Large Sheet Metal Fabricators: 8 Essential Points Before You Sign

Understanding What Defines Large Sheet Metal Fabricators

When you're sourcing sheet metal fabrication services, you'll quickly realize that not all shops are created equal. Some specialize in small, intricate components, while others handle massive industrial projects requiring specialized equipment and infrastructure. So what exactly separates large sheet metal fabricators from standard fabrication shops?

The distinction comes down to capacity—specifically, the ability to process oversized materials, handle heavy-gauge metals, and manage projects that would overwhelm conventional facilities. Understanding these differences is essential before committing to a manufacturing partner.

What Makes a Fabricator Large-Scale

Think of it this way: a standard sheet metal fabrication shop might handle sheets up to 4' x 8' and materials up to 1/4" thick. Large-scale operations push far beyond these limits. According to Bassett Mechanical's capabilities documentation, their facility can process materials up to 10' x 40' on plasma tables, with cutting capacity for metals up to 2-1/4" thick.

Similarly, icon Mechanical's heavy metal facility features a dedicated 14,400 square-foot shop designed specifically for heavy-gauge industrial metals up to 40 feet in length. Their infrastructure includes 10-ton overhead cranes for moving large-grade industrial materials—equipment you simply won't find in smaller operations.

Here's what primarily differentiates these sheet metal fabricators from standard shops:

- Equipment capacity: Press brakes ranging from 60 to 750 tons, plasma tables exceeding 20 feet, and roll forming equipment capable of handling 1-1/4" plate at 10-foot widths

- Facility size: Dedicated heavy metal shops with sufficient floor space, ceiling height, and structural support for oversized components

- Material handling systems: Multiple overhead cranes (some facilities operate 70+ cranes), specialized rigging, and staging areas for components exceeding 100 tons

- Project scope: Capability to handle complete assemblies up to 150 feet tall or long, rather than individual small parts

Key Capacity Thresholds That Matter

When evaluating metal parts manufacturing partners, specific numbers tell the story. Large-scale fabricators typically offer:

- Plate shearing capacity of 1/2" thickness with 12-foot length capability

- CNC press brakes with 20-foot-wide punches and dies

- Roll forming for plates up to 2-1/8" thick in mild steel

- Seam welding for sections up to 10 feet long with 3/8" plate capacity

Why does this matter? Certain industries can't compromise on scale. Industrial equipment manufacturers, architectural metal contractors, transportation component suppliers, and energy sector fabricators all require these capabilities. A refinery ductwork project, for instance, might demand perfectly round cylindrical sections 10 feet in length—something only achievable with specialized CNC plate rolls designed for heavy-gauge work.

Companies like metalman sheet metal products and similar large-scale providers have invested heavily in this infrastructure precisely because their target industries demand it. The equipment, facility requirements, and specialized workforce represent significant capital investments that separate true large-scale operations from shops that simply take on occasional bigger projects.

Understanding these distinctions upfront saves you from discovering mid-project that your fabricator lacks the capacity to deliver what you need.

Core Fabrication Processes at Scale

Now that you understand what qualifies a fabricator as large-scale, let's explore how the actual fabrication sheet metal processes differ when working with oversized components. The techniques themselves—cutting, bending, forming, welding—remain fundamentally the same. What changes dramatically is how they're executed, the equipment required, and the expertise needed to maintain precision across larger dimensions.

Imagine trying to bend a 20-foot steel plate with consistent accuracy along its entire length. The challenges multiply with every additional foot of material. Here's what actually happens inside a sheet metal machine shop equipped for large-scale work.

Heavy-Gauge Cutting and Forming Methods

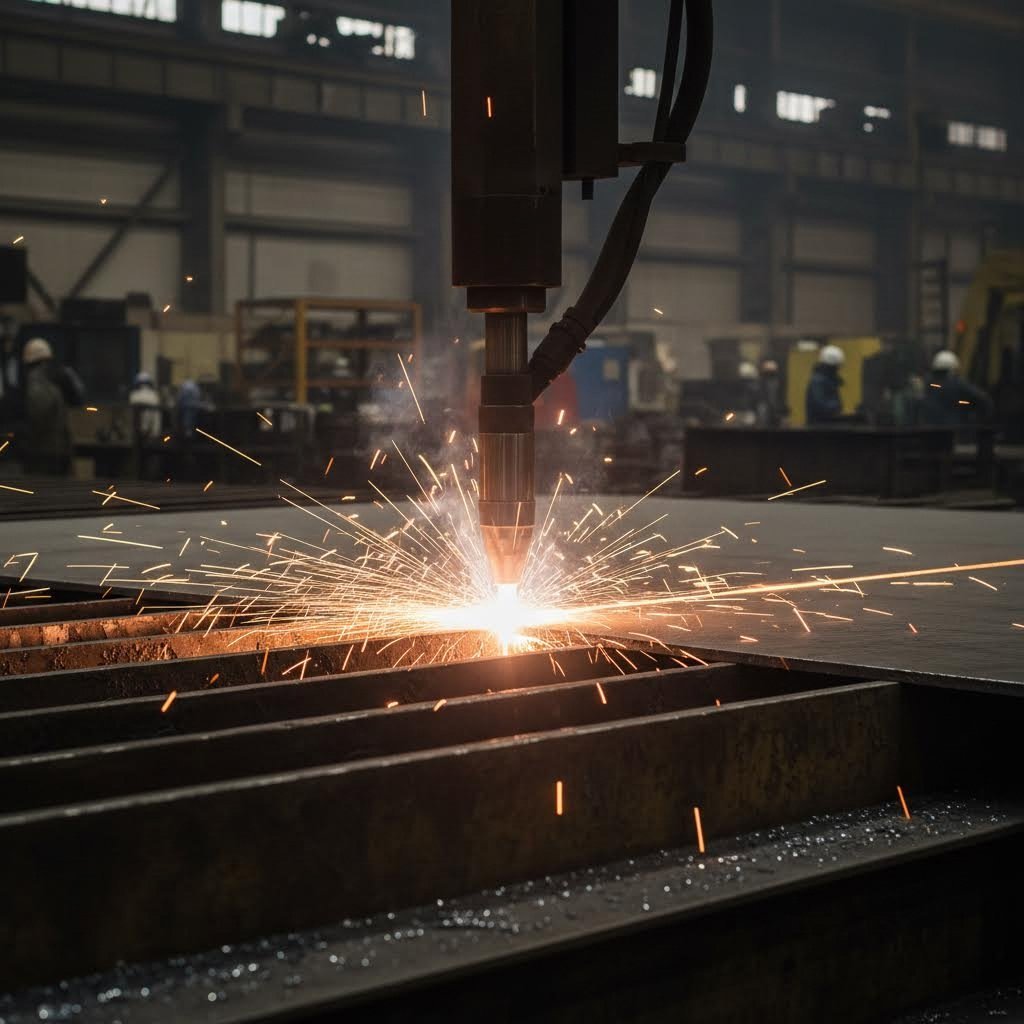

The initial step in any metal part fabrication project involves cutting raw material into required shapes. For large-scale work, this isn't as simple as loading a sheet and pressing start. According to Swanton Welding's technical documentation, heavy metal fabrication cutting typically involves multiple methods depending on material thickness and precision requirements:

- Plasma cutting: Ideal for thick plates where speed matters more than edge finish quality. Plasma tables exceeding 20 feet can handle full-size sheets in single passes.

- Laser cutting: Provides cleaner edges but faces limitations on extremely thick materials. Most effective for precision work up to 1" thickness.

- Waterjet cutting: Eliminates heat-affected zones entirely—critical when working with materials sensitive to thermal distortion.

- Flame/gas cutting: Still preferred for extremely thick plates (2"+ thickness) where other methods become impractical or cost-prohibitive.

Once cut, the sheet fabrication process moves to forming operations. This is where scale creates significant complications. Bending and rolling heavy-gauge materials demands understanding of something many buyers overlook: tonnage limitations.

Here's a reality check from Precitools' technical analysis: a press brake rated at 100 tons for 3 meters doesn't necessarily deliver 100 tons for shorter lengths. The tonnage-per-meter calculation becomes critical. If your part requires 300 tons per meter but the shop's press brake only delivers 200 tons per meter, the project simply cannot proceed—regardless of the machine's total tonnage rating.

Forming methods commonly used to fabricate metal at scale include:

- Section bending: Passing metal through shaped rollers to create curved profiles

- Plate bending: Creating cylindrical or conical shapes from flat sheets

- Press braking: Making precise angular bends using matched punch and die sets

- Tube bending: Shaping hollow sections for structural applications

Welding Techniques for Oversized Components

Welding large components presents unique challenges that go beyond simply having bigger equipment. The weld joints on a 40-foot fabrication must maintain consistent quality from start to finish—a demanding requirement when working with materials that expand and contract during the welding process.

Large-scale sheet metal machine shop operations typically employ several welding methods, each suited to specific applications:

- MIG (GMAW) welding: Fast deposition rates make this ideal for long weld runs on thick materials

- TIG (GTAW) welding: Used where precision and appearance matter, particularly on stainless steel and aluminum

- Submerged arc welding: Excellent for long, straight seams on heavy plate—the flux covering protects the weld and allows higher deposition rates

- Flux-cored arc welding: Combines MIG speed with better performance on thicker materials in outdoor or windy conditions

What makes welding at scale particularly demanding? Thermal management. A long weld seam introduces significant heat into the workpiece, causing expansion that must be accounted for in the initial setup. Experienced fabricators use specific sequences, skip welding patterns, and controlled cooling to minimize distortion.

The Large-Scale Fabrication Sequence

Understanding the typical workflow helps you evaluate whether a fabricator truly has the processes in place for your project. Here's how a large component moves from raw material to finished part:

- Material receipt and verification: Incoming sheets are inspected for dimensional accuracy, material certification, and surface condition

- Nesting and cutting optimization: CAD/CAM software maximizes material utilization, particularly important when working with expensive alloys or oversized sheets

- Primary cutting operations: Plasma, laser, or waterjet cutting creates the basic component shapes

- Secondary cutting and hole making: Drilling and punching operations prepare pieces for assembly connections

- Forming and bending: Press brake or roll forming shapes components to required profiles

- Fit-up and tacking: Components are positioned, aligned, and temporarily joined before final welding

- Welding: Final joints are completed using appropriate methods for the material and application

- Post-weld treatment: Stress relief, grinding, or other finishing as required

- Surface preparation and coating: Blasting and painting or other protective finishes

- Final inspection and documentation: Dimensional verification and quality records

Throughout this sequence, material handling becomes a constant consideration. Components weighing several tons must be moved safely between operations—requiring the cranes, rigging equipment, and trained personnel that distinguish capable large-scale fabricators from shops that merely attempt oversized work.

With the fabrication processes understood, the next critical consideration is material selection—because the metals you specify will directly impact how these processes perform and what results you can expect.

Material Selection and Handling for Large Projects

Here's something many buyers overlook when approaching large sheet metal fabricators: the material you specify doesn't just affect cost—it fundamentally changes how every fabrication process performs. A 10-foot aluminum panel behaves completely differently than a carbon steel plate of the same dimensions. Understanding these differences before you finalize specifications can save significant headaches downstream.

When you're working at scale, material properties that seem minor on small parts become major factors. Thermal expansion during welding, springback after bending, and even simple handling requirements all scale up with your project dimensions.

Material Selection for Heavy-Gauge Applications

Choosing the right metal for fabrication starts with understanding how different materials respond to large-scale processing. Let's break down the primary options and their scale-specific considerations.

According to Cut2SizeMetals' thickness guide, gauge standards vary by material type—the same gauge number corresponds to different actual thicknesses depending on whether you're working with steel, aluminum, or stainless. For aluminum sheet metal fabrication projects, sheets typically range from 0.016" to 0.19" in standard stock, while stainless steel extends from 26 gauge (0.018") to 7 gauge (0.1874").

Why does this matter for large-scale work? When you're bending a 15-foot sheet, even small variations in thickness create significant differences in required tonnage and resulting springback.

| Material | Typical Thickness Range | Weight Factor | Best Applications | Scale-Specific Challenges |

|---|---|---|---|---|

| Carbon Steel | 18 ga (0.048") to 1" plate | Heaviest option | Structural components, industrial equipment, transportation | Significant thermal expansion; rust prevention required |

| Stainless Steel (304, 316) | 26 ga (0.018") to 3/16" plate | Similar to carbon steel | Food processing, chemical handling, architectural | Work hardening during forming; higher springback |

| Aluminum (3003, 6061) | 0.016" to 0.19" sheet | ~1/3 weight of steel | Lightweight structures, aerospace, heat exchangers | Greater thermal expansion; softer surface marks easily |

| High-Strength Steel (DP grades) | 0.5mm to 3mm typical | Same as carbon steel | Automotive, safety-critical structural parts | Highest springback; requires temperature compensation |

Here's a critical consideration that research confirms: springback increases dramatically with material strength. According to a study published in Nature Scientific Reports, high-strength steels like DP1000 present significantly greater springback challenges than standard grades. The researchers found that temperature, thickness, and holding time all interact to affect springback—meaning your fabricator needs to account for multiple variables simultaneously, not just material type alone.

What does this mean practically? If your aluminum sheet metal fabrication project requires tight angular tolerances on large bends, expect your fabricator to either overbend and allow for springback or use specialized techniques like warm forming to achieve the specified dimensions.

Sourcing and Handling Oversized Stock

Finding metal supply bay area vendors or suppliers anywhere that stock oversized sheets presents real challenges. Standard mill runs produce sheets in common dimensions—typically 4' x 8' or 4' x 10' for most materials. When your project requires 5' x 12' sheets or larger, you're often looking at:

- Special mill orders: Minimum quantities typically apply, adding lead time of 6-12 weeks

- Nested cutting from plate: Starting with thicker plate stock and processing to required dimensions

- Welded blanks: Joining standard sheets before forming (adds processing time and cost)

- Coil processing: For high-volume projects, sourcing from coil stock and cutting to length

Aluminium sheet metal fabricators face particular sourcing challenges because aluminum mills produce fewer oversized options compared to steel. If your project requires large aluminum components, discuss material availability early—it often drives project timelines more than fabrication capacity.

Handling presents equally significant considerations. A single 10' x 20' steel plate at 1/2" thickness weighs approximately 4,000 pounds. Moving this through cutting, forming, and welding operations requires:

- Overhead cranes with sufficient capacity and reach

- Floor space for safe staging between operations

- Specialized fixtures to support material during processing

- Trained riggers who understand load distribution

The metal supply bay area or any regional source can only help if your fabricator has the infrastructure to receive, store, and process what you're ordering. Always verify material handling capabilities before assuming your chosen shop can work with the stock sizes your project demands.

How Material Properties Affect Large-Scale Outcomes

Three phenomena become especially problematic at scale: thermal expansion, springback, and structural integrity during handling.

Thermal expansion during welding: When welding a 20-foot seam, the heat input causes the base metal to expand significantly along its length. As the weld cools, contraction creates internal stresses that can warp the finished component. Experienced aluminium sheet metal fabrication shops use specific weld sequences, intermittent cooling, and pre-set distortion allowances to compensate. Aluminum expands approximately twice as much as steel for the same temperature change—making thermal management even more critical.

Springback in large bends: The research cited earlier confirms what fabricators experience daily: springback isn't a simple calculation. For large components, the challenge multiplies because any variation along the bend length becomes visible and potentially problematic for fit-up. High-strength steels used in automotive applications show particularly aggressive springback—the Nature study found that combining temperature control with appropriate holding time significantly reduces this effect, though it requires specialized equipment and process knowledge.

Structural integrity concerns: Large sheet metal components must support their own weight during fabrication without permanent deformation. This self-weight deflection rarely matters for small parts but becomes critical for panels exceeding 8 or 10 feet. Your fabricator should understand where to add temporary stiffeners or supports during processing—then remove them from the finished part.

With material considerations addressed, the next critical factor involves how engineering support and design optimization can prevent problems before fabrication even begins.

Engineering Support and Design Optimization

You've selected your materials and understand the fabrication processes involved. But here's where many large-scale projects succeed or fail: the engineering phase. When you're working with custom sheet metal fabrication near me searches or evaluating potential partners, design support capabilities often get overlooked in favor of equipment lists and capacity specifications. That's a mistake.

Why? Because decisions made during design directly determine whether your project runs smoothly or encounters costly mid-production revisions. According to Advantage Metal Products, sheet metal design for manufacturability goes beyond aesthetics—it leverages the technicalities of manufacturing to foster seamless production execution. When working at scale, these considerations become exponentially more important.

Design for Manufacturability in Large-Scale Work

Design for manufacturability (DFM) is a strategic approach that aligns part design with the realities of the fabrication process. For standard components, DFM might save a few dollars per piece. For large-scale custom sheet metal parts, it can mean the difference between a project that stays on budget and one that spirals into revision cycles and delays.

What makes DFM particularly critical when working with large sheet metal fabricators? Scale amplifies every design decision. A tolerance that's easily achievable on a 12-inch part might require specialized fixturing or multiple operations on a 12-foot component. A bend radius that works perfectly on thin gauge material might crack heavy plate.

Here are the key DFM considerations specific to large sheet metal components:

- Bend radius and material thickness interaction: Trying to bend thick metal into a tight curve can result in cracks and deformities. Large components require careful analysis of minimum bend radii based on material grade and thickness.

- Tolerance accumulation: On a 20-foot assembly, tolerances that seem reasonable on individual components can stack up to create fit-up problems. DFM analysis identifies where tighter controls are truly necessary versus where standard tolerances suffice.

- Hole placement for structural integrity: Strategically placed holes matter for fasteners, ventilation, and fixtures. When selecting sheet metal for fabrication of large components, hole positioning must account for structural loads and material removal effects.

- Corner design for stress concentration: Sharp corners concentrate stress. On small parts, this rarely causes issues. On large structural components under load, rounded corners become essential for longevity.

- Weld accessibility: Components must be designed so welders can actually reach all joint locations with proper angles. Large assemblies often require sequential sub-assembly welding rather than welding the complete unit.

- Handling and fixturing points: Where will cranes attach during fabrication? Where will the finished component be supported during shipping? These considerations should influence design from the beginning.

The sheet metal for fabrication you specify interacts with all these factors. Aluminum requires different bend allowances than steel. High-strength materials demand more conservative corner radii. Your engineering partner should evaluate these interactions before production begins—not discover them during fabrication.

Engineering Collaboration Throughout the Project

Sounds complex? It doesn't have to be—if you're working with fabricators who offer genuine engineering collaboration rather than simply accepting whatever drawings you provide.

According to Noble Industries, comprehensive engineering support spans the entire spectrum from pre-prototype stages to full-scale production. Their engineers specialize in materials, sheet metal fabrication, and advanced technologies including CAD and 3D modeling—focusing on streamlining designs to ensure every concept evolves into a production-ready, affordable, and highly functional product.

What does effective engineering collaboration look like in practice?

- Early design review: Your fabricator's engineers review initial concepts for manufacturability before you've invested heavily in detailed drawings

- 3D CAD modeling: Visualization tools help identify potential problems and enable design optimization before cutting any metal

- Simulation and prototyping: Software tools anticipate challenges—allowing preemptive design adjustments that reduce costly iterations

- Real-time communication: Collaboration platforms facilitate sharing of insights and refinements throughout the project lifecycle

- Feedback integration: Regular check-ins gather your input and ensure the final design aligns with your specifications and expectations

This collaborative approach matters especially when you're searching for custom metal parts fabrication near me options. A local partner who can meet face-to-face during critical design phases often delivers better outcomes than a distant supplier working solely from emailed files.

Prototype vs. Production Volume Considerations

Here's a question many buyers don't ask early enough: how does your project volume affect tooling decisions, setup costs, and lead times?

The answer varies dramatically based on scale. According to TMCO's cost analysis, a single prototype or small batch run will cost more per unit than a large-volume order because setup and programming time are spread across fewer parts.

For large-scale fabrication, this effect intensifies. Consider what's involved in setting up for a custom 15-foot component:

- CNC programming: Creating the cutting and forming programs requires hours of engineering time regardless of quantity

- Fixture development: Large components often need custom fixtures to hold material during processing—fixtures that may only be used for your project

- Press brake tooling: Specialized punches and dies may be required for unique bend profiles or heavy-gauge materials

- Weld procedure qualification: For critical applications, welding procedures must be developed and qualified before production

- First article inspection: Comprehensive dimensional verification of initial parts ensures the process produces conforming components

If you're ordering one prototype, all these costs apply to a single unit. Order 100 production pieces, and the per-unit impact drops dramatically. Understanding this dynamic helps you make informed decisions about prototype investment versus moving directly to production quantities.

What's the practical implication? If budget constraints are tight, discuss with your fabricator how prototype learnings can translate directly to production tooling. Some shops offer prototype pricing that includes partial credit toward production tooling—reducing total project cost when you're confident the design will proceed to volume manufacturing.

The engineering decisions you make now ripple through every subsequent phase—from quality control requirements to logistics planning. Speaking of quality, that's precisely where we turn next: how do large-scale fabricators verify that oversized components meet specifications when traditional inspection methods may not apply?

Quality Control Standards for Large Components

Imagine you've just received a 25-foot fabricated steel assembly. How do you verify it meets specifications? Traditional calipers and micrometers won't cut it. This challenge—verifying dimensional accuracy on oversized components—represents one of the most overlooked aspects when evaluating large sheet metal fabricators.

Quality control for large-scale fabrication isn't simply scaled-up versions of standard inspection methods. The techniques, equipment, and documentation requirements differ fundamentally from what you'd encounter in precision sheet metal shops handling smaller components. Understanding these differences helps you ask the right questions before signing a contract.

Dimensional Verification for Oversized Parts

When components exceed the measurement range of conventional tools, fabricators turn to specialized inspection methods. According to GaugeHow's technical documentation, Coordinate Measuring Machines (CMMs) represent the gold standard for precision dimensional verification—but even large CMMs have physical limitations when parts span 20 feet or more.

So what methods do sheet metal fabrication shops actually use for oversized components?

- Portable CMM arms: These articulated measurement devices can be repositioned around large workpieces, building complete dimensional maps from multiple measurement stations

- Laser trackers: Project laser beams to retroreflector targets, measuring distances and angles with accuracy to 0.001" across distances up to 100 feet

- Photogrammetry: Uses multiple photographs from calibrated cameras to calculate 3D coordinates—particularly effective for very large assemblies

- 3D laser scanning: Captures millions of surface points to create digital twins that can be compared against CAD models

- Template checking: Physical templates verify critical profiles and dimensions—a proven method still valuable for repetitive production

Here's what many buyers don't realize: measurement uncertainty increases with part size. A fabricator claiming ±0.010" tolerance on a 15-foot component needs equipment and methods that can actually verify that tolerance. Ask potential partners specifically what measurement equipment they use and what their documented measurement uncertainty is for parts of your size range.

The metal fabrication and manufacturing process generates dimensional variations at every step. Thermal expansion during welding, springback after bending, stress relief over time—all these factors affect final dimensions. Effective quality control doesn't just measure finished parts; it monitors critical dimensions throughout fabrication to catch deviations before they compound.

Industry Certifications That Matter

Certifications serve as third-party verification that a fabricator has implemented systematic quality management. But not all certifications carry equal weight for every application.

For automotive supply chain work, IATF 16949 certification represents the benchmark. According to OGS Industries, this certification builds on ISO 9001 requirements while adding specific mandates for lean manufacturing, defect prevention, variance reduction, and waste elimination. What does this mean practically? IATF 16949-certified fabricators have documented processes for:

- Consistent quality through monitored and measured processes

- Reduced product variation via reviewed and improved manufacturing systems

- Reliable supplier management establishing stronger supply chains

- Waste reduction through streamlined operations

- Defect prevention rather than just defect detection

If you're sourcing components for automotive applications—whether through sheet metal fabrication San Jose facilities or suppliers anywhere in the automotive supply chain—IATF 16949 certification should be a baseline requirement.

For general industrial applications, ISO 9001:2015 certification provides assurance of systematic quality management. According to SAS Global Corporation, ISO certification delivers traceable processes where every component is tracked, inspected, and documented at every production stage. Their documentation emphasizes that ISO isn't a static badge—it requires continuous improvement in training, inspection tools, and procedural enhancements.

Beyond quality management certifications, look for welding certifications relevant to your application:

- AWS D1.1: Structural welding code for steel—essential for load-bearing fabrications

- AWS D1.2: Structural welding code for aluminum

- ASME Section IX: Required for pressure vessel and boiler work

- AWS D17.1: Fusion welding for aerospace applications

Quality Checkpoints Throughout Fabrication

Effective quality control isn't a final inspection before shipping—it's a stage-gate process embedded throughout fabrication. According to SAS Global Corporation's documentation, their approach includes inspections at every critical juncture:

- Material verification: Incoming materials inspected for chemistry, thickness, and conformance to customer specifications before any processing begins

- Fit-up inspection: Critical dimensions and weld preparation verified before welding operations commence

- In-process weld inspection: Welds checked during fabrication using visual inspection, magnetic particle testing, dye penetrant testing, or ultrasonic testing depending on application requirements

- Dimensional inspection: Templates and calibrated instruments ensure accuracy throughout the build sequence

- Final inspection: Comprehensive review with photographic documentation before shipping

This proactive approach catches problems when they're still correctable—not after a 5,000-pound assembly has been fully welded and finished. Ask potential fabricators to describe their stage-gate inspection process. If they can only describe a final inspection, that's a red flag.

Documentation requirements also scale with project criticality. For critical applications, expect your fabricator to provide material certifications, weld procedure specifications, welder qualification records, dimensional inspection reports, and any nondestructive testing results. This documentation package protects both parties and provides traceability if questions arise later.

With quality control systems understood, there's another practical consideration that rarely appears in fabricator marketing materials but significantly impacts your project: how do you actually get a 30-foot fabricated assembly from the shop to your facility?

Logistics and Transportation Planning

You've invested significant effort selecting the right fabricator, optimizing your design, and implementing quality controls. But here's a question that catches many buyers off guard: how will your finished components actually reach your facility? For large sheet metal fabricators, the work doesn't end when welding is complete—getting oversized parts from the sheet metal workshop to your door involves its own set of challenges.

According to Endura Steel's logistics documentation, moving really big or heavy metal products is like solving a puzzle—figuring out how to get them from one place to another without breaking any rules or damaging the cargo. The reality? Transportation constraints should influence your design decisions from the very beginning, not become surprises at project completion.

Shipping Constraints for Large Fabrications

What makes transporting oversized fabricated parts so challenging? Multiple factors combine to create logistical complexity that standard freight simply doesn't encounter.

Size and weight limitations represent the most obvious constraints. According to Trinity Logistics, over-dimensional shipments are typically classified as cargo exceeding:

- Width of 8.6 feet

- Height of 13.6 feet

- Length of 48 to 53 feet

- Gross weight of 80,000 pounds

Exceed any of these thresholds, and your shipment enters the world of permits, escorts, and specialized carriers. Bridges and tunnels often have height and width restrictions that can block direct routes entirely. Road weight restrictions vary by jurisdiction, making route planning essential for heavy loads.

Here's what many local fabrication shops and their customers discover too late: the permit and escort process adds significant time and cost. According to Endura Steel, obtaining approvals can delay transportation schedules, and arranging escorts requires coordinating with specialized service providers along the entire planned route.

| Transportation Method | Size Limitations | Weight Capacity | Cost Implications | Best Applications |

|---|---|---|---|---|

| Standard Flatbed | 8.5' W x 8.5' H x 48' L | Up to 48,000 lbs | Lowest cost; no special permits | Components within legal limits |

| Step Deck / Drop Deck | 8.5' W x 10' H x 53' L | Up to 48,000 lbs | Moderate; accommodates taller loads | Tall components under 10 feet |

| Double Drop Trailer | 8.5' W x 11.5' H x 29' L (well) | Up to 40,000 lbs | Higher; specialized equipment | Very tall equipment or machinery |

| Removable Gooseneck (RGN) | Variable; up to 12' H | Up to 150,000+ lbs | Highest; requires permits and escorts | Heavy equipment, massive assemblies |

| Containerized (Intermodal) | 7.8' W x 7.8' H x 39' L (40' container) | Up to 44,000 lbs | Economical for long distances | Protected cargo; international shipping |

Beyond equipment selection, specialized handling adds cost. The safe loading of oversized or heavy metal products requires investment in cranes, forklifts, and rigging gear—equipment that local metal fabrication shop facilities may or may not have available. If your fabricator lacks adequate loading equipment, you'll need to arrange third-party rigging services.

Design Decisions That Affect Delivery

Here's the insight that separates experienced buyers from first-timers: transportation constraints should influence your design from the outset—not become problems to solve after fabrication.

According to Approved Sheet Metal, when a large part simply won't fit on standard fabrication equipment or shipping methods, modular design offers a practical solution. They routinely help customers solve problems by fabricating parts in more than one piece, then welding or fastening the pieces together. Their expertise ensures the weld will be clean and efficient and that the finished part retains its original functionality.

What modular design approaches facilitate shipping while maintaining structural integrity?

- Strategic separation points: Identifying locations where components can be divided without compromising structural performance—often at natural joint locations or areas with lower stress concentration

- Bolted and riveted joints: For large sheet metal components, bolting and riveting offer practical alternatives to welding, particularly when field assembly or future disassembly is anticipated

- Interlocking tabs and slots: These features simplify alignment during final assembly and reduce errors when joining sections at the installation site

- Knock-down assemblies: Designing for flat-pack shipping dramatically reduces transportation costs and enables final assembly at the point of use

Consider this scenario: a 25-foot enclosure panel might require specialized permits, escorts, and a step deck trailer if shipped fully assembled. The same panel designed as three bolted sections ships on a standard flatbed at a fraction of the cost—and assembles in the field with basic tools.

The decision between single-piece fabrication and modular design involves tradeoffs. Welded one-piece construction typically offers better structural performance and weather sealing. Modular approaches reduce shipping costs but add field assembly labor and potential leak points. Your fabricator should help you evaluate these tradeoffs based on your specific application requirements.

What questions should you ask early in the design phase?

- What are the finished dimensions, and do they exceed standard shipping thresholds?

- Can the design be modified to fit within legal limits without compromising function?

- If modular construction is required, where are the optimal separation points?

- What joining methods will work for field assembly at your installation site?

- Does your local metal fabrication shop have loading equipment for the finished size and weight?

Addressing these questions during engineering—not after fabrication—prevents costly surprises and keeps your project on schedule. The best large-scale fabricators proactively raise logistics considerations during design review, recognizing that their responsibility extends beyond making parts to ensuring those parts actually reach customers intact and on time.

Understanding logistics helps you plan realistically, but there's still a fundamental question many buyers struggle to answer: does your project actually require a large-scale fabricator, or would a standard shop suffice?

When You Need a Large Fabricator

Here's a question that could save you thousands of dollars—or prevent a project disaster: does your job actually require large sheet metal fabricators, or would a capable small fabrication shop handle it just fine? Not every project needs oversized equipment and specialized infrastructure. But choosing incorrectly in either direction creates problems.

Select a small metal fabrication shop for work that exceeds their capacity, and you'll face delays, quality issues, or outright project rejection mid-stream. Conversely, approach a large-scale operation for standard work, and you may pay premium rates for capabilities you don't need. According to Swanton Welding, before considering who will do your fabrication work, it's important to determine if a metal fabrication shop can handle your project—because different projects have different requirements, and a shop that works for one project may not work for another.

Project Characteristics Requiring Large-Scale Capabilities

When you're evaluating metal fab services, certain project characteristics immediately signal the need for large-scale capabilities. Think of these as threshold indicators—cross any of them, and you're likely outside what standard shops can accommodate.

Part dimensions: This is the most obvious factor. When individual components exceed 8 feet in any dimension, you're entering territory where standard equipment struggles. Press brakes with 10-foot or shorter beds can't form 12-foot panels. Welding tables designed for typical work won't support 20-foot assemblies properly. If your parts measure in the double digits, large-scale fabricators become necessary rather than optional.

Material thickness: Heavy-gauge work requires equipment most standard shops simply don't possess. Bending 1/2" plate demands press brakes with tonnage ratings that smaller operations can't justify purchasing. Cutting thick materials efficiently requires high-powered plasma or laser systems with associated infrastructure—power supply, exhaust handling, and maintenance capabilities that scale with equipment size.

Volume and weight: Even if individual part dimensions seem manageable, total project weight matters. Fabricating 50 panels that each weigh 500 pounds requires material handling infrastructure—cranes, rigging equipment, and trained personnel—that goes beyond what you'll find in a typical small metal fabrication shop.

Industry specifications: Certain industries mandate capabilities that only larger operations provide. Automotive supply chain work requiring IATF 16949 certification, aerospace projects demanding AS9100 compliance, or structural fabrication needing AWS D1.1 certified welding procedures—these specifications narrow your options to fabricators who've invested in the necessary systems and certifications.

According to LTJ Industrial, large-scale metal fabrication involves extensive quantities of metal, large dimensions, and rigorous engineering standards. The sheer volume of materials, intricate design, and strict tolerances distinguish large-scale work from smaller endeavors.

Red Flags Your Project Exceeds Standard Shop Capabilities

Sometimes it's not immediately obvious that you need large-scale capabilities. Watch for these warning signs that suggest a small fabrication shop may struggle with your project:

- The shop asks to subcontract cutting or forming operations: If they can't perform core processes in-house, you lose quality control and add coordination complexity

- Lead time quotes seem unusually long: This often indicates the shop plans to batch your work between jobs their equipment handles more efficiently

- They request you break assemblies into smaller sub-components: While sometimes legitimate, this can signal equipment limitations rather than design optimization

- Material handling discussions reveal improvised solutions: "We'll figure out how to move it" isn't the same as "Our 10-ton crane handles this routinely"

- Quality inspection capabilities seem limited for your part sizes: Asking how they'll verify dimensions on a 15-foot part should yield specific answers, not vague assurances

- They lack industry-specific certifications your application requires: Certifications take years to achieve—a shop won't obtain them for your single project

- Previous project examples don't match your scale: A portfolio of 2-foot enclosures doesn't demonstrate capability for 20-foot assemblies

Evaluating Fabricator Capacity for Your Needs

So how do you systematically evaluate whether a fabricator matches your project requirements? Use this decision framework to assess alignment between your needs and their capabilities.

Step 1: Define your dimensional requirements clearly. Document the largest single component dimensions, the heaviest individual piece, and the total weight of material the shop will handle. These numbers become your screening criteria.

Step 2: Identify critical processes. What specific operations does your project require? CNC plasma cutting? Heavy-gauge press brake forming? Certified structural welding? Multi-axis machining? List each process and the parameters involved—material type, thickness, length, tolerance requirements.

Step 3: Request specific equipment information. Don't accept generic capability statements. Ask for press brake tonnage ratings and bed lengths. Request plasma table dimensions and thickness capacities. Inquire about crane capacities and hook heights. According to Swanton Welding, understanding a shop's capabilities—including equipment, materials, staff, and production capacity—is essential before contracting.

Step 4: Verify with similar project examples. Ask for references from projects matching your scale. A fabricator experienced with your size range can provide specific examples. If examples are significantly smaller than your requirements, probe deeper about their actual large-scale experience.

Step 5: Assess supporting infrastructure. Beyond primary fabrication equipment, evaluate material handling, staging space, and shipping capabilities. Can they receive your specified material sizes? Store work-in-progress safely? Load finished components onto appropriate transport?

If you're searching for specialized capabilities like laser cutting San Jose area services or similar regional providers, apply these same evaluation criteria. Geographic convenience matters, but capability alignment matters more.

The goal isn't finding the largest fabricator available—it's finding the right match between your project requirements and their proven capabilities. A mid-sized shop with equipment perfectly suited to your dimensions may outperform a massive facility where your project becomes a low-priority job among much larger contracts.

With a clear understanding of when large-scale capabilities are necessary, the final step is knowing how to select and partner effectively with your chosen fabricator—turning your evaluation into a productive manufacturing relationship.

Selecting the Right Large-Scale Fabrication Partner

You've done the homework. You understand what defines large-scale fabricators, how their processes differ, what material and quality considerations matter, and whether your project actually requires these specialized capabilities. Now comes the decision that determines whether all that preparation pays off: choosing the right partner and building a relationship that delivers results.

According to Seconn Fabrication, manufacturers must take choosing the right fabrication partner seriously because it's crucial to success and ensures industry standard compliance. It can also help optimize costs while maintaining efficient project timelines. The selection process isn't just about finding someone who can do the work—it's about identifying a partner whose capabilities, communication style, and business practices align with your long-term needs.

Key Questions to Ask Potential Fabricators

Before signing any contract, you need answers to specific questions that reveal whether a fabricator can actually deliver on their promises. Generic capability statements won't protect you from mid-project surprises. Here's what to ask—and why each question matters.

Experience and Track Record

According to ICOM Mechanical, working with fabricators who lack ample experience in the metal fabrication industry may increase your chances of getting substandard work. Metal fabrication is a technical field, and it takes plenty of time before a fabricator can master the art—especially at scale.

- How long have you been fabricating components at this scale? Years in business matter less than years handling projects matching your dimensions and complexity.

- Can you provide references from similar projects? Speaking with past clients reveals reliability, communication quality, and problem-solving ability that portfolios don't capture.

- What industries do you primarily serve? A fabricator experienced in your industry understands relevant specifications, tolerances, and compliance requirements.

Capacity and Capabilities

According to Seconn's guidance, understanding the range of services helps determine whether the fabrication company offers services that align with project needs. Gauge their full capacity by asking about specialized services like prototyping and design assistance.

- What are your maximum part dimensions and weight capacities? Get specific numbers for press brake bed length, plasma table size, and crane tonnage—not generalizations.

- Do you handle all fabrication processes in-house? Subcontracting key operations adds coordination risk and reduces quality control. The ideal partner designs, fabricates, and finishes your project under one roof.

- What's your current capacity utilization? A shop running at 95% capacity may struggle to accommodate your timeline. One at 60% has flexibility for rush needs.

Quality Systems and Certifications

Reliable fabricators invest in stringent quality measures to uphold the highest production standards. Don't just ask if they're certified—ask how they implement those standards daily.

- What quality certifications do you hold? For automotive applications, IATF 16949 certification is essential. General manufacturing requires ISO 9001 at minimum. Structural work demands AWS welding certifications.

- What's your inspection process for large components? They should describe specific equipment—laser trackers, portable CMMs, or photogrammetry—appropriate for your part sizes.

- How do you document quality throughout fabrication? Material certifications, in-process inspection records, and final inspection reports should be standard practice.

Engineering Support and Responsiveness

This is where many buyers discover critical differences between fabricators. According to Seconn's evaluation framework, fabrication partners should optimize designs for improved cost-effectiveness, efficiency, and quality.

- Do you offer DFM (Design for Manufacturability) review? Proactive engineering feedback prevents costly mid-production revisions. Look for partners who identify potential issues before fabrication begins.

- What's your typical quote turnaround time? Responsiveness during quoting often predicts responsiveness during production. Some fabricators, like Shaoyi (Ningbo) Metal Technology, offer 12-hour quote turnaround—demonstrating systems designed for rapid customer response.

- Can you support rapid prototyping? If your project involves design iteration, prototype speed matters. Shaoyi's 5-day rapid prototyping capability, combined with their comprehensive DFM support and IATF 16949 certification for automotive applications, illustrates what's achievable when a fabricator invests in responsive engineering infrastructure.

Building a Productive Manufacturing Partnership

Finding a capable fabricator is step one. Building a partnership that delivers consistent results over multiple projects requires ongoing attention to communication, expectations, and relationship development.

According to ICOM Mechanical's guidance, proficient sheet metal fabrication companies should have experienced and well-trained professionals—but equally important is how those professionals communicate with you throughout the project lifecycle.

Establish Clear Communication Protocols

Before production begins, define how information flows between your team and theirs:

- Who's your primary contact? Having a dedicated project manager or account representative streamlines communication and prevents information gaps.

- How will design changes be handled? Mid-production modifications happen. Understand the change order process, approval requirements, and cost implications before they become urgent.

- What's the escalation path for problems? When issues arise—and they will—knowing who to contact for rapid resolution prevents delays from becoming disasters.

Set Realistic Expectations

According to Seconn's framework, meeting deadlines is essential for ensuring a smooth production process. Timely delivery requires information about capacity and lead times, strategies for meeting deadlines, and contingency plans for delays.

- Agree on realistic timelines upfront. Pushing for aggressive schedules that the fabricator can't actually meet creates friction and quality risks. Honest conversations about capacity prevent disappointment.

- Define acceptance criteria clearly. What tolerances are critical versus nominal? Which surfaces require specific finishes? Documenting these requirements prevents disputes at delivery.

- Plan for the unexpected. Material delays, equipment issues, and design clarifications happen. Build buffer time into critical path schedules.

Steps for Vetting Potential Fabricators

Ready to begin your selection process? Follow this systematic approach to evaluate candidates and make an informed decision:

- Define your requirements document. Before contacting any fabricator, document your part dimensions, material specifications, quantity requirements, quality standards, and timeline expectations. This becomes your evaluation baseline.

- Create a shortlist based on capability fit. Whether you're searching for metal fabrication San Jose CA providers, steel fabricators San Jose CA options, or metal fabrication Oakland specialists, filter candidates by confirmed capacity for your specific requirements—not general marketing claims.

- Request detailed quotes with breakdowns. Ask for itemized pricing showing material costs, fabrication operations, finishing, and any tooling charges. Transparency in quoting often reflects transparency in operations.

- Conduct facility visits or virtual tours. Seeing equipment, workflow, and organization firsthand reveals more than any capability document. Pay attention to housekeeping, material handling practices, and work-in-progress staging.

- Verify certifications independently. Request certificate copies and verify currency. For critical certifications like IATF 16949, confirm the scope covers your required processes.

- Check references thoroughly. Contact provided references, but also search for independent reviews. Ask references specifically about communication quality, problem resolution, and on-time delivery performance.

- Start with a pilot project when possible. Before committing to high-volume production or critical components, test the relationship with a smaller project. This reveals working dynamics that quotes and tours can't predict.

- Negotiate partnership terms, not just pricing. Consider volume commitments, payment terms, warranty provisions, and intellectual property protections. The lowest quote rarely represents the best total value.

Making Your Final Decision

After completing your evaluation, you'll likely have two or three strong candidates. The final decision often comes down to factors beyond pure capability:

- Cultural fit: Do their communication style and business values align with yours? Long-term partnerships require compatibility beyond technical capability.

- Growth alignment: According to Seconn's guidance, good partnerships allow for company expansion to support evolving needs and increased volumes. Your fabrication partner should scale with you as your business grows.

- Geographic considerations: For bay area metal fabrication needs or any regional requirement, proximity offers advantages for site visits, urgent deliveries, and relationship building—though capability should never be sacrificed for convenience.

- Total cost of ownership: The lowest piece price means nothing if quality issues, delivery delays, or communication failures create hidden costs. Evaluate the complete picture.

The right large-scale fabrication partner becomes an extension of your manufacturing capability—one that grows more valuable as mutual understanding deepens over successive projects. Invest the time upfront to select wisely, establish clear expectations, and build communication practices that prevent problems. That investment pays dividends in quality, reliability, and competitive advantage for years to come.

Frequently Asked Questions About Large Sheet Metal Fabricators

1. What size qualifies a fabricator as large-scale?

Large sheet metal fabricators typically process sheets exceeding 4' x 8' dimensions, handle materials over 1/4" thick, and operate press brakes ranging from 60 to 750 tons. Key indicators include plasma tables exceeding 20 feet, overhead cranes with 10+ ton capacity, and facility infrastructure designed for components up to 150 feet in length. These capabilities distinguish them from standard fabrication shops that handle smaller, lighter work.

2. How do I know if my project needs a large fabricator?

Your project requires large-scale capabilities when individual components exceed 8 feet in any dimension, material thickness surpasses 1/4", total project weight demands crane handling, or industry specifications mandate certifications like IATF 16949. Red flags include shops asking to subcontract core operations, unusually long lead times, or requests to break assemblies into smaller sub-components due to equipment limitations.

3. What certifications should large sheet metal fabricators have?

For automotive applications, IATF 16949 certification is essential as it ensures lean manufacturing, defect prevention, and reliable supply chain management. General manufacturing requires ISO 9001:2015 at minimum. Structural fabrication demands AWS D1.1 welding certification. Specialized work may require AWS D1.2 for aluminum, ASME Section IX for pressure vessels, or AWS D17.1 for aerospace applications.

4. How do fabricators inspect oversized components for quality?

Large-scale fabricators use specialized inspection methods including portable CMM arms, laser trackers accurate to 0.001" across 100 feet, photogrammetry using calibrated cameras, and 3D laser scanning. These technologies enable dimensional verification impossible with standard measurement tools. Quality control includes stage-gate inspections at material receipt, fit-up, in-process welding, and final verification with comprehensive documentation.

5. What should I ask potential large-scale fabrication partners?

Key questions include specific equipment capacities (press brake tonnage, plasma table dimensions, crane tonnage), in-house process capabilities, current capacity utilization, quality certifications, DFM support availability, and quote turnaround times. Request references from similar-scale projects and verify certifications independently. Partners like Shaoyi Metal Technology demonstrate excellence with 5-day rapid prototyping, 12-hour quote turnaround, and IATF 16949 certification for automotive applications.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —