The Essential Role of Steel Forging in Automotive Parts

TL;DR

Steel forging for automotive applications is a manufacturing process that uses intense heat and compressive force to shape steel into exceptionally strong, durable, and reliable parts. These components are not just optional upgrades; they are fundamental to the safety, performance, and longevity of critical vehicle systems, including the engine, transmission, and suspension. Forging ensures that essential parts can withstand immense stress and shock, making it an indispensable technology in modern vehicle production.

Understanding Steel Forging and Its Critical Role in the Automotive Industry

At its core, steel forging is a highly controlled process where steel is heated to a malleable temperature—often exceeding 1,500°F—and then shaped using immense pressure from hammers or presses. This method is fundamentally different from casting (pouring molten metal into a mold) or machining (cutting material away from a solid block). The intense pressure applied during forging refines the steel's internal grain structure, aligning it with the component's final shape. This creates a continuous and unbroken grain flow, which is the source of the material's signature strength and fatigue resistance.

In the automotive industry, this process is essential for manufacturing parts that are subjected to constant stress and high-impact loads. Components like those in the steering, suspension, and drivetrain must be incredibly robust to ensure driver safety and vehicle reliability. Forged parts provide a level of structural integrity that other manufacturing methods struggle to match. According to the Forging Industry Association, the unique combination of strength, reliability, and economy makes forged components ideal for these vital applications. This inherent toughness ensures that parts do not fail under pressure, contributing directly to a vehicle's overall safety and performance.

The importance of forging extends beyond raw strength. The process produces parts with a high degree of dimensional accuracy and a dense, non-porous structure. This eliminates the risk of internal defects like air pockets or cracks, which can sometimes occur in cast parts and lead to catastrophic failure. As vehicles become lighter and more efficient to meet modern fuel and emission standards, the demand for stronger, lighter components has grown, further cementing steel forging's critical role in automotive manufacturing.

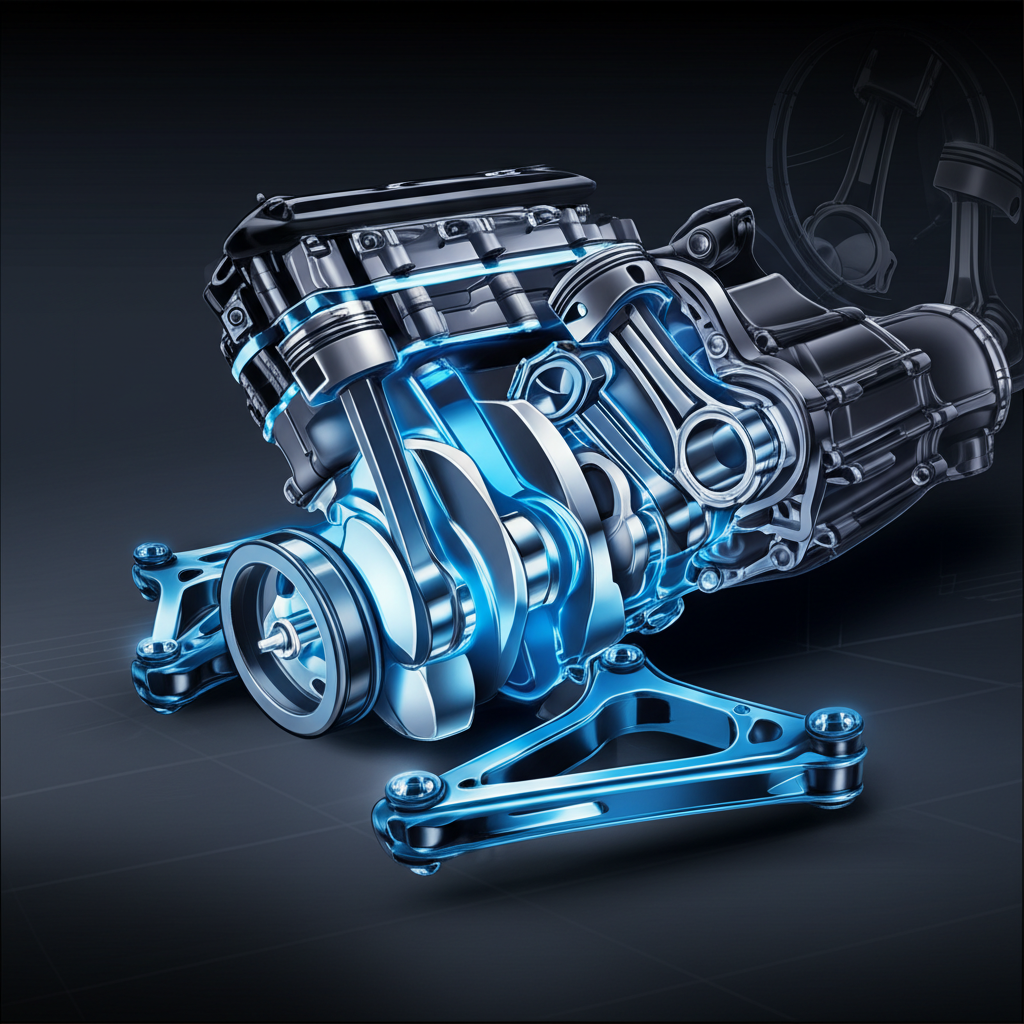

Key Applications of Forged Steel Components in Vehicles

The superior properties of forged steel make it the material of choice for a wide range of critical automotive components where failure is not an option. These parts are concentrated in the most demanding areas of a vehicle, including the powertrain and chassis, which handle immense mechanical forces during operation. The strength and resilience imparted by the forging process are essential for the longevity and safety of these systems.

Forged parts are ubiquitous in a vehicle's powertrain, the system that generates and delivers power to the wheels. Here, components must endure high temperatures, constant friction, and cyclical stress. Some of the most common forged powertrain parts include:

- Crankshafts: As the backbone of an internal combustion engine, the crankshaft converts the linear motion of the pistons into rotational motion. It must withstand enormous forces, making the strength from forging indispensable.

- Connecting Rods: These link the pistons to the crankshaft and are under constant tension and compression. Forging ensures they have the fatigue resistance to last for hundreds of millions of cycles.

- Gears and Transmission Shafts: The components inside a vehicle's transmission are subjected to high torque and wear. Forged gears and shafts offer superior durability and reliability, ensuring smooth power transfer.

- Pistons: In high-performance engines, forged pistons are used for their ability to handle extreme heat and pressure without deforming or failing.

Beyond the powertrain, the chassis and suspension systems also rely heavily on forged components to ensure vehicle stability and passenger safety. These parts must absorb shocks from the road and manage the vehicle's weight. Key examples include steering knuckles, control arms, axle beams, and ball studs. Each of these parts plays a direct role in how the vehicle handles and responds, making the reliability of forged steel a critical engineering requirement.

The Automotive Steel Forging Process: From Raw Material to Finished Part

While the principle of shaping hot metal with pressure is ancient, modern automotive forging has evolved into several precise and highly specialized processes. The choice of method depends on the part's complexity, required strength, and production volume. Each technique offers distinct advantages for creating the high-performance components that vehicles rely on. Custom forging services, such as those offered by Shaoyi Metal Technology, provide IATF16949 certified solutions for the automotive industry, from prototyping to mass production, leveraging these advanced techniques.

One of the most common methods is Impression Die Forging, also known as closed-die forging. In this process, the heated steel workpiece is placed between two custom-made dies that contain a precise impression of the final part. A powerful hammer or press forces the dies together, causing the metal to flow and fill the entire cavity. This method is ideal for producing complex shapes with high dimensional accuracy and is used for parts like connecting rods and steering components. The high initial cost of creating the dies makes it most economical for large production runs.

Another key technique is Open-Die Forging, sometimes called smith forging. Here, the workpiece is shaped between two flat or simply shaped dies that do not fully enclose the metal. The operator, or an automated system, manipulates the workpiece between strikes to gradually form it into the desired shape. This process is highly versatile and suitable for creating large, simple shapes like bars and shafts or for low-volume custom parts where the cost of a complex impression die would be prohibitive.

Other specialized processes include Roll Forging and Cold Forging. Roll forging uses opposing rollers with shaped grooves to reduce the thickness and increase the length of a workpiece, often used for creating components like axles and leaf springs. Cold forging, in contrast, is performed at or near room temperature. While it requires more powerful machinery, it produces parts with excellent surface finish and dimensional accuracy, making it suitable for smaller, high-precision components.

Material Selection: Choosing the Right Steel for Automotive Forging

The performance of a forged automotive component is determined not only by the process but also by the material itself. The selection of the right type of steel is a critical engineering decision based on the part's specific application, required strength, weight targets, and cost considerations. The automotive industry primarily relies on a few key categories of steel, each offering a unique profile of properties tailored to different needs.

Carbon steel is a foundational material in automotive forging due to its excellent strength, good machinability, and cost-effectiveness. It is often used for components that require high durability but are not subjected to the most extreme stresses, such as certain gears and shafts. Its properties can be precisely controlled through the addition of carbon and by subsequent heat treatment processes, allowing for a balance of hardness and toughness.

For more demanding applications, manufacturers turn to alloy steel. By adding elements like chromium, nickel, and molybdenum to the steel, its properties can be significantly enhanced. Alloy steels offer superior strength, hardness, and wear resistance compared to carbon steels, making them ideal for high-stress components like crankshafts, connecting rods, and high-performance gears. Similarly, microalloy steels contain very small amounts of alloying elements, providing a strength boost while maintaining good machinability and cost efficiency.

In applications where corrosion resistance is paramount, such as in exhaust components or parts exposed to the elements, stainless steel is the preferred choice. The addition of chromium creates a passive oxide layer on the surface that protects the metal from rust and degradation. As the industry pushes for lighter vehicles to improve fuel efficiency and EV range, Advanced High-Strength Steels (AHSS) are also becoming more prevalent. These materials offer exceptional strength-to-weight ratios, allowing for the design of lighter parts without compromising safety or structural integrity.

Forging vs. Other Manufacturing Methods: A Comparative Advantage

While several methods exist for shaping metal, steel forging holds a distinct advantage for critical automotive applications, particularly when compared to casting and welding. These differences lie in the material's internal structure, overall durability, and manufacturing efficiency. Understanding these distinctions clarifies why forging is the mandated choice for components where structural failure could have severe consequences.

The most significant advantage of forging is its superior strength. As noted by industry experts, the forging process refines the grain structure of the steel, creating a continuous flow that follows the contour of the part. This grain alignment eliminates internal voids and weak points, resulting in exceptional tensile strength and fatigue resistance. In a direct comparison, a forged component is inherently stronger than a cast part of the same size and material, as casting can introduce porosity or inconsistencies in the grain structure. This structural integrity is why forged parts are preferred for high-stress applications.

When comparing forging to welding, the primary difference is the integrity of the bond. A forge weld creates a solid-state diffusion bond under heat and pressure, which is often stronger than a fusion weld where the metal is melted and re-solidified. A welded joint, no matter how well executed, can introduce a heat-affected zone that may become a point of weakness. Forging, by contrast, creates a single, monolithic component with a consistent internal structure, providing more predictable and reliable performance under load.

From a manufacturing perspective, forging also offers benefits in efficiency and sustainability. The process can produce parts in a near-net shape, meaning they are very close to their final dimensions. This drastically reduces the need for subsequent machining, which saves time, energy, and material. According to Trenton Forging, this reduction in waste and operating expense is a key advantage. While the initial tooling for impression-die forging can be expensive, for high-volume production, the lower material waste and reduced machining costs make it a highly economical choice.

The Unmatched Advantage of Forged Components

In conclusion, steel forging is not merely one of many manufacturing options for the automotive industry; it is a foundational process for ensuring vehicle safety, reliability, and performance. By manipulating the internal grain structure of steel through intense heat and pressure, forging creates components with unparalleled strength and fatigue resistance. This makes it an ideal choice for critical parts within the engine, transmission, and suspension systems, where failure could lead to catastrophic outcomes.

From crankshafts and connecting rods to steering knuckles and axle beams, forged parts provide the structural backbone that allows modern vehicles to operate safely under immense stress. As the automotive sector continues to evolve toward lighter, more efficient designs and electric powertrains, the need for high-strength, lightweight components will only increase. The adaptability of the forging process and the continuous development of advanced steel alloys ensure that this age-old technique will remain at the forefront of automotive innovation for years to come.

Frequently Asked Questions

1. What is forging in the automotive industry?

In the automotive industry, forging is a manufacturing process used to create high-strength metal components by heating steel to a malleable temperature and shaping it with compressive force from a hammer or press. It is used for critical parts like engine components (crankshafts, connecting rods), transmission parts (gears, shafts), and suspension components (control arms, steering knuckles) because the process produces parts that are exceptionally strong, durable, and resistant to failure.

2. What type of steel is used for automotive?

A variety of steels are used in automotive forging, selected based on the specific needs of the component. The main types include carbon steel for its balance of strength and cost, alloy steel (containing elements like chromium and nickel) for high-stress applications requiring superior strength and wear resistance, and stainless steel for parts needing excellent corrosion resistance. Advanced High-Strength Steels (AHSS) are also increasingly used to create lighter components without sacrificing strength.

3. What are the 4 types of forging processes?

While there are many variations, four common types of forging processes are impression die forging (or closed-die forging), open-die forging, roll forging, and cold forging. Impression die forging uses custom molds to create complex parts, open-die forging shapes metal between flat dies for simpler or larger parts, roll forging uses rollers to shape long components, and cold forging shapes metal at room temperature for high-precision parts.

4. Is forging stronger than welding?

Yes, forging generally produces a stronger component than welding. Forging shapes a single piece of metal, refining its internal grain structure to be continuous and aligned with the part's shape, which maximizes strength and fatigue resistance. Welding joins two or more pieces of metal by melting them, which can create a heat-affected zone that may be weaker than the parent material. A properly executed forge weld can be stronger than a fusion weld because it creates a solid-state bond across the entire surface.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —