Pillar Stamping Automotive: Advanced Processes for UHSS & Safety

TL;DR

Pillar stamping automotive processes define the structural integrity of modern vehicles, focusing on the critical A, B, C, and D pillars. These components represent a complex engineering trade-off: maximizing crash safety through Ultra-High-Strength Steels (UHSS) while minimizing weight for fuel efficiency. The industry standard has shifted heavily toward Hot Stamping (Press Hardening) for B-pillars to achieve tensile strengths exceeding 1500 MPa, whereas A-pillars often require complex Cold Stamping or progressive die techniques to accommodate intricate geometries and visibility constraints. This guide explores the technical specifications, material science, and manufacturing methodologies required to master pillar production.

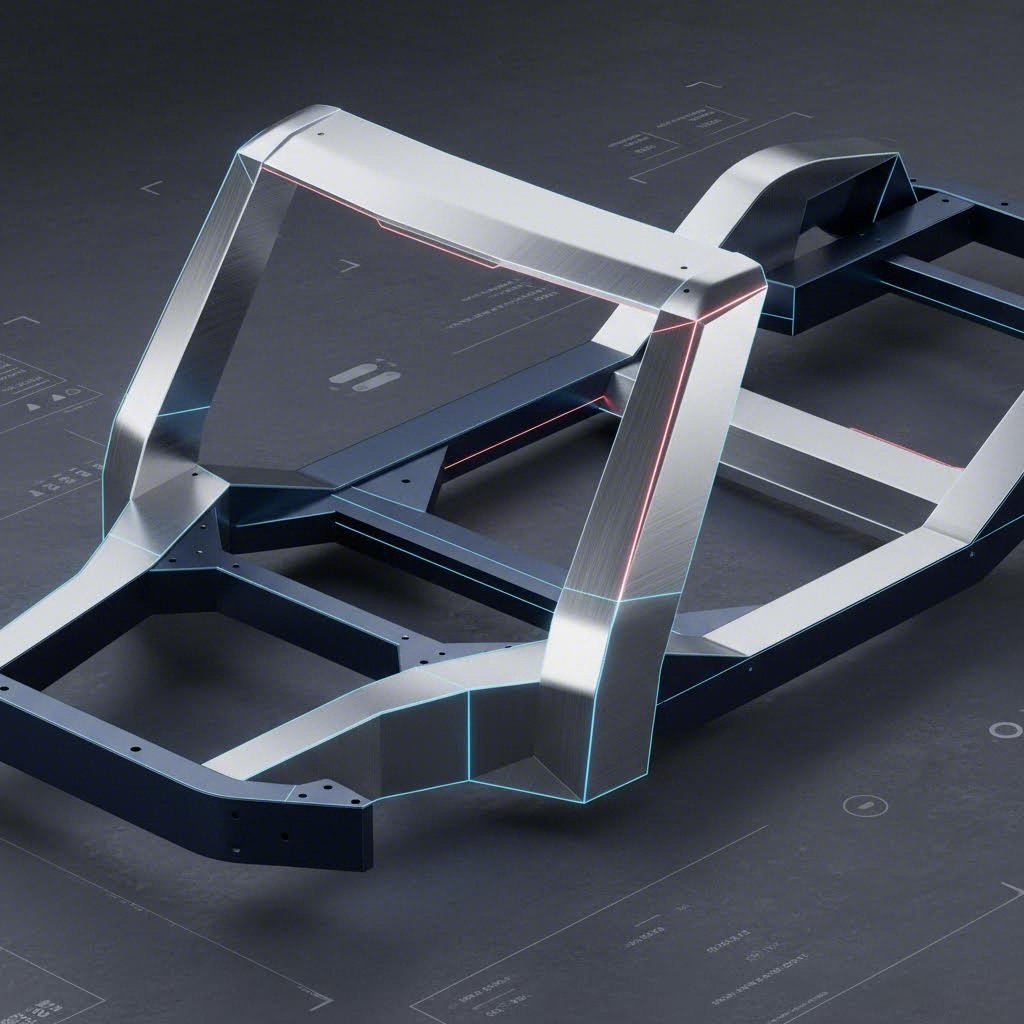

Anatomy of Safety: A-Pillar vs. B-Pillar Stamping Requirements

In automotive body-in-white (BIW) manufacturing, not all pillars are created equal. The stamping requirements for an A-pillar differ fundamentally from those of a B-pillar due to their distinct roles in occupant safety and vehicle aesthetics.

The A-Pillar Challenge: Geometry and Visibility

The A-pillar must support the windshield and withstand roof-crush forces, yet it must remain narrow to minimize the driver's blind spot. Manufacturers like Group TTM highlight that A-pillars feature intricate 3D curves, varying wall thicknesses, and numerous access holes for wiring and airbags. The stamping process here prioritizes formability and geometric precision over pure hardness, often utilizing high-strength steel that retains enough ductility for complex deep draws without splitting.

The B-Pillar Challenge: Intrusion Resistance

The B-pillar is the critical shield against side-impact collisions. Unlike the A-pillar, the B-pillar requires maximum yield strength to prevent intrusion into the passenger cabin. This necessitates the use of boron steel and other UHSS grades. The forming challenge shifts from geometric complexity to managing extreme material hardness and preventing springback. Stamping specs for B-pillars frequently demand tensile strengths exceeding 1500 MPa post-forming, a benchmark that dictates the choice between hot and cold forming technologies.

Material Science: The Shift to UHSS and Aluminum

The transition from mild steel to advanced materials has revolutionized pillar stamping automotive workflows. Engineers must select materials that balance the "Lightweighting vs. Safety" equation.

- Boron Steel (Press Hardening Steel): The gold standard for B-pillars. When heated to roughly 900°C (1,650°F) and quenched within the die, the microstructure transforms from ferrite-pearlite to martensite. This transformation yields parts with exceptional strength but zero formability post-process, making trimming and cutting challenging without laser processes.

- Aluminum Alloys (5000/6000 Series): Used increasingly to reduce weight. While aluminum offers excellent strength-to-weight ratios, it suffers from significant springback—the tendency of the metal to return to its original shape after stamping. Controlling springback in aluminum A-pillars requires advanced simulation software and die compensation strategies.

- Advanced High-Strength Steel (AHSS): Includes Dual-Phase (DP) and Transformation-Induced Plasticity (TRIP) steels. These offer a middle ground, providing higher strength than mild steel with better formability than hot-stamped boron, suitable for C and D pillars or internal reinforcements.

| Material Category | Typical Application | Primary Benefit | Stamping Challenge |

|---|---|---|---|

| Mild Steel | Non-structural trim | Low Cost, High Formability | Low Crashworthiness |

| Boron Steel (Hot Stamped) | B-Pillars, Roof Rails | Extreme Strength (>1500 MPa) | High Cycle Time, Tool Wear |

| Aluminum | A-Pillars, Body Panels | Lightweighting | High Springback, Galling |

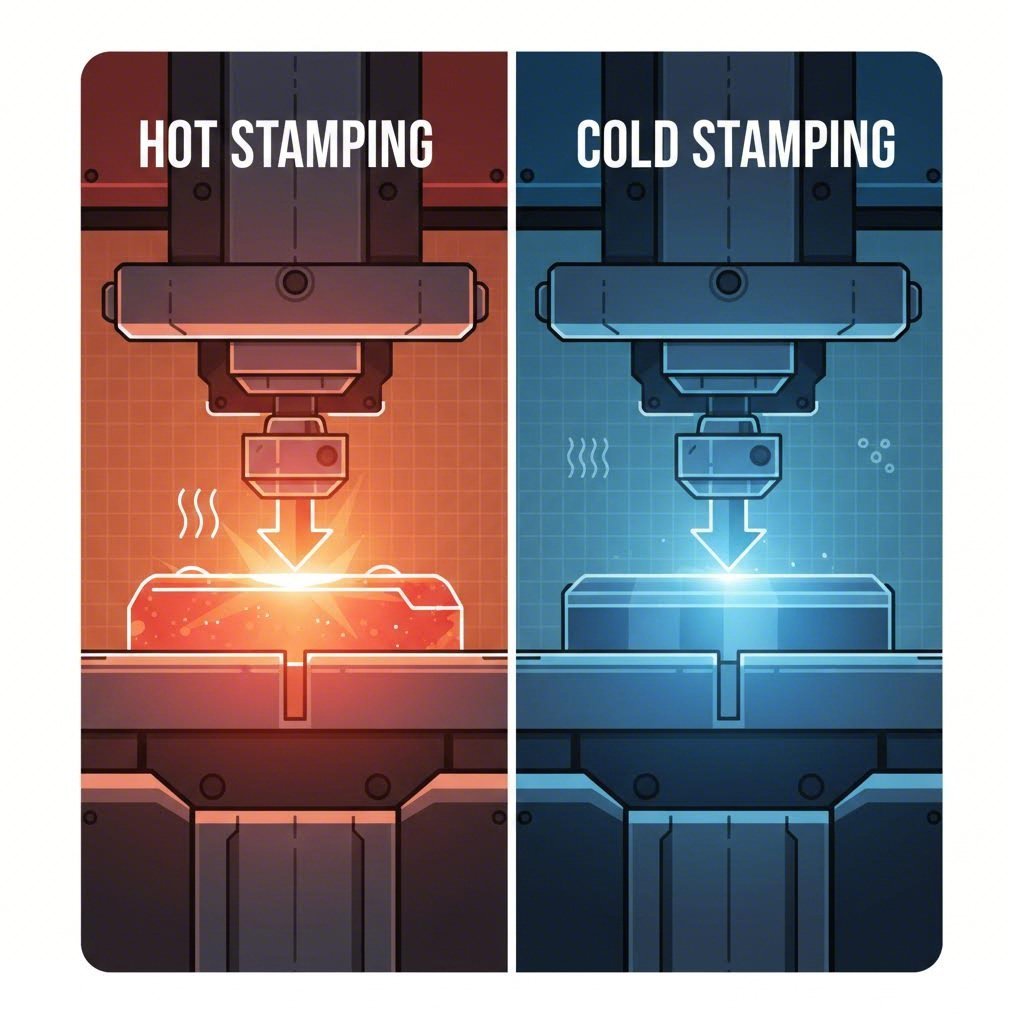

Process Deep Dive: Hot Stamping vs. Cold Stamping

The choice between hot and cold stamping is the dominant technical debate in pillar manufacturing, driven by the specific performance requirements of the component.

Hot Stamping (Press Hardening)

Hot stamping is the enabling technology for modern safety cells. As detailed by major suppliers like Magna, the process involves heating the steel blank until it becomes austenitic, transferring it to a cooled die, and forming it while simultaneously quenching it. This process freezes the martensitic microstructure, locking in ultra-high strength properties. While cycle times are longer (typically 10–20 seconds) compared to cold stamping, the elimination of springback makes it indispensable for B-pillars where dimensional accuracy is non-negotiable.

Cold Stamping

For components where extreme hardness is less critical than production speed or geometric complexity, cold stamping remains superior. It utilizes mechanical or hydraulic presses at ambient temperatures. However, when applied to UHSS, cold stamping introduces the risk of work hardening and massive springback forces. Advanced cold stamping of pillars requires high-tonnage presses (often 2000+ tons) and servo-drive technology to control the ram speed precisely during the drawing phase, reducing shock and improving material flow.

Advanced Manufacturing & Progressive Dies

To meet the demands of high-volume production, manufacturers leverage progressive die stamping and tailored blanks. Progressive dies perform multiple operations—piercing, trimming, bending—in a single pass, making them ideal for complex A-pillar reinforcements. Laser Welded Blanks (LWB) allow engineers to combine different thicknesses or grades of steel into a single blank before stamping, ensuring strength exactly where needed (e.g., the hinge area) while saving weight elsewhere.

For automotive OEMs and Tier 1 suppliers, selecting a partner with diverse capabilities is crucial for navigating these complexities. Shaoyi Metal Technology offers comprehensive automotive stamping solutions that bridge the gap from rapid prototyping to mass production. With IATF 16949 certification and press capabilities up to 600 tons, they support the fabrication of critical structural components and subsystems, ensuring strict adherence to global OEM standards whether you need a pilot run of 50 units or high-volume delivery.

Defect Prevention & Quality Control

Even with advanced machinery, defects can compromise structural integrity. Managing these requires a rigorous approach to process control.

- Springback: The elastic recovery of metal after unloading. In UHSS and aluminum, this can cause deviations of several millimeters. Solution: Over-crowning the die surface and using simulation software like AutoForm to predict and compensate for recovery.

- Wrinkling: Occurs in compressive areas, particularly in the complex roots of A-pillars. Solution: Increasing binder pressure or utilizing active draw beads to control material flow.

- Thinning & Cracking: Excessive thinning leads to structural failure. Solution: Optimizing lubrication is critical. As noted in case studies by IRMCO, replacing synthetic lubricants can reduce friction and prevent white corrosion, a common issue that leads to weld defects downstream.

Conclusion: The Future of Pillar Engineering

Mastering pillar stamping automotive workflows requires a holistic understanding of the interplay between advanced materials and forming technologies. As safety standards evolve and the push for lightweighting intensifies, the industry will continue to rely on a hybrid approach—utilizing hot stamping for the rigid B-pillar safety cage and precision cold stamping for the geometric complexity of A-pillars. For engineers and procurement leaders, success lies in validating supplier capabilities not just in tonnage, but in their ability to simulate, compensate, and control these sophisticated metallurgical processes.

Frequently Asked Questions

1. What are the 7 steps in the stamping method?

While processes vary, the seven common steps in metal stamping include blanking (cutting the rough shape), piercing (punching holes), drawing (forming the 3D shape), bending (creating angles), air bending, bottoming/coining (stamping for precision), and pinch trimming (removing excess material). For pillars, these are often combined into progressive or transfer die operations.

2. What are the pillars on a car labeled?

Vehicle pillars are labeled alphabetically from front to rear. The A-pillar holds the windshield; the B-pillar is the central support between front and rear doors; the C-pillar supports the rear window or rear door in sedans/SUVs; and the D-pillar is found on longer vehicles like station wagons and minivans as the rearmost support.

3. What are the four types of metal stamping used in automotive?

The four primary types are Progressive Die Stamping (continuous strip fed through stations), Transfer Die Stamping (parts moved mechanically between stations, common for large pillars), Deep Draw Stamping (for parts with significant depth like door panels), and Multi-Slide Stamping (for complex, small bends). Each is selected based on part volume, complexity, and size.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —