Custom Metal Stamping Decoded: 9 Essential Points Engineers Miss

What Custom Metal Stamping Really Means for Modern Manufacturing

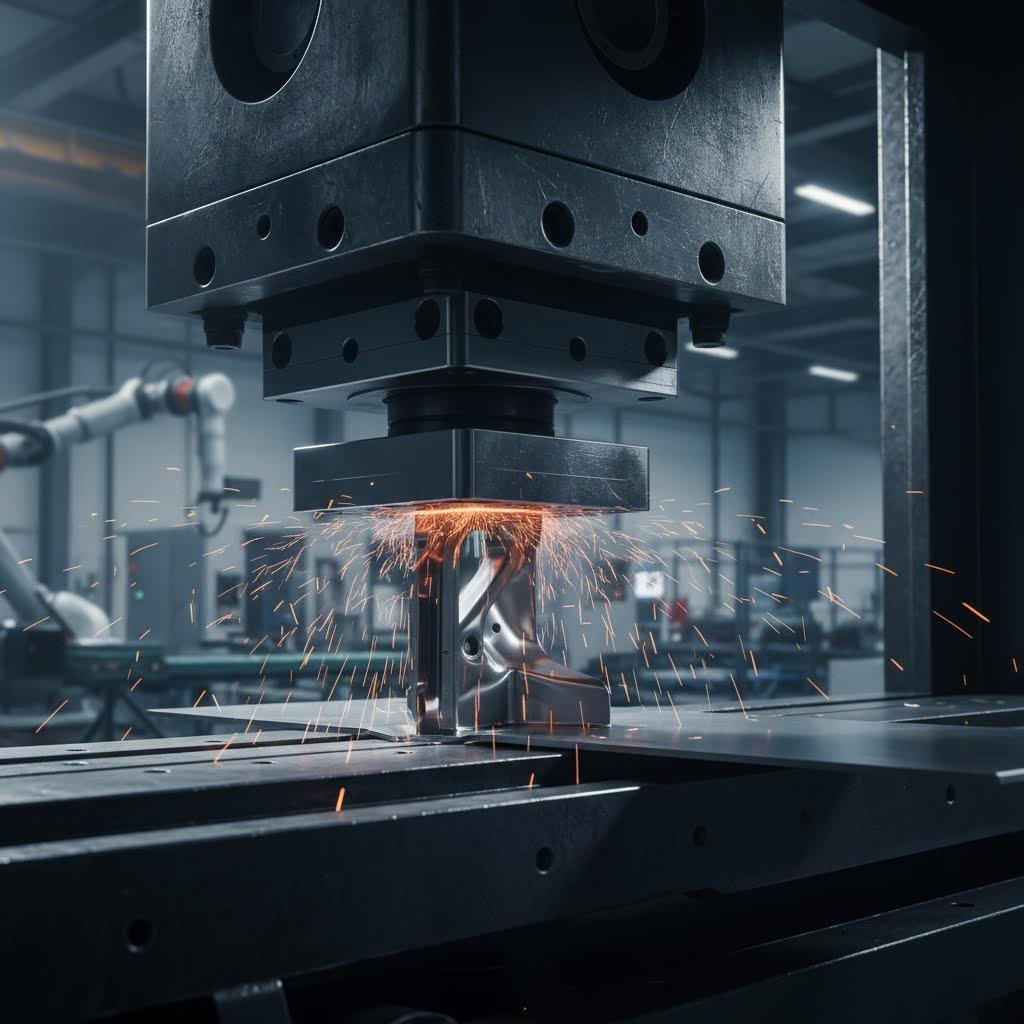

Ever wondered how manufacturers produce millions of identical, precisely shaped metal components without breaking the bank? The answer lies in custom metal stamping—a precision manufacturing process that transforms flat sheet metal into complex three-dimensional parts using specialized dies and powerful presses.

Think of it like this: standard stamping uses off-the-shelf tooling to create generic shapes. Custom metal stamping, on the other hand, is more like tailoring a suit specifically for your measurements. The dies, presses, and processes are all designed around your unique part geometry and application requirements.

From Sheet Metal to Precision Components

At its core, metal stamping manufacturing relies on a straightforward concept. A flat metal sheet or coil feeds into a press equipped with custom-designed dies. When the press closes, these dies cut, bend, and form the metal into precisely shaped components—often completing multiple operations in a single stroke.

The magic happens in those specialized dies. Unlike generic tooling, custom dies are engineered specifically for each unique part design. This tailored approach enables manufacturers to achieve tight tolerances (sometimes as precise as 0.0005 inches), create intricate geometries, and maintain remarkable consistency across production runs of thousands or even millions of parts.

What makes stamped metal components particularly valuable is their repeatability. Once the tooling is dialed in, the 500th part coming off the press matches the first one with exceptional accuracy. This consistency is critical for industries where uniformity isn't optional—it's mandatory.

Why Manufacturers Choose Custom Stamping

So why do engineers and procurement specialists consistently turn to metal stamping services over alternatives like machining, casting, or fabrication? Several compelling reasons stand out:

- Cost efficiency at volume: While tooling requires upfront investment, the per-part cost drops dramatically as production quantities increase. For high-volume runs, stamping products become significantly more economical than machined alternatives.

- Speed and throughput: Progressive stamping processes can produce complex finished parts in seconds, enabling manufacturers to meet demanding production schedules.

- Precision without compromise: Modern stamping achieves tolerances that rival machining while maintaining much higher production speeds.

- Material efficiency: Optimized die designs minimize scrap, making better use of raw materials compared to subtractive processes.

Industries ranging from automotive and aerospace to electronics and medical devices rely heavily on this process. Automotive manufacturers depend on stamped components for everything from structural brackets to electrical terminals. Aerospace engineers specify stamped parts where weight savings and precision matter. Medical device companies trust the process for creating sterile, biocompatible components with zero tolerance for defects.

Understanding these fundamentals gives engineers and product designers the foundation they need to evaluate whether custom metal stamping fits their project requirements—and how to design parts that leverage its full potential.

Stamping Process Types and When Each Method Applies

Now that you understand what custom metal stamping accomplishes, here's the question that trips up most engineers: which stamping method should you actually use? The truth is, not all stamping processes are created equal. Choosing the wrong one can mean paying more for tooling, missing tolerance requirements, or struggling with part geometries that simply don't work for your selected method.

Let's break down the four primary stamping methodologies and exactly when each one makes sense for your project.

Progressive Die Stamping for High-Volume Production

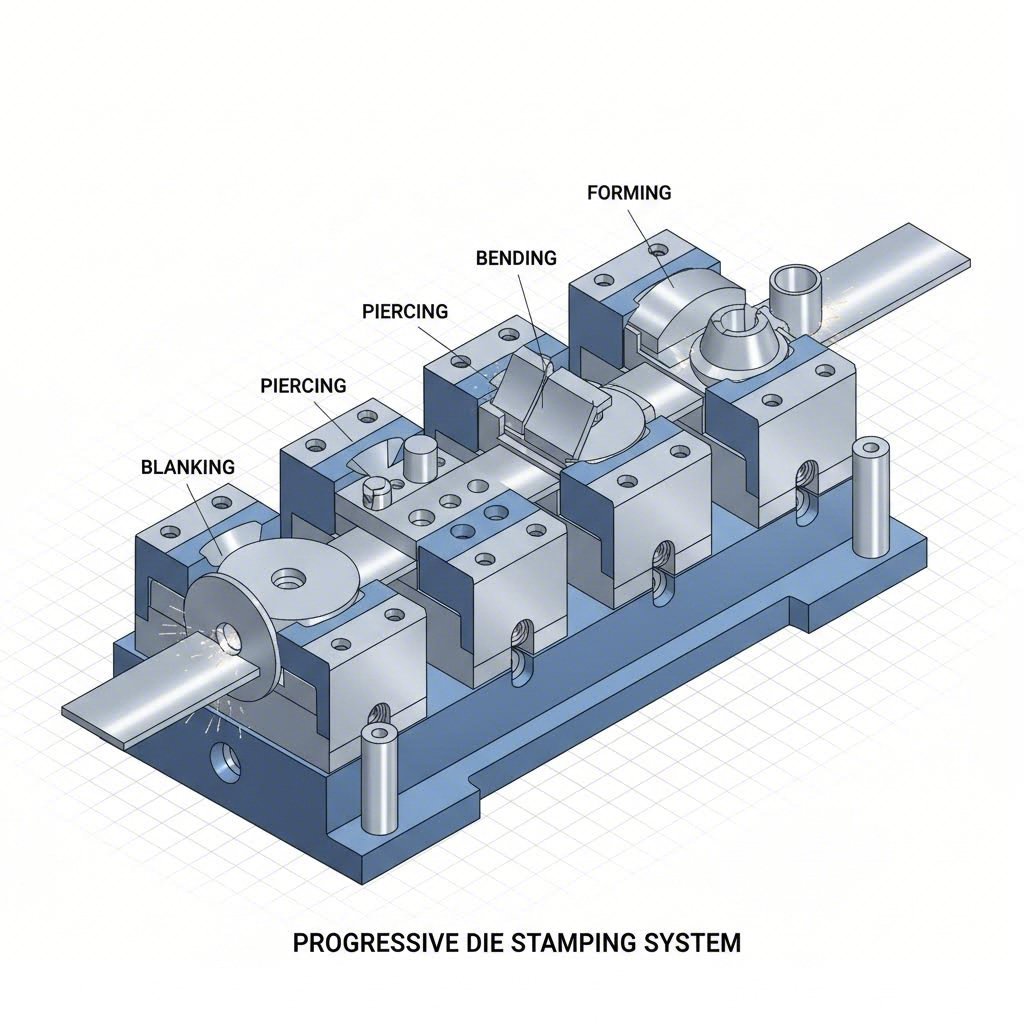

Imagine a continuous metal strip moving through a series of stations—each performing a specific operation like cutting, bending, piercing, or punching. That's progressive die stamping in action. The part stays connected to the strip throughout the process and only separates at the final station.

Why does this matter? Speed and efficiency. Progressive stamping excels at producing complex stamped parts at incredibly fast cycle times. When you need metal parts stamping in volumes of tens of thousands or millions, this method delivers the lowest per-unit costs.

You'll commonly find progressive die stamped components in:

- Automotive applications: Brackets, clips, connectors, and transmission components

- Consumer electronics: Small metal enclosures, battery contacts, and connector housings

- Industrial manufacturing: Electrical terminals, heat sinks, and precision hardware

The catch? Tooling investment runs higher upfront, and design modifications become costly once the die is built. But for high-volume production of stamped steel or aluminum components, the economics are hard to beat.

Transfer Die Stamping: When Parts Need Room to Grow

Transfer die stamping shares similarities with progressive methods—multiple stations, sequential operations—but with one critical difference. The part separates from the metal strip early in the process and gets mechanically transferred between stations.

This separation opens up possibilities that progressive stamping simply can't handle. Deeper draws, more complex geometries, and larger part sizes all become achievable when the component isn't tethered to a strip.

Transfer die stamping shines for:

- Large automotive components: Body panels, structural reinforcements, and heavy-duty brackets

- Industrial equipment: Reinforcement plates and durable enclosures

- Appliance manufacturing: Interior frameworks and stamped metal casings

Expect slightly slower cycle times compared to progressive stamping, and the added handling complexity increases costs for lower volume runs. For medium-to-large parts requiring intricate shaping, though, transfer die stamping remains the go-to choice.

Fourslide and Multislide Stamping: Bending From Every Angle

What happens when your part requires precise bends from multiple directions? Traditional vertical presses hit their limits. That's where fourslide (or multislide) stamping enters the picture.

Instead of relying solely on vertical pressure, these machines use four or more horizontal tool slides to manipulate metal from different angles simultaneously. The result? Multi-dimensional parts with complex geometries that would be nearly impossible to achieve through conventional methods.

This variety die and stamping approach works best for:

- Electrical components: Connectors, terminals, and EMI shielding

- Consumer electronics: Clips, fasteners, and intricate brackets

- Medical devices: Precision-formed micro components requiring exceptional accuracy

Fourslide stamping reduces material waste and often eliminates secondary operations. However, it's generally suited for smaller parts and thinner materials—heavy-gauge metals or larger components typically require different methods.

Deep Draw Stamping: Creating Depth and Volume

Need cup-shaped, cylindrical, or box-like components? Deep draw stamping specializes in transforming flat blanks into hollow, three-dimensional forms with significant depth relative to their diameter.

The process pulls sheet metal into a forming die, creating seamless components without welding or joining. Battery casings, beverage cans, automotive fuel tanks, and kitchen sinks all rely on deep draw techniques.

Key considerations for deep draw stamping include:

- Material ductility: The metal must stretch without cracking

- Draw ratio: The relationship between blank diameter and finished depth determines feasibility

- Wall thickness: Consistent material distribution requires careful die design

Choosing the Right Stamping Method for Your Part

Selecting the appropriate stamping process isn't guesswork—it's a strategic decision based on specific project requirements. Here's how the methods compare across critical factors:

| Stamping Method | Ideal Volume | Part Size | Complexity | Best For |

|---|---|---|---|---|

| Progressive Die | High (100K+) | Small to Medium | Moderate to High | High-speed production of complex flat parts with multiple features |

| Transfer Die | Medium to High | Medium to Large | High | Larger parts requiring deep draws and intricate shapes |

| Fourslide/Multislide | Low to Medium | Small | Very High | Intricate bends from multiple directions, thin materials |

| Deep Draw | Medium to High | Varies | Moderate | Hollow, seamless components with significant depth |

When evaluating which method fits your stamped parts requirements, start with these questions: What's your expected production volume? How complex is the part geometry? Does the design require deep forming or multi-directional bends? The answers will quickly narrow your options.

If you're searching for metal stamping near me, understanding these distinctions helps you have more productive conversations with potential suppliers—and ensures you're not paying for capabilities you don't need or settling for methods that can't deliver what you require.

With the stamping methodology sorted, the next critical step is understanding the specific operations that happen within these processes—the individual cutting, bending, and forming actions that transform flat metal into finished components.

Eight Essential Stamping Operations Every Engineer Should Understand

You've selected your stamping method—but what actually happens when that metal stamp machine goes to work? Understanding the individual operations that occur within each press stroke separates engineers who design manufacturable parts from those who end up back at the drawing board.

Every stamped component you've ever seen results from some combination of eight fundamental operations. Master these, and you'll communicate more effectively with manufacturers, design smarter parts, and avoid costly redesigns.

Core Stamping Operations Explained

Think of these operations as the building blocks of metal stamping. Each serves a distinct purpose, and knowing when to apply each one determines whether your part succeeds or fails in production.

| Operation | Definition | Typical Applications | Achievable Tolerances |

|---|---|---|---|

| Blanking | Cutting a flat shape from sheet metal where the cut-out piece becomes the workpiece | Base shapes for brackets, washers, electronic shields | ±0.001" to ±0.005" |

| Piercing | Creating holes or openings where the removed material is scrap | Mounting holes, ventilation openings, fastener locations | ±0.001" to ±0.003" |

| Bending | Forming angles, channels, or curves by applying force along a linear axis | Brackets, enclosure walls, structural reinforcements | ±0.5° to ±1° angular |

| Drawing | Creating depth and hollow forms by pulling material into a die cavity | Cups, housings, cylindrical containers | ±0.005" to ±0.010" |

| Coining | Precision compression that flows metal under extreme pressure for tight tolerances | Electrical contacts, precision surfaces, steel stamps for marking | ±0.0005" to ±0.001" |

| Embossing | Creating raised or recessed designs without cutting through the material | Logos, decorative patterns, stiffening ribs | ±0.003" to ±0.005" |

| Forming | Complex three-dimensional shaping that combines multiple deformation types | Intricate brackets, automotive components, structural parts | ±0.005" to ±0.015" |

| Lancing | Partial cuts that create tabs, vents, or louvers without fully separating material | Heat dissipation vents, attachment tabs, flexible hinges | ±0.002" to ±0.005" |

Notice how some operations—like blanking and piercing—involve cutting, while others—like bending and drawing—reshape metal without removing material. Coining stands apart because it uses extreme pressure to stamp letters into metal or create ultra-precise surfaces that other operations simply can't match.

Here's what trips up many engineers: these operations don't exist in isolation. A single die stamp might combine blanking, piercing, bending, and forming in one integrated tool. Understanding how they work individually helps you grasp how they work together.

How Operations Combine in Progressive Dies

Imagine a metal strip feeding through a progressive die with six stations. At station one, blanking creates the initial outline. Station two adds piercing for mounting holes. Stations three and four perform sequential bending operations. Station five adds embossed stiffening ribs. Station six completes the final cutoff.

The result? A finished component emerges from every single press stroke—even though six distinct operations occurred simultaneously across different parts moving through the die.

This combination approach is why progressive metal stamps achieve such remarkable efficiency. Instead of handling parts multiple times through separate operations, everything happens in one continuous flow. The key considerations for combining operations include:

- Operation sequence matters: Piercing typically occurs before bending to maintain hole accuracy

- Material flow planning: Drawing and forming operations must account for how metal moves and thins

- Station spacing: Each operation needs adequate clearance without wasting material between stations

- Force distribution: Combining heavy cutting with delicate forming requires careful load balancing

When you specify a part requiring multiple features—holes, bends, embossed logos, formed sections—you're really specifying which operations must combine within the tooling. The more operations integrated into a single progressive die, the faster production runs but the higher the initial tooling investment.

Understanding these eight operations gives you the vocabulary to discuss your requirements precisely with stamping manufacturers. Instead of vaguely describing "some holes and bends," you can specify piercing locations relative to bend lines, coining requirements for critical surfaces, or lancing patterns for ventilation—the kind of clarity that leads to accurate quotes and successful production.

With operations understood, the next consideration becomes equally critical: which materials work best for these processes, and how do material properties affect what's achievable?

Material Selection Guide for Custom Stamped Components

Here's a question that can make or break your stamping project: which metal should you actually use? Sounds straightforward, but selecting the wrong material leads to cracked parts, failed corrosion tests, or budgets blown on unnecessary performance.

The truth is, most material lists simply tell you what's available—not how to choose. Let's change that by examining the metal for stamping options that matter most and the decision criteria that actually work.

Material Properties That Affect Stamping Success

Before diving into specific metals, you need to understand four properties that determine whether a material will cooperate with your stamping process—or fight it at every step:

- Ductility: How much can the metal stretch and deform before cracking? Higher ductility means more complex shapes become achievable. Aluminum and copper excel here; high-strength steels require more careful handling.

- Tensile strength: The maximum stress a material can withstand while being stretched. Stronger materials resist deformation—great for structural parts, but requiring more press force and robust tooling.

- Work hardening: Some metals get harder and more brittle as they're formed. Stainless steel work hardens significantly, which affects how many forming operations you can perform before the material becomes uncooperative.

- Springback: After bending, metals tend to partially return toward their original shape. Materials with higher yield strength exhibit more springback, requiring die compensation to achieve target angles.

These properties interact in ways that matter for your specific application. A metal with excellent ductility but severe springback might form beautifully but miss your dimensional tolerances. Understanding these trade-offs separates successful projects from frustrating redesigns.

Matching Materials to Application Requirements

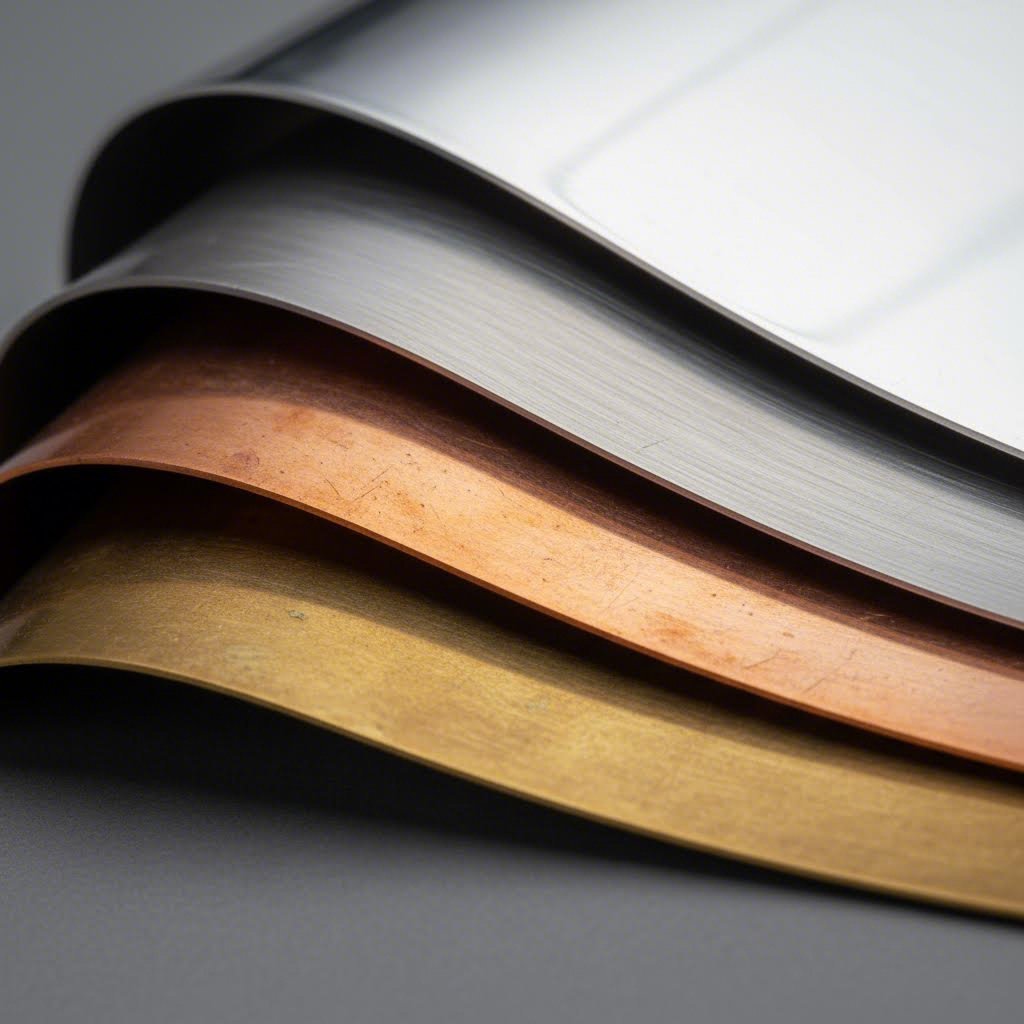

Now let's examine the five most common stamping materials and exactly when each one makes sense.

Aluminum: When weight savings and thermal performance matter, aluminum becomes the obvious choice. With a density of just 2.7 g/cm³ (roughly one-third of steel), custom aluminum stamping delivers lightweight components for everything from 5G base station heat sinks to automotive structural parts. The material offers excellent electrical and thermal conductivity, good corrosion resistance, and outstanding formability for complex stamped aluminum parts. The trade-off? Lower tensile strength compared to steel, typically ranging from 110-500 MPa depending on the alloy.

Cold Rolled Steel: For cost-effective structural components where weight isn't critical, cold rolled steel remains the workhorse of metal stamping. Excellent formability, consistent mechanical properties, and competitive pricing make it ideal for brackets, enclosures, and industrial hardware. When paired with appropriate coatings, it handles most indoor and controlled-environment applications well.

Stainless Steel: Need corrosion resistance that lasts? Stainless steel delivers tensile strength exceeding 515 MPa and salt spray resistance of 48+ hours. Medical devices, food processing equipment, and outdoor applications benefit from its durability. However, stainless steel work hardens aggressively—progressive die designs must account for this behavior, and tooling wear increases compared to softer materials. Metal stamps for steel applications require hardened tool steels and careful lubrication strategies.

Copper and Brass: Electrical conductivity drives copper selection—reaching 98% IACS (International Annealed Copper Standard), it's unmatched for terminals, connectors, and conductive components. Brass offers a cost-effective alternative with good machinability and a steel metal stamp that produces clean edges. Both materials form readily and work well for intricate geometries in electronics and decorative applications.

Galvanized Steel: When you need basic corrosion protection at minimal cost, galvanized steel fills the gap. The zinc coating (typically ≥8μm thickness) provides adequate rust prevention for chassis brackets, appliance panels, and similar applications where extreme corrosion resistance isn't required.

| Material | Tensile Strength (MPa) | Formability | Corrosion Resistance | Relative Cost | Best Applications |

|---|---|---|---|---|---|

| Aluminum | 110-500 | Excellent | Good (24-48h salt spray) | Medium | Heat sinks, lightweight structures, electronics enclosures |

| Cold Rolled Steel | 300-550 | Excellent | Poor (requires coating) | Low | Brackets, structural components, industrial hardware |

| Stainless Steel (304) | ≥515 | Good | Excellent (≥48h salt spray) | High | Medical devices, food equipment, outdoor components |

| Copper | 200-450 | Excellent | Moderate (12-24h salt spray) | High | Electrical terminals, connectors, conductive components |

| Brass (H62) | 300-600 | Very Good | Good (24-36h salt spray) | Medium-High | Lock components, decorative parts, plumbing fittings |

| Galvanized Steel | ≥375 | Good | Moderate (≥24h salt spray) | Low | Appliance panels, chassis brackets, cost-sensitive parts |

When selecting materials, match your choice to three key factors: process requirements (deep draws need ductile materials like brass; progressive dies handle most options), application environment (outdoor exposure demands stainless steel or aluminum; electronics need conductivity), and budget constraints (galvanized steel costs a fraction of stainless, making it ideal for high-volume structural parts).

Consider this real-world example: a communications company needed lightweight heat sinks for 5G base stations weighing under 100g with thermal conductivity exceeding 150 W/(m·K). Pure copper offered superior thermal performance but pushed weight over 200g. The solution? 6061-T6 aluminum achieved both targets while reducing production costs by 18%.

Material selection isn't about finding the "best" metal—it's about finding the right match for your specific requirements. With material properties understood, the next critical consideration is designing parts that take full advantage of stamping capabilities while avoiding common manufacturability pitfalls.

Design for Manufacturability Principles in Metal Stamping

You've selected your material and understand the stamping operations—but here's where most engineering projects hit a wall. Submitting a design that looks perfect in CAD only to receive feedback that it's "not manufacturable" or requires expensive tooling modifications wastes weeks and inflates budgets.

The solution? Design for Manufacturability (DFM) principles tailored specifically for custom metal stamping. These rules aren't arbitrary—they're rooted in the physical behavior of metal under stress and the practical limitations of stamping equipment. Follow them, and you'll reduce tooling costs, improve part quality, and accelerate your production timeline.

Critical Design Rules for Stampable Parts

Think of sheet metal like a piece of cardboard. Fold it too sharply, and the outer edge cracks. Push a hole too close to a bend, and it distorts. These intuitive behaviors translate directly into engineering guidelines that separate successful stamping projects from costly redesigns.

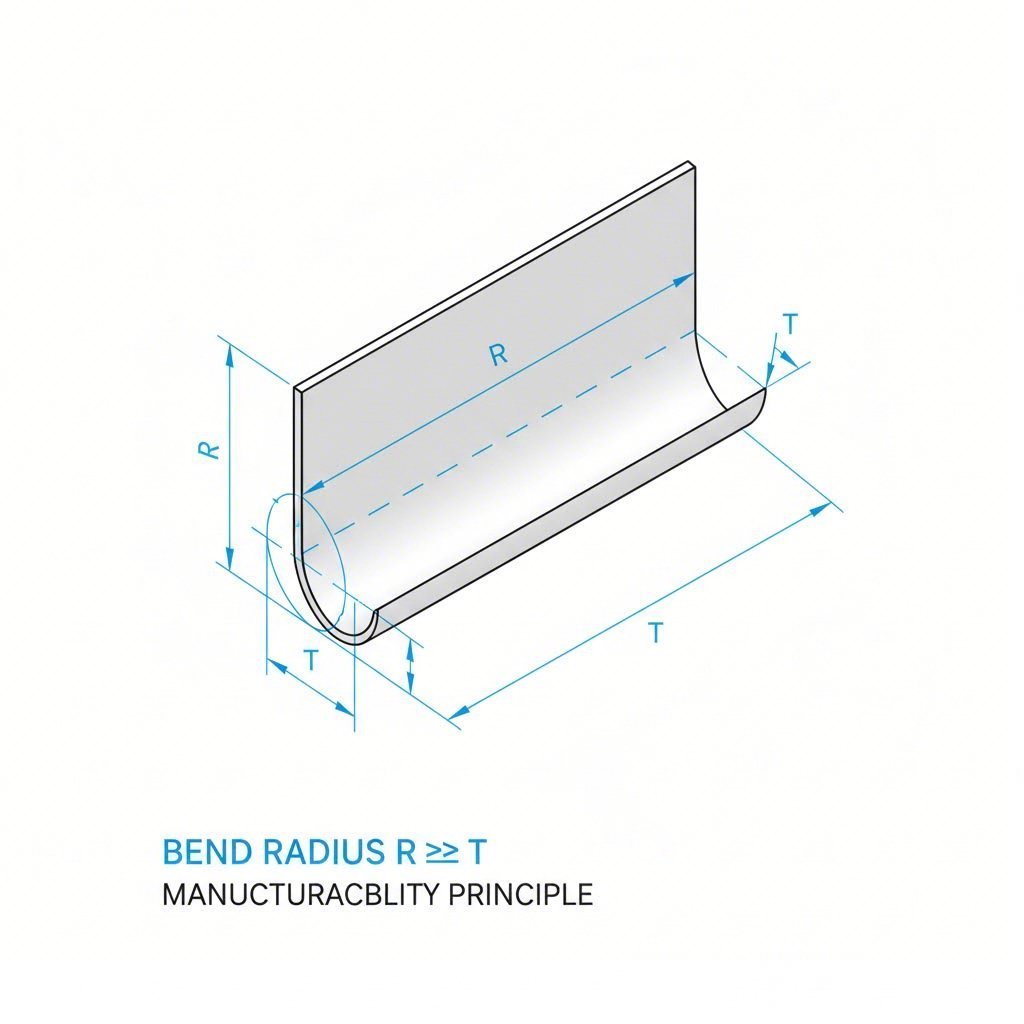

Minimum Bend Radii: The inside curve of any bend should equal at least the material thickness. Bending a 1.5mm aluminum sheet? Your minimum inside radius is 1.5mm. Go tighter, and you risk cracking on the outer surface—especially with harder materials like stainless steel. For high-strength steels, increase this to 1.5x or 2x material thickness to maintain integrity.

Hole-to-Edge and Hole-to-Bend Distances: Position holes at least two times the material thickness away from any bend line. Violate this rule, and your circular holes become ovals as the surrounding metal stretches during forming. The same principle applies to edges—keep holes far enough from part boundaries to prevent distortion or tearing during blanking operations.

Bend Relief Cuts: When a bend line meets a flat edge, metal tries to separate at the corner. Adding small rectangular or circular notches—called bend reliefs—at these intersections prevents tearing and ensures clean, professional finishes. A custom metal stamp for steel applications absolutely requires these reliefs to avoid cracked parts.

Grain Direction Awareness: Sheet metal has a "grain" from the rolling process at the mill, similar to wood grain. Bending parallel to the grain increases cracking risk, while bending perpendicular to it produces stronger, cleaner results. When designing parts with multiple bends, orient the most critical bends across the grain direction. This "hidden" rule prevents parts from failing months after delivery.

Minimum Flange Length: The portion of metal being bent upward (the flange) needs adequate surface area for tooling to grip. Standard guideline: flanges should be at least four times the material thickness. Shorter flanges require custom, expensive tooling that can double production costs.

Springback Compensation: Metal is slightly elastic. Bend it to 90 degrees, release pressure, and it springs back to perhaps 88 or 89 degrees. Managing springback requires either designing dies that overbend to compensate or accepting slightly relaxed angular tolerances. High-strength steels and aluminum alloys exhibit more springback than mild steel—your die designer must account for this behavior.

Consistent Wall Thickness in Drawn Parts: Deep draw operations thin material as it stretches. Designing for uniform wall thickness means planning for this thinning and ensuring adequate material flow. Inconsistent thickness leads to weak spots, dimensional variations, and potential failures under load.

Avoid Sharp Internal Corners: Laser cutters and stamping tools generate heat. Sharp internal corners concentrate stress and can cause warping or cracking. Maintain minimum corner radii of at least 0.5mm—and for narrow features, keep cutouts at least 1.5 times wider than material thickness to prevent heat-induced distortion.

Tolerance Considerations for Precision Components

Can you actually achieve that ±0.0005" tolerance you specified? Sometimes yes—but not universally. Understanding what factors affect achievable tolerances helps you specify realistic requirements and avoid paying premium prices for precision you don't need.

Several variables determine what's possible:

- Material type: Softer, more ductile materials like aluminum and copper hold tighter tolerances than work-hardening stainless steels. A custom metal stamp for metal like 6061 aluminum consistently achieves ±0.001" tolerances, while 304 stainless may require ±0.002" specifications.

- Part geometry: Simple flat parts with basic piercing operations hold tighter tolerances than complex three-dimensional forms with multiple bends. Each forming operation introduces potential variation.

- Operation type: Coining achieves the tightest tolerances (±0.0005"), while drawing and deep forming operations typically range from ±0.005" to ±0.010". Blanking and piercing fall between these extremes.

- Wall thickness near features: Thin walls deflect during machining and stamping. Maintaining 3mm minimum wall thickness for aluminum parts requiring tight tolerances prevents vibration-induced dimensional variations.

Here's the cost reality: tightening tolerances from ±0.005" to ±0.001" can increase machining costs by 300-500%. Before specifying ultra-tight tolerances everywhere, ask yourself: "What actually breaks if this dimension varies by ±0.005"?" Apply precision only where function demands it.

Strategic tolerance allocation—applying tight specs only to critical features like bearing seats, sealing surfaces, and alignment pins—can reduce overall manufacturing costs by 40-60% without affecting part performance.

Before submitting your custom metal stamping dies design for quoting, verify these DFM checkpoints:

- Bend radii meet or exceed material thickness requirements

- Holes positioned at least 2x material thickness from bends and edges

- Bend reliefs added at all bend-to-edge intersections

- Critical bends oriented perpendicular to grain direction

- Flange lengths exceed 4x material thickness

- Angular tolerances account for expected springback

- Wall thickness supports specified tolerances (3mm+ for ±0.001")

- Internal corner radii meet minimum requirements (0.5mm+)

- Tight tolerances applied only to functionally critical features

Following these DFM principles doesn't just improve manufacturability—it fundamentally changes the economics of your project. Proper upfront design reduces tooling iterations, minimizes rejected parts, and accelerates time-to-production. The metal stamped part that emerges matches your intent because you designed for how stamping actually works.

With your design optimized for manufacturability, the next consideration becomes equally practical: what will this actually cost, and how do production volumes affect your budget?

Cost Factors and Budget Planning for Stamping Projects

Here's the question everyone wants answered but few suppliers discuss openly: what does custom metal stamping actually cost? The frustrating reality is that pricing varies dramatically based on factors most engineers never consider until they're staring at a quote that's three times their budget.

Let's break down the cost drivers that determine whether your stamped metal parts project stays on budget—or spirals into a financial headache.

Understanding Tooling Investment and Amortization

The single largest barrier to entry in metal stamping? Tooling. Every custom metal stampings project requires dies engineered specifically for your part geometry—and these precision tools don't come cheap.

Tooling costs range dramatically based on complexity:

- Simple blanking dies: Starting around $5,000 for basic flat parts with minimal features

- Moderate progressive dies: $15,000-$40,000 for parts requiring multiple operations

- Complex progressive dies: $50,000-$100,000+ for intricate components with numerous forming stations

What drives these differences? Several factors compound quickly:

- Number of stations: Each operation—piercing, bending, forming—requires a dedicated station in the die. A three-station die costs far less than a twelve-station tool.

- Die material: Tool steel grades matter. High-quality hardened steel (like D2 or carbide) withstands millions of strikes but costs more upfront. Lower-grade steels wear faster, producing inconsistent stamped steel parts over time.

- Tolerance requirements: Tighter tolerances demand more precise die construction, adding engineering hours and machining costs.

- Part size: Larger dies require more material, larger presses, and longer machining times.

Here's the critical insight: quality tooling guaranteed for 1,000,000+ strikes effectively caps your tooling expense for the project lifecycle. That $80,000 die producing 500,000 parts adds just $0.16 per piece. The same die producing only 5,000 parts? That's $16.00 per piece in tooling alone—often making the project economically unviable.

This amortization math explains why stamping companies consistently recommend minimum volumes before tooling investment makes sense. The economics simply don't work at low quantities.

Volume Thresholds That Affect Per-Part Pricing

Production volume fundamentally transforms stamping economics. Unlike CNC machining where per-part costs remain relatively flat regardless of quantity, stamping follows an asymptotic curve—costs per piece drop dramatically as volume increases.

Consider how different production scenarios affect your budget:

| Production Volume | Tooling Impact Per Part | Best Manufacturing Approach | Economic Reality |

|---|---|---|---|

| Prototype (1-100 units) | Extremely High | Soft tooling, laser cutting, or 3D printing | Stamping rarely cost-effective; consider alternative processes |

| Short-Run (100-5,000 units) | High | Simplified dies or hybrid approaches | Marginal; depends heavily on part complexity and alternatives |

| Medium Volume (5,000-50,000 units) | Moderate | Standard progressive dies | Stamping becomes competitive with machining and fabrication |

| High Volume (50,000+ units) | Low to Negligible | Optimized progressive or transfer dies | Stamping delivers lowest per-part cost; clear economic advantage |

The volume threshold where stamping services become economical typically falls around 10,000-20,000 parts—the point where progressive die efficiency offsets the substantial initial investment. Below this threshold, machining or fabrication often proves more economical despite higher per-piece costs.

Material costs and utilization represent the second major variable expense. Raw material often accounts for 60-70% of the variable piece price for metal stamped parts. Material selection affects costs through:

- Base material pricing: Stainless steel costs significantly more than cold-rolled steel; copper and brass command premium prices

- Scrap rates: Inefficient nesting generates waste. Parts with irregular shapes that don't interlock well on the metal strip create excessive scrap—though scrap recovery partially offsets this

- Material grade: Over-specifying material thickness or alloy grade beyond what your application requires inflates costs without improving performance

Part complexity multiplies costs in ways that aren't always obvious. Every additional feature—piercing operations, forming stations, tight tolerance zones—requires corresponding die complexity. A seemingly simple bracket might need three stations; a complex automotive housing might need twenty. Smart Design for Manufacturability (DFM) principles mitigate these costs significantly.

Secondary operations add to your total project cost but often get overlooked during initial budgeting:

- Plating and finishing (zinc, nickel, powder coating)

- Heat treating for hardness or stress relief

- Assembly operations (welding, riveting, hardware insertion)

- Quality documentation (PPAP, inspection reports, certifications)

The lowest piece price is often illusory. Total Cost of Ownership—including tooling amortization, scrap rates, quality failures, and logistics—is the only metric that matters for budget planning.

When requesting quotes from stamping services providers, provide accurate estimated annual usage (EAU) figures. Suppliers use this information to recommend appropriate tooling investments and optimize production planning. Underestimating volume leads to undersized tooling that wears prematurely; overestimating means paying for capacity you'll never use.

Understanding these cost drivers positions you to make strategic decisions: when to invest in premium tooling for long-term savings, when stamping makes economic sense versus alternatives, and how to structure production volumes for optimal pricing. With budget factors clarified, the next logical question becomes: when should you choose stamping over other manufacturing methods entirely?

Custom Metal Stamping vs Alternative Manufacturing Methods

You've crunched the numbers on stamping costs—but here's the question that actually determines whether you're making the right choice: should you even be stamping this part in the first place? Plenty of engineers default to stamping because it's familiar, only to discover that CNC machining, laser cutting, or casting would have delivered better results at lower total cost.

Let's cut through the confusion and establish exactly when custom metal stamping services outperform the alternatives—and when you should walk away from stamping entirely.

When Stamping Outperforms Machining and Fabrication

Custom sheet metal stamping dominates specific manufacturing scenarios. Understanding these sweet spots prevents you from forcing a square peg into a round hole.

High-volume production with consistent geometry: This is stamping's undisputed territory. Once your progressive die is running, producing complex stamped metal components in seconds becomes routine. CNC machining simply can't compete when you're producing 50,000 or 500,000 identical parts—the per-piece time difference is measured in orders of magnitude.

Sheet metal parts with multiple features: Progressive dies combine blanking, piercing, bending, and forming in single press strokes. A bracket requiring six operations emerges as a finished part every few seconds. Fabricating that same bracket through separate cutting, punching, and bending operations takes exponentially longer and introduces quality variation at each handling step.

Tight tolerances on formed features: Stamping achieves tolerances of ±0.0005 to ±0.002 inches on precision features—comparable to CNC machining but at fraction-of-a-second cycle times. For steel sheet stamping applications requiring both precision and volume, this combination is unbeatable.

Material efficiency matters: Sheet metal stampings generate less scrap than subtractive machining, which cuts away material from solid blocks. When raw material costs represent a significant budget line, stamping's efficient material utilization translates directly to savings.

However, stamping has clear boundaries. Cross them, and you're fighting physics and economics simultaneously:

- Low volumes: Tooling investment can't amortize across small production runs. Below 5,000-10,000 units, alternatives often win on total cost.

- Complex 3D geometries: Deep internal features, undercuts, and intricate cavities that can't be formed from sheet stock require different approaches.

- Rapid design iteration: Die modifications cost time and money. If your design is still evolving, committing to hard tooling is premature.

- Exotic materials: Some high-performance alloys—titanium, Inconel, certain composites—machine better than they stamp.

Decision Framework for Manufacturing Method Selection

Choosing the right manufacturing process isn't about which method is "best"—it's about matching capabilities to requirements. Here's how the major alternatives compare across factors that actually drive decisions:

| Factor | Custom Metal Stamping | CNC Machining | Laser Cutting | Die Casting | Metal Fabrication |

|---|---|---|---|---|---|

| Ideal Volume Range | 10,000+ units | 1-5,000 units | 1-10,000 units | 5,000+ units | 1-1,000 units |

| Geometric Capabilities | 2D profiles with 3D forming; limited by sheet thickness | Complex 3D; internal features; undercuts possible | 2D profiles only; no forming | Complex 3D castable shapes; draft angles required | Assemblies; large structures; welded configurations |

| Typical Tolerances | ±0.001" to ±0.005" | ±0.0005" to ±0.002" | ±0.005" to ±0.010" | ±0.005" to ±0.010" | ±0.010" to ±0.030" |

| Tooling Requirements | High ($15K-$100K+ for progressive dies) | Minimal (standard cutting tools) | Minimal (digital programming) | High ($10K-$100K+ for molds) | Low to moderate (fixtures, jigs) |

| Per-Part Cost at Volume | Very low at high volumes | Consistent regardless of volume | Moderate; less volume sensitivity | Low at high volumes | High; labor-intensive |

| Lead Time (First Parts) | 4-12 weeks (tooling dependent) | Days to 2 weeks | Days | 6-12 weeks (mold dependent) | 1-4 weeks |

| Material Options | Sheet metals (steel, aluminum, copper, brass) | Broad (metals, plastics, composites) | Sheet metals; some plastics | Non-ferrous (aluminum, zinc, magnesium) | Most weldable metals |

How do you apply this framework? Start with three questions:

1. What's your expected lifetime volume? Below 5,000 units, CNC machining or laser cutting typically wins. Above 50,000 units, custom stamped metal parts become hard to beat economically. The 5,000-50,000 range requires careful analysis of tooling amortization against per-piece savings.

2. What geometry does your part require? If it can be made from bent and formed sheet metal, stamping is viable. If you need deep cavities, internal threads, or features that can't be pressed from flat stock, look elsewhere. Die casting handles complex 3D shapes but limits you to non-ferrous metals. CNC machining offers the broadest geometric freedom but at higher per-piece cost.

3. How stable is your design? Stamping tooling is a significant commitment. Changing a progressive die mid-production can cost weeks and thousands of dollars. If you're still iterating, CNC machining's digital flexibility—where design changes require only updated toolpaths—provides crucial agility. Once design is frozen, transition to stamping for production economics.

Consider this real-world scenario: An electronics manufacturer needs 25,000 aluminum enclosures annually. The part requires blanking, piercing for ventilation, and multiple bends. CNC machining would cost approximately $8-12 per unit with no tooling. Custom sheet metal stamping requires $45,000 in tooling but drops per-piece cost to $1.50-2.00. At 25,000 units, stamping saves over $150,000 annually after the first-year tooling payback.

Now flip the scenario: A medical device startup needs 500 precision housings for clinical trials. Same geometry, different economics. The $45,000 die adds $90 per unit before any production costs. CNC machining at $15 per unit makes far more sense—and allows design refinements based on trial feedback before committing to production tooling.

The right manufacturing method minimizes Total Cost of Ownership across the product lifecycle—not just piece price or tooling investment in isolation.

One final consideration: hybrid approaches often deliver optimal results. Prototype with laser cutting or machining to validate designs. Transition to soft tooling for bridge production. Invest in hardened progressive dies only when design is frozen and volume justifies the commitment. This staged approach de-risks major tooling investments while maintaining time-to-market.

With manufacturing method selection clarified, the next challenge becomes equally critical: how do you evaluate potential stamping partners to ensure they can actually deliver what your project requires?

Evaluating Custom Metal Stamping Suppliers and Partners

You've designed a manufacturable part, selected appropriate materials, and confirmed that stamping makes economic sense for your volumes. Now comes the decision that determines whether your project succeeds or stumbles: choosing the right stamping partner.

Here's what makes this challenging—most engineers evaluate suppliers based on price alone. That's like choosing a surgeon based on hourly rates. The cheapest quote often hides capability gaps that surface as missed deadlines, quality failures, or costly redesigns. Let's examine what actually matters when vetting metal stampers for your critical components.

Essential Capabilities to Evaluate in Stamping Partners

When searching for metal stamping companies near me, look beyond the sales pitch. These capabilities separate capable partners from vendors who'll struggle with your requirements:

Tooling Design and Build Capabilities: Does the supplier design and build dies in-house, or do they outsource this critical function? In-house tooling capability matters for several reasons:

- Communication speed: Engineers who design the die can talk directly with engineers who run production, eliminating translation errors

- Modification turnaround: Die adjustments happen in days rather than weeks when toolroom and production share a roof

- Accountability: A single source owns the entire process—no finger-pointing between die builder and stamper when issues arise

Ask potential suppliers: "Do you design and build progressive dies in-house?" If they outsource tooling, understand their vendor relationships and how they manage the communication chain.

Production Capacity and Scalability: Can the custom metal stamper handle your current volumes and scale with your growth? Assess their press tonnage range, number of available presses, and current capacity utilization. A supplier running at 95% capacity has no room for your rush orders or volume increases. Look for partners with planned capacity headroom and clear expansion strategies.

Secondary Operation Capabilities: Few stamped parts go directly from press to assembly. Most require additional processing—plating, heat treating, deburring, hardware insertion, or sub-assembly. A stamped metal parts manufacturer offering these services in-house or through managed vendor networks simplifies your supply chain dramatically. Every handoff between suppliers adds lead time, quality risk, and coordination overhead.

Prototyping and Rapid Tooling Options: Production tooling takes weeks to build. What happens when you need parts faster for validation testing or design iteration? Leading suppliers offer rapid prototyping alternatives—soft tooling, 3D-printed dies, or hybrid approaches that deliver representative parts in days rather than months. For example, Shaoyi (Ningbo) Metal Technology delivers 5-day rapid prototyping capabilities, enabling engineers to validate designs before committing to production tooling investments.

Engineering Support for DFM Optimization: The most valuable suppliers don't just build what you send them—they improve it. Comprehensive Design for Manufacturability support catches tolerance issues, suggests material optimizations, and identifies tooling simplifications before expensive mistakes get machined into steel. This collaborative engineering approach significantly reduces scrap rates and rework while accelerating time-to-production.

Quality Certifications That Matter for Your Industry

Quality certifications aren't just wall decorations—they're third-party validation that a stamping parts manufacturer has implemented rigorous quality management systems. Different industries demand different standards:

| Certification | Industry Focus | Key Requirements | Why It Matters |

|---|---|---|---|

| IATF 16949 | Automotive | Defect prevention, PPAP documentation, continuous improvement | Required by major OEMs; ensures production-grade quality systems |

| AS9100 | Aerospace | Traceability, risk management, configuration control | Mandatory for aerospace supply chains; stringent documentation requirements |

| ISO 13485 | Medical Devices | Cleanroom considerations, biocompatibility, regulatory compliance | FDA expectations for medical component suppliers |

| ISO 9001 | General Manufacturing | Quality management fundamentals, process control | Baseline certification; confirms basic quality systems exist |

| Nadcap | Aerospace/Defense | Special process accreditation (heat treating, plating, NDT) | Required for aerospace secondary operations |

Match certification requirements to your application. Automotive chassis brackets? IATF 16949 certification is non-negotiable. A custom metal stamping company like Shaoyi demonstrates automotive-grade quality systems through their IATF 16949 certification—exactly what major OEMs require for chassis, suspension, and structural components.

Lead Time Expectations: Understanding realistic timelines prevents project schedule disasters. Typical lead times break down as follows:

- Tooling development: 4-12 weeks depending on die complexity and supplier workload

- First article production: 1-2 weeks after tooling approval

- Production runs: 2-4 weeks for typical orders; can be shorter with inventory programs

- Quote turnaround: Varies dramatically—some suppliers take weeks, while responsive partners like Shaoyi provide 12-hour quote turnaround to accelerate decision-making

Evaluating Partnership Potential: Beyond capabilities, assess the intangibles that determine long-term relationship success:

- Communication responsiveness: How quickly do they answer technical questions during the quoting process?

- Industry experience: Have they served companies in your sector with similar requirements?

- Financial stability: Can they invest in capacity and weather economic cycles?

- Continuous improvement culture: Do they proactively suggest cost reductions and quality improvements?

The lowest quoted piece price rarely delivers the lowest Total Cost of Ownership. Evaluate suppliers on capability, quality systems, engineering support, and partnership potential—not just price per thousand.

When you've narrowed candidates, request references from companies with similar requirements. Ask specifically about on-time delivery performance, quality consistency, and responsiveness when problems arise. The answers reveal more than any capability presentation.

Finding the right custom metal stamps supplier is an investment in your project's success. The ideal partner brings engineering expertise, quality infrastructure, and production capability that extends your team's reach. With supplier evaluation criteria established, the final consideration becomes understanding how requirements differ across specific industry applications—because automotive stamping and medical device stamping demand fundamentally different approaches.

Industry Applications and Sector-Specific Requirements

Here's what most supplier capability lists won't tell you: the same stamping process that produces automotive brackets operates under completely different rules when creating cardiac pacemaker components. Industry-specific requirements—certifications, materials, tolerances, and documentation—fundamentally reshape how custom metal stamping projects get executed.

Understanding these differences prevents costly misalignments between your application requirements and supplier capabilities. Let's examine what each major sector demands and why those demands exist.

Automotive Stamping Requirements and Certifications

Automotive applications represent the highest-volume segment of industrial metal stamping. Chassis components, suspension brackets, structural reinforcements, and body panels all rely on stamped metal for cost-effective production at scale.

What makes custom automotive metal stamping distinct? Three factors dominate:

- IATF 16949 certification: This isn't optional for Tier 1 and Tier 2 automotive suppliers. IATF 16949:2016 harmonizes quality management across the global automotive industry, focusing on defect prevention, variation reduction, and waste minimization. Major OEMs require this certification from their supply base—without it, you're locked out of automotive contracts.

- PPAP documentation: Production Part Approval Process documentation proves your manufacturing process consistently produces parts meeting specifications. This includes dimensional reports, material certifications, process flow diagrams, and capability studies.

- Volume scalability: Automotive programs often start with prototype quantities, ramp to launch volumes, then sustain at hundreds of thousands of parts annually. Your stamping partner must handle this entire lifecycle without quality degradation.

For engineers sourcing chassis, suspension, or structural components, partnering with IATF 16949-certified suppliers is non-negotiable. Shaoyi (Ningbo) Metal Technology exemplifies focused automotive expertise—their IATF 16949 certification, combined with capabilities spanning rapid prototyping through automated mass production, demonstrates the comprehensive quality systems automotive OEMs require.

Aerospace: Precision Under Extreme Conditions

Aerospace metal stamping operates in a different universe of precision and documentation. Components must perform flawlessly under extreme temperature variations, vibration, and stress—with zero tolerance for failure.

Key aerospace requirements include:

- AS9100 certification: The aerospace equivalent of automotive's IATF 16949, this standard adds requirements for risk management, configuration control, and enhanced traceability throughout the supply chain.

- Material traceability: Every piece of raw material must trace back to its source, with mill certifications documenting chemical composition and mechanical properties. Full traceability from raw material through final inspection is mandatory for both commercial and defense applications.

- Specialized alloys: Titanium alloys for high-temperature applications, aluminum alloys optimized for strength-to-weight ratios, and corrosion-resistant stainless grades dominate aerospace material specifications.

- Nadcap accreditation: For secondary processes like heat treating, plating, and non-destructive testing, Nadcap accreditation validates that special processes meet aerospace industry standards.

Precision metal stamping services for aerospace often involve tighter tolerances than other industries demand—sometimes reaching ±0.001" on critical features. When developing a metal stamping prototype for aerospace applications, expect rigorous first article inspection requirements and extensive qualification testing before production approval.

Electronics: Miniaturization Meets Consistency

Electronic connectors, EMI shields, battery contacts, and heat dissipation components drive substantial demand for precision stamped parts. The electronics sector prioritizes different capabilities:

- Tight tolerances: Connector terminals often require dimensional control measured in thousandths of an inch. Terminal stamping specifications typically call for ±0.05mm dimensional accuracy, with critical connection points requiring ±0.02mm precision.

- Material conductivity: Copper and copper alloys dominate due to their electrical properties—conductivity around 58 MS/m for copper makes it ideal for high-current applications. Aluminum serves lower-current applications where weight matters.

- Surface finish requirements: Contact surfaces often require surface roughness of Ra ≤ 0.8 μm to ensure reliable electrical connections.

- High-volume consistency: Consumer electronics applications may require millions of identical components annually, demanding statistical process control and automated inspection systems.

Custom precision metal stamping services for electronics often combine progressive die stamping with precious metal plating operations—gold or silver over nickel for optimal contact performance.

Medical Devices: Where Biocompatibility Meets Precision

Medical device stamping introduces requirements that don't exist in other industries. When components interface with human tissue or support life-critical functions, the stakes fundamentally change.

Critical medical stamping considerations include:

- ISO 13485 certification: This quality management standard specifically addresses medical device manufacturing, with emphasis on regulatory compliance and risk management throughout the product lifecycle.

- Biocompatible materials: 316L stainless steel, titanium alloys, and other materials proven safe for medical applications dominate material specifications. Battery cases for implantable devices like pacemakers require materials that won't react with body tissues over decades of service.

- Surface finish specifications: Smooth surfaces matter for both functionality and sterilization compatibility. Rough surfaces harbor bacteria and complicate cleaning protocols.

- Cleanroom considerations: Some medical components require manufacturing in controlled environments to prevent contamination.

- Sterilization compatibility: Components must withstand gamma radiation, electron beam, or chemical sterilization processes without property degradation.

Documentation requirements for medical stamping exceed most other industries. FDA expectations for Design History Files, Device Master Records, and validated manufacturing processes add substantial compliance overhead—but these requirements exist because patient safety depends on them.

Industry-Specific Quality and Compliance Considerations

Beyond the major sectors above, custom construction metal stamping serves infrastructure and building applications with durability requirements, while industrial equipment demands components that survive harsh operating environments for extended service lives.

| Industry | Primary Certification | Key Material Requirements | Typical Tolerance Range | Documentation Emphasis |

|---|---|---|---|---|

| Automotive | IATF 16949 | High-strength steels, aluminum alloys | ±0.002" to ±0.005" | PPAP, capability studies, SPC data |

| Aerospace | AS9100, Nadcap | Titanium, aerospace aluminum, specialty stainless | ±0.001" to ±0.003" | Full material traceability, FAI reports |

| Electronics | ISO 9001 minimum | Copper, brass, beryllium copper | ±0.001" to ±0.002" | Dimensional reports, conductivity testing |

| Medical | ISO 13485 | 316L stainless, titanium, biocompatible alloys | ±0.001" to ±0.003" | Validation protocols, biocompatibility testing |

| Industrial | ISO 9001, API Spec Q1 (energy) | Carbon steel, galvanized steel, stainless | ±0.005" to ±0.010" | Material certs, dimensional inspection |

The custom metal stamp requirements for each industry reflect the consequences of failure. Automotive recalls cost millions. Aerospace failures can be catastrophic. Medical device problems affect patient health. These realities drive the certification requirements, documentation demands, and quality expectations that define industry-specific stamping.

Choosing a stamping supplier without matching certifications to your industry is like hiring a contractor without proper licensing—it might work, but you're accepting unnecessary risk.

When evaluating suppliers for industry-specific applications, verify that their quality systems align with your sector's requirements. A supplier with deep automotive experience and IATF 16949 certification—like Shaoyi with their focus on chassis, suspension, and structural components—brings industry knowledge that generic manufacturers simply don't possess. That expertise translates to faster project launches, fewer quality issues, and smoother production ramps.

Understanding these sector-specific requirements completes your foundation for successful custom metal stamping projects. From process selection through supplier evaluation, from material choices through industry compliance—you now have the knowledge to make informed decisions that deliver quality components on time and on budget.

Frequently Asked Questions About Custom Metal Stamping

1. What is custom metal stamping and how does it differ from standard stamping?

Custom metal stamping is a precision manufacturing process that transforms flat sheet metal into complex three-dimensional components using specialized dies and presses designed specifically for your unique part geometry. Unlike standard stamping which uses off-the-shelf tooling for generic shapes, custom stamping involves tailored dies engineered around your exact specifications, enabling tolerances as tight as 0.0005 inches and intricate geometries that standard methods cannot achieve. This process serves industries including automotive, aerospace, electronics, and medical devices where part consistency and precision are critical requirements.

2. How much does custom metal stamping tooling cost?

Custom metal stamping tooling costs vary significantly based on complexity. Simple blanking dies start around $5,000, moderate progressive dies range from $15,000-$40,000, while complex progressive dies with numerous forming stations can exceed $50,000-$100,000. Key cost drivers include the number of stations required, die material grade, tolerance requirements, and overall part size. However, tooling investment amortizes across production volume—an $80,000 die producing 500,000 parts adds only $0.16 per piece, making high-volume production extremely cost-effective.

3. What materials can be used in custom metal stamping?

Custom metal stamping accommodates a wide range of materials including aluminum (lightweight, excellent thermal conductivity), cold rolled steel (cost-effective with excellent formability), stainless steel (superior corrosion resistance for medical and food applications), copper and brass (optimal electrical conductivity), and galvanized steel (basic corrosion protection at lower cost). Material selection depends on four key properties: ductility (stretch capability), tensile strength, work hardening behavior, and springback characteristics. Each material offers distinct advantages—aluminum suits heat sinks and lightweight structures, while stainless steel excels in demanding environments requiring 48+ hour salt spray resistance.

4. What is the minimum order quantity for custom metal stamping?

While there is no strict minimum, custom metal stamping becomes economically viable typically around 10,000-20,000 units where progressive die efficiency offsets initial tooling investment. Below 5,000 units, CNC machining or laser cutting often proves more cost-effective despite higher per-piece costs. The economics follow an asymptotic curve—per-part costs drop dramatically as volume increases. For prototype quantities (1-100 units), alternatives like soft tooling, laser cutting, or 3D printing are recommended. Some suppliers like Shaoyi offer rapid prototyping with 5-day turnaround to validate designs before committing to production tooling.

5. How do I choose between progressive die stamping and other stamping methods?

Choose progressive die stamping for high-volume production (100K+ units) of small to medium-sized parts requiring multiple operations in sequence—it offers the lowest per-unit costs and fastest cycle times. Select transfer die stamping for medium-to-large parts requiring deep draws and complex shapes where the part must separate from the strip early. Use fourslide/multislide stamping for small, intricate parts requiring precise bends from multiple directions. Deep draw stamping is ideal for creating seamless cup-shaped, cylindrical, or box-like components with significant depth. Your decision should consider expected volume, part geometry complexity, and tolerance requirements.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —