Automotive Connector Stamping Process: Engineering Precision

TL;DR

The automotive connector stamping process is a high-precision manufacturing method that utilizes progressive die technology to transform flat metal strips into intricate electrical terminals. Operating at speeds exceeding 1,000 strokes per minute, this process demands micron-level accuracy to ensure reliable signal transmission in harsh vehicle environments. Key elements include the selection of specific copper alloys for conductivity, the application of protective plating, and strict adherence to IATF 16949 quality standards. Engineers and procurement teams rely on this process to produce millions of defect-free components essential for modern automotive electronics.

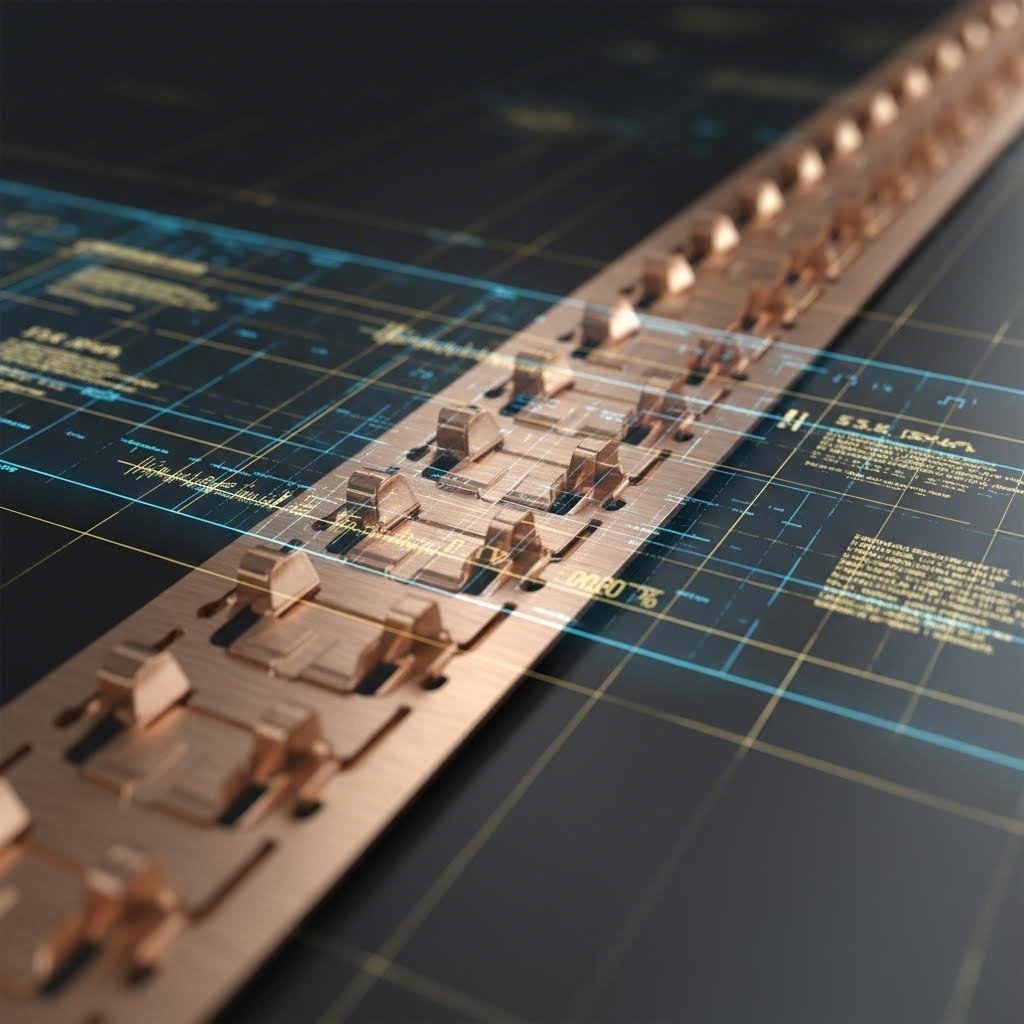

The Anatomy of High-Speed Progressive Die Stamping

At the heart of automotive connectivity lies progressive die stamping, a manufacturing capability that favors speed, consistency, and volume. Unlike single-stage stamping, where a part is made in one hit, progressive stamping feeds a continuous metal strip through a series of stations within a single die set. Each station performs a specific operation—cutting, bending, or forming—as the material advances, resulting in a finished terminal at the end of the line.

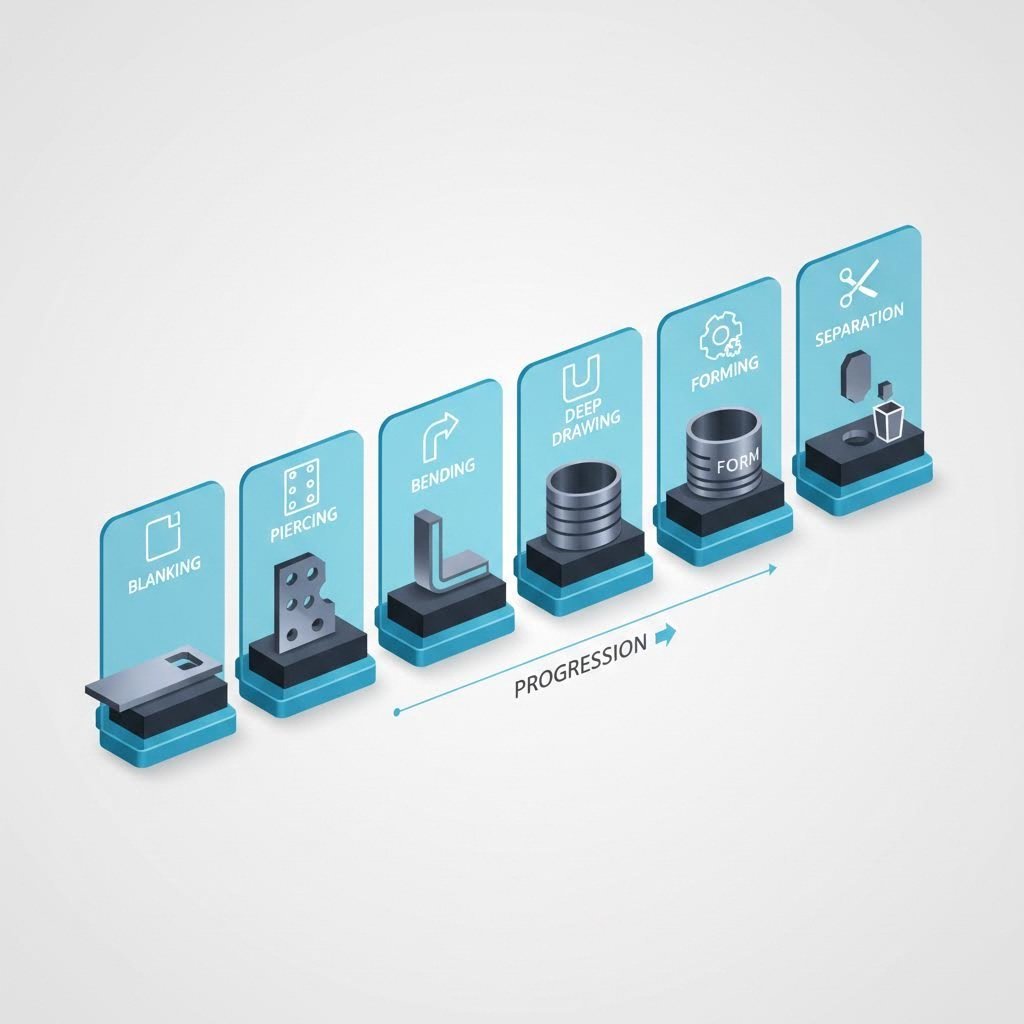

The 6-Step Manufacturing Workflow

To achieve the complex geometries required for automotive connectors, manufacturers typically employ a six-stage process derived from precision engineering principles:

- Blanking: The initial station cuts the outer perimeter of the terminal from the metal strip. This step defines the basic 2D shape and establishes the carrier strip that will transport the part through subsequent stations.

- Piercing & Piloting: Punches create holes for alignment (pilot holes) and functional features. Pilot pins then engage these holes at every station to ensure the strip is positioned within tolerances as tight as ±0.01mm.

- Bending: The flat metal is folded along calculated lines. Designers must account for "springback"—the metal's tendency to return to its original shape—by over-bending slightly to achieve the final angle.

- Deep Drawing: For socket terminals, the metal is stretched into cup-like shapes. This requires specialized lubrication and tooling to prevent tearing the material while maintaining wall thickness.

- Local Forming (Coining/Skiving): High-pressure impact changes the thickness of specific areas. Coining strengthens contact points, while skiving removes material to create flexible beams or sharp edges for wire insulation displacement.

- Separation: The final step cuts the finished terminal from the carrier strip, or in many cases, leaves it attached on a reel for automated assembly downstream.

The efficiency of this process is unmatched. Advanced presses can run 24/7, producing millions of terminals with zero human intervention. However, the complexity of the tooling means that the initial design and engineering phase is critical to success.

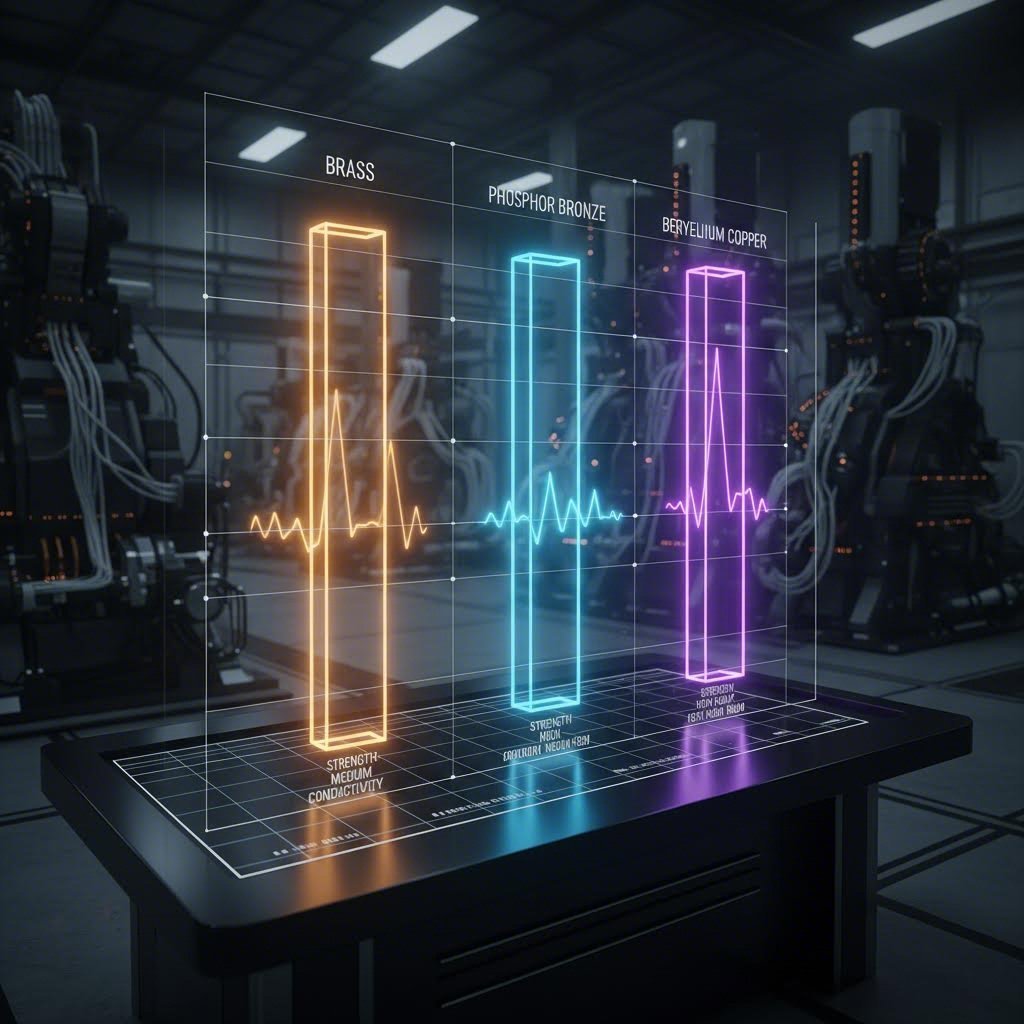

Material Selection: The Foundation of Connectivity

In the automotive sector, a connector is only as good as its base material. Engineers must balance electrical conductivity with mechanical strength and thermal resistance. While pure copper offers the best conductivity, it lacks the spring properties needed for a secure contact. Therefore, specific alloys are engineered to meet these competing demands.

Comparative Analysis of Copper Alloys

The table below outlines the most common materials found in automotive connector stamping, highlighting their trade-offs:

| Material (Alloy) | Conductivity (% IACS) | Strength & Durability | Typical Application |

|---|---|---|---|

| Brass (C26000) | ~28% | Moderate strength; excellent formability; low cost. | Standard terminals, fuse clips, non-critical dashboard connections. |

| Phosphor Bronze (C51000) | ~15% | High fatigue resistance; excellent spring properties. | Battery terminals, signal contacts prone to vibration. |

| Beryllium Copper (C17200) | ~22–25% | Superior strength; retains spring force at high temperatures. | Miniaturized connectors, EV high-voltage systems, engine sensors. |

| High-Performance Alloys (C7025) | ~40–60% | High strength combined with high conductivity. | Modern EV power terminals requiring high current and miniaturization. |

Beyond the base metal, surface plating plays a pivotal role. Pre-plated or post-plated strips typically use Tin for general cost-effective corrosion resistance, while Gold is reserved for safety-critical systems (like airbag sensors) where signal integrity cannot be compromised. Nickel underplates are standard to prevent the diffusion of copper atoms into the surface finish.

Quality Assurance & Automotive Standards

Automotive components must survive extreme temperature cycling, vibration, and moisture. Consequently, the stamping process is governed by the IATF 16949 quality management system, which mandates rigorous risk management and process control.

Zero Defect Strategies

Top-tier manufacturers employ automated in-line vision systems that inspect 100% of the parts as they exit the press. These high-speed cameras detect micron-level defects such as:

- Burrs: Sharp edges that could damage mating wires.

- Plating Voids: Missing coating that could lead to oxidation.

- Dimensional Variance: Terminals that are bent out of tolerance, preventing proper assembly.

Additionally, modern presses are equipped with force monitors. If a slug (scrap metal) is pulled back into the die, the sensors detect the slight increase in tonnage and instantly stop the press, preventing damage to the expensive tooling and ensuring no defective parts reach the customer.

Advanced Techniques & Production Scalability

As vehicle electronics shrink and electric vehicles (EVs) demand higher power densities, stamping houses are adopting advanced techniques to stay competitive.

In-Die Assembly and Micro-Stamping

To reduce costs and improve precision, manufacturers are moving secondary operations inside the stamping die. In-die assembly allows for the insertion of plastic components, contacts, or even threading operations to occur within the progressive die sequence. This eliminates the need for separate assembly stations, reducing handling errors.

Micro-stamping is another frontier, producing terminals for high-density connectors that are barely visible to the naked eye. These components require specialized "fine blanking" techniques to achieve smooth sheared edges without fracturing the material.

From Prototype to Mass Production

A critical challenge for automotive suppliers is bridging the gap between initial design and volume manufacturing. While soft tooling or laser cutting works for prototypes, it cannot replicate the material flow of a hard progressive die. Partnering with a manufacturer that offers comprehensive capabilities is essential.

For instance, Shaoyi Metal Technology provides a seamless transition from rapid prototyping to high-volume stamping. With press capabilities up to 600 tons and strict IATF 16949 adherence, they enable OEMs to validate designs quickly before scaling to millions of parts for global production. Their integrated approach ensures that the engineering intent validated during the prototype phase is fully realized in the final mass-produced component.

Conclusion

The automotive connector stamping process is a synthesis of metallurgical science, mechanical engineering, and rigorous quality control. For procurement professionals and engineers, understanding the nuances of progressive die mechanics, alloy selection, and inline inspection is key to identifying capable partners. As vehicles become increasingly electrified, the demand for stamped components that offer higher conductivity, smaller footprints, and absolute reliability will only grow, making the choice of a certified, technologically advanced stamping partner more critical than ever.

Frequently Asked Questions

1. What is the connector stamping process?

Connector stamping is a manufacturing technique where a metal strip is fed through a stamping press containing a progressive die. The die performs a series of operations—such as cutting (blanking), bending, and forming—to shape the strip into precise electrical terminals or pins. This high-speed process is designed to produce large volumes of identical parts with tight tolerances.

2. Why are copper alloys used in automotive stamping?

Copper alloys like brass, phosphor bronze, and beryllium copper are the industry standard because they offer an excellent balance of electrical conductivity and mechanical strength. Pure copper is too soft for most terminals, so alloying elements are added to improve spring properties (elasticity) and fatigue resistance, ensuring the connector maintains a secure contact even under vehicle vibration.

3. What does IATF 16949 certification mean for stamping?

IATF 16949 is the global technical specification and quality management standard for the automotive industry. For a stamping company, holding this certification means they have established rigorous processes for defect prevention, supply chain consistency, and continuous improvement, ensuring that every stamped connector meets the strict safety and reliability requirements of automotive OEMs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —