Sensor Housing Metal Stamping: The Precision Deep Draw Guide

TL;DR

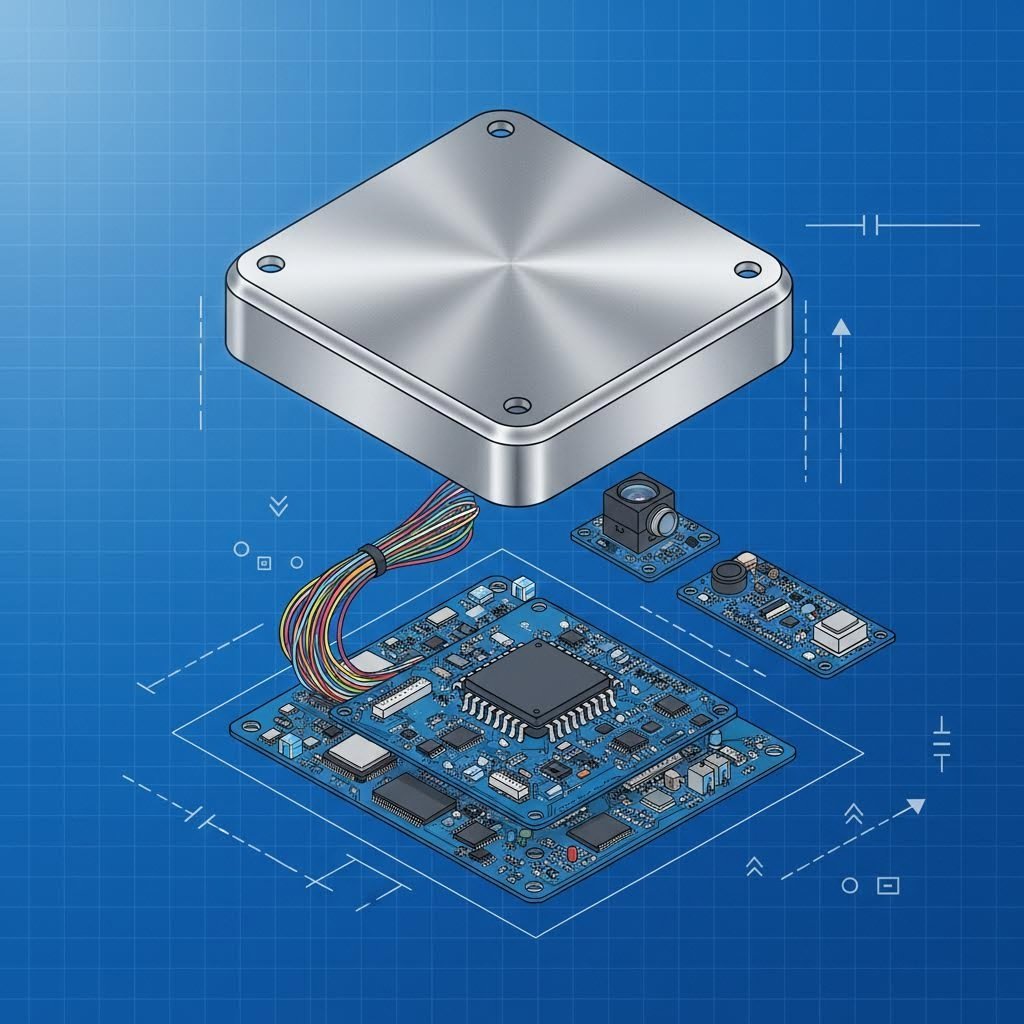

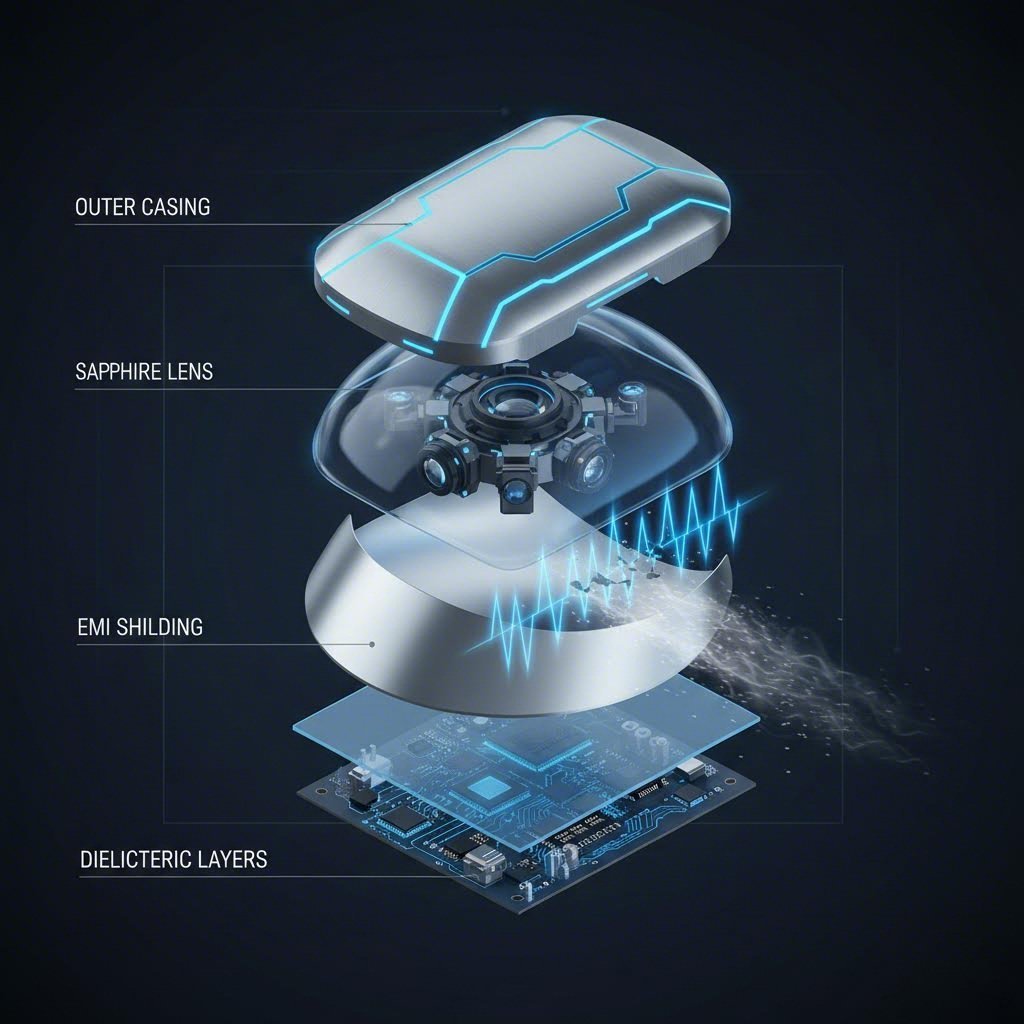

Sensor housing metal stamping is a high-precision manufacturing process, predominantly utilizing deep draw techniques, to create seamless, durable protective enclosures for sensitive electronic components. Unlike machining or plastic molding, this method offers superior electromagnetic interference (EMI) shielding, robust shock resistance, and cost-effective scalability for high-volume production runs. Engineers and procurement managers favor deep drawn metal housings for their ability to maintain tight tolerances (often within ±0.001") while ensuring hermetic integrity in harsh automotive, medical, and industrial environments.

Deep Draw Stamping: The Industry Standard for Sensor Housings

For cylindrical or box-shaped sensor enclosures, deep draw stamping has emerged as the dominant manufacturing method, surpassing traditional machining in both efficiency and structural integrity. This process involves radially drawing a metal blank into a forming die by the mechanical action of a punch. The definition of "deep" drawing typically applies when the depth of the drawn part exceeds its diameter.

The primary engineering advantage of deep drawing is the creation of a seamless, single-piece component. Unlike welded tubing or multi-part assemblies, a deep-drawn housing has no seams that could serve as potential leak paths for moisture or gas. This is critical for sensors operating in pressurized or submerged environments. Standard Die notes that deep-drawn stamping is ideal for mass production because it significantly reduces material waste and eliminates secondary assembly steps, leading to a lower cost per unit compared to turning or CNC machining.

Mechanically, the process work-hardens the material, often increasing the structural rigidity of the final part. This allows manufacturers to use thinner gauge stock without sacrificing durability, optimizing the weight-to-strength ratio—a key consideration for aerospace and automotive sensor applications.

Material Selection: Balancing Protection and Formability

Selecting the correct alloy is the first step in ensuring sensor performance. The material must balance formability (to survive the deep draw process without tearing) with environmental protection properties.

Stainless Steel (304 vs. 316L)

Stainless steel is the most common material for sensor housings due to its high hardness and resistance to deformation. CNstamping highlights stainless steel's resistance to corrosion as a primary benefit, though they note its heat dissipation is lower compared to non-ferrous metals. Grade 304 is the industry standard for general industrial use, offering excellent formability. For marine or medical applications, Grade 316L is preferred due to its superior resistance to chlorides and pitting, ensuring the housing does not degrade in saline environments.

Non-Ferrous Options: Aluminum and Copper

For applications requiring heat dissipation or specific magnetic properties, non-ferrous metals are used:

- Aluminum: Offers excellent thermal conductivity and is lightweight, making it suitable for aerospace sensors. However, it requires careful anodizing for corrosion resistance.

- Copper and Brass: Often selected for their electrical conductivity and natural EMI shielding properties, though they may require plating (nickel or gold) to prevent oxidation.

| Material | Corrosion Resistance | Formability | EMI Shielding | Typical Application |

|---|---|---|---|---|

| Stainless Steel 304 | High | Excellent | Moderate | General Industrial Sensors |

| Stainless Steel 316L | Very High | Good | Moderate | Medical/Marine Probes |

| Aluminum | Moderate (needs coating) | Very Good | Good | Aerospace/Lightweight |

| Copper/Brass | Low (needs plating) | Excellent | Excellent | Electronics/EMI Sensitive |

Why Metal? The Case Against Plastic Housings

While plastic injection molding is cheap, it often fails to meet the rigorous demands of critical sensor applications. The choice between metal and plastic often comes down to three factors: shielding, shock resistance, and thermal stability.

Electromagnetic Interference (EMI) Shielding: Electronic sensors are increasingly deployed in "noisy" environments full of wireless signals and electrical currents. Henli emphasizes that metal housings naturally act as a Faraday cage, shielding internal components from external electromagnetic interference that could distort data readings. Plastic housings require expensive conductive coatings to achieve similar results.

Physical Durability: Metal housings offer superior shock resistance. In automotive under-hood applications or industrial machinery, sensors face constant vibration and potential impact from debris. A stamped metal housing maintains its structural integrity and dimensional accuracy under these forces, whereas plastic may crack, warp, or become brittle over time, especially when exposed to UV radiation or extreme temperature cycles.

Critical Design Guidelines for Manufacturability

To maximize the benefits of metal stamping, engineers must design with the manufacturing process in mind (Design for Manufacturability, or DFM). Following these rules prevents common defects like wrinkling or tearing during the draw.

- Corner Radii: Avoid sharp corners. The radius at the bottom of the cup and the flange should be at least 4-8 times the material thickness. Generous radii reduce stress concentrations and allow the metal to flow smoothly.

- Wall Thickness Uniformity: Deep drawing naturally results in some thinning of the walls. Designs should account for this variation, typically allowing for a 10-15% reduction in thickness at critical stretch points.

- Draft Angles: While not strictly required for all stamped parts, including a slight draft angle can facilitate easier ejection of the part from the die, extending tool life and reducing scoring marks.

- Secondary Operations: As noted by Precipart, complex sensor housings often require secondary finishing. This can include passivation to remove surface iron from stainless steel, or plating with precious metals to enhance solderability and contact resistance.

Quality Assurance and High-Volume Scalability

The sensor market—driven by autonomous driving and IoT—demands zero-defect manufacturing. Precision is non-negotiable; housings often require tolerances as tight as ±0.001 inches to ensure a perfect fit with mating connectors and seals.

Achieving this consistency at scale requires advanced tooling and rigorous quality control. Manufacturers utilize in-die sensing and optical inspection systems to verify dimensions in real-time. For critical sectors like the automotive industry, suppliers must often adhere to IATF 16949 standards, which govern quality management in the automotive supply chain.

For manufacturers looking to bridge the gap between prototyping and mass production, partnering with a capable supplier is essential. Shaoyi Metal Technology’s comprehensive stamping solutions exemplify this capability, leveraging IATF 16949-certified precision and press capabilities up to 600 tons to deliver critical automotive components that meet global OEM standards.

Ultimately, the reliability of a sensor is only as good as its housing. By leveraging deep draw metal stamping, engineers ensure their devices are protected by a robust, seamless, and shielded enclosure capable of withstanding the harshest operational environments.

Frequently Asked Questions

1. What is the advantage of deep draw stamping over machining for sensor housings?

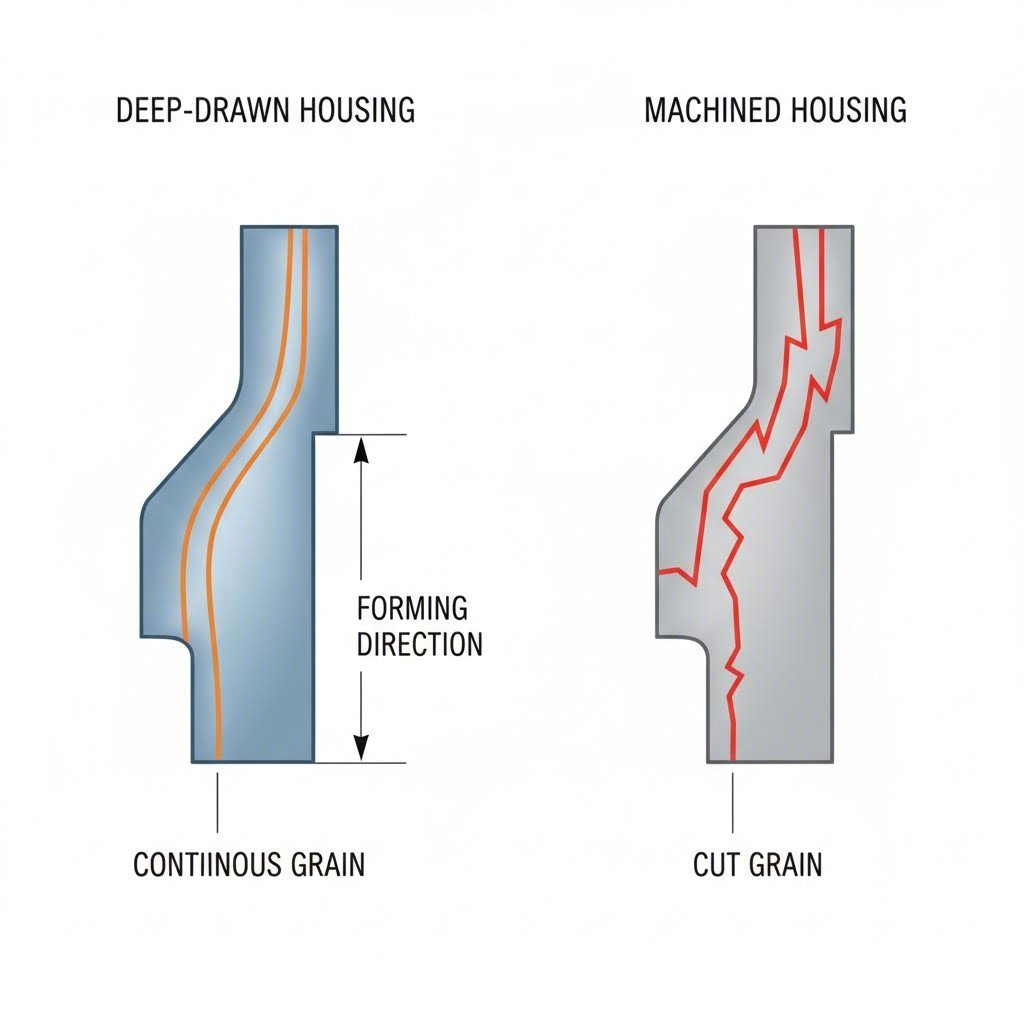

Deep draw stamping is significantly more cost-effective for high-volume production because it generates minimal material waste compared to machining, which cuts away material from a solid block. Additionally, deep drawing creates a seamless part with a continuous grain structure, offering superior strength and eliminating potential leak paths associated with welded or assembled housings.

2. Can stamped sensor housings be customized with plating?

Yes, stamped metal housings are frequently plated to enhance performance. Common treatments include nickel plating for corrosion resistance, gold plating for electrical conductivity, and silver plating for solderability. These surface treatments allow standard base metals like copper or brass to perform effectively in chemically aggressive or electrically sensitive environments.

3. Which metal is best for underwater sensor housings?

Stainless Steel 316L is typically the preferred material for underwater or marine sensor housings. It contains molybdenum, which provides exceptional resistance to pitting and crevice corrosion caused by chloride environments (saltwater), ensuring the long-term integrity of the hermetic seal.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —