Materials for Automotive Metal Stamping: The Engineer’s Guide

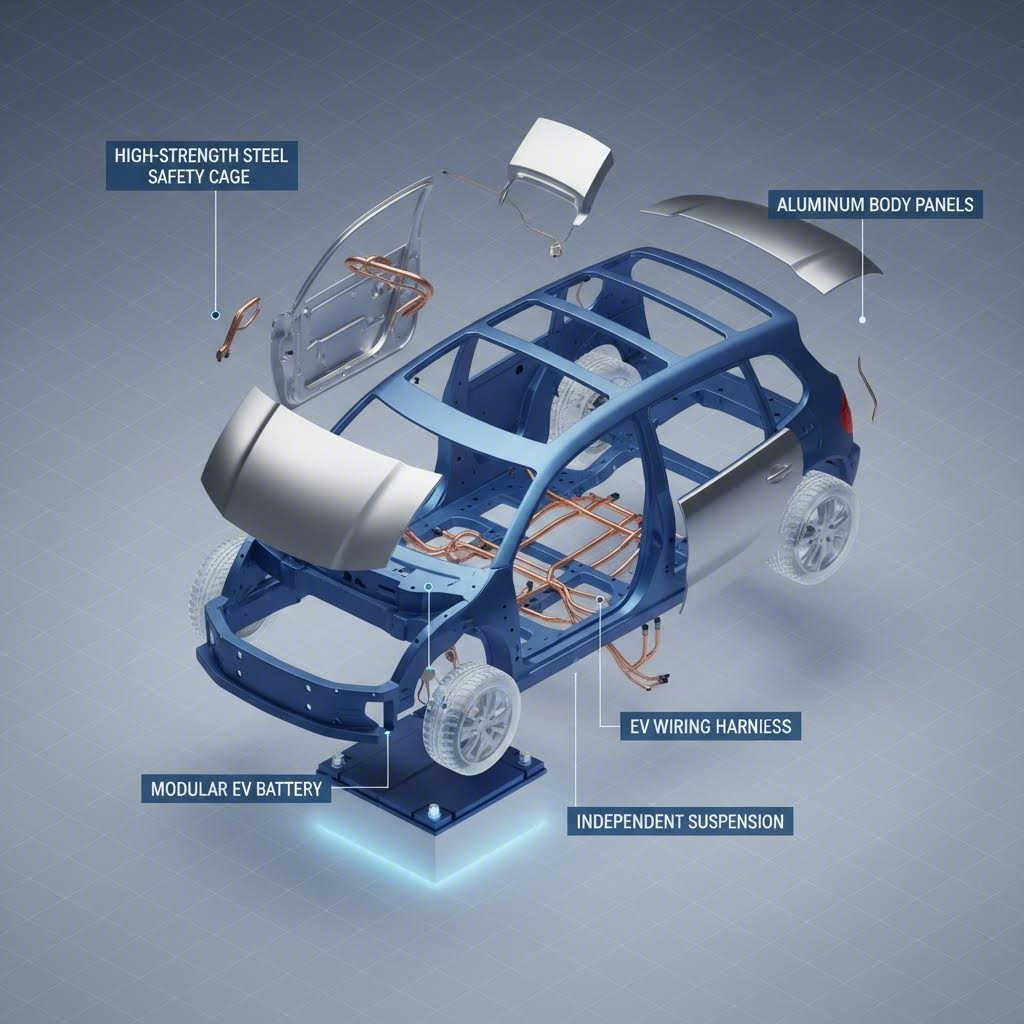

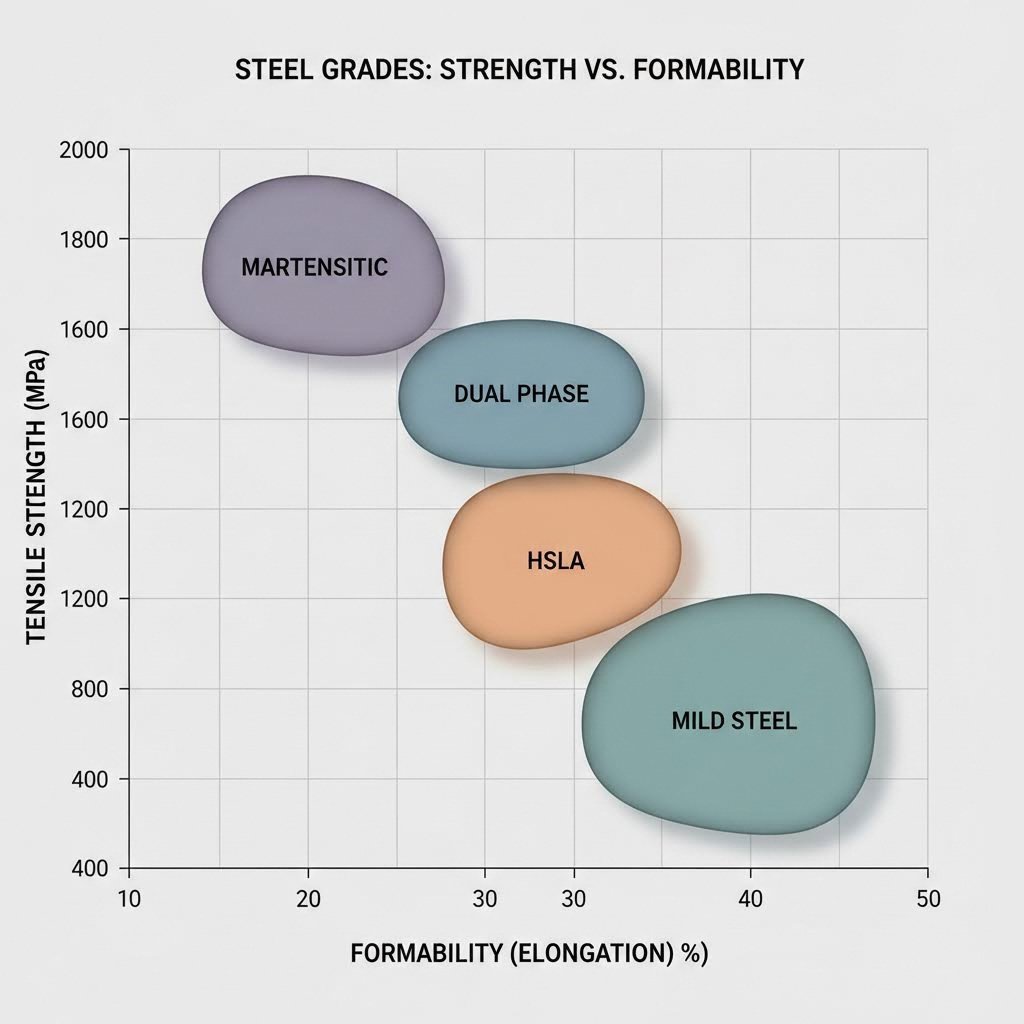

<h2>TL;DR</h2><p>Automotive metal stamping relies primarily on three material families: <strong>Steel</strong> (Advanced High-Strength Steel and HSLA) for structural integrity and crash safety, <strong>Aluminum</strong> (5xxx and 6xxx series) for lightweight body panels, and <strong>Copper</strong> for EV electrification components. Selection depends on balancing the "Iron Triangle" of manufacturing: tensile strength, weight reduction, and cost efficiency. For modern applications, engineers are increasingly shifting toward Martensitic and Dual-Phase steels for safety-critical parts, while reserving specialized alloys like Beryllium Copper for high-performance electrical connectors.</p><h2>Steel Alloys: The Structural Backbone of Automotive Stamping</h2><p>Despite the push for lightweighting, steel remains the dominant material in automotive manufacturing due to its unmatched cost-to-strength ratio and formability. However, the industry has moved far beyond basic mild steel. Today's stamping operations utilize a sophisticated hierarchy of alloys designed to meet stringent crash safety standards without adding excessive mass.</p><h3>From Mild Steel to HSLA</h3><p>Low Carbon (Mild) Steel grades, such as 1008 and 1010, are the traditional workhorses for non-critical components like floor pans and cosmetic covers. They offer excellent ductility and are easy to cold form, but they lack the yield strength required for modern safety cages. <strong>High-Strength Low-Alloy (HSLA)</strong> steel bridges this gap. By adding small amounts of vanadium, niobium, or titanium, HSLA steels achieve yield strengths up to 80 ksi (550 MPa) while maintaining weldability. These are commonly stamped into chassis components, cross members, and suspension reinforcements where structural rigidity is paramount.</p><h3>Advanced High-Strength Steel (AHSS)</h3><p>For critical safety zones like A-pillars, B-pillars, and rocker panels, engineers turn to <a href="https://www.arandatooling.com/blog/guide-to-materials-used-in-metal-stamping/">Advanced High-Strength Steels (AHSS)</a>. These multiphase steels are engineered at the microstructural level to provide extreme strength:</p><ul><li><strong>Dual-Phase (DP) Steel:</strong> Composed of a soft ferrite matrix for formability and hard martensite islands for strength, DP steels (e.g., DP590, DP980) are ideal for crash zones that require energy absorption.</li><li><strong>Transformation-Induced Plasticity (TRIP):</strong> Offers superior formability for its strength level, making it suitable for complex shapes that require high energy absorption during a collision.</li><li><strong>Martensitic (MS) Steel:</strong> The hardest of the AHSS group, used for intrusion resistance in side-impact beams and bumpers. Stamping MS steel often requires specialized "Hot Stamping" processes to prevent cracking and springback.</li></ul><h2>Aluminum Alloys: Champions of Lightweighting</h2><p>As emission regulations tighten and EV range anxiety persists, aluminum has become the standard for weight reduction ("lightweighting"). Replacing steel body panels with aluminum can reduce component weight by up to 40%, directly improving fuel economy and battery range. Stamping aluminum, however, presents challenges such as increased <strong>springback</strong>—the tendency of the metal to return to its original shape after forming.</p><h3>5xxx Series vs. 6xxx Series</h3><p>Automotive stamping predominantly uses two specific aluminum families:</p><table><thead><tr><th>Series</th><th>Common Grades</th><th>Characteristics</th><th>Typical Applications</th></tr></thead><tbody><tr><td><strong>5xxx (Magnesium)</strong></td><td>5052, 5182</td><td>Non-heat treatable, high corrosion resistance, good formability. Hardens via cold working.</td><td>Inner body panels, chassis components, fuel tanks, heat shields.</td></tr><tr><td><strong>6xxx (Magnesium + Silicon)</strong></td><td>6061, 6016</td><td>Heat treatable, higher strength. Can be hardened after stamping (during paint baking).</td><td>Outer body panels (hoods, doors, roofs), structural pillars, EV battery enclosures.</td></tr></tbody></table><p>According to <a href="https://www.wiegel.com/materials/">industry material guides</a>, the 6xxx series is particularly valuable for exterior skins because it is formable in the T4 temper but ages to a stronger T6 temper during the paint bake cycle, adding dent resistance to the finished vehicle.</p><h2>Copper and Specialty Metals: The EV Revolution</h2><p>The electrification of the powertrain has shifted material demand toward high-conductivity metals. While internal combustion engines focused on thermal resistance, Electric Vehicles (EVs) prioritize electrical efficiency.</p><h3>Copper for Connectivity</h3><p>Copper is indispensable for busbars, terminals, and lead frames. <strong>Oxygen-Free Copper (C101/C102)</strong> and <strong>Electrolytic Tough Pitch (ETP) Copper (C110)</strong> are the benchmarks for conductivity. For components requiring both conductivity and mechanical spring properties—such as battery disconnects and high-voltage connectors—<strong>Beryllium Copper</strong> is the material of choice despite its higher cost. It offers the strength of steel with conductive properties far superior to brass or bronze.</p><h3>Exotic Alloys for Extreme Environments</h3><p>Beyond the "Big Three" (Steel, Aluminum, Copper), niche applications utilize exotic alloys:</p><ul><li><strong>Titanium:</strong> Used in exhaust systems and valve springs for high-performance vehicles due to its heat resistance and strength-to-density ratio.</li><li><strong>Inconel & Hastelloy:</strong> These nickel-based superalloys resist extreme heat and corrosion, making them essential for turbocharger components and gaskets in high-output engines.</li></ul><h2>Strategic Selection: Balancing Performance and Cost</h2><p>Selecting the right material for automotive metal stamping is a complex trade-off between the "Iron Triangle" factors: <strong>Performance (Weight/Strength)</strong>, <strong>Formability</strong>, and <strong>Cost</strong>.</p><h3>The Cost-Weight Trade-off</h3><p>While aluminum offers significant weight savings, it can cost up to three times more than mild steel. Consequently, procurement teams often reserve aluminum for large surface areas where weight savings are maximized (hoods, roofs), while retaining AHSS for the safety cage to keep costs manageable. <a href="https://americanindust.com/blog/material-selection-for-progressive-stamping-factors-and-trade-offs/">Material selection factors</a> also include tooling costs; stamping AHSS requires carbide dies and higher-tonnage presses, which increases initial tooling investment compared to milder steels.</p><h3>Partnering for Production Success</h3><p>The complexity of modern materials—from springback-prone aluminum to ultra-hard Martensitic steel—requires a manufacturing partner with advanced metallurgical capabilities. Whether validating a new EV battery enclosure prototype or scaling up production of HSLA structural beams, the stamper’s equipment must match the material's demands. For OEMs seeking a bridge between rapid prototyping and mass production, <a href="https://www.shao-yi.com/auto-stamping-parts/">Shaoyi Metal Technology</a> offers IATF 16949-certified stamping services, utilizing presses up to 600 tons to handle complex automotive alloys with precision.</p><h2>Conclusion</h2><p>The era of using a single grade of mild steel for an entire vehicle body is over. Modern automotive metal stamping is a multi-material discipline that demands a nuanced understanding of metallurgy. By strategically deploying AHSS for safety, aluminum for efficiency, and copper for electrification, engineers can optimize vehicles for the next generation of mobility. The key lies in early collaboration with stamping partners who understand the unique forming behaviors of these advanced materials.</p><section><h2>Frequently Asked Questions</h2><h3>1. What is the best material for automotive metal stamping?</h3><p>There is no single "best" material; the choice depends on the part's function. Advanced High-Strength Steel (AHSS) is best for structural safety components due to its high yield strength. Aluminum (5xxx/6xxx series) is best for body panels to reduce weight. Copper is essential for electrical components in EVs due to its conductivity.</p><h3>2. Why is aluminum harder to stamp than steel?</h3><p>Aluminum has a higher degree of "springback" than mild steel, meaning it tends to return to its original shape after the stamping press releases. This requires sophisticated die design and simulation software to over-bend the material precisely so it relaxes into the correct final tolerance. It is also more prone to cracking if the bend radius is too tight.</p><h3>3. What is the difference between HSLA and AHSS?</h3><p>High-Strength Low-Alloy (HSLA) steel derives its strength from micro-alloying elements like vanadium and is typically used for chassis parts. Advanced High-Strength Steel (AHSS) uses complex multiphase microstructures (like Dual-Phase or TRIP) to achieve significantly higher strength-to-weight ratios, making it superior for crash-critical safety zones.</p></section>

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —