Bumper Reinforcement Stamping Process: Mastering Hot Stamping & UHSS

TL;DR

The bumper reinforcement stamping process for modern vehicles is predominantly achieved through Hot Stamping (also known as Press Hardening). This method transforms boron alloy steel (typically 22MnB5) into Ultra-High Strength Steel (UHSS) components with tensile strengths exceeding 1,500 MPa. The process involves heating blanks to over 900°C to reach an austenitic state, followed by rapid transfer to a water-cooled die where forming and quenching occur simultaneously. This eliminates springback and enables the creation of complex, lightweight, and crash-resistant structures essential for meeting global safety standards.

The Engineering Role of Bumper Reinforcements

Bumper reinforcements, commonly referred to as bumper beams, serve as the primary structural backbone of a vehicle's impact management system. Functioning as the connection point between the external fascia and the vehicle's chassis (often via crash boxes), these components must absorb and dissipate kinetic energy during front or rear collisions. The engineering challenge lies in balancing crashworthiness with lightweighting (LW) mandates driven by fuel economy regulations and EV range requirements.

Historically, bumper beams were manufactured from mild steel using cold stamping methods. However, the demand for superior safety ratings has shifted the industry standard toward Ultra-High Strength Steels (UHSS), specifically boron-manganese alloys like 22MnB5. While aluminum alloys (6000 or 7000 series) are utilized in some premium applications for their high strength-to-weight ratio, boron steel remains the dominant material due to its exceptional cost-performance ratio and ability to achieve martensitic hardening.

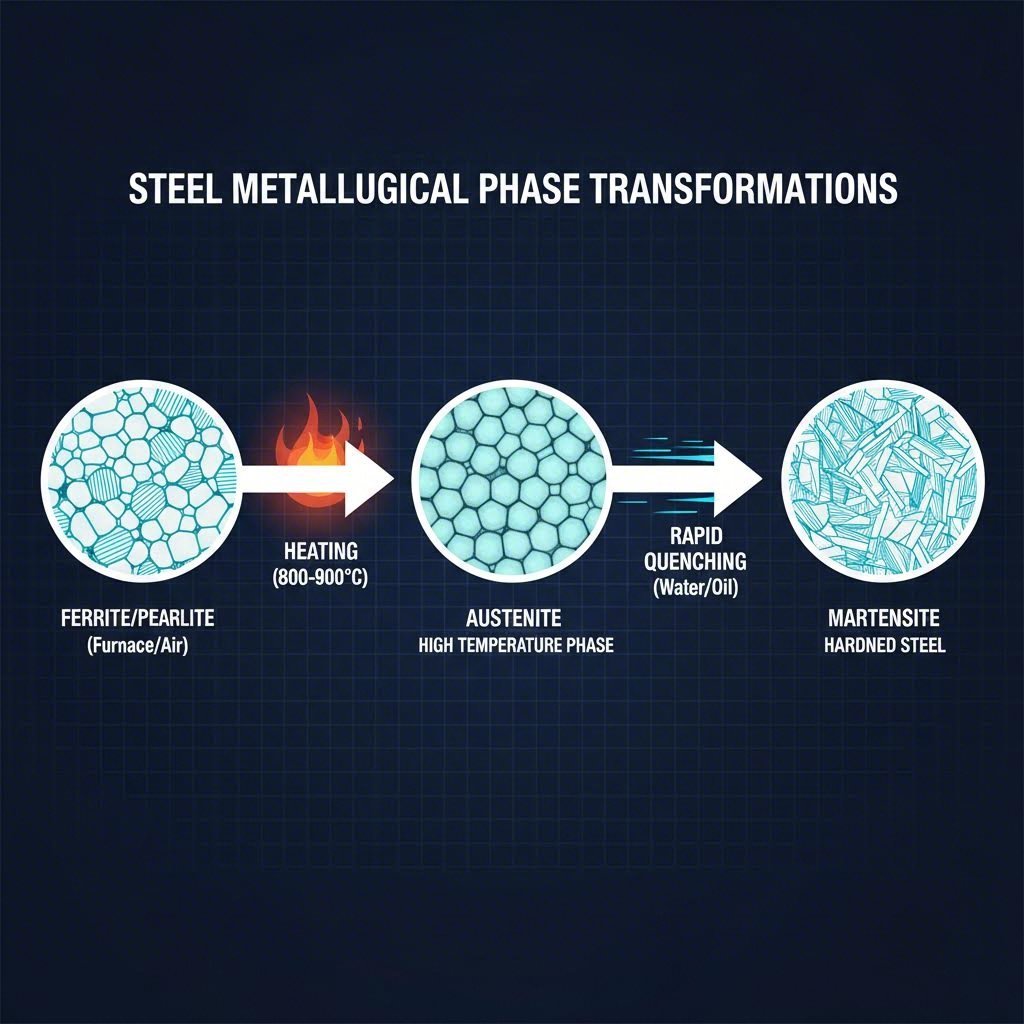

The metallurgical transformation is critical: the steel begins with a ferritic-pearlitic microstructure (tensile strength ~600 MPa) and is thermally processed to achieve a fully martensitic structure (tensile strength >1,500 MPa). This transformation allows engineers to reduce wall thickness—often down to 1.2mm–2.0mm—without compromising structural integrity.

Core Process: Hot Stamping (Press Hardening) Workflow

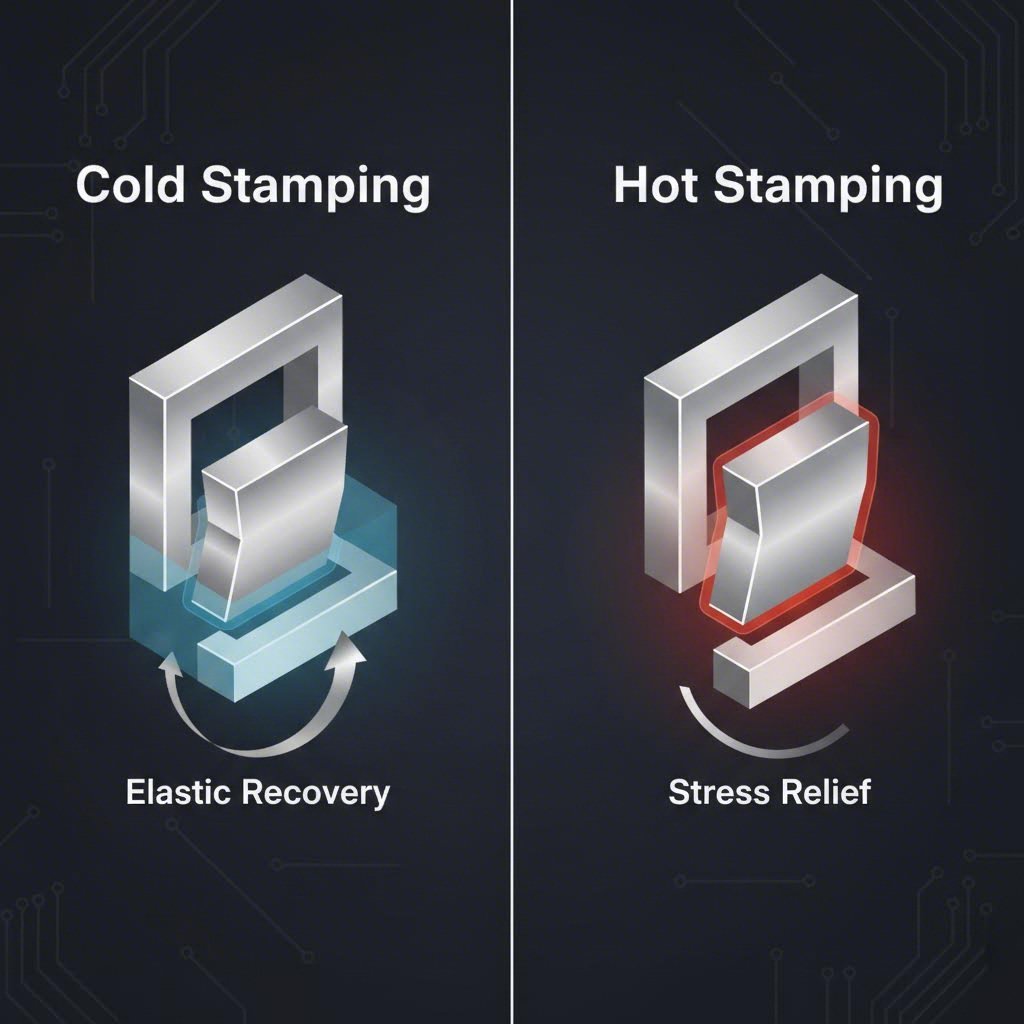

Hot stamping is the only manufacturing process capable of forming 1,500+ MPa bumper beams without the massive springback issues associated with cold forming. The workflow is a precision-controlled thermal cycle that integrates forming and heat treatment.

1. Austenitization (Heating)

The process begins by de-stacking pre-cut blanks (often Al-Si coated to prevent scaling) and feeding them into a roller hearth furnace. The blanks are heated to approximately 900°C–950°C and held for a specific dwell time. This thermal soak converts the steel's microstructure from ferrite to austenite, rendering the material highly malleable and reducing its yield strength to approximately 200 MPa for easier forming.

2. Transfer and Forming

Once the blank exits the furnace, speed is paramount. Robotic transfer arms move the glowing blank into the press die within seconds (typically <3 seconds) to prevent premature cooling. The hydraulic or servo-mechanical press then closes rapidly. Closing speeds often range from 500 to 1,000 mm/s to ensure the material is formed before the phase transformation begins.

3. In-Die Quenching

This is the defining step of the bumper reinforcement stamping process. The die is equipped with intricate internal cooling channels through which chilled water circulates. As the press reaches bottom dead center (BDC), it dwells, holding the formed part under high tonnage (typically 500–1,500 tons depending on part size). This contact rapidly extracts heat, achieving a cooling rate exceeding 27°C/s. This rapid quenching bypasses the pearlite/bainite formation zones and transforms the austenite directly into martensite.

4. Part Ejection

After a quench time of roughly 5 to 10 seconds, the press opens, and the hardened part is ejected. The component now possesses its final mechanical properties: extreme hardness, high tensile strength, and zero springback, as the thermal stresses are relieved during the phase change.

Comparing Manufacturing Methodologies

While hot stamping is the gold standard for high-performance reinforcements, cold stamping and roll forming remain relevant for specific applications. Understanding the trade-offs is essential for process selection.

| Feature | Hot Stamping (Press Hardening) | Cold Stamping | Roll Forming |

|---|---|---|---|

| Material Strength | Very High (>1,500 MPa) | Low to Medium (<1,000 MPa) | High (>1,200 MPa possible) |

| Springback | Eliminated (Thermal stress relief) | Significant (Requires compensation) | High (Difficult control) |

| Geometry Complexity | High (Variable sweep, deep draw) | Medium | Low (Constant cross-section only) |

| Cycle Time | Slow (10–30 seconds) | Fast (1–5 seconds) | Continuous (Very Fast) |

| Tooling Cost | High (Cooling channels, heat resistant) | Medium | High (Roll sets) |

Cold stamping serves well for lower-strength components or mild steel brackets where cost and cycle time are prioritized over weight reduction. However, forming UHSS cold leads to severe tool wear and unpredictable springback. Roll forming is efficient for beams with a constant cross-section (straight beams) but cannot accommodate the complex sweeping curves and integrated mounting features required by modern aerodynamic designs.

For manufacturers navigating these options, selecting the right fabrication partner is crucial. Companies like Shaoyi Metal Technology bridge this gap by offering comprehensive stamping capabilities. With IATF 16949 certification and press capacities up to 600 tons, they support automotive projects from rapid prototyping to mass production, handling critical structural components with the precision required for global OEM standards.

Post-Processing and Quality Control

The extreme hardness of hot-stamped bumper reinforcements introduces unique challenges in downstream processing. Traditional mechanical trimming dies typically fail or wear instantly against 1,500 MPa steel.

Laser Trimming and Cutting

To achieve final dimensions and cut mounting holes, manufacturers predominantly use 5-axis laser cutting cells. This non-contact method ensures precise edges without micro-cracks, which are potential failure points in crash scenarios. Although slower than mechanical piercing, laser trimming offers the flexibility needed for different bumper variants on the same line.

Surface Treatment

If the boron steel blank was uncoated, the high furnace temperatures cause surface oxidation (scale). These parts must undergo shot blasting before e-coating to ensure proper adhesion. Alternatively, Al-Si (Aluminum-Silicon) pre-coated blanks prevent scale formation but require careful process control to avoid coating delamination during the forming phase.

Quality Verification

Rigorous testing protocols are non-negotiable for safety parts. Standard quality control measures include:

- Vickers Hardness Testing: verifying the martensitic conversion across critical zones.

- 3D Blue Light Scanning: checking dimensional accuracy against CAD data, ensuring mounting points align with the chassis.

- Microstructure Analysis: periodic destructive testing to confirm the absence of bainite or ferrite in the load-bearing areas.

Optimizing Production Strategy

The transition to hot-stamped bumper reinforcements represents a definitive shift in automotive manufacturing, prioritizing passenger safety and vehicle efficiency. By mastering the variables of temperature, transfer speed, and quenching pressure, manufacturers deliver components that withstand immense forces while minimizing mass. As steel grades evolve toward 1,800 MPa and beyond, the precision of the stamping process remains the critical factor in defining the next generation of vehicle safety structures.

Frequently Asked Questions

1. What is the difference between direct and indirect hot stamping?

In direct hot stamping, the blank is heated first and then formed and quenched in a single step. This is the most common method for bumper beams. Indirect hot stamping involves cold-forming the part to nearly its final shape first, then heating it, and finally placing it in a cooled die for quenching and calibration. Indirect stamping allows for more complex geometries but is more expensive due to the additional tooling required.

2. Why is boron added to the steel used in bumper reinforcements?

Boron is added in minute quantities (typically 0.002%–0.005%) to significantly improve the hardenability of the steel. It delays the formation of softer microstructures like ferrite and pearlite during cooling, ensuring that the steel fully transforms into hard martensite even at the cooling rates achievable in industrial stamping dies.

3. Can hot-stamped parts be welded?

Yes, hot-stamped boron steel parts can be welded, but they require specific parameters. Because the heat from welding can locally anneal (soften) the heat-treated zone, creating a "soft spot," the welding process—whether spot welding or laser welding—must be carefully controlled. Often, laser ablation is used to remove the Al-Si coating in the weld areas prior to assembly to ensure weld integrity.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —