Sheet Metal Finishing Secrets: From Raw Stock To Flawless Surface

Understanding Sheet Metal Finishing and Its Critical Role

When you receive parts fresh from laser cutting or waterjet processing, what do you actually see? Burrs on bottom faces, handling marks, frosting near cut lines, and remnants of manufacturing tabs. This is where sheet metal finishing transforms raw fabricated components into functional, visually appealing products ready for real-world applications.

So, what are metal finishes exactly? They encompass any process that modifies the metal surface to achieve specific characteristics—whether that's enhanced appearance, improved durability, corrosion resistance, or better functionality. Finishing metal isn't merely cosmetic; it directly determines how your parts perform over their entire service life.

What Sets Sheet Metal Finishing Apart

Unlike general metalworking applications, sheet metal presents unique challenges. You're working with thin-gauge materials where even minor finishing processes can impact dimensional accuracy. The flat, expansive surfaces common in sheet metal parts show imperfections more readily than complex machined geometries. Mill marks, fingerprints, and oxidation become immediately visible on these broad metal surfaces.

Additionally, sheet metal components often feature precise bends, formed features, and tight tolerances. Your chosen metal finish must account for material thickness changes and potential distortion during processing. A finish that works perfectly on a solid block might compromise the integrity of a 0.030-inch stainless steel bracket.

Why Surface Treatment Decisions Matter Early

Here's something many engineers learn the hard way: finishing decisions made during design directly affect manufacturing success. According to Xometry's research on post-processing, different finishing methods cause varying degrees of dimensional change—some processes add material, others remove it, and thermal treatments can induce expansion or contraction.

The finishing method you select doesn't just affect final appearance—it influences part dimensions, assembly tolerances, and the entire manufacturing workflow from initial design through final production.

Consider this practical example: powder coating typically adds 1-3 mils of thickness per side. If you've designed mating parts with tight clearances, that coating thickness could prevent proper assembly. Conversely, electropolishing removes material, potentially pushing dimensions outside acceptable tolerances on thin sections.

Proper surface preparation also plays a critical role. As noted by Basilius manufacturing experts, preparation involving cleaning, degreasing, and sometimes roughening the surface ensures finishing treatments adhere properly and perform as expected. Skipping these steps compromises quality regardless of which finishing process you select.

Understanding these fundamentals positions you to make informed decisions throughout this guide—whether you're selecting finishes for corrosion protection, aesthetic appeal, or specialized automotive applications.

Types of Metal Finishes Explained by Process Category

Ever wondered why there are so many different types of surface finishes available for sheet metal? The answer lies in understanding that each finishing method serves distinct purposes—and organizing them by how they interact with the metal surface makes selection far more intuitive.

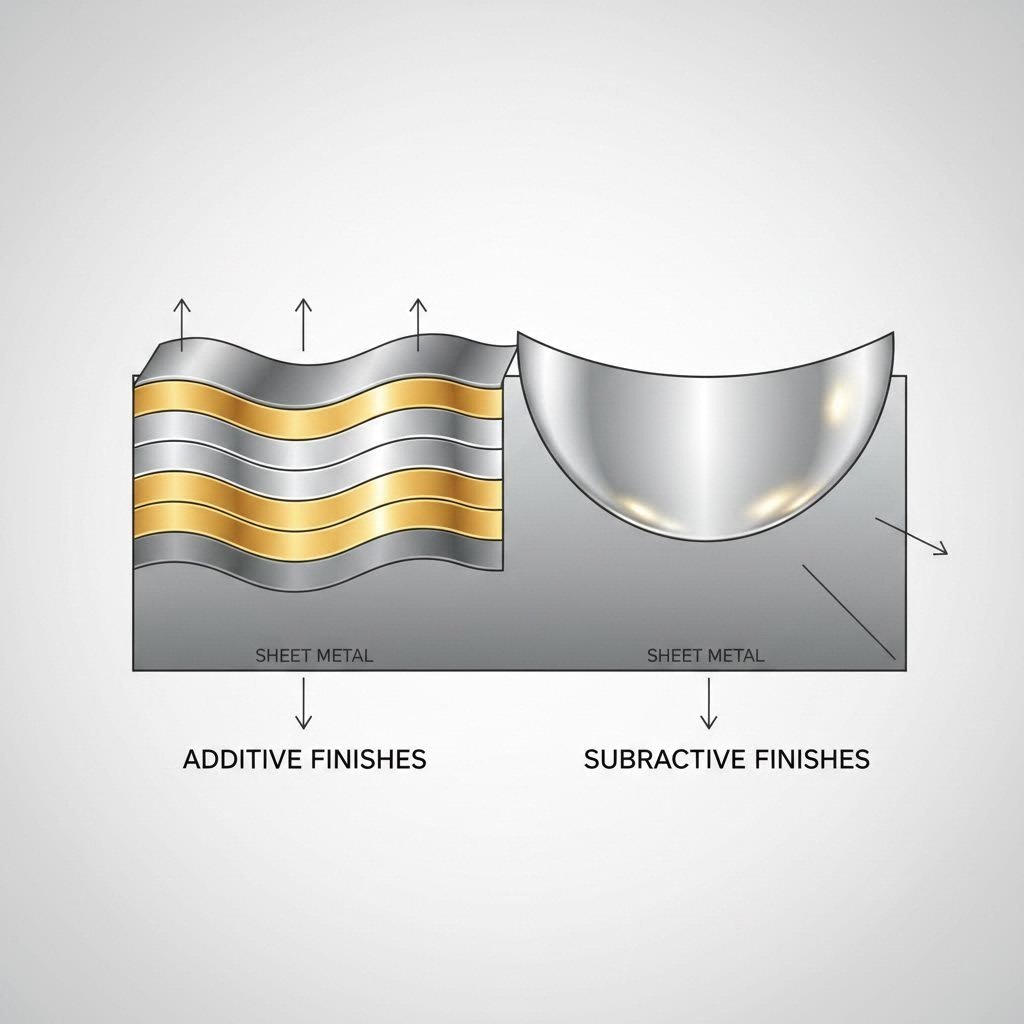

Rather than memorizing an alphabetical list of options, think about sheet metal finishes through a simple framework: some methods add material to your parts, while others remove it. This additive versus subtractive distinction fundamentally changes how each process affects dimensions, tolerances, and performance characteristics.

Additive Finishing Methods That Build Protection

Additive processes deposit new material onto your metal surface—whether that's another metal layer, a polymer coating, or a chemically converted oxide film. These finishes for metal build protective barriers that shield the base material from environmental attack.

Electroplating uses electrical current to deposit metal ions onto your workpiece. According to IQS Directory's metal finishing guide, the process involves submerging parts in an electrolytic solution where metal atoms migrate from a positively charged anode to your negatively charged component. Common plating metals include zinc, nickel, chrome, and gold—each offering specific benefits from corrosion resistance to enhanced conductivity.

Powder coating applies dry polymer powder electrostatically, then cures it under heat to form a seamless protective layer. This process produces durable finishes resistant to chipping, scratching, and fading while generating virtually no hazardous emissions. However, powder coating typically adds 1-3 mils of thickness, which you'll need to account for in tight-tolerance designs.

Hot-dip galvanizing involves immersing steel parts in molten zinc heated to approximately 830°F (443°C). This creates a robust zinc-iron alloy layer that provides exceptional corrosion protection for structural components exposed to harsh environments. The coating thickness is substantial, making this method ideal for construction hardware and outdoor equipment rather than precision assemblies.

Conversion coatings work differently—they chemically alter the existing surface rather than depositing entirely new material. Processes like phosphating and chromate conversion create protective oxide or phosphate layers that guard against corrosion while enhancing paint adhesion. Anodizing, primarily used on aluminum, builds a controlled oxide layer through an electrolytic process, offering wear resistance and decorative color options.

Subtractive Techniques for Precision Surfaces

Subtractive finishing removes material from the metal surface to achieve specific characteristics—whether that's improved smoothness, reduced roughness, or enhanced corrosion resistance through surface purification.

Electropolishing reverses the electroplating concept, using electrical current and chemicals to dissolve a thin layer of metal with precision up to 0.0002 inches. This smooths microscopic peaks and valleys, creating a bright, clean surface with reduced corrosion susceptibility. For stainless steel finishes, electropolishing is often followed by passivation to maximize corrosion protection.

Mechanical polishing and grinding use abrasives to refine surfaces by physically removing rough edges, weld marks, and imperfections. These steel finishes range from coarse grinding for material removal to fine buffing for mirror-like appearances. The degree of smoothness depends on abrasive grit selection and processing time.

Media blasting employs various abrasive materials—from aluminum oxide to glass beads—propelled at high velocity to clean, deburr, and texture metal surfaces. This versatile method removes scale, rust, and old coatings while creating specific surface profiles for subsequent treatments.

Passivation chemically removes free iron and contaminants from stainless steel surfaces, enhancing the natural oxide layer that provides corrosion resistance. Unlike coating methods, passivation doesn't change appearance or add thickness—it simply optimizes the metal's inherent protective properties.

Comparing Types of Finishes by Application and Cost

Understanding different types of surface finishes becomes practical when you can match them to your specific requirements. The following comparison organizes major finishing categories by their process characteristics:

| Finishing Method | Process Type | Typical Applications | Relative Cost |

|---|---|---|---|

| Electroplating (Zinc, Nickel, Chrome) | Additive | Automotive fasteners, electronics, decorative hardware | Medium |

| Powder Coating | Additive | Enclosures, brackets, consumer products, outdoor equipment | Low to Medium |

| Hot-Dip Galvanizing | Additive | Structural steel, guardrails, utility poles, construction hardware | Low |

| Anodizing | Additive (Conversion) | Aluminum enclosures, architectural components, consumer electronics | Medium |

| Phosphate Coating | Additive (Conversion) | Paint preparation, automotive bodies, appliances | Low |

| Electropolishing | Subtractive | Medical devices, food processing, semiconductor equipment | Medium to High |

| Mechanical Polishing/Grinding | Subtractive | Decorative trim, precision surfaces, weld finishing | Low to Medium |

| Media Blasting | Subtractive | Surface preparation, rust removal, texturing | Low |

| Passivation | Subtractive (Chemical) | Stainless steel components, medical instruments, food equipment | Low to Medium |

Notice how types of surface finishes cluster around specific industries? Automotive applications frequently combine phosphating with painting or powder coating. Medical and food processing industries favor electropolishing and passivation for their cleanliness and corrosion benefits. Construction relies heavily on galvanizing for long-term outdoor protection.

Your selection ultimately depends on balancing functional requirements against budget constraints and production volumes. Understanding whether a finish adds or removes material helps you anticipate dimensional impacts—a critical consideration when specifying tolerances and designing mating assemblies.

With this framework established, the next essential step is understanding how surface preparation determines whether any of these finishing methods will perform as expected.

Pre-Finishing Preparation and Surface Requirements

Imagine spending hours applying a premium powder coat only to watch it peel away within weeks. Frustrating? Absolutely. Preventable? Almost always. The root cause of most finishing failures isn't the coating itself—it's what happens before the coating ever touches the metal surface.

According to Alliance Chemical's industrial guide, "I've seen more high-performance coatings fail, more welds crack, and more sensitive electronics short-circuit because of one simple oversight: improper surface preparation." This reality makes metal surface finishing preparation the most critical—yet frequently overlooked—step in achieving lasting results.

Surface Preparation Steps That Prevent Finishing Failures

Think of surface preparation as building a foundation. You wouldn't construct a house on unstable ground, and you shouldn't apply finishes to contaminated or improperly prepared surfaces. The goal is achieving a pristine substrate free of any contaminants that could cause failure.

Surface finish metal contamination falls into two distinct categories that require different treatment approaches:

- Organic contaminants: Oils, greases, cutting fluids, waxes, fingerprints, and adhesives—these are non-polar substances that require solvent-based cleaning

- Inorganic contaminants: Rust, heat scale, mineral deposits, and dust—polar substances that often require mechanical or acid-based removal

The chemical principle of "like dissolves like" determines your cleaning approach. Non-polar solvents tackle organic soils effectively, while different methods address inorganic contamination.

Here's a systematic preparation sequence that prevents common defects:

- Initial cleaning: Remove bulk contamination—chips, debris, and loose particles—through wiping or compressed air

- Degreasing: Eliminate oils and cutting fluids using appropriate solvents (acetone or MEK for quick prep, isopropyl alcohol for electronics, mineral spirits for heavy grease)

- Deburring: Remove sharp edges and burrs from cut or machined features that could compromise coating adhesion or create stress concentrations

- Rust and scale removal: Address inorganic contamination through mechanical abrasion, acid treatment, or conversion processes

- Surface profiling: Create appropriate texture for coating adhesion through media blasting or chemical etching

- Final rinse: Use deionized water to ensure a perfectly clean, spot-free surface before finishing

Matching Prep Methods to Your Chosen Finish

Not every metal surface finish requires identical preparation. The substrate material and intended finishing method dictate specific requirements. Here's where material compatibility becomes critical—the best degreaser is useless if it damages your parts.

For steel and iron components destined for plating or coating, aggressive cleaning with solvents and sodium hydroxide solutions works well. However, aluminum requires a gentler approach. As noted by industrial specialists, sodium hydroxide will actively corrode aluminum surfaces, making it entirely unsuitable for these applications.

When preparing surface finishes for metal parts, consider these method-specific requirements:

- For powder coating: Phosphate conversion coating creates ideal adhesion while providing baseline corrosion protection

- For electroplating: Absolutely clean, oxide-free surfaces ensure uniform metal deposition without pitting or adhesion failures

- For anodizing: Etching creates proper surface profile while removing contamination that would cause uneven oxide formation

- For painting: Light abrasion or chemical etching provides mechanical tooth for coating adhesion

Understanding Surface Roughness Specifications

When specifying metal surface finish requirements, engineers use RA (Roughness Average) measurements expressed in microinches (µin) or micrometers (µm). This value represents the average deviation from the mean surface line—essentially, how smooth or textured your surface is.

A class A surface finish—typically required for visible cosmetic surfaces—demands RA values below 16 µin (0.4 µm). Industrial components might accept 63-125 µin, while prepared surfaces for coating often benefit from 125-250 µin to promote adhesion.

The key insight? Smoother isn't always better. Many coatings require specific surface roughness profiles to achieve proper mechanical bonding. Media blasting specifically creates controlled texture that helps paints and powder coats adhere firmly.

Finish Thickness and Dimensional Impact

Every additive finishing process changes your part dimensions. Accounting for these changes during design prevents assembly failures and tolerance violations.

According to SendCutSend's finishing specifications, typical thickness additions include:

- Type II Anodizing: Adds approximately 0.0004"-0.0018" to overall thickness

- Zinc electroplating: Adds approximately 0.0006" to overall thickness

- Nickel plating: Adds approximately 0.0004" to overall thickness

- Powder coating: Adds approximately 0.004"-0.01" to overall thickness

Notice the significant difference between plating processes and powder coating? A zinc-plated part gains roughly 0.0003" per side, while powder coating adds 0.002"-0.005" per side—nearly ten times more. For mating assemblies with tight clearances, this distinction matters enormously.

When specifying tolerances, subtract anticipated finish thickness from your design dimensions. If you need a final hole diameter of 0.500" and plan to powder coat, design the hole at 0.504"-0.510" to accommodate coating buildup on internal surfaces.

With proper preparation protocols established and dimensional impacts understood, you're positioned to select finishes based on specific functional requirements—whether that's corrosion protection, aesthetic appeal, or specialized performance characteristics.

Selecting the Right Finish Based on Functional Goals

You've identified your finishing options. You understand preparation requirements. Now comes the practical question every buyer and engineer faces: which finish actually solves your specific problem? Rather than starting with available processes, let's flip the approach—start with what you need your parts to accomplish, then work backward to the ideal solution.

Different types of sheet metal demand different finishing strategies. Aluminum behaves differently than steel. Stainless steel has unique requirements compared to carbon steel. And your functional priorities—whether corrosion protection, visual appeal, wear resistance, or electrical performance—dramatically narrow your choices.

Choosing Finishes for Maximum Corrosion Resistance

When your parts face harsh environments—outdoor exposure, salt spray, chemical contact, or high humidity—corrosion resistance becomes your primary selection criterion. But here's the challenge: multiple types of metal finish claim excellent corrosion protection. How do you distinguish between them?

The answer lies in matching your base material to the appropriate protective strategy. According to Haizol's finishing guide, aluminum parts benefit most from anodizing, which grows a hard oxide film directly from the base material. Steel parts, however, require barrier protection through galvanizing or electroplating with zinc or nickel.

Consider the trade-offs carefully:

- Galvanizing offers exceptional protection for steel at low cost but adds significant thickness and creates a matte gray appearance—ideal for structural components, problematic for precision assemblies

- Zinc electroplating provides thinner, more controlled deposits with better dimensional accuracy but offers less protection than hot-dip galvanizing in severely corrosive environments

- Electroless nickel plating delivers outstanding protection across virtually any conductive metal, with salt spray resistance exceeding 1,000 hours—but at higher cost and with strict process control requirements

- Powder coating creates effective chemical and moisture barriers while enabling color customization, though it lacks the sacrificial protection that zinc-based finishes provide

For mixed metal assemblies where galvanic corrosion poses risks, electroless nickel plating often emerges as the best compromise—it bonds uniformly to diverse substrates and provides consistent protection across different materials.

When Aesthetics Drive Your Finishing Decision

Sometimes appearance matters as much as—or more than—protection. Consumer products, architectural elements, and visible enclosures demand metal surface finishes that look as good as they perform.

Your aesthetic options fall into three broad categories:

- Color and texture finishes: Powder coating leads here, offering virtually unlimited colors, gloss levels, and textures from smooth to heavily textured. Anodizing provides durable, vibrant colors specifically for aluminum, with excellent UV stability

- Reflective metallic finishes: Electropolishing and mechanical polishing create mirror-like surfaces on stainless steel. Chrome plating delivers the classic bright metallic look, though environmental regulations increasingly limit its use

- Natural metal appearances: Brushed finishes create fine parallel lines that hide fingerprints while showcasing the metal itself. Clear anodizing preserves aluminum's natural appearance while adding protection

According to Sytech Precision's analysis, "Polished finishes involve buffing the metal surface to a high shine. This process removes imperfections and creates a smooth, reflective surface." For applications where a flawless, reflective finish matters most, electropolishing followed by passivation delivers optimal results on stainless steel.

The trade-off? Highly reflective finishes on metal show every scratch, fingerprint, and imperfection during use. Brushed or textured finishes often prove more practical for frequently handled components.

Balancing Wear Resistance and Friction Requirements

Parts that slide, rotate, or contact other surfaces face wear challenges that require specific finishing approaches. A metal finisher evaluating wear resistance considers both surface hardness and lubricity—two properties that don't always align.

Hard chrome plating delivers exceptional wear resistance but creates high friction coefficients. Electroless nickel with high phosphorus content offers a good balance of hardness and reduced friction. PTFE-infused coatings sacrifice some hardness for dramatically improved lubricity.

For types of finishes on metal components subject to sliding contact:

- High-phosphorus electroless nickel (11-13% P) provides consistent hardness around 48-52 RC with good corrosion resistance

- Hard chrome plating achieves hardness levels of 65-70 RC but requires careful thickness control to prevent cracking

- Nickel-PTFE composite coatings combine moderate hardness with coefficient of friction values as low as 0.1

Electrical Performance Considerations

Electronics enclosures, grounding components, and EMI shielding applications require finishes that maintain or enhance electrical conductivity. Here, many protective finishes create problems—anodizing, for example, produces an electrically insulating layer that prevents proper grounding.

For electrical applications, consider:

- Conversion coatings (chromate or non-chromate) on aluminum preserve conductivity while adding corrosion protection

- Zinc or cadmium plating maintains good conductivity for grounding surfaces

- Selective masking allows protective finishes on non-critical areas while leaving contact points uncoated or minimally treated

Matching Finishes to Functional Requirements

The following comparison helps you identify which finishes excel—or underperform—for each primary functional goal:

| Finish Type | Corrosion Resistance | Aesthetic Appeal | Wear Resistance | Electrical Conductivity |

|---|---|---|---|---|

| Hot-Dip Galvanizing | Excellent | Poor | Fair | Good |

| Zinc Electroplating | Very Good | Fair | Fair | Good |

| Electroless Nickel | Excellent | Good | Very Good | Fair |

| Chrome Plating | Good | Excellent | Excellent | Fair |

| Powder Coating | Very Good | Excellent | Good | Poor (Insulating) |

| Anodizing (Type II) | Very Good | Excellent | Good | Poor (Insulating) |

| Electropolishing | Good | Excellent | Fair | Good |

| Chromate Conversion | Good | Fair | Poor | Good |

| Passivation | Good | Fair | Poor | Good |

Notice how no single finish dominates every category? This reality drives many specifications toward combination approaches—phosphating followed by powder coating, zinc plating with clear chromate conversion, or anodizing with masked areas for electrical contact.

When specifying finishes on metal for your applications, document your priority ranking. If corrosion resistance matters most, accept aesthetic limitations from galvanizing. If appearance drives decisions, understand that powder coating may require additional treatments for wear-critical areas. This clarity helps your metal finisher recommend appropriate solutions rather than defaulting to standard options.

With functional selection criteria established, automotive applications introduce additional complexity through industry-specific standards and certification requirements that govern acceptable finishing approaches.

Automotive Metal Finishing Standards and Requirements

When sheet metal components end up in vehicles, the stakes change dramatically. Your chassis bracket doesn't just need to look acceptable—it needs to survive salt-laden roads, temperature swings from -40°F to 180°F, and millions of stress cycles without degradation. Automotive metal finishing operates under strict industry standards that go far beyond general manufacturing requirements.

Why does automotive finishing demand such rigor? Consider what happens when a suspension component fails at highway speeds, or when corrosion compromises a structural member in a crash scenario. The consequences extend beyond warranty claims into safety-critical territory—and that's why automotive OEMs enforce finishing specifications that might seem excessive for other industries.

Automotive-Grade Finish Standards and Certifications

If you're supplying components to automotive manufacturers, you'll encounter IATF 16949 certification requirements almost immediately. According to Xometry's certification guide, this framework "distills information and useful points from the ISO 9001 standard into a set of guidelines that are useful for automotive-specific manufacturers and companies."

What makes IATF 16949 different from general quality certifications? The standard specifically addresses consistency, safety, and quality across automotive products through documented processes and rigorous auditing. While not legally mandated, suppliers without certification often find themselves excluded from OEM consideration entirely—it's become the de facto entry requirement for the automotive supply chain.

The certification process involves both internal and external audits covering seven major sections. Key areas evaluated include:

- Process control documentation: Every steel finishing operation must follow documented procedures with verified parameters

- Traceability systems: Materials and processes must be traceable from raw stock through completed parts

- Defect prevention protocols: Systems must exist to identify and prevent quality issues before they reach customers

- Continuous improvement evidence: Organizations must demonstrate ongoing process refinement and waste reduction

As the certification guide notes, "Adherence to the requirements proves a company's ability and commitment to limit defects in the products and thus also reduces waste and wasted effort." For sheet metal painting and other finishing operations, this translates to controlled coating thicknesses, documented cure cycles, and verified corrosion protection levels.

Understanding the Class A/B/C Finish Classification System

Beyond certification, automotive components receive finish classifications that define acceptable quality levels based on visibility and function. According to Sintel's powder coating standards guide, these classifications provide "manufacturers and customers the language to set clear expectations for cost, quality, and performance right from the start."

Class A finishes represent premium visual quality reserved for customer-facing surfaces. Think dashboard components, door panels, and exterior trim. These require:

- Minimal or zero visible defects

- Smooth, uniform texture and consistent gloss

- Extended inspection time and tighter tolerances

- Higher cost due to stringent quality standards

Class B finishes balance aesthetics with practicality for visible but non-focal surfaces. Exterior panels, machinery covers, and component housings typically fall here. Slight surface imperfections are acceptable provided they don't compromise function or safety. Subcategories like B-1 (linear grain), B-2 (orbital finish), and B-3 (tumble finish) further define acceptable surface characteristics.

Class C finishes prioritize protection over appearance for hidden components. Internal brackets, enclosure interiors, and structural elements that remain invisible during normal operation receive this classification. Visible blemishes within acceptable limits are permitted, dramatically reducing costs while maintaining corrosion protection.

When you finish aluminum components for automotive applications, anodizing often delivers Class A results efficiently—but understand that color matching across production lots requires careful process control.

Finishing for High-Stress Structural Components

Chassis, suspension, and structural components face unique finishing challenges. These parts experience continuous mechanical stress, vibration, and environmental exposure that test every aspect of your finishing specification.

Key considerations for automotive structural applications include:

- Salt spray resistance: Minimum 500 hours for mild steel finishes in underbody applications, with many OEMs requiring 720+ hours. Testing per ASTM B117 validates coating performance

- Thermal cycling tolerance: Finishes must survive repeated transitions between temperature extremes without cracking, peeling, or adhesion loss

- Mechanical stress compatibility: Coatings on flex-prone components must accommodate substrate movement without fracturing

- Stone chip resistance: Underbody and wheel well components require impact-resistant finishes that maintain protection after debris strikes

- Chemical resistance: Exposure to fuels, lubricants, de-icing chemicals, and cleaning agents cannot compromise finish integrity

For types of stainless steel finishes in automotive applications, electropolishing followed by passivation delivers excellent corrosion resistance for exhaust components and fasteners. However, carbon steel structural members typically receive zinc-based protection—either electroplated zinc with chromate conversion or electrodeposited zinc-nickel alloys for enhanced performance.

Environmental and Sustainability Considerations

Modern automotive finishing increasingly addresses environmental impact alongside performance requirements. OEMs now evaluate suppliers on sustainability metrics as part of their qualification process.

Powder coating has emerged as an environmentally preferred option for many applications—it produces virtually no VOC emissions and allows overspray recovery for reuse. Chromate conversion coatings, once standard for aluminum, face restrictions under REACH and similar regulations, driving adoption of trivalent chromium or chromate-free alternatives.

Water treatment, energy consumption, and waste generation all factor into sustainable finishing operations. Manufacturers implementing closed-loop rinse systems, energy-efficient curing ovens, and waste minimization programs position themselves favorably for OEM partnerships increasingly focused on supply chain sustainability.

Understanding these automotive-specific requirements establishes the quality foundation—but achieving consistent results at production volumes requires appropriate equipment and process capabilities, which we'll examine next.

Metal Finishing Equipment and Production Capabilities

You've selected the perfect finish for your application. Your surfaces are properly prepared. Now comes a practical question that directly impacts your timeline and budget: what equipment actually applies that finish, and how does it scale from one-off prototypes to thousands of production parts?

The gap between finishing a single sample by hand and running thousands through an automated line isn't just about speed—it affects consistency, cost per part, and achievable quality levels. Understanding metal finishing machinery options helps you set realistic expectations when working with finishing partners.

Manual vs. Automated Finishing Equipment

The choice between manual and automated approaches depends on your production volume, required precision, and budget constraints. According to industry analysis from Polishing Mach, "one of the most significant differences between manual and automated polishing is labor costs"—but that's only part of the equation.

Manual finishing equipment gives operators direct control over the process. Hand-held grinders, polishing wheels, spray guns, and brush plating systems allow skilled technicians to address complex geometries, reach difficult areas, and adjust technique in real-time. This flexibility proves invaluable for:

- Prototype development requiring frequent adjustments

- Low-volume production runs (typically under 25 parts)

- Complex shapes with varying surface requirements

- Repair and rework operations

- Custom or bespoke finishing specifications

The trade-off? Manual operations introduce variability. Two technicians finishing identical parts may produce slightly different results. Processing times depend on individual skill levels, and labor costs scale linearly with volume—doubling your order roughly doubles your finishing expense.

Automated metal finishing machines eliminate operator variability through programmed, repeatable processes. A sheet metal finishing machine designed for production maintains consistent parameters across every part: identical spray patterns, uniform plating thickness, and precisely controlled polish cycles.

According to Superfici America's automation case study, modern metal finishing lines incorporate "pre-programmed 'recipe' selection and part tracking" that display "the current state of your finishing line in the glance of a screen." These systems manage automatic color changes, thickness adjustments, and parameter modifications at the push of a button.

Automated systems excel at:

- High-volume production (hundreds to thousands of parts)

- Consistent quality requirements across batches

- Reduced per-part labor costs at scale

- Documented process parameters for quality certification

- Faster turnaround on repeat orders

Scaling from Prototype to Mass Production

Your production volume directly determines which metal finishing machinery makes economic sense. According to Approved Sheet Metal's fabrication guide, the transition from prototype through batch production to mass production fundamentally changes finishing approaches.

Prototype quantities (1-25 parts) typically use manual or semi-automated equipment:

- Hand polishing and grinding stations

- Small-batch immersion tanks for plating and conversion coatings

- Manual spray booths for painting and powder coating

- Bench-top anodizing systems

Processing times at prototype volumes vary widely—expect 1-3 days for simple finishes like passivation, up to 1-2 weeks for complex plating operations requiring multiple process steps.

Batch production (25-5,000 parts) justifies investment in dedicated tooling and semi-automated metal finishing process lines:

- Automated spray systems with programmable reciprocators

- Barrel or rack plating lines with automated hoist systems

- Conveyor-fed powder coating booths with automatic guns

- Vibratory finishing machines for deburring and polishing

At batch volumes, per-part costs drop significantly while consistency improves. Turnaround expectations compress to 3-7 days for most finishing types once production tooling is established.

Mass production (5,000+ parts) demands fully automated metal finishing lines with integrated material handling:

- Continuous conveyor systems moving parts through sequential finishing stages

- Robotic loading and unloading systems

- In-line quality inspection with automated rejection

- RFID or barcode tracking integrated with warehouse systems

Custom metal plating automation at these volumes achieves remarkable efficiency. Superfici's automated finishing technology demonstrates how "handling robotics...save companies and employees hundreds of hours a year" through automatic sorting based on color, material, and SKU.

How Equipment Choice Affects Quality and Cost

The relationship between equipment investment and per-part cost follows predictable patterns. Manual operations have low capital requirements but high per-part labor content. Automated systems reverse this equation—substantial upfront investment yields dramatically lower marginal costs.

Consider powder coating as an example. A manual spray booth might cost $15,000-$30,000 to establish, with operators coating 20-40 parts per hour depending on complexity. An automated line with automatic guns, conveyor systems, and integrated curing ovens might require $200,000-$500,000 investment—but processes 200-500 parts per hour with 1-2 operators monitoring the system.

For high-volume manufacturers, custom metal plating automation delivers additional benefits beyond speed:

- Thickness consistency: Automated systems maintain plating thickness within ±5% versus ±15-20% for manual operations

- Defect reduction: Programmed parameters eliminate human error in process timing, temperature control, and chemical concentration

- Documentation: Automated systems log process data supporting IATF 16949 and similar quality certifications

- Reproducibility: Stored recipes ensure identical results across production runs separated by months or years

The equipment decision ultimately balances your volume requirements, quality expectations, and budget constraints. Low-volume specialty work favors skilled manual operations. High-volume production demands automation. Many finishing operations maintain both capabilities—using manual equipment for prototypes and development while running production through automated metal finishing lines.

With equipment capabilities understood, the final consideration involves maintaining finish quality after production—proper care, inspection methods, and realistic lifespan expectations for different finishing types.

Post-Finishing Care and Quality Verification

Your parts emerge from the finishing line looking flawless. The powder coat gleams uniformly, the zinc plating shows perfect coverage, and inspection confirms thickness specifications are met. But here's the reality many manufacturers overlook: what happens after finishing determines whether that quality persists through storage, shipping, assembly, and years of service life.

According to the High Performance Coatings maintenance guide, "High-performance coatings provide excellent protection for metal surfaces, but proper maintenance is essential to ensure their longevity and effectiveness." This principle applies across all metal finishing techniques—the finish itself is only half the equation.

Extending Finish Lifespan Through Proper Care

Every finish on metal has specific care requirements that maximize its protective capabilities. Treating all finishes identically leads to premature failures and unnecessary refinishing costs.

For coated surfaces like powder coating and paint, regular inspection forms the foundation of effective maintenance. As noted by conservation specialists at the Canadian Conservation Institute, "Regular inspection is the foundation of effective maintenance. Examine coated surfaces often looking for signs of damage such as damage, chips, or areas where the coating appears worn or discolored."

Your cleaning approach matters significantly. Use mild, pH-neutral detergents with soft cloths or sponges—avoid abrasive cleaning tools or harsh chemicals that can degrade protective layers. Always rinse thoroughly with clean water after cleaning to remove residue that could damage coatings over time.

Environmental factors require adjusted maintenance schedules:

- Coastal environments: Salt deposits accelerate corrosion, requiring more frequent cleaning cycles

- Industrial settings: Chemical contaminants may need specialized cleaning protocols beyond standard procedures

- Outdoor applications: UV radiation degrades many coatings, potentially requiring additional protective treatments

For plated surfaces, maintaining the barrier integrity proves critical. According to conservation research, "plating usually lifts because the corrosion products of the underlying metal expand" when damage occurs. Any scratch or dent that exposes base metal creates a corrosion initiation point that spreads beneath the plating layer.

Metal finishing tools used during handling can inadvertently damage finished surfaces. Always use appropriate protective materials when moving finished parts—felt pads, foam inserts, or dedicated racks prevent metal-to-metal contact that causes scratches.

Comparing Finish Lifespan and Maintenance Requirements

Different metal part finishing processes deliver vastly different service lives. Understanding these expectations helps you specify appropriate finishes for your application lifecycle and budget appropriately for maintenance or replacement.

| Finish Type | Expected Lifespan (Indoor) | Expected Lifespan (Outdoor) | Maintenance Requirements |

|---|---|---|---|

| Powder Coating | 15-20+ years | 10-15 years | Annual cleaning; inspect for chips; touch-up as needed |

| Hot-Dip Galvanizing | 50+ years | 25-50 years (varies by environment) | Minimal; periodic visual inspection |

| Zinc Electroplating | 10-15 years | 5-10 years | Keep dry; address scratches promptly |

| Electroless Nickel | 20+ years | 15-20 years | Periodic cleaning; avoid abrasive contact |

| Anodizing (Type II) | 20+ years | 15-20 years | Mild soap cleaning; avoid harsh chemicals |

| Chrome Plating | 10-20 years | 5-10 years | Regular polishing; avoid chloride exposure |

| Passivation (Stainless) | Indefinite with care | 10-20+ years | Avoid chloride contamination; re-passivate if damaged |

Notice how environmental exposure dramatically impacts lifespan? A galvanized component lasting 50 years indoors might show significant degradation after 25 years of outdoor exposure—and coastal environments compress that timeline further.

Quality Verification and Inspection Methods

Identifying finish degradation early prevents catastrophic failures and enables cost-effective touch-up rather than complete refinishing. Custom metal part finishing quality depends on knowing what to look for during inspections.

For coated surfaces, watch for:

- Discoloration or fading: Indicates UV degradation or chemical attack

- Chalking: Powdery surface residue signals coating breakdown

- Blistering or bubbling: Suggests moisture penetration beneath the coating

- Cracking or checking: Shows coating becoming brittle with age

- Edge corrosion: Often the first failure point on painted or powder-coated parts

For plated surfaces, degradation appears differently:

- White corrosion products: On zinc plating, indicates active corrosion

- Peeling or lifting: Shows adhesion failure, often from base metal corrosion

- Pitting: Small holes indicate localized plating defects or chemical attack

- Color changes: Tarnishing on nickel or chrome suggests environmental contamination

When Refinishing Becomes Necessary

Even with proper care, all finishes eventually require renewal. When damage occurs, prompt action prevents minor issues from becoming major problems. As noted by coating specialists, "Small chips or scratches can often be repaired with touch-up products recommended by the coating manufacturer. For larger areas of damage, consult with coating specialists to determine the best approach for repair or reapplication."

Signs that refinishing is needed rather than simple repair:

- Coating adhesion failure across more than 10-15% of the surface area

- Visible base metal corrosion beneath the finish

- Systemic cracking or checking patterns indicating material failure

- Performance testing showing inadequate remaining protection

Plan for reapplication before coatings deteriorate to the point where underlying metal becomes exposed and vulnerable. Metal varnishing and other protective treatments work best when applied over sound substrates—waiting until corrosion establishes itself dramatically increases preparation costs and may compromise adhesion of new coatings.

Storage and Handling of Finished Parts

The period between finishing and assembly presents significant risk for damage. Improper storage conditions can undo the protection your finishing specification intended to provide.

Critical storage considerations include:

- Humidity control: Store finished parts in dry environments—relative humidity below 50% prevents moisture-related corrosion initiation

- Physical separation: Use appropriate interleaving materials to prevent metal-to-metal contact that causes scratches and galvanic corrosion

- Clean handling: Fingerprints contain salts that cause localized corrosion; use clean gloves when handling finished parts

- Protective packaging: VCI (vapor corrosion inhibitor) bags or papers provide additional protection during extended storage

- Temperature stability: Avoid rapid temperature changes that cause condensation on cold metal surfaces

Document all maintenance activities and keep records of inspection findings, treatments applied, and environmental conditions. This documentation proves invaluable for warranty claims, quality investigations, and planning future maintenance schedules.

With proper post-finishing care established, the final step involves integrating these considerations into your overall manufacturing workflow—from initial design through production partnership selection.

Optimizing Your Sheet Metal Finishing Workflow

You've mastered the fundamentals—finish types, preparation requirements, selection criteria, and maintenance protocols. Now comes the practical challenge that determines whether all this knowledge translates into successful production: integrating finishing decisions into your design process and building effective partnerships with manufacturers who deliver consistent results.

According to Pro-Cise's manufacturing guide, "Roughly 70% of manufacturing costs result from design decisions made early in the process." This statistic applies directly to your metal finishing process—the choices you make during initial design lock in finishing costs, timelines, and quality outcomes long before parts ever reach production.

Integrating Finishing Into Your Design Process

Treating finishing as an afterthought creates expensive problems. Parts designed without considering coating thickness may not fit during assembly. Geometries that ignore plating current distribution result in uneven protection. Features that trap cleaning solutions cause corrosion months after production.

Design for Manufacturing (DFM) support addresses these issues proactively. The DFM process involves optimizing your product's design to improve manufacturing efficiency, quality, and cost-effectiveness—including finishing operations. Core elements include standardizing components, reducing part count, and streamlining processes to reduce complexity.

When integrating sheet metal finish considerations into your design workflow, focus on these critical areas:

- Dimensional allowances: Account for additive finish thickness in tolerance stackups—powder coating adds 0.004"-0.01" that affects mating surfaces

- Geometry accessibility: Design features that allow complete coverage during plating or coating—avoid deep recesses, blind holes, and sharp internal corners that trap solutions or block spray patterns

- Material selection: Choose base materials compatible with your intended steel finish or aluminum treatment—some alloys plate poorly or anodize unevenly

- Surface requirements mapping: Identify which surfaces need Class A finishes versus functional-only protection, reducing costs through selective specification

- Assembly sequence consideration: Determine whether parts finish before or after assembly—this affects masking requirements, handling procedures, and achievable quality levels

According to manufacturing specialists, discussing your design with your manufacturer helps ensure your design incorporates good manufacturing principles for your selected finishing process. This collaborative approach prevents costly redesigns after tooling investment.

Partnering for Consistent Quality Results

Your finishing outcomes depend heavily on partner selection. Metal process services vary dramatically in capability, certification status, and technical expertise. The right partner provides more than processing capacity—they contribute engineering knowledge that improves your specifications.

When evaluating finishing partners, consider certification status carefully. For automotive applications, IATF 16949 certification proves a company's ability and commitment to limit defects while reducing waste and wasted effort. This framework addresses consistency, safety, and quality through documented processes and rigorous auditing—exactly what finish metal operations require for repeatable results.

Partners offering comprehensive DFM support streamline the specification process significantly. Rather than submitting drawings and hoping for acceptable results, you collaborate on finishing requirements during design—identifying potential issues before they become production problems.

For automotive applications requiring rapid prototyping alongside consistent mass production quality, Shaoyi (Ningbo) Metal Technology demonstrates how integrated metal finishing processes work in practice. Their 5-day rapid prototyping capability allows finish validation before production commitment, while IATF 16949 certification ensures the same quality standards apply across prototype and production volumes for chassis, suspension, and structural components.

Specifying Finishing Requirements Effectively

Clear specifications prevent misunderstandings that cause rejected parts, delayed shipments, and damaged relationships. When working with manufacturers on metal finishing processes, follow this systematic approach:

- Define functional requirements first: Document what the finish must accomplish—corrosion resistance levels (salt spray hours), wear resistance (hardness specifications), electrical conductivity, or aesthetic standards (Class A/B/C designation)

- Specify the finish type and thickness: Include acceptable ranges rather than single values when possible—"zinc electroplate per ASTM B633, Type II, 0.0003"-0.0005" thickness" provides clear, measurable requirements

- Identify critical surfaces: Use drawings to indicate which surfaces require full specification compliance versus areas where relaxed requirements are acceptable

- Document testing requirements: Specify acceptance tests, sample sizes, and frequency—"salt spray testing per ASTM B117, 96 hours minimum, one sample per lot"

- Establish inspection criteria: Define what constitutes acceptable versus rejectable quality—surface defect limits, color matching tolerances, and measurement methods

- Include handling and packaging requirements: Specify protection needed between finishing and delivery to prevent damage that compromises your quality investment

- Request process documentation: For certified quality systems, require evidence of process control—temperature records, solution analysis data, and thickness measurements

Partners with 12-hour quote turnaround capability—like those serving automotive supply chains—indicate systems designed for rapid response. This responsiveness extends beyond pricing into production scheduling, engineering support, and issue resolution.

Building Long-Term Finishing Partnerships

The most successful sheet metal finishing relationships extend beyond transactional processing. Effective partnerships involve:

- Early engagement: Involve your finishing partner during design reviews, not after drawings are released

- Open communication: Share end-use requirements so partners can recommend optimal solutions rather than simply executing specifications

- Continuous improvement focus: Review quality data together and identify process refinements that benefit both parties

- Volume planning: Provide forecasts that enable partners to maintain appropriate capacity and inventory

According to manufacturing relationship guidance, effective agreements should include clear quality control provisions specifying inspection and testing methods, acceptance criteria, and remedies for quality failures. For finishing operations specifically, document continuous improvement expectations and how feedback loops operate between your organizations.

When your manufacturing partner combines stamping, forming, and finishing capabilities under integrated quality systems, coordination improves dramatically. Parts move directly from fabrication to finishing without shipping delays, handling damage, or communication gaps between separate suppliers. This integration proves particularly valuable for automotive metal finishing where traceability requirements demand documented chain of custody from raw material through completed assembly.

The journey from raw sheet metal stock to flawless finished surface involves countless decisions—material selection, process specification, preparation protocols, equipment choices, and quality verification methods. By integrating finishing considerations from initial design, partnering with certified manufacturers offering genuine DFM support, and specifying requirements clearly, you transform finishing from a production bottleneck into a competitive advantage that delivers consistent quality at optimal cost.

Frequently Asked Questions About Sheet Metal Finishing

1. What is the typical surface finish for sheet metal?

Powder coating is the most common surface finish for sheet metal components due to its ability to create a continuous, even coating that protects against corrosion while improving aesthetics. It adds 1-3 mils of thickness per side and offers virtually unlimited color options. For stainless steel, electropolishing followed by passivation delivers excellent results. Aluminum parts typically receive anodizing, which builds a controlled oxide layer directly from the base material. The choice ultimately depends on your functional requirements—corrosion resistance, wear protection, electrical conductivity, or visual appeal.

2. What type of finishes can be added to sheet metal?

Sheet metal finishes fall into two main categories: additive and subtractive processes. Additive methods include powder coating, electroplating (zinc, nickel, chrome), hot-dip galvanizing, anodizing, and conversion coatings like phosphating. These build protective layers onto your metal surface. Subtractive techniques include electropolishing, mechanical polishing, media blasting, and passivation—these remove material to achieve specific characteristics. For IATF 16949-certified automotive applications, manufacturers like Shaoyi Metal Technology offer comprehensive finishing options integrated with their stamping and fabrication services.

3. How to finish a metal sheet?

Finishing sheet metal involves three critical phases: preparation, application, and verification. First, clean the surface through degreasing, deburring, and rust removal to ensure proper adhesion. Next, apply your chosen finish—whether plating deposits new metal layers, powder coating adds polymer protection, or polishing removes material for a refined surface. Finally, verify quality through thickness measurements, adhesion testing, and visual inspection. The process varies by finish type: powder coating requires electrostatic application and heat curing, while electroplating uses electrical current in chemical baths. Proper preparation prevents 90% of finishing failures.

4. What are the different types of metal finishing?

Metal finishing encompasses electroplating (zinc, nickel, chrome, gold), electroless plating, powder coating, hot-dip galvanizing, anodizing, passivation, electropolishing, mechanical polishing, media blasting, and conversion coatings. Each serves distinct purposes: galvanizing offers exceptional corrosion protection for structural steel; anodizing provides wear resistance and color options for aluminum; electropolishing creates ultra-smooth surfaces for medical devices; powder coating delivers durable, decorative finishes for consumer products. Selection depends on base material, functional requirements, environmental exposure, and budget constraints.

5. How does finish thickness affect sheet metal part dimensions?

Different finishes add varying thickness that must be factored into design tolerances. Powder coating adds approximately 0.004"-0.01" to overall thickness—nearly ten times more than zinc electroplating at 0.0006". Type II anodizing adds 0.0004"-0.0018", while nickel plating adds roughly 0.0004". For mating assemblies with tight clearances, subtract anticipated finish thickness from design dimensions. A hole requiring 0.500" final diameter with powder coating should be designed at 0.504"-0.510" to accommodate coating buildup. Subtractive processes like electropolishing remove material, potentially affecting thin sections.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —