Sheet Metal And Fabrication Costs Exposed: What Shops Won't Tell You

What Is Sheet Metal Fabrication and Why It Matters

Ever wondered how a flat piece of aluminum transforms into an aircraft fuselage or how steel becomes the frame of your car? The answer lies in sheet metal fabrication, a manufacturing process that quietly powers industries worth billions of dollars globally.

Sheet metal fabrication is the process of creating parts, components, assemblies, and structures from flat metal sheets through cutting, forming, bending, and joining operations.

Sounds simple enough, right? But here's what most people don't realize: this process encompasses dozens of specialized techniques, each with unique cost implications that fabrication shops rarely discuss upfront.

From Flat Stock to Functional Parts

Imagine starting with a plain metal sheet and ending up with complex brackets, enclosures, chassis, or even rocket components. That's exactly what metal fabrication accomplishes. The raw materials are flat metal sheets of various sizes, thicknesses, and compositions. Through a carefully orchestrated sequence of operations, fabricators transform these materials into everything from smartphone housings to submarine hulls.

The transformation happens in stages. First, designers create 3D CAD models that generate machine-readable code. Then, CNC-controlled machines execute precise cuts and bends according to those specifications. Finally, joining and finishing operations complete the product. Each stage adds value, but also adds cost, which is why understanding this workflow matters for your budget.

The Manufacturing Process That Shapes Modern Industry

Metal fabrication isn't limited to one sector. According to industry research, the global sheet metal fabrication services market is projected to surpass £15 billion by 2030. Here's where you'll find these processes at work:

- Automotive: Over 50% of car components come from sheet metal, including body panels, floor pans, and mounting brackets

- Aerospace: Aircraft bodies, fuselages, engine components, and spacecraft rely on precision metal sheet forming

- Electronics: Device enclosures, chassis, and heat shields protect sensitive components

- Construction: Roofing, cladding, HVAC systems, and structural elements all depend on fabricated metal

Why Sheet Metal Remains Essential in Manufacturing

When you're sourcing parts or planning a project, understanding what is metal fabrication gives you negotiating power. Engineers who grasp the process can design more cost-effective parts. Procurement professionals who understand material and process options avoid overpaying. Designers who know the limitations can create manufacturable products the first time.

The metal fab industry offers something few other manufacturing methods can match: versatility combined with scalability. You can produce a single prototype or millions of identical parts using the same fundamental techniques. That flexibility, however, comes with complexity in pricing, which is exactly what we'll expose throughout this guide.

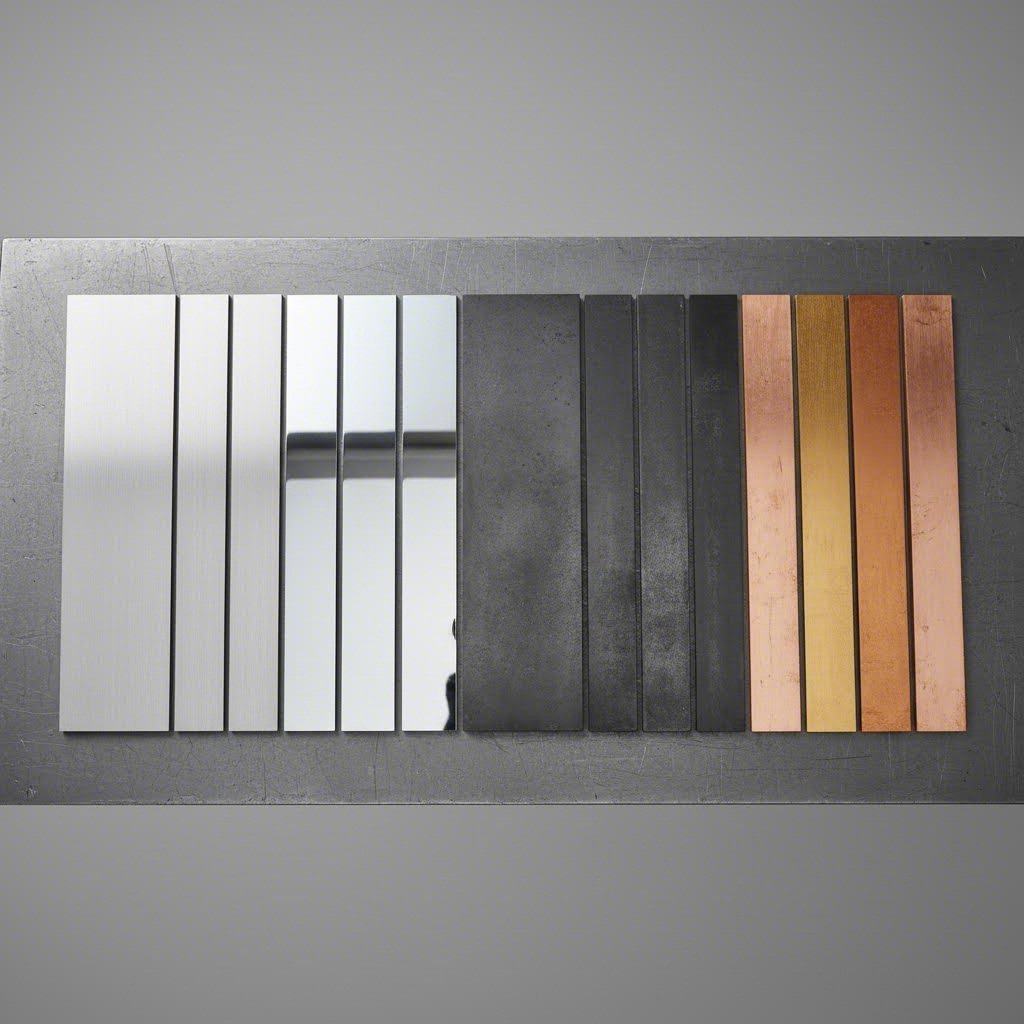

Essential Materials for Sheet Metal Projects

Choosing the wrong material can double your project costs overnight. Most fabrication shops won't volunteer this information, but material selection impacts everything from tooling wear to scrap rates to finishing requirements. Understanding what you're buying, and why, gives you leverage at the quoting table.

Here's what complicates matters: each metal behaves differently under stress, reacts uniquely to cutting and bending operations, and carries vastly different price tags. Let's break down exactly what you need to know before committing to a material specification.

Aluminum vs Steel for Your Project

This comparison comes up in nearly every project discussion. An aluminum sheet offers roughly one-third the weight of steel at comparable dimensions. That sounds perfect until you realize aluminum's tensile strength ranges from 70 to 700 MPa depending on the alloy, while carbon steel delivers 400 to 550 MPa consistently.

When should you choose aluminum sheet metal? Aircraft components, consumer electronics housings, and applications where weight reduction justifies higher material costs. Aluminum naturally resists corrosion because it forms a protective oxide layer when exposed to air, eliminating the need for protective coatings in many applications.

Steel plate remains the workhorse of industrial fabrication for good reason. Carbon steel welds easily, machines predictably, and costs significantly less per pound. However, it rusts without protective treatment, adding finishing costs back into your budget. High-strength low-alloy (HSLA) steels offer improved performance while maintaining weldability, making them ideal for automotive chassis and structural components.

Stainless steel sheet splits the difference. The chromium content (typically 11% or higher) creates a self-healing protective layer that prevents rust and staining. You'll pay 3 to 5 times more than carbon steel, but you may eliminate finishing operations entirely. According to industry experts, stainless steel remains both strong and corrosion-resistant while staying relatively easy to work with.

Understanding Material Properties and Selection Criteria

Beyond the aluminum versus steel debate, several critical properties determine whether a material suits your application:

- Tensile strength: How much pulling force the material handles before breaking. Stainless steel excels here; aluminum requires thicker gauges to match.

- Corrosion resistance: Titanium and aluminum lead the pack. Carbon steel fails quickly without treatment.

- Formability: Copper and brass bend without cracking. High-carbon steel fights every operation.

- Weldability: Carbon steel joins easily. Aluminum demands specialized equipment and expertise, increasing labor costs.

- Thermal conductivity: Copper conducts heat exceptionally well, making it essential for heat exchangers and electrical components.

Speaking of copper and its alloys, the brass vs bronze question surfaces frequently in decorative and marine applications. Brass (copper plus zinc) offers excellent machinability and a gold-like appearance. Bronze (copper plus tin) provides superior corrosion resistance, especially in saltwater environments. Both cost more than steel but deliver properties no ferrous metal can match.

| Material Type | Tensile Strength Range | Best Applications | Thickness Availability | Relative Cost |

|---|---|---|---|---|

| Aluminum (6061-T6) | 124-310 MPa | Aerospace, electronics enclosures, automotive panels | 0.5mm - 6mm common | $$ |

| Carbon Steel | 400-550 MPa | Construction, automotive frames, industrial equipment | 0.4mm - 12mm+ | $ |

| Stainless Steel (304) | 515-620 MPa | Food processing, medical, marine, architectural | 0.5mm - 6mm common | $$$ |

| Copper | 210-220 MPa | Electrical components, heat exchangers, roofing | 0.3mm - 3mm common | $$$$ |

| Brass | 340-470 MPa | Decorative hardware, plumbing, musical instruments | 0.5mm - 3mm common | $$$ |

Reading the Gauge Size Chart Correctly

Here's where fabrication shops often create confusion, sometimes intentionally. Gauge sizes don't translate directly across materials. As manufacturing references confirm, a 16-gauge steel sheet isn't the same thickness as 16-gauge aluminum.

The gauge system originated as 19th-century manufacturing shorthand. Lower gauge numbers mean thicker material, which already feels counterintuitive. Worse, galvanized steel, stainless steel, and aluminum each follow different conversion standards. A 16-gauge steel measures approximately 1.52mm, while 16-gauge aluminum runs around 1.29mm.

Most professional specifications now call out thickness directly in millimeters or inches rather than relying on gauge sizes. If your shop quotes gauge numbers without clarifying actual dimensions, ask for explicit measurements. This small step prevents costly manufacturing surprises when parts arrive thinner or thicker than expected.

What does this mean for your budget? Material thickness directly affects weight, which drives material costs. It also influences forming operations. Thicker materials require more powerful equipment and slower processing speeds, increasing labor and machine time charges. Understanding the gauge size chart helps you specify exactly what you need without overpaying for unnecessary thickness or underspecifying critical structural components.

The Step-by-Step Sheet Metal Fabrication Process

Most fabrication shops quote your project as a single line item. What they don't show you is the complex sequence of operations happening behind that number. Each step carries its own cost drivers, and understanding them reveals where your money actually goes.

The sheet metal manufacturing process follows a predictable sequence, but the devil lives in the details. Miss a tolerance specification at the design stage, and you'll pay for it in scrap and rework costs downstream. Let's walk through exactly what happens from the moment you submit a design file to when finished parts ship.

The Complete Fabrication Workflow Explained

Every steel fabrication project moves through five distinct phases. Some shops combine operations to save handling time, while others specialize in just one or two stages. Here's the complete sequence:

- Design Preparation and Engineering Review: Your CAD files get converted into machine-readable formats. Engineers verify manufacturability, checking bend radii, hole placements, and material specifications. This stage catches problems that would become expensive later.

- Material Cutting: Laser cutting, plasma cutting, or waterjet systems slice raw sheets into flat patterns called blanks. The machine follows nested layouts that maximize material usage and minimize waste.

- Forming and Bending: Press brakes and forming tools transform flat blanks into three-dimensional shapes. Each bend requires specific tooling and precise positioning to hit dimensional targets.

- Joining and Assembly: Welding, riveting, fastening, or adhesive bonding connects individual components into assemblies. Joint design affects both structural integrity and cosmetic appearance.

- Finishing and Quality Control: Surface treatments protect against corrosion and improve aesthetics. Inspection verifies that parts meet tolerance requirements before shipping.

Sounds straightforward? Here's what complicates everything: decisions made at each stage ripple forward. A cutting method that leaves rough edges demands more finishing work. A bend sequence that traps tooling access points forces manual workarounds. These hidden dependencies explain why seemingly similar quotes vary by 40% or more between shops.

From Design File to Finished Part

The cutting phase deserves special attention because it sets the foundation for everything that follows. When a laser or plasma torch cuts through metal, it removes material. That removed material, called kerf, ranges from 0.1mm for fiber lasers to 6mm or more for plasma systems.

Why does kerf matter to your budget? Imagine ordering parts where holes must align precisely. If the programmer doesn't compensate for kerf width, every hole ends up oversized. Parts fail inspection, material gets scrapped, and your delivery date slips. Experienced programmers adjust toolpaths automatically, but verification still costs time.

After cutting, steel sheet bending transforms flat patterns into three-dimensional geometry. This is where fabrication gets genuinely technical. Every bend creates a neutral axis where material neither stretches nor compresses. Outside that axis, metal elongates. Inside, it compresses. Fail to account for this, and your flat pattern dimensions won't produce correct final dimensions.

The bend radius calculation determines how much material "grows" during bending. Tighter radii create more elongation but risk cracking, especially in harder materials. Standard practice uses a minimum inside bend radius equal to the material thickness for ductile metals like mild steel. Aluminum and stainless steel often require 1.5 to 2 times material thickness to avoid surface cracking.

Critical Checkpoints in the Manufacturing Sequence

Joining operations introduce another cost variable that shops rarely discuss openly. The choice between mig vs tig welding significantly impacts both quality and price. MIG (Metal Inert Gas) welding runs faster, making it economical for long seams and thicker materials. TIG (Tungsten Inert Gas) welding produces cleaner, more precise joints but takes three to four times longer.

Aluminum welding presents particular challenges. The oxide layer that protects aluminum from corrosion also prevents proper fusion. Welders must use alternating current TIG equipment and specialized techniques to break through this layer. Expect aluminum welding costs to run 50% to 100% higher than comparable steel work.

Tolerance standards tie everything together. Industry-standard tolerances for sheet metal typically follow these guidelines:

- Linear dimensions: ±0.5mm for features under 150mm, ±0.8mm for larger dimensions

- Bend angles: ±1 degree for standard press brake operations

- Hole locations: ±0.25mm when laser cut, ±0.5mm for punched holes

- Overall flatness: 1mm per 300mm of surface length

Tighter tolerances are absolutely achievable, but they cost more. Each decimal place of precision requires slower machine speeds, more frequent inspection, and higher rejection rates. Before specifying ±0.1mm on every dimension, ask yourself which features actually need that precision. Relaxing non-critical tolerances often reduces costs by 15% to 25% without affecting function.

Understanding this complete workflow gives you something valuable: the ability to ask informed questions. When a shop quotes bending at a certain rate, you can ask about their minimum bend radius capabilities. When cutting costs seem high, you can inquire about kerf compensation and nesting efficiency. That knowledge transforms you from a passive buyer into an informed partner who recognizes fair pricing from inflated margins.

Cutting Methods Compared for Optimal Results

Here's a secret fabrication shops rarely share upfront: the cutting method they choose for your project can swing costs by 300% or more. Most quotes simply list "cutting" as a line item without explaining why they selected one technology over another. That opacity benefits the shop, not you.

Each metal cutter technology excels in specific situations and fails miserably in others. Understanding these differences helps you question quotes intelligently and sometimes request alternative approaches that deliver the same results at lower costs. Let's dissect the four primary cutting technologies you'll encounter.

Laser Cutting vs Plasma vs Waterjet

Think of these three technologies as different tools in a toolbox. You wouldn't use a sledgehammer to hang a picture frame, and you shouldn't use plasma cutting when laser precision is essential. Each technology operates on fundamentally different principles.

Laser cutting uses a focused beam of light to melt, burn, or vaporize material. According to manufacturing experts, the process uses compressed gas (often oxygen or nitrogen) and electric current to produce coherent light that can be focused precisely. This makes laser cutter technology ideal for thin to medium thickness materials up to around 25mm, delivering extremely clean edges and fine feature capabilities.

Pros of Laser Cutting

- Exceptional precision with tolerances as tight as ±0.1mm

- Fast cutting speeds on thin materials

- Minimal material distortion due to small heat-affected zones

- Capable of cutting both metals and non-metals

- Excellent edge quality requiring little to no finishing

Cons of Laser Cutting

- Struggles with highly reflective materials like copper and brass

- Limited thickness capacity compared to plasma or waterjet

- Higher initial equipment costs translate to higher per-part pricing

- Produces hazardous fumes requiring proper ventilation systems

Plasma cutting forces electrically ionized gas through a torch nozzle at high pressure. When power activates, the spark heats gas until it reaches the fourth state of matter, plasma, which turns metal into molten slag. This method handles conductive materials like steel and aluminum quickly but sacrifices precision for speed.

Pros of Plasma Cutting

- Significantly faster than laser or waterjet on medium to thick materials

- Lower equipment and operating costs

- Handles materials up to 160mm thick

- Excellent for carbon steel and aluminum

- Lower barrier to entry for shops, often meaning lower quotes

Cons of Plasma Cutting

- Less precise than laser cutting with larger kerf widths

- Creates larger heat-affected zones that may require secondary operations

- Limited to conductive materials only

- Rougher edge quality compared to laser or waterjet

Waterjet cutting pushes water mixed with abrasive particles through a ceramic nozzle at pressures exceeding 50,000 PSI. This cold cutting process works on virtually any material without thermal distortion. The trade-off? It's messy, slower, and the garnet abrasive adds significant operating costs.

Pros of Waterjet Cutting

- Cuts virtually any material including stone, glass, and composites

- No heat-affected zone preserves material properties

- Excellent edge quality and precision

- Ideal for heat-sensitive materials that would distort under thermal cutting

- Handles thick materials that challenge other methods

Cons of Waterjet Cutting

- Slower cutting speeds than laser or plasma

- High operating costs due to abrasive consumption

- Maintenance-intensive equipment

- Requires water management and disposal systems

Choosing the Right Cutting Technology

So what does CNC meaning have to do with cutting precision? CNC stands for Computer Numerical Control, and it transforms any cutting technology into a precision instrument. Whether laser, plasma, waterjet, or routing, CNC systems execute programmed toolpaths with repeatability measured in hundredths of a millimeter.

A cnc router cnc system adds another dimension to your options. Unlike the thermal and abrasive methods above, CNC routing uses rotating cutting tools to physically remove material. This works exceptionally well for aluminum, plastics, and wood where you need machined features like pockets, counterbores, or complex 3D contours that flat cutting methods cannot produce.

When evaluating shops, especially if you're searching for metal cutting near me options, ask which technologies they operate. A shop with only plasma capability will struggle with precision aluminum work. Conversely, a shop focused on thin-gauge laser work may need to outsource your thick steel plate requirements.

| Method | Material Compatibility | Thickness Range | Precision Level | Edge Quality | Speed | Best Applications |

|---|---|---|---|---|---|---|

| Laser Cutting | Metals, plastics, wood, ceramics | 0.5mm - 25mm | ±0.1mm | Excellent | Fast (thin materials) | Precision parts, electronics enclosures, intricate patterns |

| Plasma Cutting | Conductive metals only | 1mm - 160mm | ±0.4mm - 1.2mm | Good | Very fast | Structural steel, thick plate, high-volume production |

| Waterjet Cutting | Any material including stone, glass | 0.5mm - 200mm+ | ±0.1mm - 0.25mm | Excellent | Slow to moderate | Heat-sensitive materials, thick composites, precision work |

| CNC Routing | Aluminum, plastics, wood, composites | 3mm - 100mm | ±0.05mm - 0.1mm | Good to excellent | Moderate | 3D features, pockets, complex geometries, prototyping |

When Precision Matters Most

Certain applications demand tighter tolerances than others. Medical device housings, aerospace brackets, and optical equipment mounts cannot tolerate the edge variation plasma cutting produces. For these projects, laser cutting or waterjet becomes non-negotiable despite higher costs.

Industry analysis confirms that precision and tolerance requirements are crucial when selecting cutting technology. Laser and EDM (Electrical Discharge Machining) excel for high-precision applications offering fine detail and accuracy. Waterjet provides strong precision especially for intricate shapes with minimal distortion.

Consider these decision factors when your project demands precision:

- Mating surfaces: Parts that interface with other components need consistent edge geometry. Laser or waterjet delivers this reliability.

- Cosmetic requirements: Visible edges on consumer products cannot show the dross and oxidation plasma leaves behind.

- Heat sensitivity: Hardened materials or those with critical temper specifications require waterjet's cold cutting process.

- Complex geometry: Intricate patterns with small features need laser's fine kerf width to maintain design intent.

What about speed versus quality trade-offs? Plasma cutting rips through quarter-inch steel plate faster than any alternative. If your structural application tolerates rougher edges and slightly wider tolerances, plasma delivers significant cost savings. The key is matching the technology to actual requirements, not defaulting to the most precise option when it isn't necessary.

Armed with this comparison, you can now challenge quotes that specify expensive laser cutting for applications where plasma would perform identically. You can also insist on precision methods when edge quality and dimensional accuracy directly affect your product's function. That knowledge shifts bargaining power from the fabrication shop to you.

Design for Manufacturability Guidelines

Here's an uncomfortable truth: most sheet metal projects that run over budget weren't quoted incorrectly. They were designed incorrectly. Fabrication shops see the same preventable mistakes week after week, and they'll happily charge you to work around them. Understanding Design for Manufacturability (DFM) principles transforms you from a customer who pays for problems into one who avoids them entirely.

Think about it this way. Every feature you design must be physically created by machines with real limitations. Ignore those limitations, and you're paying premium rates for workarounds, secondary operations, and scrap parts that never should have been made. Let's examine the specific design rules that separate cost-effective sheet metal working from expensive trial-and-error.

Design Rules That Reduce Manufacturing Costs

The fundamentals of precision sheet metal fabrication start with bend geometry. According to manufacturing experts, designing your bends correctly can eliminate setup changes, reduce tooling costs, and prevent material failures.

Bend Radius Requirements: The inside curve of any bend should at least match the material thickness. Think of bending metal like folding cardboard. Too sharp, and the outer surface cracks. For ductile materials like mild steel, a 1:1 ratio works well. Harder materials like 6061-T6 aluminum require minimum bend radii of 4 times material thickness to prevent surface fractures.

Minimum Flange Length: Your press brake needs something to grab. Industry guidelines specify that flanges should measure at least 4 times the material thickness. Shorter flanges force manufacturers to use custom, expensive tooling that can double production costs. A 2mm steel sheet requires minimum 8mm flanges to use standard equipment.

Bend Relief Design: When a bend runs into unbent material, stress concentrations cause tearing. Bend relief, a small rectangular or circular cutout at bend terminations, allows controlled deformation. Engineering references recommend bend relief width greater than or equal to half the material thickness.

Hole Placement Relative to Bends: Place holes too close to a bend line, and they stretch into ovals during forming. The simple rule? Keep holes at minimum 2 times material thickness from any bend location. Some manufacturers recommend the 4T rule: maintain 4 times material thickness clearance for all features near bends. For a 1.27mm copper sheet, that means 5.08mm minimum clearance.

Avoiding Common Sheet Metal Design Mistakes

Even experienced engineers make these errors. Recognizing them before submitting designs saves revision cycles and prevents costly rework.

- Mistake: Submitting solid 3D models without bend information. Solution: Provide CAD files that appear folded but clearly indicate bend locations, radii, and directions. Sheet metal is flat stock that gets formed; your model must reflect that reality.

- Mistake: Specifying different bend radii throughout a part. Solution: Standardize on a single radius wherever possible. Each radius change requires tooling changes, adding setup time and cost to your project.

- Mistake: Designing perfectly perpendicular corners. Solution: Recognize that press brakes create rounded bends, not sharp angles. The internal radius (typically 0.76mm default) affects both appearance and dimensional accuracy.

- Mistake: Ignoring material grain direction. Solution: Orient bends perpendicular to the rolling direction whenever possible. Bending with the grain causes cracking, especially in hardened aluminum alloys.

- Mistake: Creating narrow slots or tabs that warp during cutting. Solution: Keep cutout widths at least 1.5 times material thickness. Laser heat distorts thin fingers into unusable shapes.

- Mistake: Specifying unnecessarily tight tolerances. Solution: Apply precision only where function demands it. Standard sheet metal tolerances of ±0.5mm work for most applications. Tighter specs increase inspection time and rejection rates.

Prototyping Best Practices for Faster Iteration

Sheet metal prototyping differs fundamentally from production manufacturing. The goal isn't efficiency; it's learning. Smart prototype sheet metal strategies help you discover problems cheaply before committing to production tooling.

When developing a sheet metal prototype, consider these approaches:

- Start with laser cutting: Laser systems offer flexibility for design changes without tooling modifications. Your first prototype will likely need revisions, so avoid processes that require expensive setup.

- Use standard tooling whenever possible: Custom metal parts that require special punches or dies add weeks to timelines and thousands to budgets. Design around standard hole sizes and bend radii during prototyping phases.

- Test forming operations on scrap: Before cutting expensive material, verify that your bend sequences work without trapping tooling access. Nested bends often require specific order of operations that aren't obvious from CAD models.

- Document everything: Each sheet metal prototyping iteration should produce notes about what worked, what failed, and what needs adjustment. These records prevent repeating mistakes and accelerate design convergence.

The cost difference between well-designed and poorly designed parts compounds at every production stage. A hole placed correctly costs nothing extra. A hole placed 3mm too close to a bend requires secondary machining operations, adding handling time, fixturing, and quality inspection steps. Multiply that across hundreds or thousands of parts, and DFM knowledge becomes worth tens of thousands of dollars.

Before finalizing any design, run through a simple checklist: verify bend radii meet minimum requirements, confirm flange lengths accommodate standard tooling, check hole and feature clearances from all bends, and ensure bend relief exists wherever bends terminate at edges. These few minutes of review prevent weeks of production headaches and the budget overruns that shops quietly add to invoices.

Surface Finishing Options and Treatments

Your fabrication shop just delivered beautifully formed parts. Now comes the decision that determines whether those parts last 2 years or 20: surface finishing. Most quotes bundle finishing as a single line item, hiding the dramatic cost and performance differences between treatment options. Understanding these distinctions helps you specify exactly what your application needs without overpaying for unnecessary protection.

Surface treatments serve three primary purposes: corrosion protection, aesthetic enhancement, and functional performance. Some finishes excel at all three. Others specialize in one area while sacrificing another. Let's examine what each option actually delivers.

Powder Coating vs Anodizing Explained

These two finishing methods dominate the sheet metal and fabrication industry, yet they work through completely different mechanisms. Choosing incorrectly wastes money and delivers disappointing results.

Powder coating applies pigmented powder electrostatically to metal surfaces, then cures it in an oven to create a durable protective film. Think of it as paint without the solvent. The powder particles carry an electrostatic charge that attracts them uniformly across the workpiece surface. According to industry specialists, this method excels at safeguarding metal products from corrosion and physical harm while offering a broad color palette and customizable surface textures.

Powder coat finishes work on virtually any metal substrate: steel, aluminum, stainless steel, and even brass. The typical coating thickness ranges from 60 to 80 microns, providing excellent impact resistance and UV stability. Powder coating services often stock hundreds of standard colors, making custom matching straightforward and economical.

Anodizing takes a fundamentally different approach. Rather than applying a coating over the metal, anodizing grows a protective oxide layer from the aluminum itself through an electrochemical process. As finishing experts explain, aluminum oxide is a hard, durable, weather-resistant substance that protects the base metal. The coating is integral to the metal and cannot peel or flake.

Here's the critical distinction: anodized aluminum creates a finish that becomes part of the metal structure. Scratching through powder coat exposes bare metal. Scratching anodized aluminum reveals more aluminum oxide underneath. This makes anodizing superior for high-wear applications like door handles, kick plates, and architectural trim.

However, anodizing only works on aluminum and its alloys. Steel, copper, and brass require alternative treatments. The process also limits color options compared to powder coating, though vibrant dyes can be absorbed into the porous oxide layer before sealing.

Protective Finishes for Long-Term Performance

Beyond these two dominant methods, several specialized treatments address specific performance requirements.

Electroplating deposits thin metal layers onto substrates using electric current. Zinc plating protects steel from rust. Nickel plating adds hardness and corrosion resistance. Chrome plating delivers the mirror-bright finish you see on automotive trim. Industry sources confirm that electroplating creates a protective "coat" for the metal, enhancing its ability to resist corrosion, wear, and the test of time.

Passivation removes free iron from stainless steel surfaces and enhances the natural chromium oxide protective layer. This chemical treatment is virtually invisible and doesn't alter the workpiece's appearance or thickness. For stainless steel components in medical or food processing applications, passivation is often mandatory.

Phosphating creates crystalline phosphate layers that improve paint adhesion and provide temporary corrosion protection. You'll find this treatment on automotive chassis components where it serves as a primer before powder coating or painting.

Understanding copper and oxidation reveals why some metals need protection while others don't. Copper naturally develops a protective patina over time, the greenish layer you see on aged bronze statues. This self-protecting behavior makes copper excellent for roofing and decorative applications where the aged appearance is desirable. However, when consistent appearance matters, clear lacquer or specialized copper treatments prevent patina formation.

| Finish Type | Process Description | Durability | Appearance Options | Ideal Materials |

|---|---|---|---|---|

| Powder Coating | Electrostatic powder application followed by oven curing at 180-200°C | Excellent impact and UV resistance; 15-20 year exterior life | Virtually unlimited colors; matte, satin, gloss, textured finishes | Steel, aluminum, stainless steel, brass |

| Anodizing | Electrochemical oxide growth from aluminum surface | Superior abrasion resistance; renewable through cleaning; 20+ year life | Clear, bronze, black; limited dye colors available | Aluminum and aluminum alloys only |

| Zinc Plating | Electrodeposition of zinc layer onto steel substrates | Good corrosion protection; sacrificial protection for steel | Bright silver, yellow chromate, black chromate | Carbon steel, low-alloy steel |

| Nickel Plating | Electrodeposition of nickel for hardness and corrosion resistance | Excellent wear resistance; good chemical resistance | Bright metallic silver finish | Steel, copper, brass, aluminum (with zincate) |

| Passivation | Chemical treatment to enhance natural oxide layer | Enhances inherent corrosion resistance; invisible treatment | No change to appearance | Stainless steel |

Choosing Surface Treatments for Your Application

Selecting the right finish requires balancing several factors that shops rarely discuss during quoting.

Environment exposure: Outdoor applications demand finishes rated for UV stability and moisture resistance. Industry specifications like AAMA 2605 require actual ten-year Florida exposure testing for architectural coatings. Interior applications can often use less expensive treatments.

Abrasion requirements: High-traffic areas favor anodizing's integral hardness over powder coating's applied film. Anodizing's Achilles heel, however, is chemical resistance. Urban environments with acidic pollutants eventually degrade anodized surfaces, though they can often be cleaned and renewed.

Color matching: When precise color matching matters, powder coating offers unmatched flexibility. Anodizing produces color through optical interference effects, making exact matching between batches challenging.

Cost considerations: Powder coating typically costs less than anodizing for comparable coverage. However, anodizing may eliminate recoating costs over a building's lifetime since it can be renewed through cleaning rather than requiring complete refinishing.

Consider these application-specific recommendations:

- Automotive components: Powder coating over phosphate pretreatment for body panels; zinc plating for fasteners and brackets

- Electronics enclosures: Anodized aluminum for heat dissipation and EMI shielding; powder coat for steel chassis

- Architectural elements: Class I anodizing (0.7 mils minimum) for storefronts; PVDF coatings for curtainwall systems

- Food processing equipment: Passivated stainless steel; electropolished surfaces where cleanability is critical

- Marine applications: Anodized aluminum or specialized marine-grade powder coatings rated for salt spray exposure

The finishing decision ultimately affects your total cost of ownership, not just initial project pricing. A cheaper finish that fails in three years costs far more than a premium treatment lasting decades. When evaluating quotes, ask specifically about finish specifications, thickness requirements, and warranty terms. That information reveals whether you're getting genuine protection or just cosmetic coverage.

Industry Applications and Use Cases

Ever wonder why the same fabrication shop quotes dramatically different prices for seemingly similar parts? The answer often lies in industry-specific requirements that shops don't explain. A bracket destined for an airplane demands certifications, material traceability, and inspection protocols that a similar bracket for an HVAC duct never needs. Understanding these differences helps you avoid paying aerospace premiums for commodity applications.

Each industry sector brings unique demands to sheet metal and fabrication projects. According to manufacturing specialists, professional sheet metal work forms the structural foundation of thousands of applications across diverse industries, directly influencing function and longevity. Let's examine what these requirements actually mean for your budget and specifications.

Automotive Applications and Requirements

The automotive sector consumes more fabricated sheet metal than perhaps any other industry. From chassis rails to battery enclosures in electric vehicles, every gram matters while structural integrity remains non-negotiable.

- Chassis and structural components: Floor pans, cross members, and subframes require high-strength steels capable of absorbing crash energy. Tolerance requirements typically fall within ±0.5mm for mounting locations.

- Body panels and closures: Door skins, hoods, and fenders demand Class A surface quality with no visible forming marks. Aluminum increasingly replaces steel for weight reduction.

- Battery housings and EV components: Industrial fabrication for e-mobility requires lightweight yet highly stable components where every gram is crucial. Complex edge sequences and welded assemblies characterize this work.

- Brackets and mounting systems: Engine mounts, transmission supports, and suspension brackets use HSLA steels for strength-to-weight optimization.

Material preferences in automotive lean heavily toward high-strength steels and aluminum alloys. Production typically involves complex forming sequences that require specialized tooling and precise bend calculations. When searching for steel fabricators capable of automotive work, verify they understand crash performance requirements and material certifications specific to this sector.

Industry-Specific Fabrication Standards

Beyond automotive, several other sectors demand specialized approaches that affect both capability requirements and pricing.

Aerospace and Defense:

- Structural brackets, interior panels, and engine components dominate this category

- Titanium and specialty aluminum alloys like 7075-T6 provide strength without weight penalties

- Tolerances often tighten to ±0.1mm with mandatory first-article inspection

- Manufacturing for aerospace requires maximum precision through processes like 5-axis laser cutting or waterjet to minimize thermal influences

- Full material traceability and certified welding procedures are standard requirements

Electronics and IT Equipment:

- Control cabinets, server housings, front panels, and EMI shielding enclosures represent typical applications

- Lightweight aluminum alloys (raw or anodized) and thin galvanized steel predominate

- Key requirements include precise tolerances for mounting standardized components, effective thermal management, and perfect fit of doors and panels

- Precise laser cutting combined with pressed-in fastening elements simplifies downstream assembly

Medical Technology:

- Housings for diagnostic devices, surgical equipment frames, and patient bed components require absolute hygiene compliance

- High-quality stainless steel (grades 1.4301 and 1.4404) and titanium dominate material selection

- Burr-free cuts through fine laser cutting and non-porous TIG welded connections ensure cleanability

- Surface treatments like electropolishing often follow fabrication to ensure maximum purity

HVAC Systems:

This sector represents some of the highest-volume sheet metal work globally. SMACNA standards govern duct construction, with nearly 100 years of industry specifications covering metal and flexible duct fabrication and installation requirements. Galvanized steel dominates material selection, with gauge thickness determined by duct dimensions and operating pressure. Unlike precision industries, HVAC tolerances are relatively generous, making this sector accessible to fabrication shops near me without specialized certifications.

From Consumer Electronics to Heavy Equipment

The spectrum of industrial fabrication extends from delicate smartphone chassis to massive construction equipment panels. Understanding where your project falls on this spectrum helps you find appropriate manufacturing partners.

Consumer electronics demand cosmetic perfection alongside tight dimensional control. Think laptop housings, speaker enclosures, and appliance panels. These applications favor anodized aluminum and precision laser cutting with tolerances around ±0.2mm. Even decorative applications like custom metal signs for retail environments increasingly rely on precision fabrication techniques.

Construction and Architecture:

- Facade elements, roof drainage systems, and decorative cladding represent primary applications

- Materials range from brushed stainless steel and Corten steel to powder-coated aluminum

- Key requirements focus on weather resistance, resistance to thermal expansion and contraction, and precise execution for complex geometries

- Longer design freedom makes this sector accessible to many fabrication shops near me

Mechanical and Plant Engineering:

- Machine cladding, control cabinets, guards, and conveyor system components make up typical work

- Powder-coated steel or corrosion-resistant stainless steel handle harsh production environments

- Precise laser cutting and exact CNC bending ensure perfect fit even for large assemblies

- Requirements for easy replacement of wear parts often dictate fastener selection and access panel design

When evaluating metal fabrication near me options, match the shop's expertise to your industry requirements. A fabricator specializing in HVAC ductwork may lack the certifications needed for medical devices. Conversely, paying aerospace-certified rates for straightforward industrial equipment brackets wastes budget without adding value.

The tolerance standards, material certifications, and quality documentation requirements vary dramatically across these sectors. Before requesting quotes, determine which industry specifications actually apply to your application. That clarity prevents both underpaying for inadequate capability and overpaying for unnecessary certifications.

Understanding Fabrication Costs and Pricing Factors

Here's what your fabrication shop won't volunteer during the quoting process: that single line item labeled "fabrication" actually contains dozens of hidden cost drivers. Some you can control. Others you can negotiate. Most remain invisible until you understand what's really happening behind that number.

When it comes to sheet metal and fabrication, cost is usually one of the most underrated aspects. According to industry specialists, many people don't realize that understanding cost drivers helps avoid wasteful expenses while maintaining quality. Let's expose exactly what influences your project pricing and how to optimize each factor.

What Drives Fabrication Costs

Every metal fabrication shop calculates quotes using the same fundamental inputs, though they weight them differently based on their equipment, expertise, and overhead structure. Understanding these variables gives you leverage.

- Raw material costs: Material often represents 30% to 50% of your total project cost. Carbon steel sits at the bottom of the price spectrum, while stainless steel runs 3 to 5 times higher. Copper and titanium occupy premium tiers. Beyond material type, thickness directly affects weight and therefore cost per part.

- Part complexity: Each additional bend, cutout, or feature adds programming time, machine cycles, and inspection requirements. Industry data confirms that increased complexity equals increased cost. Parts with intricate geometries, numerous bends, and tight tolerances require more skilled labor and create higher scrap potential.

- Tolerance specifications: Standard tolerances of ±0.5mm cost nothing extra. Tighten that to ±0.1mm, and you're paying for slower machine speeds, more frequent inspection, and higher rejection rates. Before specifying precision everywhere, identify which features actually need it.

- Production quantity: Setup costs get amortized across your order. A 10-piece run might cost $50 per part while 1,000 pieces drops to $8 each. The first article consumes the same programming and fixturing time regardless of quantity.

- Finishing requirements: Cost estimates suggest basic powder coating or painting runs approximately $2 to $5 per square foot. Specialized plating or multiple-layer finishes can reach $15+ per square foot. Masking for selective finishing adds labor costs.

- Lead time demands: Standard lead times allow shops to schedule production optimally. Rush orders interrupt this flow, requiring overtime, expedited material orders, and priority scheduling over other jobs, all commanding premium charges.

- Skilled labor rates: Geographic location dramatically impacts labor costs. Industry comparisons show skilled CNC programmers in America command $30 to $60 per hour, while comparable expertise in Asia runs $10 to $25 per hour.

What about specific process costs? Manufacturing references indicate laser or plasma cutting typically costs $1.50 to $6.00 per linear foot depending on material and complexity. Simple bending operations run roughly $1 to $5 per bend, increasing with material thickness and tighter tolerances. Welding ranges from $20 to $50 for basic tack welds up to $200 to $1,000+ for extensive TIG work on stainless or aluminum.

Optimizing Your Project Budget

Cost optimization starts long before you request quotes. The decisions you make during design directly determine what you'll pay during manufacturing. Here's how to reduce expenses without sacrificing function.

- Simplify design geometry: Question every feature. Can that complex curve become a simple bend? Can multiple parts consolidate into one? Reducing bends, holes, welds, and fasteners delivers direct cost savings.

- Right-size material specifications: Avoid over-specifying. If carbon steel meets functional requirements, using stainless steel wastes budget. Consider processability and finishing compatibility alongside raw material costs.

- Optimize for nesting efficiency: Can your part dimensions adjust slightly to fit better onto standard sheet sizes? Minimizing scrap directly reduces material costs. Consult with your fabricator about optimal yields for their standard stock.

- Standardize components: Use common hole sizes, bend radii, and hardware across your product line. This allows shops to leverage existing tooling, reduce setup times, and benefit from bulk purchasing.

- Engage fabricators early: This is perhaps the most impactful optimization strategy. Engaging a knowledgeable fabricator during design allows their DFM expertise to identify potential cost drivers before designs are finalized. This collaborative approach prevents costly redesigns downstream.

- Consider production scaling: If volumes will increase significantly, discuss this upfront. This information might influence initial tooling decisions, potentially saving money long-term compared to scaling up inefficiently later.

When evaluating metal fabrication companies near me, look beyond the initial quote. A shop offering rapid sheet metal prototyping capabilities can accelerate your design iterations, reducing total development costs even if per-part pricing runs slightly higher. The time saved in bringing products to market often outweighs small manufacturing cost differences.

Getting Accurate Quotes Faster

The quoting process itself costs time and money. Every email exchange, clarification request, and revision cycle delays your project and consumes engineering resources. Streamlining this process creates real savings.

Manufacturing experts recommend suppressing any details in your models that aren't pertinent to your manufacturer. Unnecessary data slows down estimating and can create confusion about project scope. Include complete hardware bills of materials with precise specifications so systems can automatically generate accurate requirements.

What separates efficient quoting from frustrating back-and-forth exchanges?

- Submit complete files: Include 3D models in standard formats (STEP, IGES, X_T) along with 2D drawings specifying tolerances, materials, and finish requirements.

- Specify quantities and delivery requirements upfront: Volume dramatically affects pricing. Let shops quote your actual needs rather than guessing.

- Identify critical features: Call out dimensions that require tighter tolerances versus those where standard precision suffices.

- Request DFM feedback: Custom metal fabricators with strong engineering support can identify cost reduction opportunities you might have missed.

Quote turnaround time itself becomes a cost factor. Waiting days for pricing delays decision-making and extends project timelines. Manufacturers offering rapid response, such as Shaoyi (Ningbo) Metal Technology's 12-hour quote turnaround, compress this cycle significantly. Their 5-day rapid prototyping capability further accelerates development, allowing you to validate designs quickly before committing to production tooling.

Custom fabrication projects benefit enormously from partners who combine speed with expertise. Look for shops offering comprehensive DFM support alongside quick response times. This combination identifies cost optimization opportunities while maintaining project momentum.

Before requesting quotes from any metal fabrication shop, prepare this information:

- Complete CAD files with bend information clearly indicated

- Material specifications including grade and thickness

- Tolerance requirements for critical dimensions

- Quantity requirements including prototype and production volumes

- Surface finish specifications

- Delivery timeline expectations

- Any certification or documentation requirements

Armed with this preparation and understanding of cost drivers, you transform from a passive recipient of quotes into an informed buyer who recognizes fair pricing. That knowledge shifts negotiating power from the fabrication shop to you, ensuring you pay for value rather than opacity.

Choosing the Right Fabrication Partner

You've optimized your design, selected appropriate materials, and understand the cost drivers. Now comes a decision that can make or break your entire project: selecting the right fabrication partner. This choice extends far beyond comparing line-item pricing. According to industry experts, your reputation with customers depends in part on the quality of products you provide, and the work your fabricator delivers becomes a reflection of you.

What separates reliable sheet metal fabricators from problematic ones? The answer lies in systematic evaluation rather than gut instinct. Let's build a framework that protects your projects and your reputation.

Evaluating Fabrication Partners

When searching for sheet metal fabrication near me or custom sheet metal fabrication near me options, resist the temptation to simply accept the lowest quote. Manufacturing procurement specialists emphasize that treating supplier selection as a strategic decision rather than just a cost quote is essential for long-term success.

Start with these fundamental evaluation criteria:

- Industry experience: Has the fabricator worked in your sector before? A partner familiar with your industry understands quality standards and best practices. They'll anticipate potential issues and may offer design suggestions based on relevant experience.

- Equipment capabilities: Is the company's equipment up to date? State-of-the-art equipment delivers more value and demonstrates the company's commitment to quality work. Outdated machines limit precision and increase scrap rates.

- In-house capabilities: Does the shop handle everything from design through finishing internally? Fabricators who outsource stages of your project cannot guarantee quality as strongly as those who work on it from start to finish.

- DFM support: Look for partners offering Design for Manufacturability and Assembly (DFMA) consultation. This process refines your design to optimize production, supporting faster lead times by reducing rework and waste.

- Workforce stability: High turnover signals problems. Longtime, experienced workers produce consistent quality. Ask about the production staff who will handle your project.

- Customer references: Request a portfolio of previous projects and customer feedback. Use your industry network to gather firsthand experiences with potential partners.

A precision sheet metal fabricator worth partnering with will demonstrate capabilities across multiple areas. Whether your project involves aluminum fabrication, stainless steel fabrication, or complex multi-material assemblies, verify the shop has documented experience with your specific requirements.

Certification Standards That Matter

While many fabricators measure performance against internal standards, third-party certifications provide independent validation that carries far more weight. Industry guidance confirms that certifications from organizations like ISO or the American Welding Society tell you how companies serve their customers.

For automotive applications, one certification stands above others: IATF 16949. According to quality management specialists, this international standard sets the framework that suppliers and manufacturers must follow to ensure products meet the rigorous demands of the automotive industry.

Why does IATF 16949 certification matter for your automotive sheet metal projects?

- Consistency: Every product meets the same high standards of quality and performance across all production runs.

- Compliance: Certified suppliers meet both customer-specific requirements and international regulations.

- Continuous improvement: The standard promotes ongoing review and enhancement of production processes.

- Quality assurance: Certified suppliers reduce defects, prevent quality issues, and maintain consistent product excellence.

- Cost efficiency: Lean manufacturing principles encouraged by the certification reduce waste and improve cost management.

Many large automotive manufacturers only work with certified suppliers, making IATF 16949 essential for accessing market opportunities in this sector.

For industrial fabrication services outside automotive, ISO 9001 provides baseline quality management assurance. Medical device manufacturers should verify ISO 13485 compliance. Welding-intensive projects benefit from AWS (American Welding Society) certified personnel.

Matching Capabilities to Project Needs

The best fabrication partner isn't necessarily the most capable or the cheapest. It's the one whose strengths align with your specific requirements. Use this checklist when evaluating potential partners:

- Technical capability match: Can they handle your material types, thicknesses, and tolerance requirements? Verify specific equipment for your processes.

- Volume compatibility: Does their production capacity match your needs? A shop optimized for high-volume runs may struggle with prototype quantities, and vice versa.

- Lead time alignment: Can they meet your delivery requirements consistently? Ask about typical turnaround times and their process for handling rush orders.

- Geographic considerations: Location affects shipping costs, communication convenience, and supply chain resilience. Consider where your manufacturing partner is located and how they manage logistics.

- Financial stability: A partner unstable in operations or finances poses risk to your supply chain. Evaluate their business health and longevity.

- Communication and responsiveness: How quickly do they respond to inquiries? Strong partnerships require clear communication and mutual understanding.

- Contractual clarity: Ensure pricing, payment terms, intellectual property protection, and liability provisions are clearly documented.

For automotive chassis, suspension, and structural components, consider manufacturers demonstrating comprehensive capabilities across the entire production spectrum. Shaoyi (Ningbo) Metal Technology exemplifies this approach, combining IATF 16949 certification with 5-day rapid prototyping, automated mass production capabilities, and comprehensive DFM support. Their 12-hour quote turnaround accelerates decision-making during critical project phases.

Ultimately, selecting the right fabrication partner means finding alignment between your project requirements and their proven capabilities. Invest time in thorough evaluation upfront, and you'll avoid the costly consequences of mismatched partnerships. The goal isn't finding the cheapest quote. It's building a relationship with a manufacturer who protects your quality standards and delivers consistently over time.

Frequently Asked Questions About Sheet Metal Fabrication

1. What is sheet metal and fabrication?

Sheet metal fabrication is the manufacturing process of transforming flat metal sheets into functional parts, components, and assemblies through cutting, forming, bending, and joining operations. This versatile process serves industries including automotive, aerospace, electronics, and construction. The workflow typically involves design preparation, material cutting using laser or plasma systems, press brake forming, welding or fastening for assembly, and surface finishing for protection and aesthetics.

2. How much does it cost to fabricate sheet metal?

Sheet metal fabrication costs vary significantly based on material selection, part complexity, tolerances, quantity, and finishing requirements. Material costs represent 30-50% of project totals, with carbon steel being most economical and stainless steel costing 3-5 times more. Laser cutting runs $1.50-$6.00 per linear foot, bending operations cost $1-$5 per bend, and welding ranges from $20 for basic tacks to $1,000+ for extensive TIG work. Powder coating adds $2-$5 per square foot. Engaging fabricators early for DFM support helps optimize costs before production.

3. What is the highest paid sheet metal worker?

Sheet metal foremen command the highest salaries in the field, earning $57,000-$77,000 annually. Sheet metal journeymen follow at $51,000-$64,500, while technicians earn $43,500-$61,000. Specialized roles like CNC programmers in fabrication shops can earn $30-$60 per hour in the US. Experience with advanced equipment, certifications from organizations like AWS, and expertise in precision industries like aerospace or medical devices typically command premium compensation.

4. What materials work best for sheet metal fabrication projects?

Material selection depends on application requirements. Carbon steel offers the best value for structural applications but requires protective finishing. Aluminum provides excellent weight reduction at one-third the weight of steel and natural corrosion resistance, making it ideal for aerospace and electronics. Stainless steel costs 3-5 times more than carbon steel but eliminates finishing needs and resists corrosion. Copper excels in electrical and thermal applications. Material thickness follows gauge systems that differ between metals, so always specify actual dimensions in millimeters rather than gauge numbers.

5. How do I choose between laser cutting, plasma cutting, and waterjet cutting?

Each cutting method excels in specific applications. Laser cutting delivers exceptional precision (±0.1mm tolerances) and clean edges for thin to medium materials up to 25mm, ideal for electronics enclosures and intricate patterns. Plasma cutting offers the fastest speeds and lowest costs for conductive metals up to 160mm thick, perfect for structural steel work. Waterjet cutting handles any material without thermal distortion, essential for heat-sensitive applications and thick composites. Match the technology to your material, thickness, precision requirements, and budget constraints.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —