Metal Laser Cut Secrets: Fiber Vs CO2 Vs Diode Decoded

What Is Metal Laser Cutting and Why It Matters

Imagine slicing through a sheet of steel with nothing but light. Sounds impossible? That's exactly what metal laser cutting achieves every day in manufacturing facilities worldwide. This technology uses highly concentrated laser beams directed onto metal surfaces, where intense heat melts or vaporizes the material to produce remarkably clean, accurate cuts.

So what is laser cutting, really? At its core, metal laser cutting is a non-contact fabrication process that transforms raw sheets into precision components without any physical tool ever touching the workpiece. Unlike traditional mechanical methods that rely on blades, saws, or punches, a laser for cutting machine focuses energy with pinpoint accuracy. This eliminates the mechanical stress and tool wear that plague conventional approaches.

How Focused Light Transforms Raw Metal

The magic happens when optical components concentrate a powerful laser beam into an incredibly small focal point. This concentrated energy reaches temperatures high enough to instantly melt metals like steel, aluminum, and even titanium. As the beam moves along a programmed path, it creates cuts with tolerances that traditional methods simply cannot match.

Here's what makes this process stand apart from conventional cutting:

- No direct mechanical contact - The laser beam does all the work, preventing material distortion

- Microscopic precision - Typical tolerances reach ±0.1mm for parts under 50mm

- Complex geometries - Intricate patterns and tight corners that would challenge any cutter machine metal tool become effortless

- Minimal heat-affected zones - Fast cutting speeds reduce thermal damage to surrounding material

Metal laser cutting delivers positional accuracy within ±0.05mm and repeatability that makes it the gold standard for industries demanding tight tolerances and flawless edge quality.

The Science Behind Precision Metal Fabrication

Why has laser cutting become the preferred metal cutting machine technology for aerospace, automotive, and medical device manufacturers? The answer lies in consistency. Every cut follows the exact same programmed path with identical parameters. Whether you're producing one prototype or ten thousand production parts, each piece maintains the same dimensional accuracy.

Traditional cutting methods like shearing or sawing struggle with intricate designs. They generate mechanical forces that can warp thin materials or create rough edges requiring secondary finishing. Plasma cutting offers speed but sacrifices precision. Waterjet provides clean cuts but operates more slowly.

Laser cutting strikes a balance that few alternatives can match. It handles thin to medium-thickness metals with exceptional speed while maintaining the edge quality that downstream processes like welding and painting demand.

Throughout this guide, you'll discover the differences between fiber, CO2, and diode laser technologies. You'll learn which metals respond best to laser cutting and how assist gases dramatically affect your results. We'll break down the cost factors, safety requirements, and decision frameworks that help you choose the right approach for your specific project. Whether you're exploring metal laser cutting for the first time or optimizing an existing workflow, the insights ahead will transform how you approach precision metal fabrication.

Fiber vs CO2 vs Diode Laser Technologies Explained

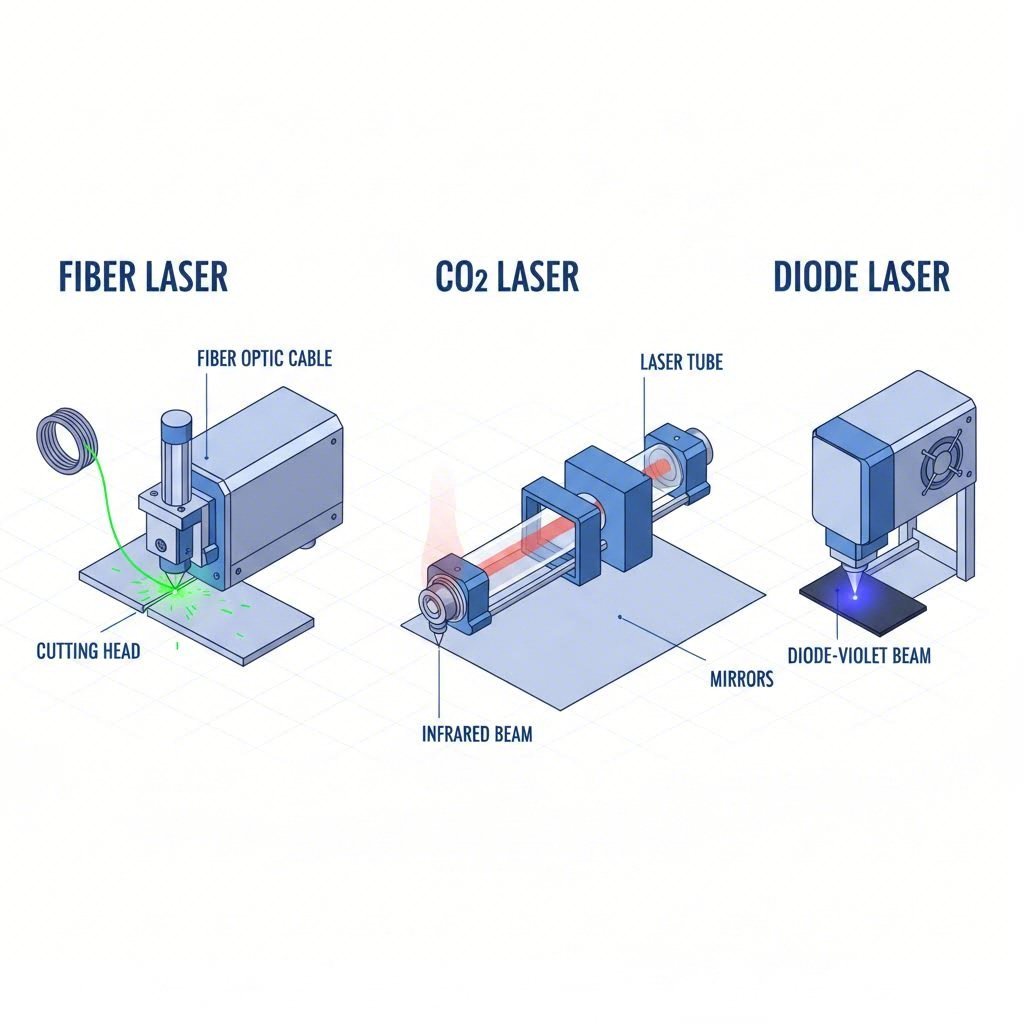

Not all lasers are created equal when it comes to cutting metal. The technology behind your laser metal cutting machine fundamentally determines what materials you can process, how fast you can work, and what your operating costs will look like. Understanding these differences helps you match the right tool to your specific application.

Three laser technologies dominate the metal cutting landscape: fiber lasers, CO2 lasers, and direct diode lasers. Each operates at different wavelengths, which dramatically affects how metals absorb the energy. Think of wavelength like a key that either fits perfectly into a lock or doesn't quite work. Metals respond to certain wavelengths far better than others.

Fiber Lasers and Their Speed Advantage

Fiber lasers have revolutionized metal cutting over the past decade. Operating at approximately 1.06 micrometers, their wavelength is absorbed readily by metallic surfaces. This means more cutting power reaches your workpiece rather than bouncing away.

What does this translate to in practical terms? A cnc fiber laser cutting machine can slice through thin steel at speeds two to three times faster than equivalent CO2 systems. But speed isn't the only advantage. Fiber laser metal cutting also delivers:

- Lower operating costs - Electrical efficiency reaches 30-50% compared to 10-15% for CO2 lasers

- Reduced maintenance - No mirrors to align, no gas tubes to replace

- Excellent performance on reflective metals - Copper, brass, and aluminum that challenge other technologies

- Compact footprint - Solid-state design requires less floor space

Power levels for fiber laser cutters range dramatically. Entry-level machines start around 500W to 1.5kW, handling sheets up to 3mm thick. Mid-range systems between 3kW and 6kW tackle most industrial applications. Heavy-duty operations pushing 10kW to 40kW cut through plates exceeding 25mm with impressive speed.

When CO2 Lasers Still Make Sense

Despite fiber's dominance in pure metal cutting, CO2 lasers maintain their relevance. Their 10.6 micrometer wavelength isn't ideal for metals, but it excels with non-metallic materials like wood, acrylic, leather, and fabrics.

If your shop processes both metals and non-metals, a CO2 laser and cnc combination offers versatility that fiber systems cannot match. These machines cut thin metal sheets up to 25mm while also handling the organic materials that fiber lasers struggle with. Power typically ranges from 40W to 150W for standard commercial units.

CO2 systems also provide excellent edge quality on thin stainless steel and aluminum when equipped with proper assist gas systems. For mixed-material workshops, this versatility often outweighs the speed advantages of dedicated fiber systems.

Direct diode lasers occupy a different niche entirely. While higher-powered units approaching 40W to 60W can engrave metals and cut very thin sheets, they primarily serve hobbyists and small studios working with wood, leather, and acrylics. A desktop laser engraver using diode technology makes an excellent entry point for learning laser cnc fundamentals, but serious metal cutting demands fiber or high-power CO2 systems.

Desktop fiber laser units have emerged for jewelry makers and small-scale metal fabricators, offering genuine metal cutting capability in compact packages. These machines bridge the gap between hobbyist equipment and industrial systems.

| Parameter | Fiber Laser | CO2 Laser | Diode Laser |

|---|---|---|---|

| Wavelength | 1.06 μm | 10.6 μm | 0.8-1.0 μm |

| Best Materials | Steel, stainless, aluminum, copper, brass | Metals plus wood, acrylic, glass, leather | Wood, leather, paper, dark acrylic |

| Metal Cutting Speed | Fastest | Moderate | Limited to engraving/thin sheets |

| Operating Costs | Lowest per cut | Moderate | Very low |

| Initial Investment | Highest | Mid-range | Lowest |

| Typical Power Range | 500W - 40kW | 40W - 150W | 5W - 60W |

| Primary Applications | Industrial metal fabrication, precision parts | Mixed-material shops, signage | Hobbyist projects, engraving |

Choosing between these technologies comes down to your primary materials and production volume. For dedicated metal cutting, fiber lasers deliver unmatched efficiency and speed. Mixed-material shops benefit from CO2 versatility. And for those exploring laser fabrication on a budget, diode systems provide an accessible starting point before graduating to more powerful equipment.

Understanding which laser type fits your needs is just the first step. The next critical factor involves matching your technology choice to specific metals and their unique cutting requirements.

Complete Material Guide From Steel to Specialty Alloys

Every metal behaves differently under a laser beam. What works perfectly for mild steel might ruin a sheet of copper. Understanding these material-specific characteristics transforms good cuts into exceptional ones and prevents costly mistakes before they happen.

The key factors influencing how any metal responds to laser cutting include its reflectivity, thermal conductivity, melting point, and thickness. When you laser cut metal sheets, these properties determine your power settings, cutting speed, assist gas selection, and ultimately the edge quality you achieve.

Steel and Stainless Steel Cutting Parameters

Carbon steel and stainless steel remain the workhorses of laser cutting. Both materials absorb laser energy efficiently and produce consistently clean edges across a wide range of thicknesses.

Mild Steel (Low Carbon Steel)

Mild steel offers the most forgiving laser cutting experience. Its combination of moderate melting point and good energy absorption makes it ideal for both beginners and high-volume production. Fiber lasers handle mild steel exceptionally well, with high-power systems cutting through plates up to 25mm thick.

- Recommended power settings: 1-2kW for sheets up to 6mm; 3-6kW for 6-12mm; 8-15kW for thicker plates

- Edge quality: Excellent with proper settings; oxygen assist produces slight oxidation but faster speeds

- Heat-affected zone: Moderate; manageable with appropriate cutting speeds

- Common applications: Structural components, brackets, enclosures, automotive parts

Stainless Steel Laser Cutting

Stainless steel demands slightly more attention than mild steel. Its higher chromium content creates a more reflective surface, and the material's strength requires slower cutting speeds to achieve clean edges. However, the results justify the extra care—stainless produces beautiful, corrosion-resistant parts straight off the cutting bed.

- Recommended power settings: 1-4kW depending on thickness; speeds between 10-20 mm/s for optimal results

- Edge quality: Exceptional when nitrogen assist is used; oxide-free edges ready for welding or painting

- Heat-affected zone: Keep minimal by maintaining appropriate speeds; critical for maintaining corrosion resistance

- Common applications: Food processing equipment, medical devices, architectural panels, marine hardware

Tackling Reflective Metals Like Aluminum and Copper

Can you laser cut aluminum? Absolutely—but it requires understanding the unique challenges reflective metals present. Older CO2 lasers struggled with aluminum, copper, and brass because their wavelengths bounced off these shiny surfaces rather than being absorbed. Modern fiber lasers have changed the game entirely.

Aluminum Laser Cutting

Aluminum combines high reflectivity with excellent thermal conductivity—a double challenge for laser cutting. Heat dissipates quickly through the material, requiring more power to maintain cutting temperature. Despite these challenges, fiber lasers cut aluminium with impressive precision when properly configured.

- Recommended power settings: Higher than equivalent steel thickness; 60-80% power with speeds of 10-20 mm/s

- Cutting gas: Nitrogen essential for clean, oxide-free edges; high pressure helps expel molten material

- Edge quality: Good to excellent; some striation possible on thicker sections

- Maximum practical thickness: Up to 12mm with high-power fiber systems

- Common applications: Aerospace components, electronics enclosures, signage, automotive trim

The key to successful laser cutting aluminum lies in balancing speed and power. Too slow, and heat builds up causing warping. Too fast, and the cut doesn't penetrate completely. Nitrogen assist gas at high pressure helps blow away molten material while preventing the oxidation that creates rough edges.

Copper and Brass

Copper presents the greatest reflectivity challenge among common metals. Its thermal conductivity exceeds even aluminum, meaning heat escapes almost as fast as you can apply it. Brass, a copper-zinc alloy, behaves similarly but proves slightly more manageable.

- Recommended power settings: Highest available; specialized nozzles and nitrogen cooling often required

- Edge quality: Achievable with high-precision fiber lasers; requires careful parameter optimization

- Heat-affected zone: Significant thermal conductivity demands faster processing to prevent heat spread

- Maximum practical thickness: Generally limited to 6-8mm for copper; slightly more for brass

- Common applications: Electrical components, decorative items, heat exchangers, musical instruments

For both copper and brass, fiber lasers with wavelengths around 1.06 micrometers penetrate effectively where CO2 lasers fail. The shorter wavelength overcomes the reflectivity barrier, making these previously difficult metals accessible to laser fabrication.

Specialty Metals

Beyond the common metals, several specialty materials deserve attention:

Titanium boasts the highest strength-to-weight ratio and excellent corrosion resistance. It cuts well with fiber lasers but commands premium pricing. Reserve titanium for aerospace, medical implants, and applications where no substitute exists.

Galvanized Steel processes similarly to mild steel but releases zinc fumes requiring robust ventilation. Moderate power settings work well, though the zinc coating can affect edge appearance.

Nickel Alloys like Inconel resist extreme temperatures, making them essential for aerospace and industrial applications. Their toughness demands higher power and slower speeds, but laser cutting remains far easier than mechanical alternatives.

Not every metal suits laser cutting equally. Very thick materials beyond 25-30mm often process more economically with plasma or waterjet. Extremely reflective polished surfaces may require special preparation. And certain exotic alloys produce hazardous fumes demanding specialized extraction systems.

Knowing which materials respond best to laser cutting—and when alternative methods make more sense—saves time, money, and frustration. The next critical factor affecting your cut quality involves the assist gases that work alongside the laser beam itself.

Assist Gases and Their Impact on Cut Quality

Your laser beam does the cutting, but the assist gas determines whether you get a pristine edge or a rough, oxidized mess. This often-overlooked element of sheet metal laser cutting can mean the difference between parts ready for welding and parts headed for the scrap bin.

Assist gases serve multiple critical functions during laser cutting metal sheet operations. They blow molten material away from the cut zone, cool the surrounding area to minimize heat damage, and protect the focusing lens from debris. But perhaps most importantly, they interact chemically with the heated metal to influence both cutting speed and edge quality.

Three gases dominate metal fabrication: oxygen, nitrogen, and compressed air. Each brings distinct advantages depending on your material, thickness, and quality requirements.

Oxygen Cutting for Carbon Steel

Oxygen transforms laser cutting steel sheet into a remarkably efficient process. When oxygen meets molten steel, an exothermic reaction occurs—the oxygen actually burns the iron, generating additional heat that accelerates cutting. This chemical boost means you can cut thicker materials with less laser power.

Think of it like adding fuel to a fire. The oxygen doesn't just remove molten material; it actively participates in the cutting process. For carbon steel applications, this translates to:

- Increased cutting speed - Up to 30% faster than inert gas cutting on thick plates

- Deeper penetration - Handle plates up to 22mm with moderate laser power

- Lower power requirements - The exothermic reaction supplements laser energy

- Reduced gas consumption - Lower pressures (3-10 Bar) compared to nitrogen

The tradeoff? Oxygen creates an oxide layer on cut edges. This dark, scale-like coating forms as iron reacts with the gas at high temperatures. For structural applications heading to paint or powder coating, this oxidation rarely matters. But for parts requiring welding or visible edges, you may need secondary cleaning.

Oxygen purity matters significantly. Industry standards recommend 99.5% or higher purity to maintain consistent cutting quality. Even small drops in purity—from 99.97% to 99.95%—can noticeably reduce cutting speeds on thin metals.

Nitrogen for Clean Stainless Edges

Nitrogen takes the opposite approach. As an inert gas, it doesn't react with heated metal at all. Instead, nitrogen creates an oxygen-free environment around the cut zone, preventing any oxidation from occurring. The result is a bright, clean edge that needs no post-processing.

For stainless steel, aluminum, and any application where edge appearance matters, nitrogen delivers superior results. A laser sheet metal cutter running nitrogen produces edges ready for immediate welding, painting, or visible installation.

However, nitrogen demands more from your system:

- Higher operating pressures - Typically 15-30 Bar compared to 3-10 Bar for oxygen

- Greater gas consumption - Flow rates between 50-150 cubic meters per hour depending on thickness

- Increased costs - Roughly 2-3 times more expensive per cut than oxygen

- Slower thick-plate speeds - No exothermic boost means the laser does all the work

Nitrogen purity requirements exceed oxygen standards. For applications where edge color is critical—aerospace, medical devices, architectural panels—purity levels of 99.99% or higher prevent any discoloration. Lower purities introduce trace oxygen that can cause subtle yellowing on stainless steel edges.

Compressed air offers a middle ground for budget-conscious operations. Containing approximately 78% nitrogen and 21% oxygen, shop air provides partial oxidation benefits while keeping costs minimal. For laser cutting of metal sheets under 3mm thick, compressed air often produces acceptable results at a fraction of specialty gas costs.

The oxygen content in compressed air creates lighter oxidation than pure oxygen cutting, resulting in grayish edges rather than dark scale. This finish works well for parts heading to paint, powder coating, or applications where edge appearance isn't critical.

Air systems require pressures between 150-200 psi and demand proper filtration to protect optical components. Any oil or moisture contamination can damage lenses and distort the beam, so invest in quality drying and filtration equipment.

Selecting the right gas comes down to matching your priorities:

- Carbon steel with secondary finishing? Choose oxygen for speed and cost efficiency

- Stainless or aluminum requiring clean edges? Nitrogen delivers oxide-free results

- Thin materials with budget constraints? Compressed air provides economical processing

- Parts heading to welding? Nitrogen prevents oxidation that weakens weld joints

- Visible architectural components? High-purity nitrogen ensures bright, consistent edges

Gas pressure directly affects cut quality beyond just material removal. Higher pressures expel molten metal more aggressively, reducing dross formation on the bottom edge. But excessive pressure can cause turbulence that creates rough cut surfaces. Finding the sweet spot—typically 8-12 Bar for oxygen on thick steel and 18-25 Bar for nitrogen on stainless—requires testing with your specific equipment and materials.

Understanding how assist gases influence your laser cut sheet metal results puts you in control of both quality and costs. But gas selection represents just one variable affecting your final edge quality. The next consideration involves the precision parameters and defects that separate acceptable parts from exceptional ones.

Precision Parameters and Edge Quality Standards

Ever wonder why some laser cut parts drop out of the sheet perfectly while others need extensive cleanup? The difference comes down to understanding kerf width, tolerances, and the subtle parameters that separate professional-grade results from mediocre cuts.

When a metal laser cutting machine slices through material, it doesn't remove a razor-thin line. The beam vaporizes a small channel of material called the kerf. This cut width varies based on your laser type, material, thickness, and focus settings—and ignoring it during design leads to parts that don't fit together properly.

Understanding Kerf Width and Tolerance Ranges

Kerf width typically ranges from 0.1mm to 0.5mm depending on your setup. For thin sheet metal under 3mm, expect kerf widths around 0.1-0.2mm. Thicker materials expand this gap as the beam spreads through deeper cuts. Fiber lasers generally produce narrower kerfs than CO2 systems due to their tighter beam focus.

Why does this matter for your designs? Imagine cutting interlocking parts where tabs fit into slots. If your CAD file shows a 10mm tab and a 10mm slot, they won't actually fit—the kerf removes material from both features. Professional precision laser cutting services account for kerf compensation automatically, but understanding the concept helps you communicate requirements effectively.

Dimensional accuracy in laser cutting typically falls within ±0.005 inches (approximately ±0.127mm), with cut widths as narrow as 0.004 inches possible depending on laser power and material thickness. This laser cutting precision exceeds what plasma cutting achieves (typically ±0.020 inches) and approaches the accuracy of more expensive machining operations.

Positional accuracy and repeatability determine whether your hundredth part matches your first. Quality metal laser cutting machines maintain positional accuracy within ±0.05mm and repeatability that ensures consistent dimensions across production runs. For laser cut metal panels destined for architectural installations, this consistency means every panel aligns perfectly during assembly.

Tolerance expectations vary by application:

- Laser cut decorative metal panels: ±0.25mm typically acceptable; visual appearance matters more than dimensional precision

- Structural components: ±0.1-0.15mm ensures proper fitment with mating parts

- Precision laser cut parts for aerospace or medical: ±0.05mm or tighter may be required; discuss capabilities with your fabricator

- Electronics enclosures: ±0.1mm maintains proper component mounting and assembly

Preventing Dross, Burrs, and Heat Damage

Even with perfect machine calibration, cut quality problems arise from the complex interaction between laser beam, assist gas, and material. Understanding what causes common defects empowers you to either adjust parameters yourself or communicate intelligently with your fabrication partner.

The physics behind burr formation explains why simply slowing down often makes things worse. When the laser beam dwells too long at any point, excess heat causes vaporization that disturbs the gas flow. This turbulence prevents proper evacuation of molten material, which then solidifies as burrs on the bottom edge. Counter-intuitively, increasing cutting speed often eliminates burrs by reducing heat buildup.

| Defect | Appearance | Primary Causes | Prevention Strategies |

|---|---|---|---|

| Dross | Solidified metal droplets on bottom edge | Cutting speed too slow; insufficient gas pressure; contaminated nozzle | Increase speed; optimize gas pressure; maintain clean nozzle |

| Burrs | Sharp protrusions along cut edge | Excess heat input; improper focus position; gas flow disturbance | Increase cutting speed slightly; verify focus calibration; check nozzle condition |

| Striations | Visible lines or grooves on cut face | Beam oscillation; improper speed/power ratio; thick material effects | Optimize power and speed balance; use appropriate nozzle design for thickness |

| Heat Discoloration | Blue, yellow, or brown tinting near edges | Excessive heat-affected zone; slow cutting speed; insufficient gas purity | Increase speed; use higher purity nitrogen; verify proper gas flow |

| Incomplete Cuts | Material not fully separated | Insufficient power; speed too fast; focus position incorrect | Reduce speed; increase power; recalibrate focus height |

Focus position deserves special attention because it affects nearly every quality parameter. When the focal point sits too high in the cut, spiky dross forms on the bottom edge. Position it too low, and you sacrifice cutting speed while potentially creating bead-like formations from overflushing. Modern machines calibrate focus automatically, but verification remains essential for consistent results.

Edge quality differences between materials reflect their unique thermal properties. Stainless steel produces the cleanest edges when cut with nitrogen assist at proper speeds. Carbon steel accepts slight oxidation in exchange for faster processing with oxygen. Aluminum requires careful parameter balancing to prevent the thermal conductivity from causing edge roughness.

Gas dynamics play a larger role than many operators realize. The nozzle standoff distance should equal one nozzle diameter—too high and the assist gas struggles to evacuate molten material cleanly. With nitrogen cutting, the gas flow becomes supersonic and produces shock waves. When nozzle height deviates from optimal, these shock waves interact negatively with the kerf, causing erratic molten metal evacuation that solidifies into burrs.

Ambient conditions even influence cut quality. Hot gas molecules move faster and interact differently with the assist gas stream. Operators may need different pressure settings on a humid July afternoon compared to a dry January morning. This explains why parameters that worked perfectly last week suddenly produce inferior results.

For laser cut parts requiring the tightest tolerances and cleanest edges, communicate your quality requirements clearly before production begins. Specify whether edges need to be weld-ready, paint-ready, or suitable for visible applications. This information helps fabricators optimize their parameters for your specific needs rather than applying generic settings.

Quality parameters and edge standards set the foundation for successful metal fabrication. But understanding precision is only valuable when you can select the right cutting method for your project. The decision between laser, waterjet, and plasma cutting depends on factors that extend well beyond tolerance specifications.

Laser Cutting vs Waterjet vs Plasma Decision Framework

You've mastered precision parameters and understand what makes a clean edge. Now comes the practical question: is a laser cutter for metal actually the right choice for your project, or would another cutting method serve you better?

This isn't about finding the "best" technology—it's about matching the right cutting metal machine to your specific requirements. Each method excels in different scenarios, and understanding these distinctions saves you money while delivering superior results.

When Laser Cutting Beats Waterjet and Plasma

Laser cutting dominates when you need precision, speed, and clean edges on thin to medium-thickness metals. According to testing across hundreds of applications, laser cutting delivers exceptional performance for thin sheets requiring precise, intricate cuts. The focused beam creates sharp corners and smooth edges that often need no additional finishing.

Consider laser cutting your first choice when:

- Intricate designs matter - Small holes, tight corners, and complex patterns that challenge other methods

- Thin to medium materials - Sheets from 0.5mm up to approximately 20mm for carbon steel

- High-volume production - Speed advantages compound with quantity

- Minimal post-processing desired - Edges often ready for immediate welding or painting

- Precision requirements are tight - Tolerances within ±0.1mm consistently achievable

A metal cutting laser machine truly shines with electronics enclosures, precision brackets, decorative panels, and any application where detail and edge quality justify the investment. For medical devices and aerospace components requiring exacting specifications, laser cutting delivers the consistency these industries demand.

However, laser cutting meets its limits with very thick materials. Industrial applications regularly find that carbon steel beyond 20mm and stainless steel beyond 16mm significantly reduce cutting speed and increase operating costs per part.

Understanding Your Alternatives

Plasma Cutting

Plasma uses an electrical arc and compressed gas to blast through conductive metals at impressive speeds. If you're working with thick steel plates—particularly half-inch or thicker—plasma offers unbeatable cost efficiency.

Testing reveals that plasma cutting 1-inch steel runs approximately 3-4 times faster than waterjet, with operating costs roughly half as much per linear foot. The equipment investment also favors plasma—complete systems run around $90,000 compared to approximately $195,000 for similar-sized waterjet equipment.

The tradeoff involves precision and edge quality. Plasma generates significant heat, creating larger heat-affected zones. Cut edges typically require secondary finishing for precision applications, and achieving tolerances tighter than ±1mm proves challenging.

Waterjet Cutting

Waterjet technology uses high-pressure water mixed with abrasive particles to slice through virtually any material—steel, stone, glass, composites, even titanium. The waterjet market's projected growth to over $2.39 billion by 2034 reflects its expanding role in precision manufacturing.

The critical advantage? No heat whatsoever. Waterjet cutting creates zero heat-affected zones, meaning no warping, no hardening, and no thermal distortion of material properties. For heat-sensitive materials or components where metallurgical integrity cannot be compromised, waterjet stands alone.

Accuracy rivals laser cutting, reaching ±0.1mm with dynamic systems capable of ±0.02mm precision. But speed becomes the limitation—waterjet processes material significantly slower than either laser or plasma, making it unsuitable for large-scale mass production where cycle time matters.

| Criteria | Laser Cutting | Plasma Cutting | Waterjet Cutting |

|---|---|---|---|

| Material Thickness Range | 0.5mm - 25mm (varies by material) | 1mm - 120mm | 0.8mm - 100mm+ |

| Precision/Tolerance | ±0.1mm (excellent) | ±1mm (moderate) | ±0.1mm to ±0.02mm (excellent) |

| Edge Quality | Excellent - often ready for welding | Moderate - typically requires finishing | Excellent - smooth, no heat effects |

| Cutting Speed | Fast on thin/medium materials | Fast on thick materials | Slow across all thicknesses |

| Cost Per Part (Volume) | Low for thin materials | Lowest for thick steel | Higher due to consumables and time |

| Heat Effects | Minimal HAZ with proper parameters | Significant heat-affected zone | None - cold cutting process |

| Material Versatility | Primarily metals (fiber); metals plus non-metals (CO2) | Conductive metals only | Any material except tempered glass |

| Best Applications | Precision parts, electronics, detailed designs | Structural steel, heavy fabrication | Heat-sensitive materials, composites, stone |

Matching Your Project to the Right Cutting Method

Making the right choice starts with honestly assessing your project requirements. Ask yourself these questions:

What material and thickness are you cutting?

For steel under 20mm, a metal cutting laser machine typically offers the best combination of speed, precision, and edge quality. Beyond 25mm, plasma becomes increasingly attractive for carbon steel. Waterjet handles the widest thickness range but at slower speeds.

How precise must the finished parts be?

Tight tolerances below ±0.5mm favor laser or waterjet. If ±1mm suffices for your application—common in structural fabrication—plasma's speed advantage makes economic sense.

Does heat affect your material properties?

Hardened materials, heat-treated alloys, or components requiring specific metallurgical properties demand waterjet's cold cutting process. Laser cutting creates minimal heat-affected zones but cannot match waterjet's complete thermal neutrality.

What quantity do you need?

Batch size dramatically affects method selection. For prototypes and small runs, setup time and per-piece precision matter most—laser or waterjet excel here. High-volume production amplifies laser's speed advantage, making it the best laser for cutting thousands of identical parts economically.

Many fabrication shops recognize that no single technology covers every situation. Plasma and laser often pair well for shops handling diverse work, with waterjet adding versatility for challenging materials.

The decision framework in practice:

- Thin sheet metal with intricate patterns? Laser cutting—no contest

- Heavy steel plate for structural applications? Plasma delivers speed and value

- Heat-sensitive aerospace composites? Waterjet preserves material integrity

- Mixed materials including stone or glass? Waterjet's versatility wins

- High-volume precision components? Laser that cuts metal offers unmatched throughput

Understanding these distinctions puts you in control of your fabrication decisions. But selecting the right cutting technology represents just one piece of the cost puzzle. The factors that determine your actual quote—material, complexity, quantity, and finishing requirements—deserve equally careful consideration.

Understanding Metal Laser Cutting Costs and Pricing

You've selected the right cutting technology and understand what quality to expect. Now comes the question that determines whether your project moves forward: what will it actually cost?

Here's what surprises most people about laser cutting charges: the price per square foot tells you almost nothing useful. A simple square panel and an intricate decorative piece cut from identical material sheets can have wildly different prices. Understanding why helps you budget accurately and even reduce your costs.

The fundamental pricing formula breaks down like this: Final Price = (Material Costs + Variable Costs + Fixed Costs) × (1 + Profit Margin). Variable costs—primarily machine time—drive the biggest differences between quotes. This is where design decisions directly impact your wallet.

Breaking Down Per-Part Pricing Factors

When a sheet metal cutting machine processes your design, multiple cost drivers accumulate into your final quote. Understanding each factor reveals opportunities to optimize your spending.

- Material type and grade - Stainless steel costs more than mild steel; aerospace-grade aluminum commands premiums over standard alloys. The raw material price sets your baseline.

- Sheet utilization efficiency - How well your parts nest on standard sheet sizes determines waste. Poor nesting means paying for material that becomes scrap.

- Cutting time based on perimeter length - The total linear distance the laser travels matters more than part area. A 10-inch square with 40 inches of perimeter costs less than a complex shape with 80 inches of cuts.

- Pierce count - Every hole, slot, or cutout requires the laser to pierce fresh material. A design with 50 small holes costs significantly more than one large opening—each pierce adds time.

- Setup charges - Loading material, calibrating the machine, and preparing your file require operator time regardless of quantity.

- Secondary operations - Bending, tapping, deburring, powder coating, or other finishing adds separate charges beyond the cutting itself.

Material thickness deserves special attention because its impact is non-linear. Doubling material thickness can more than double cutting time and cost because the laser must move significantly slower to achieve clean penetration. Whenever your design allows, specifying the thinnest material that meets structural requirements produces immediate savings.

Machine hourly rates typically range from $60 to $120 depending on equipment capability. Higher-powered industrial systems command premium rates but often complete jobs faster, potentially offsetting the hourly difference.

How Complexity and Quantity Affect Your Quote

Design complexity creates a multiplier effect on machine time. Intricate patterns with tight curves force the cutting head to slow down repeatedly. Sharp corners require acceleration changes that add seconds per feature—seconds that compound across hundreds of parts.

Tight tolerances specified beyond what your application actually requires represent another hidden cost driver. Holding ±0.05mm precision demands slower, more controlled machine movements than ±0.25mm tolerances. Before specifying tight requirements, honestly assess what your assembly or function actually needs.

Quantity transforms the economics entirely. Those fixed setup costs—file preparation, machine calibration, material loading—spread across every part in your order. Order ten parts, and setup adds significantly to each piece. Order a thousand, and setup becomes negligible per unit.

Volume discounts for high-quantity orders can reach as high as 70% compared to single-piece pricing. Even modest increases from 10 to 50 pieces often unlock meaningful price breaks.

Custom laser cutting projects benefit enormously from design optimization before requesting quotes. Simplifying geometries where possible, reducing pierce counts by combining small holes into slots, and ensuring your CAD file contains no duplicate lines all reduce machine time directly.

Efficient nesting—arranging parts to minimize wasted sheet material—represents another optimization opportunity. Some fabricators use advanced nesting software automatically, while others appreciate receiving pre-nested files that demonstrate material efficiency.

When requesting quotes, prepare this information for accurate pricing:

- Complete CAD files in compatible formats (DXF, DWG, or STEP preferred)

- Material specification including type, grade, and thickness

- Quantity needed and whether repeat orders are anticipated

- Tolerance requirements—only specify tighter than standard when truly necessary

- Secondary operations needed (bending, finishing, hardware insertion)

- Delivery timeline expectations

Asking about laser cutting machine price when considering in-house equipment? Entry-level systems start around $20,000-$50,000 for basic capability, while industrial fiber laser machines for sale range from $100,000 to over $500,000 for high-power configurations. Most projects find outsourcing more economical until volume justifies capital investment.

Getting multiple quotes helps benchmark pricing, but the lowest number isn't always the best value. A fabricator offering free Design for Manufacturability feedback might identify changes that reduce your long-term costs more than any quote difference. Understanding how much is a laser cutting machine worth to your specific application—whether through service providers or ownership—requires examining your volume, complexity, and timeline requirements honestly.

Cost optimization puts you in control of your fabrication budget. But before any metal gets cut, safety protocols and proper ventilation must be in place—especially when different metals produce different hazards during processing.

Safety Protocols and Ventilation Requirements

Every metal you cut releases something into the air. Steel laser cutting produces metal vapor and oxide particles. Galvanized steel releases zinc fumes that can cause metal fume fever—a flu-like illness that hits within hours of exposure. Aluminum generates fine particulates. Without proper extraction and protection, these hazards accumulate invisibly until health problems emerge.

Understanding material-specific risks transforms safety from a checkbox into genuine protection. Whether you're running an industrial laser cutting operation or a smaller steel laser cutting machine setup, the principles remain constant—only the scale changes.

Fume Extraction for Different Metal Types

Different metals produce distinctly different emissions, requiring tailored extraction approaches. When a laser steel cutting machine processes carbon steel with oxygen assist, the exothermic reaction generates metal vapor, metal oxide particles, and potentially hazardous compounds depending on any coatings present.

Stainless steel introduces additional concerns. Cutting releases chromium compounds that pose serious respiratory risks with repeated exposure. Aluminum produces fine oxide particles that remain airborne longer than heavier steel particulates. Copper and brass emit their own characteristic fumes requiring robust capture at the source.

Galvanized steel demands the most caution. The zinc coating vaporizes at temperatures well below the steel's melting point, releasing zinc oxide fumes before the laser even penetrates the base metal. Metal fume fever from zinc exposure causes chills, fever, muscle aches, and nausea—symptoms that mimic influenza and typically resolve within 24-48 hours but indicate dangerous exposure levels.

Effective fume extraction systems share common components regardless of operation size:

- Enclosures and capture hoods - Position directly above the cutting zone; high CFM ratings improve capture efficiency

- Proper ducting - Transport contaminated air to filtration units maintaining 100 to 150 feet per minute airflow velocity for effective capture

- HEPA filtration - Captures harmful particles with 99.97% efficiency

- Activated carbon filters - Remove volatile organic compounds and odors the HEPA stage misses

For smaller operations using a laser cutter for steel, portable fume extractors offer flexibility without permanent installation. Position the extraction arm within inches of the cutting zone—effectiveness drops dramatically as distance increases.

Essential Safety Protocols for Metal Laser Operations

Beyond fume extraction, comprehensive safety requires addressing multiple hazard categories simultaneously. A machine for cutting steel generates intense light, extreme heat, and fire risks alongside airborne contaminants.

Required safety equipment includes:

- Eye protection - Laser-specific safety glasses matched to your wavelength; standard welding shades don't protect against laser radiation

- Respiratory protection - Respirator selection based on thorough hazard assessment of materials being cut

- Fire prevention - Keep flammable materials away from cutting areas; maintain fire extinguishers rated for metal fires within reach

- Protective clothing - Long sleeves and closed-toe shoes protect against sparks and hot metal ejection

- Ventilation monitoring - Regular checks ensure extraction systems maintain adequate airflow

Reflective hazards from polished metals create additional concerns. Highly polished copper, brass, or aluminum surfaces can reflect laser energy unpredictably, potentially damaging equipment or creating unexpected burn hazards. Slightly texturing reflective surfaces or using anti-reflective coatings reduces this risk.

Professional industrial laser cutting environments implement interlocked enclosures that prevent laser operation when doors open. Smaller operations should establish clear safety zones and never bypass safety interlocks—even momentarily.

Comprehensive safety training ensures every operator understands both the equipment and the specific hazards of materials being processed. Training should cover emergency procedures, proper PPE usage, and recognition of exposure symptoms like the respiratory irritation or flu-like effects that signal inadequate protection.

Regular maintenance of both cutting equipment and safety systems prevents gradual degradation that creates invisible hazards. Filters require scheduled replacement—pre-filters monthly and HEPA filters every several months to one year depending on usage intensity. Waiting until visible performance degradation means exposure has already occurred.

Safety investment protects more than health—it protects productivity and equipment longevity. Clean air prevents optical contamination that degrades cut quality. Proper extraction extends component life. And healthy operators maintain the focus and precision that quality metal fabrication demands.

Choosing Your Metal Laser Cutting Path Forward

You've absorbed the technology differences, material requirements, safety protocols, and cost factors. Now comes the decision that turns knowledge into action: which metal laser cutting approach actually fits your project?

The answer depends on where you fall on the fabrication spectrum. A hobbyist creating custom motorcycle parts faces entirely different constraints than an automotive supplier producing thousands of chassis components monthly. Understanding your position on this spectrum clarifies your best path forward.

From Rapid Prototypes to Mass Production

Your volume requirements fundamentally shape which approach makes sense. Consider how your needs align with these three distinct paths:

DIY Desktop Solutions

Entry-level desktop fiber laser systems now bring genuine metal cutting capability to small workshops and serious hobbyists. Units in the 20W-60W range handle thin sheets for jewelry, art pieces, and light prototyping. While capabilities remain limited compared to industrial equipment, these machines offer hands-on learning and complete creative control.

Desktop solutions work best when you're cutting thin materials under 2mm, creating one-off designs or small batches, and have flexibility on turnaround time. The initial investment ranges from $3,000 to $15,000—far more accessible than industrial equipment.

Professional Laser Cut Services

For most projects, outsourcing to established metal laser cutting services delivers the best value. Professional fabricators bring industrial-grade equipment, material expertise, and quality systems you'd spend years developing in-house.

When searching for laser cutting services near me, evaluate potential partners on more than just price. Capability verification, quality certifications, and communication responsiveness predict success better than the lowest quote.

In-House Industrial Equipment

Bringing a laser metal cutter in-house makes sense only at significant volume thresholds. According to industry analysis, equipment costs range from $200,000 to $500,000—and that's before factoring in installation, training, maintenance, and consumables. The breakeven calculation requires honest assessment of your projected volumes and the hidden costs of in-house operations.

Before investing in equipment, sending out a few small projects to professional fabricators helps benchmark costs and quality against what in-house operations would realistically achieve.

Key selection criteria to evaluate:

- Volume requirements - Prototypes and small batches favor laser cut services; consistent high-volume production may justify equipment investment

- Turnaround needs - Same-week prototyping requires responsive service providers; production schedules allow optimization across order quantities

- Quality standards - Industry certifications like IATF 16949 verify capability for automotive and aerospace applications

- Budget constraints - Per-piece outsourcing costs versus capital investment payback periods

- Secondary operations - Projects requiring bending, stamping, welding, or finishing benefit from integrated fabrication partners

Partnering With the Right Metal Fabrication Specialist

The most successful metal fabrication projects often require more than just laser cutting. Automotive components frequently combine precision laser-cut blanks with stamping operations that form complex three-dimensional shapes. Structural assemblies integrate cut parts with welding, bending, and surface finishing.

This is where full-service fabricators demonstrate their value. Rather than coordinating multiple vendors—each adding lead time, handling, and quality risk—integrated manufacturers streamline your supply chain under one roof. Combining laser cutting with bending, stamping, machining, and assembly under unified quality control keeps projects precise and on schedule.

For automotive applications, IATF 16949 certification signals a fabricator's commitment to the rigorous quality systems the industry demands. Manufacturers meeting this standard maintain the process controls, traceability, and continuous improvement practices that chassis, suspension, and structural components require.

When your project requires both precision cutting and complex forming operations, consider partners like Shaoyi (Ningbo) Metal Technology. Their combination of custom metal stamping capabilities with 5-day rapid prototyping accelerates automotive supply chains while maintaining IATF 16949-certified quality. The 12-hour quote turnaround and comprehensive DFM support prove particularly valuable when projects involve multiple fabrication processes that must work together seamlessly.

Design for Manufacturability feedback from experienced fabricators often delivers more value than any price negotiation. A partner who identifies design changes that improve cut quality, reduce material waste, or simplify downstream assembly transforms your project economics before production begins.

Questions to ask when evaluating a laser cutting service near me:

- What certifications do you maintain, and what industries do you primarily serve?

- Can you handle secondary operations like bending, stamping, or finishing?

- What's your typical turnaround for prototypes versus production quantities?

- Do you provide DFM feedback on submitted designs?

- What tolerances can you consistently hold on my material type and thickness?

Whether you're exploring metal laser cutting for a first prototype or optimizing an established production workflow, the principles remain constant: match your technology choice to your materials, select partners whose capabilities align with your quality requirements, and design with manufacturability in mind from the start.

The precision, speed, and versatility of modern laser cutting have transformed what's possible in metal fabrication. Armed with the knowledge from this guide—from fiber versus CO2 technology selection through material parameters, assist gas optimization, and cost factors—you're equipped to make informed decisions that deliver exceptional results.

Frequently Asked Questions About Metal Laser Cutting

1. What is the difference between fiber and CO2 lasers for metal cutting?

Fiber lasers operate at 1.06 micrometers wavelength, which metals absorb more readily, making them two to three times faster than CO2 lasers for metal cutting with lower operating costs and maintenance requirements. CO2 lasers at 10.6 micrometers excel with non-metallic materials like wood and acrylic while still handling thin metal sheets. For dedicated metal fabrication, fiber lasers deliver superior efficiency, while CO2 systems suit mixed-material workshops processing both metals and organics.

2. Can you laser cut aluminum and other reflective metals?

Yes, modern fiber lasers effectively cut aluminum, copper, and brass despite their high reflectivity. The 1.06 micrometer wavelength penetrates these surfaces where older CO2 lasers struggled. Aluminum requires higher power settings and nitrogen assist gas at high pressure to achieve clean, oxide-free edges. Copper presents the greatest challenge due to extreme thermal conductivity but remains achievable with high-power fiber systems up to 6-8mm thickness.

3. What determines metal laser cutting costs and pricing?

Metal laser cutting pricing depends on multiple factors: material type and grade, sheet utilization efficiency, cutting time based on total perimeter length, pierce count for holes and cutouts, setup charges, and secondary operations like bending or finishing. Complexity significantly impacts cost since intricate patterns slow machine speed. Volume discounts can reach up to 70% for high-quantity orders as fixed setup costs spread across more parts.

4. How do I choose between laser cutting, waterjet, and plasma cutting?

Choose laser cutting for thin to medium metals requiring precision tolerances within plus or minus 0.1mm and clean edges ready for welding. Select plasma for thick steel plates over 25mm where speed and cost efficiency matter more than precision. Opt for waterjet when processing heat-sensitive materials or composites since it creates zero heat-affected zones. Your material thickness, precision requirements, and production volume determine the most economical method.

5. What safety measures are required for metal laser cutting operations?

Essential safety measures include proper fume extraction systems with HEPA filtration capturing 99.97% of harmful particles, laser-specific eye protection matched to your wavelength, respiratory protection based on materials being cut, and fire prevention equipment. Different metals produce unique hazards—galvanized steel releases zinc fumes causing metal fume fever, while stainless steel emits chromium compounds requiring robust extraction. Regular maintenance of filters and safety system verification prevents invisible hazard accumulation.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —