Stamping Transmission Components: Precision for High-Volume Manufacturing

TL;DR

Stamping transmission components is the industry-standard manufacturing solution for producing high-precision automotive parts like gears, clutch hubs, and housings at scale. Unlike machining, which removes material, metal stamping utilizes progressive die and deep draw techniques to form complex geometries with superior speed and repeatability. For automotive engineers and procurement officers, this process offers a critical advantage: the ability to maintain micron-level tolerances while reducing unit costs by over 40% in high-volume production runs (typically >100,000 units).

Critical Transmission Components Produced via Stamping

Modern automotive transmissions rely on stamped metal architecture to replace heavier, more expensive cast or machined alternatives. The transition to stamped components has allowed manufacturers to reduce powertrain weight without sacrificing torque capacity. Based on current manufacturing capabilities, several critical assemblies are now predominantly produced via precision stamping.

Core Powertrain Elements

- Clutch Hubs and Drums: These complex cylindrical parts require deep draw processes to form the housing, followed by secondary operations to cut splines. Stamping ensures the high material density needed to withstand rotational stress.

- Transmission Gears: While heavy-duty gears are often forged, lighter transmission gears for auxiliary functions or smaller assemblies are frequently stamped. This process ensures a "perfect fit" for smooth operation and noise reduction, a critical quality factor highlighted by manufacturers like Hidaka USA.

- Reaction Shells and Carriers: These structural components house the planetary gear sets. Stamping allows for the creation of intricate locking features and tabs in a single pass, eliminating the need for welding multiple pieces together.

Fluid Management and Housing

Beyond torque transfer, stamping is essential for the transmission's hydraulic integrity. Oil pans and valve covers are classic examples of deep-drawn components. These parts must meet strict flatness requirements to ensure a leak-proof seal against the transmission case. Manufacturers utilize specialized hydraulic presses to draw these deep shapes from flat blanks without thinning the material walls to the point of failure.

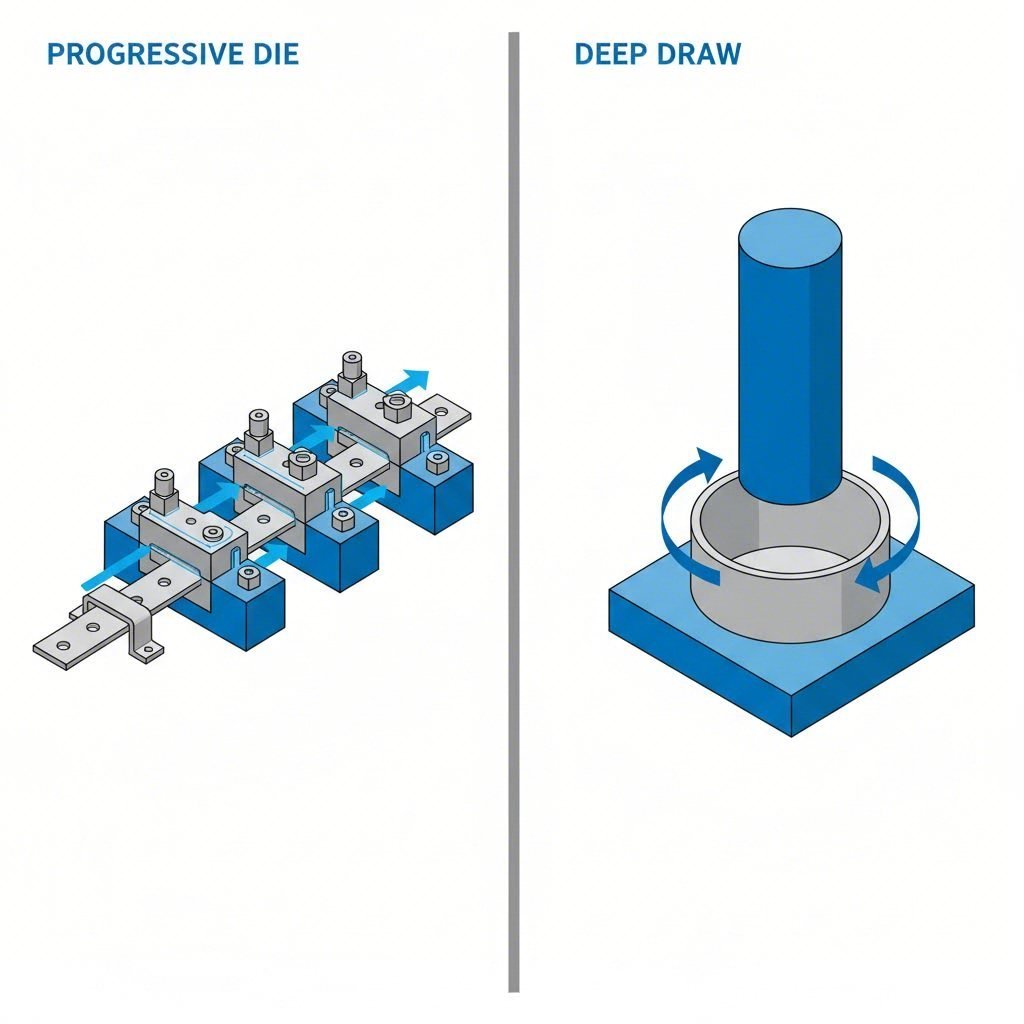

Manufacturing Processes: Progressive Die vs. Deep Draw

Selecting the correct stamping methodology is the first step in cost optimization. Two primary techniques dominate the production of transmission components, each serving distinct geometric needs.

| Feature | Progressive Die Stamping | Deep Draw Stamping |

|---|---|---|

| Best Application | Small, complex parts with multiple features (brackets, clips, flat gears). | Cylindrical or box-shaped parts where depth > diameter (housings, pans). |

| Process Mechanics | A metal strip feeds through multiple stations; each station performs a cut/bend until the part is severed at the end. | A punch forces a flat blank into a die cavity, stretching the metal into a 3D shape. |

| Material Usage | Higher scrap rate due to the "carrying web" needed to move parts between stations. | More efficient material utilization; circular blanks are often optimized to reduce waste. |

| Speed | Extremely high (hundreds of strokes per minute). | Slower; requires time for material flow to prevent tearing. |

Progressive die stamping is the preferred method for high-speed production of smaller precision parts. As explained by ESI Engineering, this method allows for secondary operations like coining and piercing to happen in-die, delivering a finished part with every cycle of the press. Conversely, deep draw is indispensable for creating the seamless, cup-like structures found in clutch pistons and accumulators, where welding seams would introduce points of failure.

Stamping Materials for High-Torque Applications

Transmission environments are hostile, characterized by high heat, friction, and shear forces. Material selection is therefore dictated by the balance between formability (for the stamping process) and durability (for the end application).

Low Carbon Steel remains the workhorse for deep-drawn stampings. According to material data from Trans-Matic, low carbon steel offers an excellent strength-to-weight ratio and work-hardens during forming, which naturally enhances the structural integrity of the finished part. This makes it ideal for clutch cylinders and oil pans that must resist deformation under pressure.

Aluminum Alloys are increasingly specified for housings and covers to meet corporate average fuel economy (CAFE) standards. While aluminum is more difficult to stamp due to its tendency to crack (lower formability limit), its weight is roughly one-third that of steel, providing significant mass reduction for the overall transmission assembly.

For specialized applications, Copper and Brass are utilized in sensor components and washers within the transmission's electronic control units (ECUs). These materials provide necessary conductivity and corrosion resistance, though they lack the structural strength of steel.

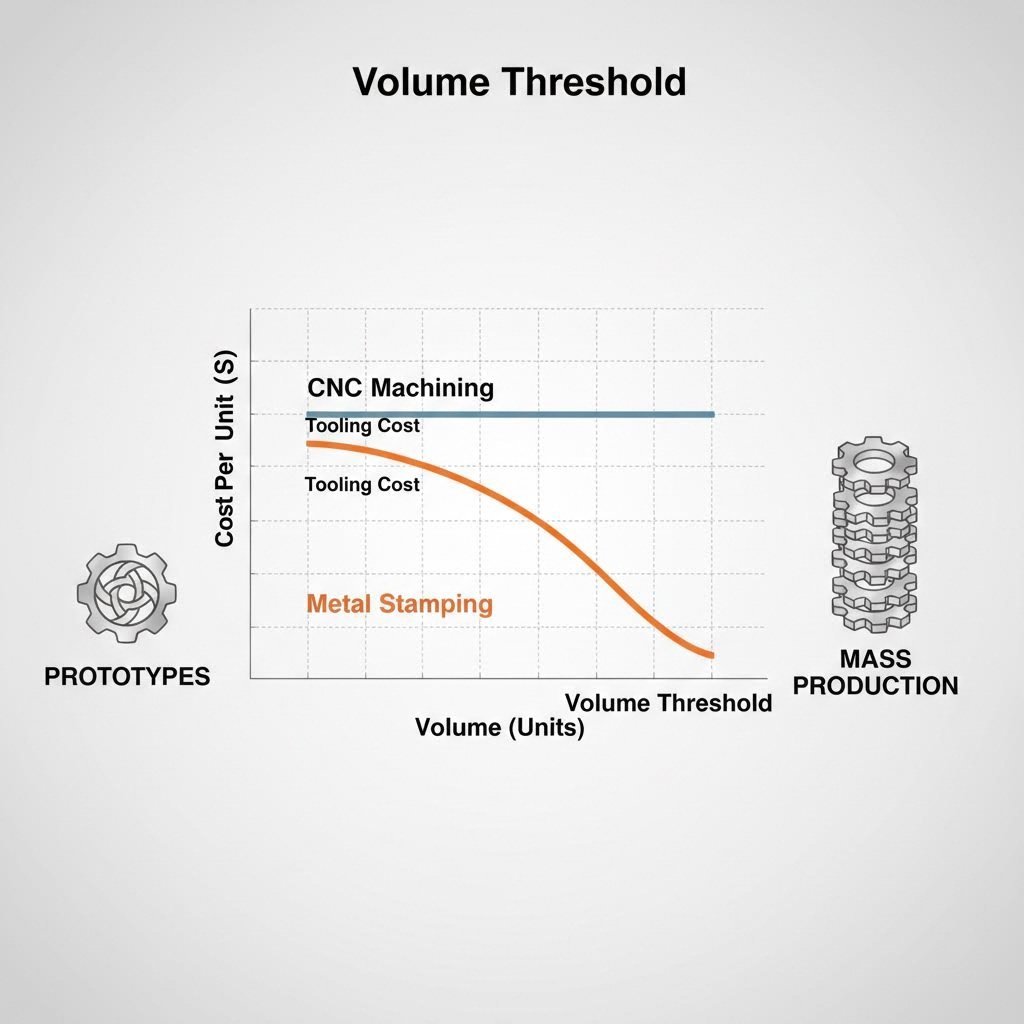

Strategic Analysis: Stamping vs. CNC Machining

The decision to stamp or machine a transmission component typically hinges on volume and geometry. This "Make vs. Buy" analysis is a critical pivot point for procurement strategy.

The Volume Threshold: CNC machining is subtractive and linear—producing one part takes a fixed amount of time. Stamping is transformative and parallel. Once the tooling (die) is built, the cost per unit drops precipitously. Generally, volumes under 5,000 units favor machining to avoid tooling costs, while volumes over 50,000 overwhelmingly favor stamping.

Bridging the Gap: A major challenge arises when projects move from prototype to mass production. OEMs often need a partner who can handle both initial low-volume validation and eventual high-volume scaling. Shaoyi Metal Technology specializes in this transition, offering capabilities ranging from rapid prototyping to 600-ton press manufacturing. Their IATF 16949-certified processes ensure that components like control arms and subframes meet rigorous global standards, whether you need fifty prototypes for testing or millions of units for assembly.

Precision Capabilities: Historically, machining held the edge in tolerance control. However, modern precision stamping can now achieve tolerances as tight as ±0.001 inches (0.025mm) for many features. Shaving and sizing operations integrated into the stamping die can produce gear teeth surfaces that rival machined finishes, often eliminating the need for secondary grinding.

Quality Assurance and Precision Standards

In the automotive sector, a transmission failure is catastrophic. Therefore, stamped components undergo rigorous quality assurance protocols that go far beyond basic dimensional checks.

Manufacturers employ in-die sensing technology to monitor the stamping process in real-time. Sensors detect misfeeds or slug marks that could damage the part or the tool, stopping the press immediately to prevent defective batches. Furthermore, post-stamping optical inspection systems measure critical dimensions—such as the inner diameter of a clutch hub or the flatness of a mounting flange—against digital CAD models.

Adherence to standards like IATF 16949 is non-negotiable for transmission suppliers. This certification ensures that the stamper has a mature quality management system capable of defect prevention and continual improvement, reducing the risk of warranty claims for the automotive OEM.

Driving Efficiency in Powertrain Production

Stamping transmission components represents the intersection of metallurgical science and high-volume industrial engineering. By leveraging processes like progressive die and deep draw stamping, manufacturers can deliver the complex, lightweight, and durable parts required by modern powertrains.

For procurement teams, the value lies in the scalability. While the upfront investment in tooling is significant, the long-term reduction in piece price and the assurance of repeatable precision make stamping the superior choice for mass-market automotive transmission programs.

Frequently Asked Questions

1. What are stamped transmission components?

Stamped transmission components are metal parts formed by pressing flat sheet metal into specific shapes using high-tonnage presses and dies. Common examples include clutch hubs, reaction shells, oil pans, valve covers, and certain types of gears. These parts replace heavier cast or machined alternatives to reduce weight and cost.

2. What are the 7 steps in the stamping method?

The stamping process typically involves a sequence of operations that may happen in a single progressive die or across multiple stations: Blanking (cutting the initial shape), Piercing (punching holes), Drawing (forming 3D shapes), Bending (creating angles), Air Bending (forming without bottoming out), Coining (stamping for surface finish/detail), and Trimming (removing excess material).

3. How precise is metal stamping for gears?

Modern fineblanking and precision stamping can produce gear teeth with tolerances within thousandths of an inch, suitable for many transmission applications. While high-load primary drive gears are often forged or machined, stamped gears are widely used for internal mechanisms, parking pawls, and fluid pump gears due to their cost-effectiveness and sufficient durability.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —