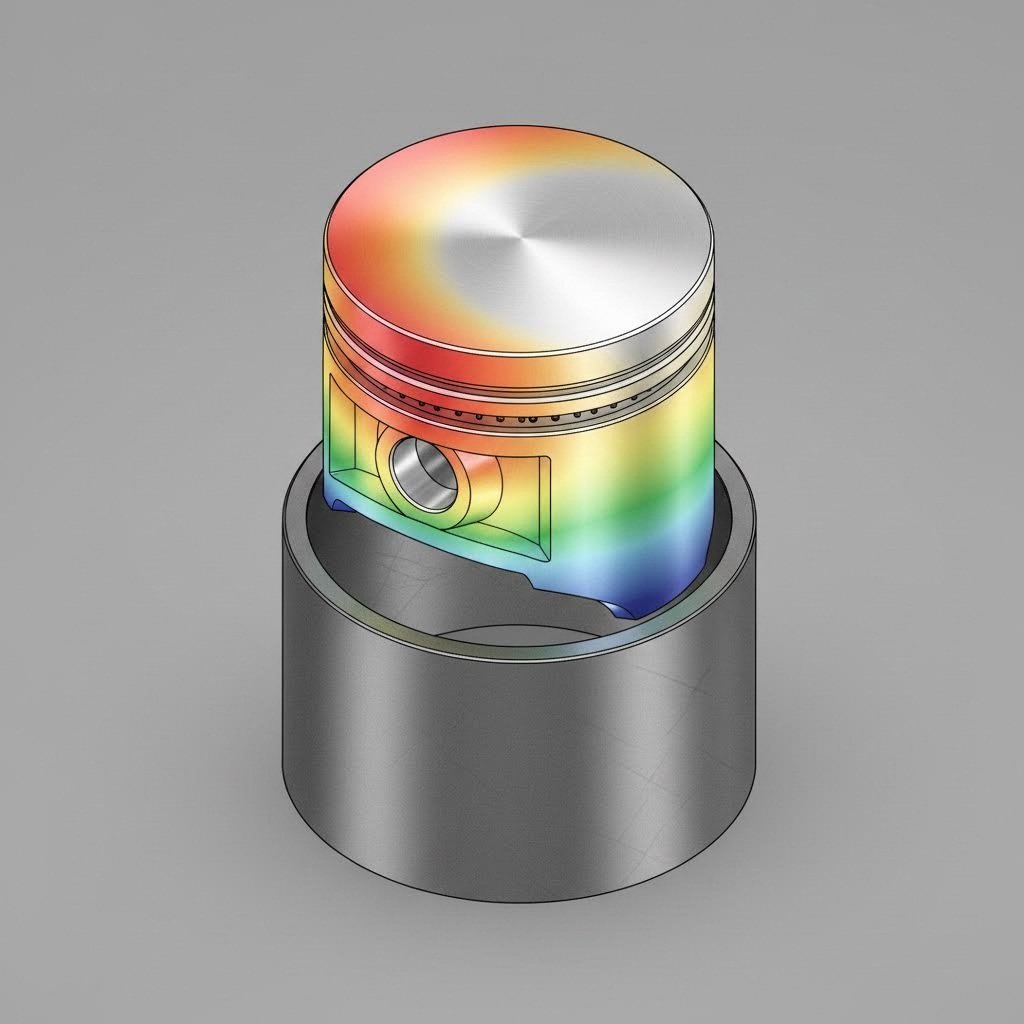

Pistons endure some of the most brutal conditions inside any engine. According to JE Pistons, these components face violent combustion explosions reaching upwards of 1,000°F, followed immediately by blasts of cool air during intake strokes. They move at varying speeds while resisting immense forces threatening to drive them through cylinder walls. Now imagine adding boost or aggressive timing to that equation.

When comparing 2618 vs 4032 pistons, you're essentially weighing two fundamentally different approaches to handling these extreme conditions. One prioritizes dimensional stability and quiet operation. The other sacrifices refinement for survival under the harshest abuse. Neither is universally "better"—but one is definitely right for your specific build goals.

The Hidden Cost of Choosing Wrong

Here's what most builders discover too late: mismatching piston material to your actual use case creates problems that compound over time. Choose 4032 alloy for a high-boost application, and you risk cracking under detonation events. Select 2618 for a daily driver, and you'll live with cold-start noise, accelerated ring wear, and more frequent rebuilds. The piston material decision ripples through every aspect of engine behavior—from how quickly you can get on the throttle after startup to how many track days you'll see before needing a refresh.

Think about it this way: a mustang gt 0-60 run puts serious stress on pistons during those initial moments when temperatures are still climbing. The wrong alloy with improper clearances can suffer during exactly these transitional conditions.

Beyond Marketing Claims: What Actually Differs

Most content covering forged piston alloys falls into one of two camps. You'll find purely theoretical comparisons focused on metallurgical properties—interesting but disconnected from real-world application. Or you'll encounter enthusiast forum discussions heavy on anecdotal experience but light on specifications. This guide bridges both perspectives.

Throughout this comparison, we'll cover specific piston-to-wall clearance specifications, break-in procedure differences between alloys, and platform-specific recommendations that go far beyond generic "forced induction vs naturally aspirated" guidance. Whether you're building a weekend warrior or a dedicated track machine, understanding the real differences between these alloys ensures your piston choice matches your actual driving intentions—not just your aspirational build goals.

How We Evaluate Forged Piston Alloys

Comparing 4032 aluminum to 2618 aluminum requires more than glancing at spec sheets. These alloys behave differently under heat, stress, and extended use—and understanding why demands a structured evaluation framework. Before diving into application-specific recommendations, let's establish the five core criteria that actually matter when selecting forged piston material for your build.

- Thermal Expansion Characteristics: How much the piston grows as temperatures climb directly determines required piston-to-wall clearances and cold-start behavior.

- Silicon Content and Metallurgical Impact: The percentage of silicon fundamentally alters expansion rates, wear resistance, and ductility—making this the primary differentiator between alloys.

- Tensile Strength at Operating Temperatures: How well the material maintains structural integrity under extreme heat determines survival in high-stress applications.

- Thermal Conductivity for Heat Dissipation: The alloy's ability to transfer heat away from combustion surfaces affects ring land temperatures and overall durability.

- Wear Pattern Longevity: How quickly ring grooves, skirts, and pin bores degrade under normal operation dictates rebuild intervals and long-term reliability.

Thermal Expansion: The Primary Differentiator

When you're wondering what are pistons made of and why it matters, thermal expansion tells most of the story. According to JE Pistons, a 2618 piston will expand 15 percent more than a comparable 4032 version. That's not a subtle difference—it fundamentally changes how each alloy must be installed and operated.

Higher expansion rates mean looser cold clearances. Looser clearances mean audible piston slap during cold starts and extended warm-up periods. For a daily driver, this matters. For a dedicated race engine that reaches operating temperature before leaving the pits, it's irrelevant. Your cooling system components—whether you're running a stock setup or upgraded CSF radiator—work to stabilize these temperatures, but the alloy's inherent expansion behavior determines baseline clearance requirements.

Silicon Content and What It Actually Does

Here's where the metallurgy gets interesting. 4032 aluminum contains approximately 11-12% silicon, while 2618 aluminum carries only 0.8-1.2%. This isn't a minor formulation tweak—it's a completely different approach to piston design philosophy.

Silicon atoms integrate into the aluminum matrix and physically restrict how much the material can expand when heated. As Smith's High Performance explains, the high silicon content in 4032 makes manufactured pistons more durable and lighter than if produced in 2618. However, this same silicon content reduces overall ductility, meaning the piston becomes less resistant to high-impact loads like detonation events.

Think of it this way: silicon makes the alloy dimensionally stable but also more brittle under shock loading. The 2618's low silicon content creates a more malleable piston that can absorb punishment without cracking—but at the cost of greater thermal expansion and reduced wear resistance.

Strength Under Heat: Real Operating Conditions

Tensile strength numbers on a spec sheet tell only part of the story. What matters is how each alloy performs at actual operating temperatures—not room temperature laboratory conditions.

The 2618 alloy is renowned for its excellent high-temperature strength, making it the preferred choice for extended wide-open-throttle competition. When combustion temperatures spike during sustained high-load operation, 2618 maintains structural integrity better than 4032. However, 4032 offers the highest tensile strength of all aluminum alloys in the 4000 series at moderate temperatures, making it exceptionally strong for street applications that rarely see prolonged extreme heat.

Ring groove wear provides a practical illustration of these differences. A 4032 piston will maintain proper ring groove clearance and seal for more miles traveled under typical street conditions. But in racing applications where pistons are replaced in the search for ultimate power long before significant wear develops, the 2618's reduced wear resistance becomes irrelevant—while its superior ductility under detonation events becomes critical.

Understanding these evaluation criteria sets the foundation for comparing specific alloy characteristics. With this framework established, let's examine exactly how 4032 performs in its ideal applications.

4032 Alloy Deep Dive and Best Applications

If precision and refinement define your build goals, 4032 aluminum deserves serious consideration. This high-silicon alloy has earned its reputation as the street performance standard for good reason—it delivers tighter tolerances, quieter operation, and exceptional longevity in applications that don't push extreme thermal limits. But understanding exactly where 4032 excels requires examining its behavior from cold start through sustained operation.

Tighter Clearances Mean Quieter Operation

The 4032 alloy's defining characteristic—its high silicon content (11-13.5%)—translates directly into practical benefits you'll notice every time you start your engine. According to JE Pistons, this additional silicon content greatly reduces aluminum's expansion rate, allowing pistons to run with tighter cold clearances.

What does this mean in real numbers? A 4032 piston typically runs 0.0005 to 0.001 inches tighter than a comparable 2618 forging. That might sound insignificant, but it's the difference between a refined cold start and audible piston slap that takes minutes to quiet down. For daily drivers and street machines, this matters every single morning.

Here's how the clearance difference plays out in practice:

- Cold Start Behavior: Tighter clearances mean the piston contacts cylinder walls more consistently before reaching operating temperature, eliminating the characteristic "slap" sound associated with looser-fitting pistons.

- Blow-By Reduction: Better ring seal when cold translates to less combustion gas escaping past the rings during warm-up cycles, protecting oil quality and reducing emissions.

- Ring Stability: Consistent piston-to-wall contact keeps rings properly seated and oriented, promoting better sealing throughout the entire thermal cycle.

Imagine settling into comfortable braum seats for your morning commute—you want that engine experience to match. The 4032's refined cold-start behavior delivers exactly that kind of polished feel from the moment you turn the key.

The Street Performance Sweet Spot

Where does 4032 truly shine? In applications where dimensional stability and long-term durability outweigh the need for extreme abuse tolerance. As Mountune USA explains, 4032 is a more stable alloy that retains characteristics such as ring groove integrity for longer life cycle applications.

This stability makes 4032 the logical choice for several common build scenarios:

- Naturally aspirated performance builds where cylinder pressures remain moderate and detonation risk stays low

- Mild forced induction applications running conservative boost levels with proper tuning

- Daily drivers with performance modifications that still accumulate significant street miles

- Budget-conscious builds prioritizing extended service intervals over maximum power potential

The ring groove wear advantage deserves special attention. Many builders overlook how critical ring groove integrity is for maintaining cylinder seal over time. A 4032 piston will maintain proper ring groove clearance and seal for more miles traveled, directly translating to consistent compression readings and power output throughout the engine's service life. When a ring popped or ring land failure occurs, it's often because the softer 2618 alloy wore beyond acceptable tolerances in high-mileage street applications.

When Precision Matters Most

The 4032 alloy's characteristics create specific advantages that compound over time. Manufacturers like Silvolite pistons and other quality forgings leverage these properties for applications where predictable, long-term performance trumps ultimate abuse resistance.

Pros of 4032 Alloy

- Quieter cold-start operation due to tighter piston-to-wall clearances

- Better ring seal when cold reducing blow-by during warm-up cycles

- Longer ring life in moderate-load applications thanks to superior ring land wear resistance

- Extended rebuild intervals for street-driven engines accumulating real-world miles

- Slightly lighter weight compared to equivalent 2618 designs—even Pro Stock teams have experimented with 4032 for this reason

Cons of 4032 Alloy

- Less forgiving of detonation events due to reduced ductility from high silicon content

- Temperature ceiling limitations making it unsuitable for sustained extreme heat applications

- Not ideal for extreme boost levels where cylinder pressures exceed the alloy's impact resistance

- Cracking risk under high-impact loads if unexpected detonation or mechanical contact occurs

According to JE Pistons, 4032 alloy can be used in performance and even competition applications with excellent results—its reduced ductility simply makes the alloy less resistant to cracking with extreme impact loads such as detonation or unforeseen physical contact than 2618.

For naturally aspirated builds and mild forced induction setups where proper tuning eliminates detonation risk, 4032 delivers a compelling combination of precision, durability, and refined operation. However, when cylinder pressures climb into extreme territory, a different alloy philosophy becomes necessary—which brings us to the 2618's purpose-built approach for high-stress survival.

2618 Alloy Analysis for Extreme Builds

When engine builders push beyond conservative power levels into territory where survival matters more than refinement, 2618 pistons become the obvious choice. This low-silicon alloy exists for one primary purpose: absorbing punishment that would destroy lesser materials. But understanding exactly why race teams and high-boost street builds gravitate toward 2618 requires examining both its exceptional strengths and the trade-offs that come with them.

Built to Survive Abuse

The 2618 alloy's defining characteristic is its remarkable ductility—the ability to deform under stress without cracking. According to Engine Builder Magazine, this very low silicon content (just 0.18% compared to 4032's 12.2%) makes the 2618 piston much more malleable and offers advantages under high load, high stress applications.

What does this mean in practice? When detonation occurs—whether from a momentary lean condition, aggressive timing, or unexpected fuel quality issues—the 2618 piston absorbs the impact energy by deforming slightly rather than cracking catastrophically. A 4032 piston experiencing the same detonation event might develop crown cracks or ring land failures that end your engine's life instantly.

This survival advantage extends beyond just detonation resistance. High cylinder pressures from aggressive boost levels create enormous forces trying to push the piston crown through the skirts. The 2618's superior fatigue endurance (18,000 psi versus 4032's 16,000 psi) means it handles these repeated high-stress cycles without developing the fatigue cracks that eventually sideline less robust forgings.

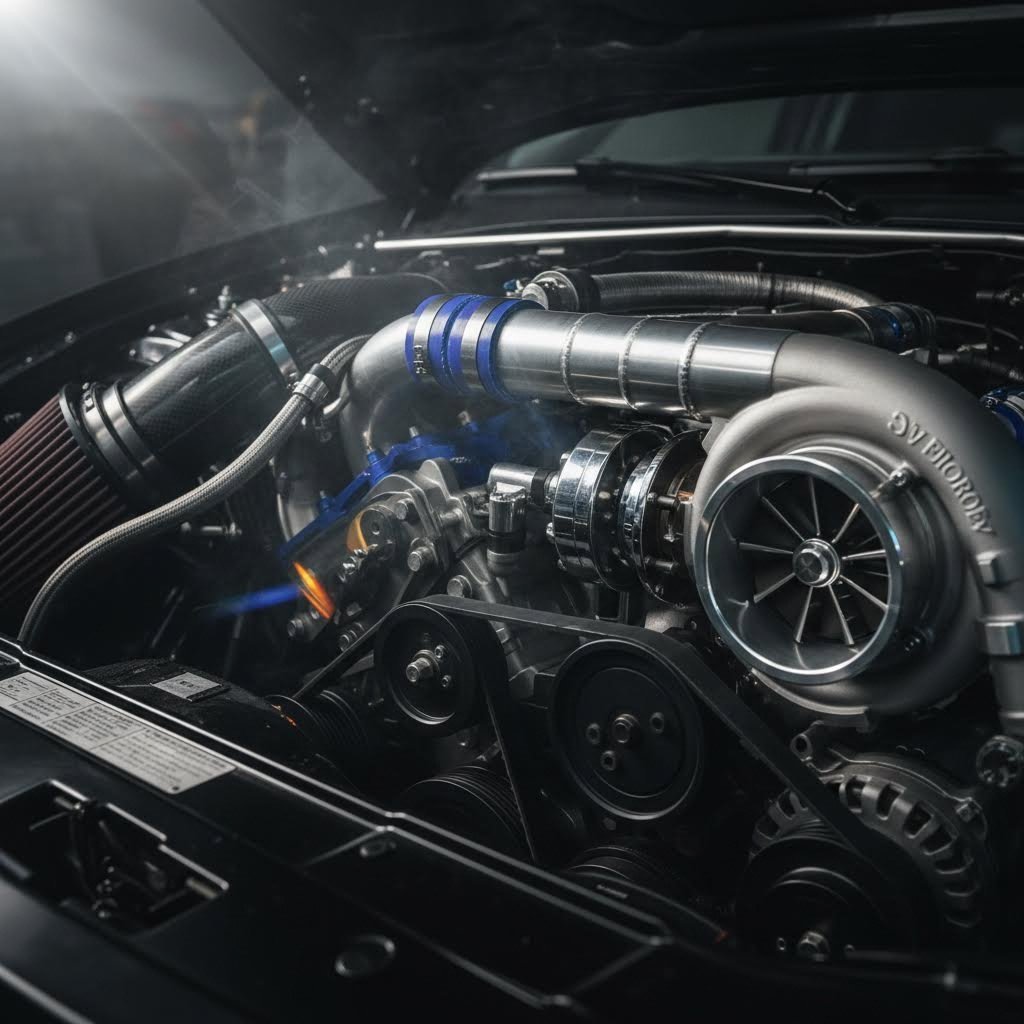

The Forced Induction Standard

For high-boost applications with a front facing plenum intake manifold pushing serious airflow, or builds equipped with a Tial BOV managing boost transitions, 2618 aluminum has become the de facto standard. As Mountune USA confirms, 2618 is used for high boost and extreme-duty racing applications such as Touring Car, Formula, and Rally.

The alloy's material specifications tell the story clearly:

| Characteristic | 2618 Alloy | Advantage |

|---|---|---|

| Tensile Strength | 64,000 psi | 16% stronger than 4032 |

| Yield Strength | 54,000 psi | 17% higher than 4032 |

| Fatigue Endurance | 18,000 psi | 12.5% better than 4032 |

| Melting Point | 1,020 – 1,180°F | Higher ceiling than 4032 |

These numbers explain why builds running e85 fueling with upgraded Hellcat fuel pump or Walbro 450 setups overwhelmingly specify 2618 pistons. The combination of alcohol fuel's aggressive combustion characteristics and high boost levels creates exactly the conditions where 2618's ductility provides essential insurance against catastrophic failure.

Oval track racing with methanol presents perhaps the most demanding piston application. Extended wide-open-throttle operation combined with alcohol fuel's higher cylinder pressures makes 2618 the only sensible choice. The alloy is renowned for its excellent high-temperature strength, making it the preferred choice for endurance racing where pistons see sustained punishment that would overwhelm 4032's capabilities.

Why Race Teams Choose 2618

Professional racing operations have converged on 2618 for applications exceeding street-level stress. The reasoning combines several factors beyond raw survival capability.

First, race engines operate at temperature from the moment competition begins. The cold-start noise issues that plague 2618 pistons in street applications become irrelevant when engines are pre-heated before leaving the pits. Second, race engine rebuild intervals are measured in race hours rather than street miles—the 2618's faster wear rate in street use simply doesn't factor into competition schedules.

However, the clearance trade-off deserves honest discussion. A 2618 piston requires significantly looser cold clearances—typically 0.004 to 0.006 inches compared to 4032's 0.0015 to 0.0025 inch range. This 15 percent greater expansion rate mandates the additional room for thermal growth.

Pros of 2618 Alloy

- Survives detonation events that would crack less ductile alloys

- Handles extreme heat with excellent high-temperature strength retention

- Preferred for high-boost applications where cylinder pressures exceed 4032's comfort zone

- Better fatigue resistance under repeated high-stress loading cycles

- Higher tensile and yield strength providing structural advantage under maximum loads

- Anodizing option available for builds requiring extended ring groove durability

Cons of 2618 Alloy

- Noisier cold operation with audible piston slap until reaching operating temperature

- Faster ring wear in street use due to lower silicon content reducing surface hardness

- Requires more frequent rebuilds in daily driver applications accumulating high mileage

- Wider cold clearances creating extended warm-up periods before spirited driving

- Reduced ring groove longevity without anodizing treatment

Remember: despite the differences in piston-to-wall clearances when cold, once the pistons reach operating temperature, both the 2618 and 4032 alloys operate with very similar clearances. The 2618's looser cold clearance simply accommodates its greater thermal expansion.

For builders whose applications genuinely demand 2618's abuse tolerance, these trade-offs represent acceptable compromises. The cold-start noise becomes a reminder that your engine carries serious hardware. The reduced street longevity becomes irrelevant when track-day preparation includes proper warm-up procedures.

Understanding these alloy-specific behaviors sets the stage for making direct specification comparisons—which brings us to the head-to-head data that quantifies exactly how these materials differ across every meaningful metric.

4032 vs 2618 Specification Showdown

You've seen the individual alloy profiles. Now it's time to put them side by side and let the numbers speak. When comparing 4032 vs 2618 forged piston material, having concrete specifications eliminates guesswork and ensures your alloy selection matches your build's actual demands. This head-to-head comparison consolidates the data points that matter most—from thermal behavior to expected service life—into a single reference you can use when planning your next engine project.

Head-to-Head Specification Comparison

The following table compiles verified specifications from MakeItFrom.com and Engine Builder Magazine, providing an objective comparison across every metric that influences piston selection:

| Specification | 4032 Alloy | 2618 Alloy | What This Means |

|---|---|---|---|

| Thermal Expansion Coefficient | 19 µm/m-K | 22 µm/m-K | 2618 expands 15% more, requiring looser clearances |

| Typical Clearance Range | 0.0015 - 0.0025 inches | 0.004 - 0.006 inches | Tighter 4032 clearances mean quieter cold operation |

| Silicon Content | 11 - 13.5% | 0.1 - 0.25% | High silicon reduces expansion but decreases ductility |

| Tensile Strength (UTS) | 55,000 psi (390 MPa) | 64,000 psi (420 MPa) | 2618 offers 16% greater ultimate strength |

| Yield Strength | 46,000 psi (320 MPa) | 54,000 psi (350 MPa) | 2618 resists permanent deformation better |

| Fatigue Endurance | 16,000 psi | 18,000 psi | 2618 survives more stress cycles before failure |

| Maximum Mechanical Temperature | 200°C (392°F) | 210°C (410°F) | 2618 maintains strength at higher temperatures |

| Melting Range | 990 - 1,060°F | 1,020 - 1,180°F | 2618 has higher thermal ceiling |

| Thermal Conductivity | 140 W/m-K | 160 W/m-K | 2618 dissipates heat slightly faster |

| Detonation Resistance | Moderate | Excellent | 2618's ductility absorbs impact without cracking |

| Street Service Life | Extended (50,000+ miles) | Moderate (25,000-40,000 miles) | 4032's wear resistance favors high-mileage use |

| Race Service Life | Adequate | Extended | 2618 handles repeated abuse in competition |

| Relative Cost | Standard aftermarket pricing | 10-20% premium | 2618 costs more due to manufacturing complexity |

The Numbers That Matter

Looking at raw specifications reveals why each alloy dominates specific applications. The 2618's superior tensile strength (64,000 psi versus 55,000 psi) and yield strength (54,000 psi versus 46,000 psi) explain its preference in high-stress environments. When cylinder pressures spike during boost onset or aggressive timing, that additional structural capacity provides essential margin against failure.

However, strength numbers alone don't tell the complete story. The 4032's dramatically lower thermal expansion coefficient (19 µm/m-K versus 22 µm/m-K) creates practical advantages that compound during real-world operation. That 15% reduction in thermal expansion translates directly into the tighter clearance specifications you see in the table—and those tighter clearances deliver tangible benefits:

- Reduced cold-start piston slap that would otherwise persist for several minutes

- Better ring seal during warm-up reducing blow-by and protecting oil quality

- Longer ring groove life from consistent piston-to-wall contact

- More consistent compression readings throughout the engine's service life

The cost differential deserves attention as well. The 2618 alloy typically commands a 10-20% premium over comparable 4032 forgings. This pricing difference reflects both material costs and manufacturing complexity—the 2618's different heat treatment requirements (including a more lengthy aging process) add production time and expense. For budget-conscious builds where 4032's characteristics suffice, that premium buys capability you may never need.

Choosing Based on Your Actual Use Case

Sounds complex? It doesn't have to be. The specification comparison simplifies into a straightforward decision framework once you honestly assess your build's operating conditions.

Before finalizing your alloy selection, consider running a boost leak tester on your intake system. Even the best pistons can't compensate for boost leaks that create inconsistent cylinder pressures and unpredictable detonation events. Taking time to check for boost leak issues before engine assembly protects your investment regardless of which alloy you choose.

Here's how the data translates into practical recommendations:

Choose 4032 when your build includes:

- Daily driving with occasional spirited use

- Naturally aspirated configurations prioritizing longevity

- Mild forced induction under 12-15 psi with conservative timing

- Budget constraints where the 2618 premium isn't justified

- Cold-climate operation where quiet starts matter

- Extended service intervals between rebuilds (50,000+ miles)

Choose 2618 when your build includes:

- High-boost forced induction exceeding 15 psi

- Aggressive timing curves pushing detonation thresholds

- Dedicated track use with proper warm-up procedures

- Alcohol or E85 fueling with their higher cylinder pressures

- Applications where detonation events are possible despite tuning

- Competition schedules with planned rebuild intervals

Notice how both lists connect alloy selection to actual use patterns rather than theoretical maximums. A spark plug gap tool and spark plug gap gauge might seem like basic equipment, but proper ignition setup—combined with correct piston selection—prevents the detonation events that test your alloy's limits. Similarly, having a helicoil kit available for thread repairs during assembly reflects the practical mindset that keeps builds running reliably.

Remember: despite different cold clearances, both alloys operate with very similar clearances once they reach operating temperature. The specification differences primarily affect cold-start behavior, warm-up requirements, and how each alloy responds to unexpected stress events.

The data clearly shows neither alloy is universally superior. The 4032's dimensional stability and wear resistance make it exceptional for street-driven builds accumulating real miles. The 2618's strength and ductility make it essential for high-stress applications where survival matters more than refinement. Your specific use case—not marketing claims or forum preferences—should drive the decision.

With these specifications established, the next logical question becomes: which alloy fits specific engine platforms? The answer varies significantly depending on whether you're building a BMW N54, an LS V8, or a Japanese import powerplant.

Platform-Specific Piston Alloy Recommendations

Generic "forced induction equals 2618" advice ignores the reality that different engine platforms present unique challenges. Your BMW N55 running a bolt-on turbo upgrade faces completely different thermal and stress conditions than an LS3 making similar power naturally aspirated. Platform-specific guidance helps match piston alloy selection to the actual operating characteristics of your engine—not just theoretical power levels.

BMW N54 and N55 Platform Guidance

The N54 and N55 platforms have become favorites for enthusiasts chasing serious power from turbocharged inline-sixes. But the upgrade path from stock to Stage 2+ dramatically changes piston requirements, and understanding where alloy selection becomes critical prevents expensive mistakes.

For N54 builds staying under 500 wheel horsepower with conservative timing, 4032 pistons can deliver excellent results. The factory turbochargers and mild boost increases don't generate the cylinder pressures that demand 2618's ductility. Many MHD N54 options for tuning focus on optimizing factory hardware, and builds at this level benefit from 4032's tighter clearances and refined cold-start behavior.

However, once you're exploring an N54 single turbo kit pushing beyond 600 horsepower, the equation changes entirely. These builds typically run aggressive boost levels and timing curves where detonation becomes a real possibility despite careful tuning. At this threshold, 2618 becomes essential insurance against catastrophic failure.

The N55 follows similar logic with one consideration: if you're upgrading ignition components—perhaps searching for an N55 Eldor coil part number to address misfires under boost—you're likely pushing the platform hard enough that 2618 makes sense. The N55's single turbo twin-scroll design creates excellent spool characteristics, but builds maximizing that potential generate cylinder pressures that favor 2618's impact resistance.

- Stock to Stage 1 (under 400 whp): 4032 recommended—tighter clearances, quieter operation, extended service life

- Stage 2 to Stage 2+ (400-550 whp): 4032 acceptable with conservative tuning; 2618 preferred for aggressive timing

- Single turbo conversions (550+ whp): 2618 mandatory—cylinder pressures exceed 4032's safe operating envelope

LS and Modern V8 Recommendations

The LS platform's legendary aftermarket support means builders can configure these engines for virtually any application—from mild street cruisers to 1,500+ horsepower monsters. Piston alloy selection must match your actual build intent.

According to Wiseco, their Pro Tru Street pistons forged from certified 4032 aluminum alloy are ideal for street-driven, naturally aspirated LS builds producing up to 750 horsepower. That's a substantial power threshold where 4032's dimensional stability and wear resistance deliver tangible daily-driver benefits without sacrificing performance.

For forced induction LS builds, the picture shifts. Wiseco's Race Engineered Design (RED) Series steps up to high-strength 2618 aluminum for increased resilience under high cylinder pressures, targeting engines running forced induction or nitrous pushing past 1,000 horsepower. Their Professional Series, also forged from 2618 alloy, handles LS builds exceeding 1,500 horsepower with features specifically designed for extreme drag, road course, and endurance racing.

The iron-block LQ4 and LQ9 variants deserve special mention. These "junkyard kings" handle serious abuse exceptionally well, and their robust construction pairs naturally with 2618 pistons for high-boost builds. The extra block weight becomes irrelevant when you're building for maximum power, and the iron's thermal stability complements the 2618's operating characteristics.

- Naturally aspirated street builds (under 750 hp): 4032 delivers excellent longevity and refinement

- Moderate boost street/strip (750-1,000 hp): 2618 recommended for detonation protection

- High-boost dedicated race (1,000+ hp): 2618 mandatory with proper clearances and anodized ring grooves

Import Performance Platforms

Japanese platforms like the 2JZ and EJ25 have earned legendary status in the tuning community, but each presents unique considerations for piston alloy selection.

The 2JZ's reputation for handling extreme power makes it a natural candidate for 2618 pistons in most performance applications. According to MotoIQ, high-boost 2JZ builds typically use JE forged pistons made of tough 2618 low silicon aluminum alloy with CNC machining to tight tolerances. These builds commonly target 800+ horsepower where 2618's ductility provides essential protection against the inevitable tuning adventure that pushes detonation limits.

The Subaru EJ25 presents different challenges. Its boxer configuration creates unique cooling characteristics, and the platform's historical sensitivity to ringland failures makes alloy selection particularly important. For EJ25 builds exceeding 400 horsepower, 2618 pistons help address the platform's tendency toward detonation-related failures. Builds staying under that threshold with conservative tuning can benefit from 4032's tighter clearances and reduced cold-start piston slap.

- 2JZ street builds (under 600 hp): 4032 acceptable with conservative timing; 2618 preferred for peace of mind

- 2JZ high-boost (600+ hp): 2618 mandatory—the platform's boost capability demands impact resistance

- EJ25 moderate builds (under 400 hp): 4032 viable with careful tuning and proper cooling

- EJ25 aggressive builds (400+ hp): 2618 strongly recommended given the platform's detonation sensitivity

Seasonal and Climate Considerations

Here's a factor most piston alloy discussions completely ignore: ambient temperature dramatically affects clearance requirements and cold-start behavior. Builders in Minnesota face different realities than those in Arizona, and your alloy selection should account for these conditions.

Cold-climate operation amplifies the 2618's piston slap characteristics. Starting your engine at -20°F with 0.005-inch cold clearances means extended warm-up periods before the noise subsides. For daily drivers in northern climates, this reality makes 4032's tighter clearances particularly attractive—assuming your power goals don't demand 2618's strength.

Conversely, hot-climate builders should consider how sustained high ambient temperatures affect operating clearances. An engine that's already heat-soaked from sitting in Phoenix summer sun reaches operating temperature faster, minimizing 2618's cold-start noise disadvantages while providing full access to its strength benefits.

Machine shop clearance specifications should account for your typical operating environment:

- Cold climates (regularly below 20°F): Consider the tighter end of recommended clearance ranges to minimize extended cold-start noise

- Hot climates (regularly above 90°F): Target the middle of recommended ranges to ensure adequate clearance during heat-soaked restarts

- Extreme temperature swings: Discuss your specific conditions with your machine shop to optimize clearances for your reality

Platform-specific guidance and climate considerations narrow the alloy decision significantly. However, even with proper alloy selection, installation mistakes can undermine your build. Understanding the myths that lead builders astray—and the installation truths that ensure success—completes the knowledge you need for a bulletproof piston choice.

Common Myths and Installation Truths

You've selected the right alloy for your application. But even the perfect piston choice becomes worthless if installation myths lead you astray or clearance mistakes compromise your build. The gap between theoretical material properties and practical installation considerations has ended more engines than most builders realize. Let's separate fact from fiction and establish the installation truths that keep builds running reliably.

Myth: 2618 Is Always Better for Performance

Walk into any performance forum and you'll encounter the persistent belief that 2618 represents the "better" alloy—period. This oversimplification has convinced countless builders to specify 2618 pistons for applications where 4032 would actually deliver superior results.

Here's the reality: according to JE Pistons, there have been Pro Stock teams that experimented with 4032 pistons because the alloy is slightly lighter. When professional drag racing teams—operating at the absolute pinnacle of naturally aspirated performance—consider 4032 for competition, the "2618 is always better" myth falls apart completely.

The scenarios where 4032 genuinely outperforms 2618 include:

- Street engines accumulating real mileage where 4032's superior ring groove wear resistance extends service life significantly

- Naturally aspirated builds where detonation risk remains minimal and dimensional stability matters more than impact resistance

- Cold-climate daily drivers where 2618's extended piston slap during warm-up creates unacceptable noise

- Budget-conscious builds where the 10-20% premium for 2618 buys capability that will never be needed

The truth? Both alloys can be excellent choices—but only when matched to actual use cases. Choosing 2618 for a naturally aspirated street engine means accepting noisier cold starts, faster ring wear, and shorter rebuild intervals for absolutely no benefit. That's not performance—that's misapplication.

The best piston alloy is the one matched to your actual driving patterns—not your aspirational build goals or what you might do "someday." Build for how you'll actually use the engine, not the theoretical maximum you'll likely never approach.

Break-In Procedures Differ Significantly

Different expansion characteristics demand different break-in approaches. Treating a 2618 piston like a 4032 during initial operation—or vice versa—creates problems that may not manifest until thousands of miles later.

According to Wiseco, when the engine is running at operating temperature, every point on the piston skirt and the ring land area has a specified clearance designed to ensure proper function of the piston and associated ring pack. Getting to that operating temperature properly matters tremendously during break-in.

2618 Break-In Requirements:

- Requires more careful heat cycling due to greater thermal expansion

- Multiple warm-up and cool-down cycles help seat rings progressively

- Avoid sustained high-load operation until rings have fully seated

- Extended initial warm-up periods before any spirited driving

- Monitor oil consumption closely during the first 500 miles

4032 Break-In Requirements:

- Can be driven more normally sooner due to tighter initial clearances

- Rings seat faster thanks to more consistent piston-to-wall contact

- Still benefits from varied RPM operation during initial miles

- Shorter warm-up periods acceptable before moderate acceleration

- Generally reaches stable operation faster than 2618

Think of break-in like preparing your workspace before a project—just as you'd position a flooring jack properly before lifting, you need to approach engine break-in with the right procedure for your specific components. Rushing the process or using the wrong approach invites premature wear and reduced longevity.

Clearance Mistakes That Kill Engines

Improper piston-to-wall clearance causes more engine failures than alloy selection errors. Whether you're running 4032 or 2618, clearance mistakes create problems that compound rapidly under operating conditions.

As Wiseco explains, it is universally understood that proper clearance is essential to successful operation, and that too much or too little can easily lead to fatal engine damage. The consequences differ depending on which direction you err:

Too Tight:

- Piston scuffing as thermal expansion eliminates oil film clearance

- Cylinder scoring that requires boring and new pistons

- Potential seizure under sustained high-load operation

- Excessive friction reducing power output even before failure

Too Loose:

- Excessive piston slap accelerating skirt and bore wear

- Ring flutter compromising cylinder seal and power

- Increased blow-by contaminating oil with combustion byproducts

- Unstable ring platform reducing sealing efficiency

Working with your machine shop effectively requires clear communication about your alloy choice and intended application. Bring your piston spec sheets to clearance discussions—don't assume the shop knows which alloy you're running. Confirm measuring location and technique match manufacturer recommendations, since clearance measured at the wrong point creates dangerous false confidence.

Before final assembly, verify clearances yourself using appropriate measuring tools. Just as you'd use a spark plug gapping tool to confirm proper electrode spacing, taking personal responsibility for clearance verification catches errors before they become catastrophic. Apply dielectric grease on spark plugs during installation and apply the same attention to detail throughout your assembly process—details matter.

Consider having your machine shop document the actual measured clearances for each cylinder. This creates a baseline reference for future tear-downs and helps diagnose any issues that develop during operation. Some builders apply spark plug grease during assembly for easier future removal—that same forward-thinking approach to documentation serves your build long-term.

The relationship between theoretical alloy properties and real-world results depends entirely on proper installation. Walnut blasting your intake ports delivers worthless results if your pistons are incorrectly clearanced. Every component in your build must work together, and piston installation represents one of the most critical junctions where attention to detail pays dividends.

With myths busted and installation truths established, the final step is synthesizing everything into clear decision criteria. Your build type, driving patterns, and performance goals point toward one alloy or the other—and the final section delivers the framework to make that call with confidence.

Final Verdict and Smart Selection Guide

You've absorbed the metallurgical differences, examined platform-specific recommendations, and learned the installation truths that separate successful builds from expensive lessons. Now it's time to consolidate everything into a clear decision framework. The 4032 vs 2618 forged piston material choice ultimately comes down to one question: what will your engine actually experience in real-world operation?

Your Build Type Determines Your Alloy

Stop thinking about what your engine could theoretically handle. Start thinking about what it will actually encounter. That mental shift transforms piston alloy selection from an anxiety-inducing decision into a straightforward matching exercise.

Consider how your typical driving session unfolds. Do you fire up the engine on cold mornings and immediately head into traffic? Or does your car sit in a heated pit area reaching operating temperature before the green flag drops? Do you accumulate 15,000 miles annually on varied roads, or does your engine see 50 race hours between scheduled rebuilds? These patterns—not horsepower dreams—should drive your alloy selection.

The builder chasing an N54 engine for sale to build a weekend warrior faces different realities than someone constructing a dedicated drag car. Both might target similar power numbers, but their operational profiles demand different material choices. Recognizing this distinction prevents the common mistake of over-specifying components for conditions that will never materialize.

The Decision Framework

Use these guidelines to match your alloy selection to your actual build intent:

Choose 4032 Alloy When Your Build Includes:

- Daily drivers with mild modifications: The tighter clearances deliver quiet cold starts and refined operation for vehicles accumulating real street miles

- Naturally aspirated builds: Without forced induction's cylinder pressure spikes, 4032's dimensional stability and wear resistance provide tangible longevity advantages

- Street cars with occasional track days: Moderate heat cycles and proper cool-down periods keep 4032 well within its comfort zone

- Budget-conscious builds prioritizing longevity: The 10-20% savings versus 2618 buys capability that aligns perfectly with conservative power goals

- Cold-climate daily operation: 4032's reduced cold-start piston slap matters when you're starting your engine at freezing temperatures every morning

- Classic muscle applications like 390 FE pistons: Heritage builds benefiting from 4032's period-appropriate clearances and refined operation

Choose 2618 Alloy When Your Build Includes:

- Dedicated race engines: Competition schedules with planned rebuild intervals make 2618's faster street wear irrelevant

- High-boost forced induction exceeding 15 psi: Cylinder pressures at these levels demand 2618's superior impact resistance

- Engines running aggressive timing: Pushing ignition advance toward detonation thresholds requires ductile pistons that absorb unexpected events

- Builds where detonation risk exists: Alcohol fuels, variable fuel quality, or tuning experimentation benefit from 2618's forgiveness

- Sustained wide-open-throttle operation: Endurance racing or extended high-load use favors 2618's high-temperature strength

- Builds with upgraded boost management: If you're installing a Tial blow off valve and pushing serious boost, 2618 provides essential insurance

Notice how each recommendation connects to operational reality rather than theoretical capability. A loading booster for your trailer might help get your race car to the track, but it doesn't change whether your engine needs 2618—your actual boost levels and tuning approach do.

Making the Right Call for Your Goals

The performance parts industry sometimes encourages over-building. There's always a stronger component, a more exotic material, a higher-rated option. But wisdom lies in matching components to genuine requirements—not purchasing insurance against scenarios that will never occur.

For builders running water to air intercooler setups pushing aggressive power levels, 2618 makes obvious sense. The thermal management that intercooling provides doesn't eliminate the cylinder pressure spikes that test piston integrity during boost onset. However, for the street car with bolt-on modifications staying well within conservative limits, specifying 2618 means accepting daily compromises for zero practical benefit.

The best piston is the one matched to your actual use case—not your theoretical maximum performance or what you might build someday. Build for reality, and your engine rewards you with reliability.

For builders seeking precision-forged components with exact specifications, material quality and dimensional accuracy become non-negotiable requirements. Working with IATF 16949 certified manufacturers like Shaoyi Metal Technology ensures consistent metallurgical quality critical for proper piston-to-wall clearance. Their hot forging expertise delivers the precision that performance builds demand—because even the correct alloy choice fails if manufacturing inconsistencies create out-of-spec components.

Consider these final checkpoints before finalizing your piston order:

- Verify your power goals align with your alloy selection—not your dream build, but your actual planned configuration

- Confirm clearance specifications with your machine shop—bring manufacturer spec sheets and discuss your specific climate conditions

- Plan your break-in procedure—different alloys demand different approaches to ring seating

- Budget for proper tuning—the best pistons can't compensate for detonation caused by improper calibration

- Document everything—measured clearances, installation dates, and operating notes create valuable reference for future maintenance

The 4032 vs 2618 decision doesn't need to create paralysis. Both alloys represent proven solutions engineered for specific operating conditions. Match your selection to your reality, execute installation with precision, and your build will deliver the performance and reliability you're chasing. The alloy that survives your build is simply the one that belongs there in the first place.

Frequently Asked Questions About 4032 vs 2618 Piston Alloys

1. What is 2618 material?

2618 aluminum is an age-hardenable alloy containing magnesium and copper with very low silicon content (0.1-0.25%). This composition creates exceptional ductility and high-temperature strength, making it the preferred choice for extreme performance applications. The alloy offers 64,000 psi tensile strength, superior fatigue endurance of 18,000 psi, and can survive detonation events that would crack higher-silicon alloys. However, its greater thermal expansion (15% more than 4032) requires looser piston-to-wall clearances of 0.004-0.006 inches.

2. Which material is best for pistons?

The best piston material depends entirely on your application. For street-driven, naturally aspirated, or mild forced induction builds under 15 psi, 4032 aluminum offers tighter clearances, quieter cold starts, and longer service life. For high-boost forced induction exceeding 15 psi, aggressive timing, or dedicated race engines, 2618 aluminum provides essential detonation resistance and superior high-temperature strength. Neither alloy is universally better—matching the material to your actual operating conditions determines success.

3. Who makes the best forged pistons?

Quality forged pistons come from manufacturers like JE Pistons, Wiseco, Diamond, Ross, CP, Mahle, and Manley. Each offers excellent products in both 4032 and 2618 alloys. For precision manufacturing with IATF 16949 certification, Shaoyi Metal Technology delivers consistent metallurgical quality critical for proper clearances. When selecting pistons, consider having skirts coated, tops thermal-coated for nitrous or supercharged applications, and gas-porting ring lands for improved sealing.

4. How much more does a 2618 piston expand compared to 4032?

A 2618 piston expands approximately 15% more than a comparable 4032 piston due to its lower silicon content. This significant difference requires 2618 pistons to run with 0.004-0.006 inch cold clearances versus 4032's 0.0015-0.0025 inch range. The expanded clearance causes audible piston slap during cold starts until operating temperature is reached. Once at operating temperature, both alloys achieve similar running clearances—the difference primarily affects cold-start behavior and warm-up requirements.

5. Can I use 4032 pistons for a boosted engine?

Yes, 4032 pistons can work in mild forced induction applications running under 12-15 psi with conservative timing and proper tuning that eliminates detonation risk. Many street-driven turbo and supercharged builds successfully use 4032 for its tighter clearances and refined cold-start operation. However, for high-boost applications exceeding 15 psi, aggressive timing curves, or builds where detonation events are possible despite tuning, 2618 becomes necessary due to its superior ductility and impact resistance.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —