Automotive Stamping Cost Estimation: Formulas, Breakdowns & ROI

TL;DR

Automotive stamping cost estimation fundamentally relies on balancing high upfront tooling investments ($5,000–$100,000+) against low variable piece prices. The core estimation formula is: Total Cost = Fixed Costs (Design + Tooling + Setup) + (Variable Cost/Unit × Volume). For automotive projects exceeding 10,000 units annually, investing in complex progressive dies typically yields the lowest total cost of ownership (TCO) by drastically reducing cycle times and labor. accurate budgeting requires detailed analysis of material utilization (nesting), press tonnage (machine hourly rates), and scrap recovery rates.

The Anatomy of Stamping Costs: Fixed vs. Variable

In automotive manufacturing, cost estimation is an exercise in amortization. Unlike low-volume processes like laser cutting or CNC machining where costs remain relatively flat per unit, stamping follows an asymptotic curve where cost per part drops precipitously as volume increases. Understanding this requires splitting your budget into two distinct buckets: fixed capital investment and variable production expenses.

Fixed Costs (The "Sunk" Investment)

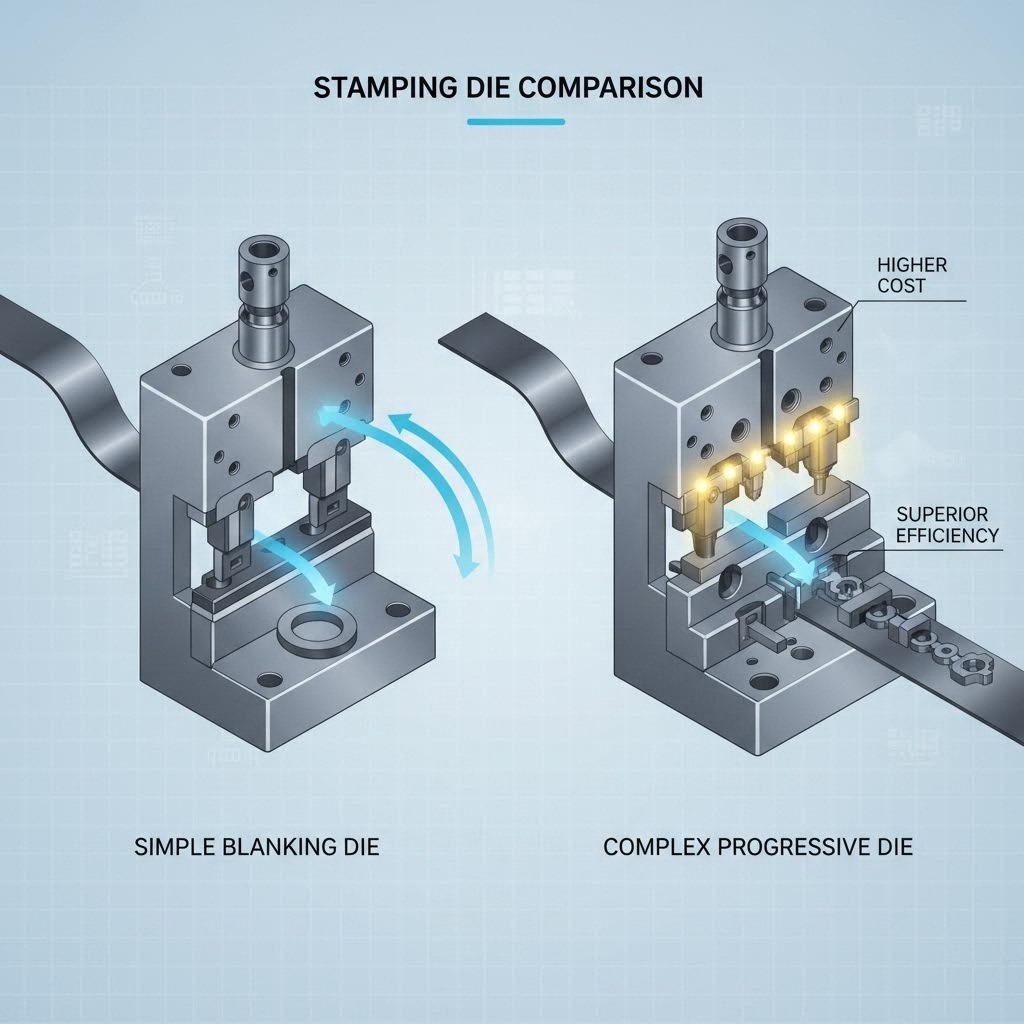

The largest barrier to entry is tooling. A custom die is a precision-engineered asset, often machined from hardened tool steel to withstand millions of impact cycles. Tooling costs can range dramatically, from approximately $5,000 for simple blanking dies to over $100,000 for complex progressive dies with multiple forming stations. This category also includes engineering design hours, die assembly, and the initial "tryout" phase where the tool is calibrated. While this upfront number is high, high-quality dies—like those guaranteed for 1 million strikes—effectively cap your tooling spend for the lifecycle of the project.

Variable Costs (The Running Rate)

Once the die is built, the "piece price" takes over. This includes the raw material (steel/aluminum coils), machine hourly rates (based on press tonnage and energy consumption), labor, and overhead. For a 100-ton press running at 60 strokes per minute, the labor cost per part is negligible compared to the material cost. The strategic goal of stamping estimation is to determine the volume threshold—typically around 10,000 to 20,000 parts—where the efficiency of the progressive die offsets its massive initial price tag.

Step-by-Step Cost Estimation Formula

To move beyond rough guesses, engineers use a structured calculation. While software like AutoForm can automate this for complex geometries, a manual estimation follows this logic:

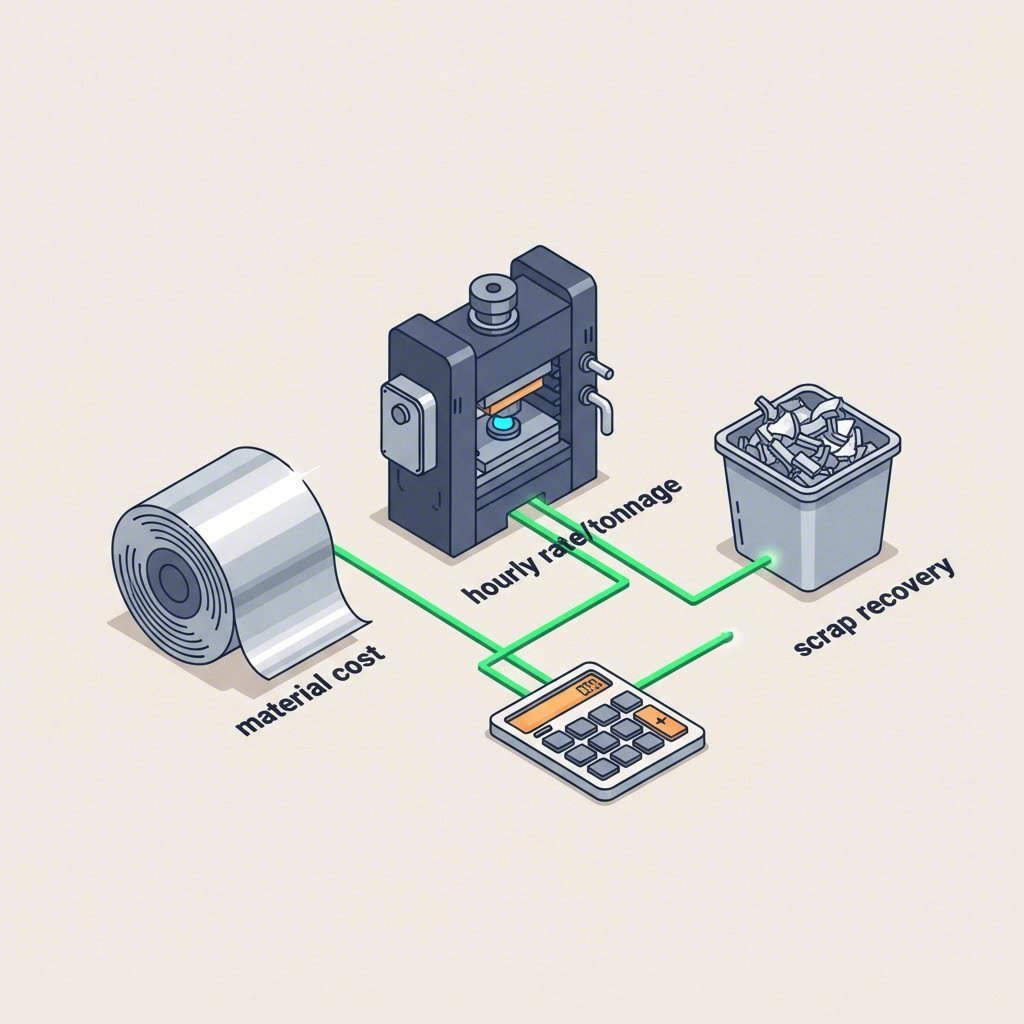

1. Calculate Net Material Cost

Automotive stamping is material-intensive. The formula starts with the blank size (length × width × thickness × density).

Material Cost = (Gross Weight × Material Price/kg) - (Scrap Weight × Scrap Value/kg)

Note that "Gross Weight" includes the engineered scrap—the skeleton of metal left behind after the part is punched out. Efficient nesting can reduce this waste, but some scrap is inevitable.

2. Determine Machine Hourly Rate

Presses are rated by tonnage (force) and bed size. A 600-ton press commands a higher hourly rate than a 100-ton press due to energy and amortization.

Machine Cost = (Hourly Rate ÷ Strokes Per Hour) × (1 ÷ Efficiency Factor)

Efficiency is never 100%; factor in coil changes, maintenance intervals, and unplanned downtime (typically 80-85% OEE).

3. Amortize Tooling

Spread the fixed cost over the expected production life.

Tooling Cost Per Part = Total Die Investment ÷ Total Lifetime Volume

If a progressive die costs $80,000 but produces 500,000 parts over five years, the tooling add-on is just $0.16 per part. Conversely, for a run of only 5,000 parts, that same die adds $16.00 per part, likely making the project unviable.

Material & Process Drivers

Design choices made early in the engineering phase act as multipliers for the final quote. The relationship between part complexity and cost is not linear; it is exponential. A seemingly minor tolerance adjustment can force a move from a standard mechanical press to a high-precision servo press, or require expensive secondary operations.

Material Selection and Utilization

Raw material often accounts for 60-70% of the variable piece price. While high-strength steel (HSS) or aluminum reduces vehicle weight, they often require larger, more expensive presses to form without cracking. Furthermore, "nesting" efficiency is critical. Parts designed with irregular shapes that don't interlock well on the metal strip create excessive scrap. Simulation technology is frequently used to optimize blank shapes before a physical tool is ever cut, saving percentage points that translate to millions of dollars in high-volume runs.

Complexity and DFM (Design for Manufacturability)

Every feature on a part requires a corresponding station in the die. A simple bracket might need three stations: punch, bend, cut. A complex automotive housing might need twenty. Smart DFM guidelines can mitigate these costs significantly:

- Bend Radii: Adhere to standard bend radii (typically 1x material thickness) to prevent cracking without expensive heat treating.

- Edge Spacing: Keep holes at least 2x material thickness away from edges to prevent deformation, which otherwise requires slower processing or complex support tooling.

- Tolerances: Avoid default tight tolerances (e.g., +/- 0.001") where they aren't functionally critical. Standard stamping tolerances (+/- 0.005" to 0.010") are much cheaper to maintain than precision machining standards.

Hidden Costs & Risk Factors

Budget overruns in automotive stamping rarely come from the steel price; they come from the "unseen" operational realities. When building your estimate, you must account for the supporting infrastructure that ensures the part actually meets OEM standards.

Quality Control and Certifications

Automotive components require rigorous validation, often involving PPAP (Production Part Approval Process) levels 1-5. This documentation is not free; it requires inspection fixtures, CMM time, and engineering hours. Furthermore, choosing a supplier without the right certifications can lead to costly recalls or quality failures down the line. Partnering with a manufacturer that bridges the gap from prototyping to mass production is crucial for risk management.

For instance, Shaoyi Metal Technology leverages IATF 16949-certified precision and press capabilities up to 600 tons to deliver critical components like control arms and subframes. Their ability to handle both rapid prototyping (e.g., 50 parts in five days) and high-volume manufacturing ensures that the cost model remains stable as you scale, without the need to switch vendors and re-qualify tools.

Maintenance and Logistics

Dies do not last forever. An accurate estimate includes a "die maintenance" buffer—typically 2-5% of the tooling cost annually—for sharpening punches and replacing worn die sections. Finally, consider logistics. While an overseas tool might be 30% cheaper upfront, the cost of shipping heavy steel dies, potential port delays, and the inability to quickly troubleshoot engineering changes can negate the initial savings. Total Landed Cost (TLC) is the only metric that matters.

Conclusion

Accurate automotive stamping cost estimation is a multi-dimensional puzzle that goes far beyond the price per pound of steel. It requires a strategic view of the entire product lifecycle—from the amortization of $100,000 tooling investments to the micro-optimization of cycle times and scrap rates. By leveraging simulation data, adhering to Design for Manufacturability principles, and selecting partners with the right capacity and certifications, engineers can transform stamping from a cost center into a competitive advantage. The lowest piece price is often illusory; the lowest Total Cost of Ownership is the true target.

Frequently Asked Questions

1. Is metal stamping expensive compared to CNC machining?

For low volumes (under 1,000 units), stamping is generally more expensive due to high upfront tooling costs ($5,000+). However, for high volumes (10,000+ units), stamping becomes significantly cheaper than CNC machining because the cycle time per part is measured in seconds rather than minutes, and the labor cost is spread over a much larger quantity.

2. What is the standard formula for stamping cost estimation?

The standard formula is: Total Cost = Tooling Investment + (Material Cost + Processing Cost) × Quantity. Processing cost is derived from the hourly press rate divided by the production rate (parts per hour). Material cost must account for the gross weight of the blank minus the scrap value of the recovered metal.

3. What does a "1 million strike" die guarantee mean for estimation?

A "1 million strike" guarantee implies that the tooling is built from high-grade hardened steel (like carbide or D2) and is engineered to produce one million parts before requiring major refurbishment or replacement. For cost estimation, this allows you to amortize the tooling cost over a very long lifespan, effectively lowering the allocated tooling cost per unit to a negligible amount for high-volume runs.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —