Custom Forged Aluminum Car Parts: Strength Meets Precision

TL;DR

Custom forged aluminum car parts are high-strength, lightweight components produced by specialized manufacturers for demanding automotive applications. The forging process creates parts with a superior grain structure, making them significantly stronger and more durable than cast or machined alternatives. This results in enhanced vehicle performance, improved fuel efficiency, and exceptional reliability for critical components like wheels, suspension parts, and engine components.

The Superiority of Forged Aluminum for Automotive Components

When performance, safety, and efficiency are paramount, the choice of material and manufacturing process is critical. Forged aluminum stands out as a premier option for automotive components, offering a distinct set of advantages over traditional materials like steel or processes like casting. The forging process, which involves shaping aluminum alloys under immense pressure, refines the metal's internal grain structure, aligning it with the part's final shape. This metallurgical enhancement is the source of its superior qualities.

One of the most significant benefits is an exceptional strength-to-weight ratio. Forged aluminum parts can be as strong as certain steel components while being significantly lighter. This weight reduction is crucial in modern vehicles for improving fuel economy, reducing emissions, and enhancing handling dynamics by lowering unsprung mass. Furthermore, the forging process eliminates common defects found in casting, such as porosity, shrinkage, and blowholes, resulting in a denser, more uniform material with outstanding durability and fatigue resistance. This makes forged parts ideal for high-stress applications like suspension arms, brake calipers, and wheels, where failure is not an option.

The precision achieved through impression die forging (a common method for custom parts) also means that components can be manufactured to near-net shapes. This minimizes the need for extensive secondary machining, saving both time and cost in the production cycle. The resulting components feature tight tolerances and excellent surface finishes, contributing to both performance and aesthetics. Below is a comparison highlighting the key differences between forged and cast aluminum.

| Feature | Forged Aluminum | Cast Aluminum |

|---|---|---|

| Strength & Durability | Superior due to refined, continuous grain structure. High fatigue and impact resistance. | Lower strength due to random grain orientation and potential for internal defects like porosity. |

| Weight | Higher strength allows for lighter part designs for the same performance level. | Often requires more material (and thus more weight) to achieve comparable strength. |

| Structural Integrity | Non-porous and free from hidden voids, ensuring maximum reliability. | Can suffer from porosity, shrinkage, and other casting defects that create weak points. |

| Performance | Ideal for high-stress, safety-critical applications where failure is not an option. | Suitable for less critical components with lower stress loads. |

| Cost | Higher initial tooling cost, but can be cost-effective for high-volume runs due to less material waste and machining. | Lower tooling cost, making it viable for complex shapes in smaller quantities. |

Understanding the Custom Aluminum Forging Process

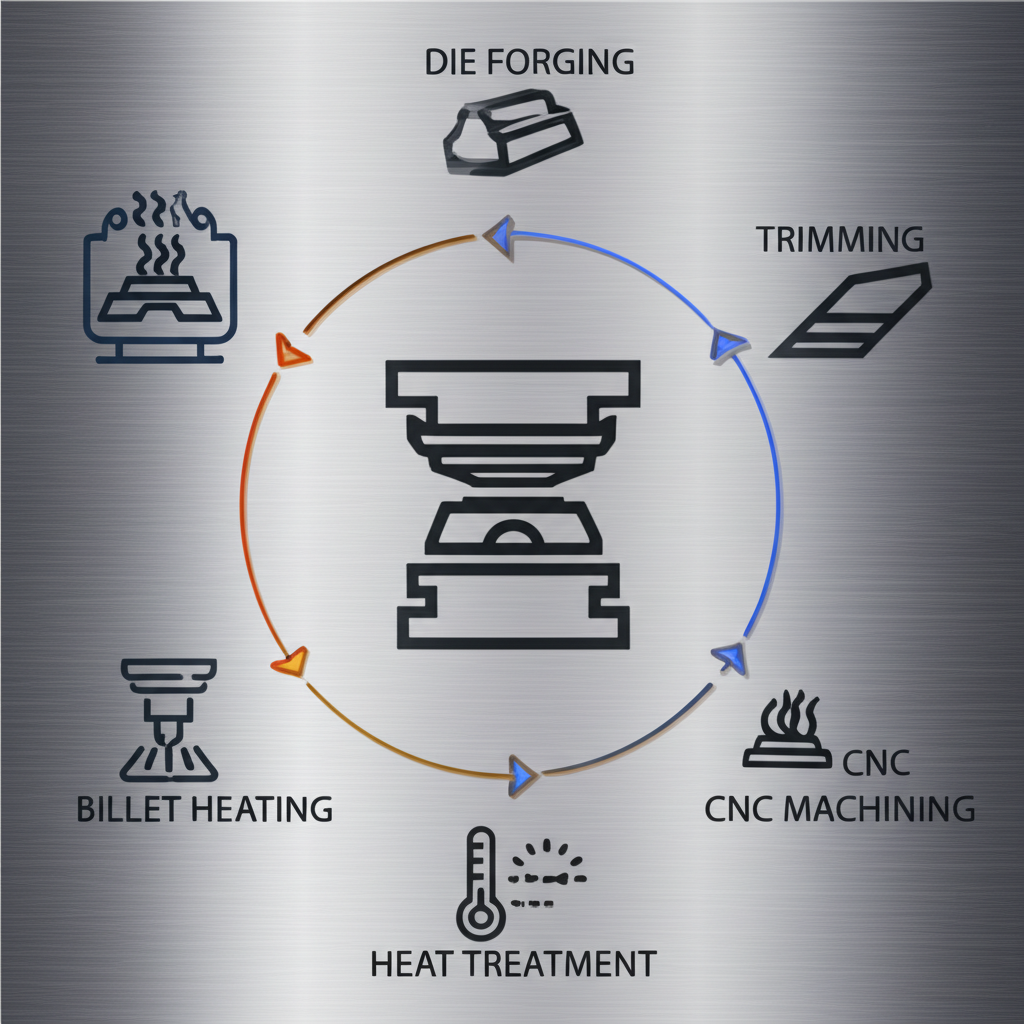

Creating a custom forged aluminum part is a sophisticated engineering process that transforms a simple aluminum billet into a high-performance component. While aluminum is more malleable than steel, it requires precise temperature control to achieve the desired mechanical properties without introducing defects. The most common method for producing complex automotive parts is impression die forging, also known as closed-die forging. This technique uses two custom-made dies that completely enclose the workpiece, forcing the heated metal to conform to the die's exact shape. The typical journey from concept to finished part involves several key stages.

The process is meticulous, ensuring each part meets exacting specifications for strength, weight, and dimensional accuracy. Each step builds upon the last to create a component that is structurally superior to its cast or machined counterparts.

- Design & Engineering: The process begins with a detailed 3D model and technical drawings of the final part. Engineers analyze the design for forgeability, ensuring the geometry allows for proper material flow within the die. This stage is critical for optimizing strength and minimizing material waste.

- Tool & Die Creation: Based on the final design, specialized dies are machined from high-strength tool steel. These dies are a negative impression of the desired part. The precision of the die is essential for the dimensional accuracy of the final forging.

- Billet Heating: A solid block of a specific aluminum alloy, known as a billet, is cut to size and heated in a furnace to a precise temperature. This temperature makes the aluminum malleable but is carefully controlled to be below its melting point to maintain its structural integrity.

- The Forging Operation: The heated billet is placed on the bottom die. A powerful forging press or hammer then forces the top die down onto the billet with immense pressure, squeezing the metal and forcing it to fill every cavity of the die impression. This action refines the grain structure of the aluminum.

- Post-Forging Treatments: After forging, the part undergoes several finishing steps. This includes trimming away excess material (flash), heat treatment (like T6 tempering) to achieve the desired hardness and strength, and surface finishing such as shot blasting or CNC machining for final dimensional precision.

Key Factors in Choosing a Custom Forging Manufacturer

Selecting the right manufacturing partner is as crucial as the forging process itself. A supplier's capabilities directly impact the quality, performance, and reliability of the final components. When evaluating potential manufacturers for your custom forged aluminum parts, it's essential to look beyond the price and consider their technical expertise, quality systems, and overall capacity. A strong partner acts as a collaborator, offering design feedback and material suggestions to optimize your component for both performance and manufacturability.

For robust and reliable automotive components, for instance, a manufacturer like Shaoyi Metal Technology exemplifies the qualities to look for. They specialize in high-quality, IATF 16949 certified hot forging for the automotive industry, which is a critical quality standard. Look for companies that offer a comprehensive service, from initial design support and in-house die manufacturing to a full range of post-forging treatments. Material expertise is also non-negotiable. A top-tier supplier should have deep knowledge of various aluminum alloys, such as the 2000, 6000, and 7000 series, and be able to recommend the ideal alloy for your specific application's stress, temperature, and corrosion resistance requirements.

Finally, consider their quality control and logistical capabilities. A manufacturer should have rigorous inspection processes at every stage. Certifications like IATF 16949 for automotive or AS9100 for aerospace indicate a commitment to the highest quality standards. A strategic location and efficient logistics can also ensure timely delivery, which is vital for keeping production schedules on track. Before making a final decision, use the following checklist to guide your evaluation.

- Engineering & Design Support: Do they offer design for manufacturability (DFM) analysis to optimize your part for the forging process?

- Material Expertise: Can they source and work with the specific aluminum alloy your application requires (e.g., 6061, 7075, 2014)?

- Quality Certifications: Do they hold relevant industry certifications, such as IATF 16949 for automotive?

- In-House Capabilities: Do they manage the entire process, including die creation, heat treating, and precision machining, in-house?

- Production Capacity: Can they handle your required volume, from small-batch prototypes to large-scale production runs?

- Track Record & Experience: Do they have a proven history of producing similar components for your industry?

Common Applications and Innovations in Forged Automotive Parts

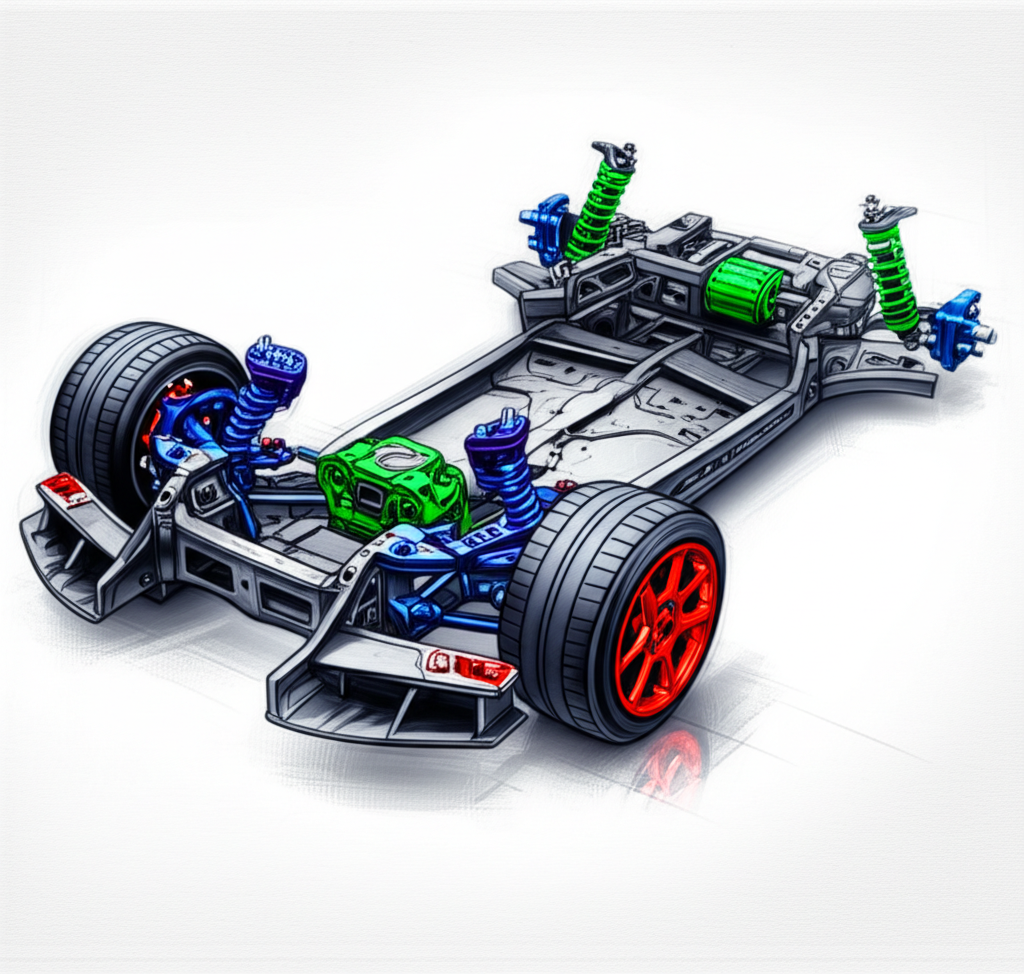

The unique combination of strength, light weight, and reliability makes forged aluminum the material of choice for a wide array of critical automotive components. While custom forged wheels are perhaps the most well-known application, the technology is integral to nearly every system in a modern vehicle, from the chassis to the powertrain. The use of these advanced components is a key strategy for automakers to enhance performance, improve safety, and meet increasingly stringent efficiency standards.

In suspension and chassis systems, forged aluminum is used for parts like control arms, steering knuckles, ball joint housings, and tie rod ends. These components are subjected to constant stress and impact, and the superior fatigue resistance of forging ensures their long-term durability and safe operation. In the powertrain, forged aluminum pistons, connecting rods, and crankshafts are essential for high-performance engines, where they must withstand extreme temperatures and mechanical forces while minimizing reciprocating mass for higher RPMs and better engine response.

The innovation is not limited to traditional vehicles. The rise of new energy vehicles (NEVs) and electric vehicles (EVs) has further expanded the applications for forged aluminum. In EVs, lightweighting is even more critical to maximize battery range and offset the weight of the battery pack. Forged aluminum is used for motor housings, battery enclosure components, and various structural elements. The simplicity of EV designs, with fewer moving parts, makes the high-performance and reliability of forged components an even more attractive and cost-effective solution for ensuring long-term vehicle integrity.

Frequently Asked Questions

1. Is forged aluminum better?

Yes, for most performance-critical applications, forged aluminum is significantly better than cast aluminum. The forging process refines the metal's grain structure, eliminating porosity and enhancing its strength, ductility, and resistance to impact and fatigue. This results in components that are both stronger and more reliable than their cast counterparts.

2. Can you forge aluminum like steel?

While both metals can be forged, the process differs. Aluminum has a lower forging temperature than steel and a narrower temperature range in which it can be effectively shaped. It requires very careful temperature control to avoid defects like cracking. However, aluminum is also more malleable than steel, allowing it to be formed into complex shapes with less pressure.

3. What are the 4 types of forging?

The four main types of forging processes are open-die forging, impression die (or closed-die) forging, cold forging, and seamless rolled ring forging. Impression die forging is the most common method for producing complex, custom automotive parts with high precision. Cold forging is done at or near room temperature and is used for softer metals to create parts with excellent surface finish and dimensional accuracy.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —