Aerospace Sheet Metal Fabrication: From Raw Alloy To Flight-Ready Parts

Understanding Aerospace Sheet Metal Fabrication Fundamentals

What transforms a simple flat sheet of aluminum into a critical aircraft component capable of withstanding extreme forces at 35,000 feet? The answer lies in aerospace sheet metal fabrication—a specialized manufacturing discipline that converts raw metal sheets into precision components for aircraft and spacecraft applications. Unlike general industrial metalwork, this process demands an uncompromising commitment to accuracy, with tolerances often measured in thousandths of an inch.

Imagine you're building a puzzle where every piece must fit perfectly, and a single misaligned edge could compromise the entire structure. That's the reality facing aerospace fabricators every day. This specialized field combines advanced engineering, rigorous material science, and meticulous quality control to produce parts that quite literally keep people safe in the sky.

What Sets Aerospace Fabrication Apart from Industrial Metalwork

You might wonder: isn't sheet metal fabrication essentially the same across all industries? Not quite. While a commercial HVAC duct might tolerate variations of 1/16 inch or more, aerospace fabrication typically requires tolerances of ±0.005 inches or tighter for critical dimensions. This extreme precision isn't optional—it's mandatory.

Three key factors distinguish aerospace fabrication from its industrial counterparts:

- Material specifications: Aerospace-grade alloys must meet stringent chemical composition and mechanical property requirements, with full traceability from mill to finished part

- Regulatory oversight: Compliance with FAA regulations, AS9100D certification, and Aerospace Material Specifications (AMS) governs every step of the manufacturing process

- Quality verification: Non-destructive testing, comprehensive documentation, and in-process inspections are standard requirements rather than optional add-ons

According to Pinnacle Precision, precision is paramount in this field because the intricate components must adhere to strict tolerances and quality standards to ensure the structural integrity and reliability of final products.

The Critical Role of Sheet Metal in Flight-Ready Components

Every aerospace fabrication decision revolves around three interconnected pillars: structural integrity, weight optimization, and aerodynamic performance. These aren't competing priorities—they're inseparable requirements that must be balanced in every component.

Consider an aircraft fuselage skin panel. It must be strong enough to withstand pressurization cycles, light enough to maximize fuel efficiency, and precisely shaped to maintain aerodynamic properties. Achieving all three requires deep fabrication knowledge that goes far beyond standard manufacturing techniques.

In aerospace manufacturing, even the smallest error can have significant consequences. The industry operates under some of the strictest standards, where components must consistently meet exacting tolerances to ensure safety and performance.

This insight from Mitutoyo's aerospace manufacturing guide underscores why aerospace fabrication demands such extraordinary attention to detail. A minor dimensional deviation in a wing spar or a slight material inconsistency in an engine mount could compromise an entire aircraft's airworthiness.

The stakes extend beyond individual components. Each fabricated part must integrate seamlessly with thousands of other precision elements—from hydraulic system brackets to structural bulkheads. This systems-level thinking separates aerospace fabrication specialists from general metal fabricators and explains why certifications, traceability protocols, and continuous improvement processes are woven into every aspect of the discipline.

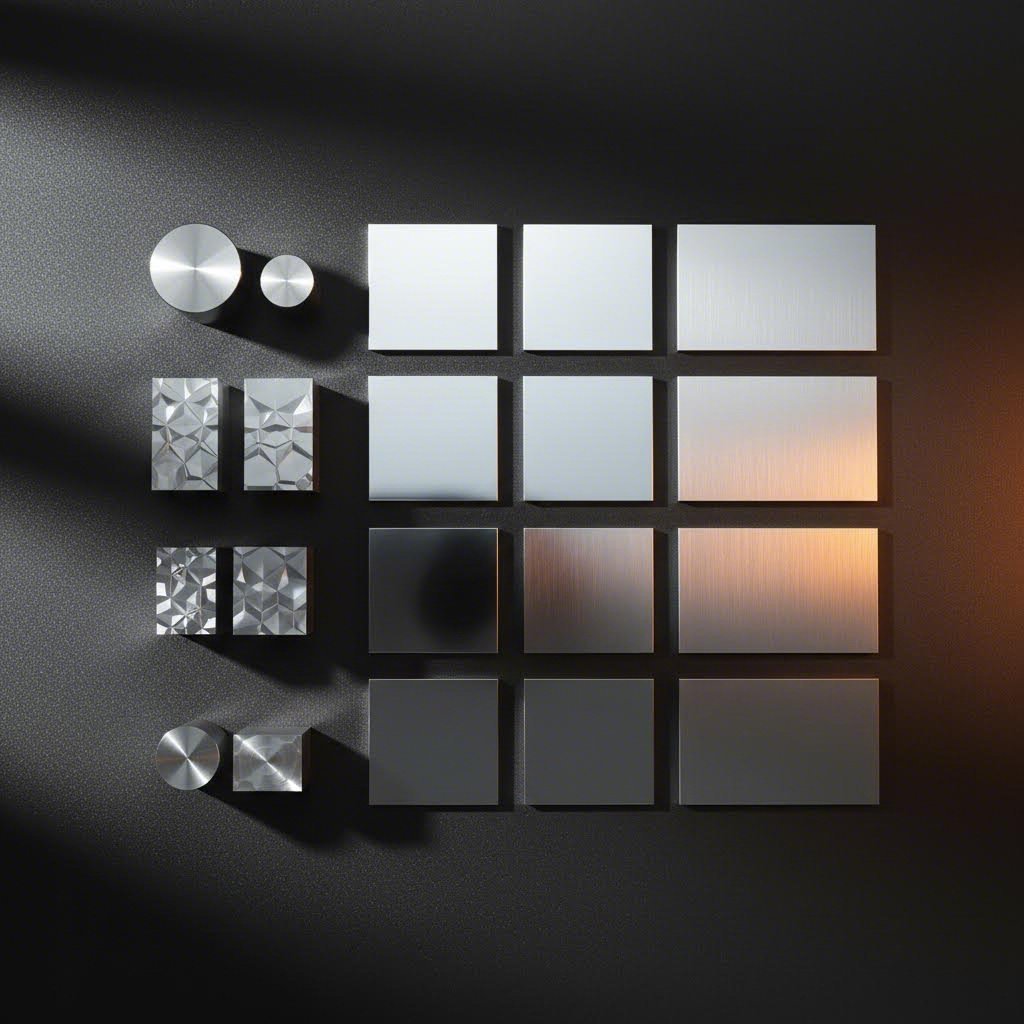

Aerospace-Grade Materials and Selection Criteria

So how does an engineer decide which metal belongs in a wing spar versus a turbine shroud? The answer starts with understanding that aerospace metal selection isn't guesswork—it's a precise calculation balancing performance requirements against fabrication constraints. Each alloy family brings distinct advantages, and selecting the wrong material can mean the difference between a flight-ready component and an expensive scrap pile.

When an aircraft component is fabricated from an aluminum alloy, the choice reflects careful analysis of operating conditions. Will the part experience repeated stress cycles? Does it require welding during assembly? Must it withstand temperatures exceeding 300°F? These questions drive material decisions that cascade through every subsequent fabrication step.

Aluminum Alloys and Their Aircraft Applications

Aluminum alloys dominate metal aerospace applications, and for good reason. They offer an exceptional strength-to-weight ratio combined with excellent corrosion resistance and proven fabrication characteristics. However, not all aerospace aluminum is created equal—three alloys stand out for distinct applications.

2024 Aluminum: This Al-Cu-Mn alloy serves as the workhorse for fatigue-critical structures. According to Aircraft Aluminium, 2024 is a high-strength hard aluminum that can be strengthened through heat treatment, offering medium plasticity in quenched states with good spot welding performance. You'll find it in skeleton parts, skins, bulkheads, ribs, spars, and rivets—essentially the structural backbone of aircraft. One limitation: its corrosion resistance isn't exceptional, so fabricators typically specify anodic oxidation or painting for protection.

6061 Aluminum: Need weldability without sacrificing structural integrity? This Al-Mg-Si alloy delivers excellent processing performance with superior welding characteristics. It's the go-to choice for aircraft skins, fuselage frames, girders, rotors, propellers, and even rocket forging rings. While its raw strength can't match 2xxx or 7xxx series alloys, 6061 offers compact, defect-free material that polishes beautifully and produces excellent anodizing results.

7075 Aluminum: When maximum strength matters most, this Al-Zn-Mg-Cu cold-treated forging alloy steps up. It's better than mild steel in strength characteristics after heat treatment, making it ideal for mold processing, mechanical equipment, and high-stress aircraft structures. The trade-off? Higher zinc and magnesium content increases tensile strength but reduces stress corrosion and exfoliation corrosion resistance.

| Material | Tensile Strength | Density | Max Service Temp | Key Characteristics | Typical Aerospace Applications |

|---|---|---|---|---|---|

| 2024 Aluminum | ~470 MPa | 2.78 g/cm³ | 150°C (300°F) | Excellent fatigue resistance, good machinability | Fuselage skins, wing structures, rivets, bulkheads |

| 6061 Aluminum | ~310 MPa | 2.70 g/cm³ | 150°C (300°F) | Superior weldability, excellent anodizing | Fuel tanks, landing gear pillars, spacecraft wall panels |

| 7075 Aluminum | ~570 MPa | 2.81 g/cm³ | 120°C (250°F) | Highest strength aluminum, cold-forged | Wing spars, high-stress fittings, tooling fixtures |

| Ti-6Al-4V (Grade 5) | ~950 MPa | 4.43 g/cm³ | 315°C (600°F) | Outstanding strength-to-weight, biocompatible | Engine mounts, firewalls, high-temp structural parts |

| Inconel 625 | ~830 MPa | 8.44 g/cm³ | 1093°C (2000°F) | Extreme heat/corrosion resistance | Turbine blades, exhaust systems, combustion chambers |

| 316 Stainless Steel | ~580 MPa | 8.00 g/cm³ | 870°C (1600°F) | Excellent corrosion resistance, formable | Hydraulic fittings, fasteners, exhaust components |

When Titanium and Superalloys Become Essential

Aluminum handles most airframe applications beautifully—until temperatures climb or corrosive environments enter the picture. That's when aerospace metal fabricators turn to titanium and nickel-based superalloys.

Titanium Alloys: Picture components sitting near jet engines or in high-temperature zones where aluminum would simply lose strength. Titanium, particularly Grade 5 (Ti-6Al-4V), maintains 80% of its yield strength up to 600°F according to PartMFG's metal strength analysis. Its density of 4.43 g/cm³ makes it 40% lighter than steel while delivering 950 MPa tensile strength. You'll find it in engine mounts, firewalls, and structural components exposed to elevated temperatures.

Inconel Superalloys: When conditions get truly extreme—think jet engine combustion chambers operating at 2000°F—Inconel becomes essential. This nickel-chromium superalloy retains strength at temperatures where other metals would fail catastrophically. As noted by YICHOU's materials comparison, Inconel excels in turbine blades, exhaust systems, and nuclear reactor components. The trade-off? It's expensive, difficult to machine, and significantly heavier than aluminum alternatives.

Stainless Steel Grades: For applications demanding corrosion resistance without titanium's cost, aerospace-grade stainless steels fill the gap. Type 316 offers excellent resistance to saltwater and chemical exposure, making it suitable for hydraulic fittings and fasteners. Its 580 MPa tensile strength and formability characteristics provide fabricators with reliable processing options.

How Thickness Selection Drives Fabrication Methods

Material choice is only half the equation—thickness selection directly impacts which fabrication processes are viable. Aerospace sheet metal typically ranges from thin gauge skins (0.016" to 0.040") up to thicker structural members (0.125" to 0.250" or more).

Thin gauge materials—commonly used for fuselage skins and fairings—require careful handling to prevent distortion during forming. These sheets respond well to stretch forming and hydroforming, where uniform pressure distribution minimizes localized stress concentrations.

Thicker structural members demand different approaches. Press brake operations become practical, and springback compensation calculations grow more critical as material thickness increases. A 0.190" 7075 aluminum plate behaves very differently under bending loads than a 0.032" 2024 skin panel, requiring adjusted tooling and process parameters.

Understanding these material-thickness relationships prepares fabricators for the forming and bending challenges that transform flat sheets into complex aerospace geometries.

Forming and Bending Processes for Aircraft Components

How do fabricators transform a flat aluminum sheet into a curved fuselage panel that maintains structural integrity under thousands of pressurization cycles? The answer lies in specialized aerospace metal forming & bending techniques—each designed to achieve complex geometries while preserving the material properties that keep aircraft safe.

Unlike industrial forming where minor imperfections might pass inspection, aircraft sheet metal demands processes that control every variable. Grain structure, surface finish, and dimensional accuracy must survive the transformation from flat stock to flight-ready component. Let's explore how modern fabricators accomplish this.

Precision Forming Techniques for Complex Aerospace Geometries

Each aerospace metal fabrication method offers distinct advantages depending on part geometry, production volume, and material characteristics. Understanding when to apply each technique separates experienced fabricators from general metalworking shops.

Stretch Forming: Imagine gripping a sheet at both ends and pulling it over a curved die while simultaneously pressing it into shape. That's stretch forming in essence. According to LMI Aerospace, this technique provides better shape control, structural integrity, and surface quality than other metal forming methods. It excels at producing fuselage skins, leading edges, and large curved panels where surface smoothness is critical. The stretching action works the entire sheet uniformly, reducing residual stresses that could cause warping later.

Hydroforming: Picture hydraulic fluid pressing a sheet into a die cavity with uniform pressure from all directions. This process creates complex shapes impossible to achieve with conventional stamping—think compound curves, deep draws, and intricate contours. The fluid pressure distributes evenly across the workpiece, minimizing thinning and maintaining consistent wall thickness throughout the part.

Roll Forming: For components requiring consistent cross-sections—stringers, channels, and curved structural members—roll forming passes sheet metal through successive roller stations. Each station progressively shapes the material until the final geometry emerges. This continuous process delivers excellent repeatability and handles longer workpieces than press-based methods.

Press Brake Operations: When sharper bends and angular geometries are needed, CNC press brakes provide precise control over bend angle, location, and sequence. Modern aerospace press brakes achieve positioning accuracy within ±0.0004 inches, enabling the tight tolerances critical structural components demand.

Controlling Springback in High-Strength Alloys

Here's a challenge that frustrates many fabricators: you execute a perfect bend, release the tooling pressure, and watch the metal partially return toward its original shape. This phenomenon—springback—represents one of aerospace forming's most critical variables.

As explained in research from Inductaflex, springback occurs because part of the deformation during bending remains elastic rather than plastic. The metal "remembers" its original shape and tries to return to it. In tight-tolerance aerospace applications, even a few degrees of rebound can create serious assembly problems—misalignment, rework, or compromised structural integrity.

Different alloys behave very differently:

- 6061-T6: Popular and versatile with manageable springback—bends well when properly compensated

- 7075-T6: Extremely strong but problematic for tight-radius bends due to brittleness; often formed in softer tempers (T73 or W) then heat-treated

- 5xxx series (like 5083): Naturally bends well with minimal rebound, making it reliable for forming work

Fabricators combat springback through several proven strategies:

- Overbending: Intentionally bending past the target angle so springback brings the part to specification

- Mandrels and wiper dies: Maintaining shape control during the bending operation itself

- Controlled heating: Localized induction or resistance heating softens the material and guides plastic flow—though excessive heat can permanently alter strength properties in alloys like 6061-T6

- CNC compensation: Multi-axis systems that correct angles in real-time as the bend progresses

Key Forming Considerations for Aerospace Applications

Beyond springback, successful aerospace forming requires attention to multiple interconnected factors. Miss any one of these, and you risk scrapping expensive material or—worse—producing parts that fail inspection.

- Material grain orientation: Bending perpendicular to the rolling direction typically produces better results with less cracking risk; improper grain alignment increases springback and can cause surface defects

- Tooling requirements: Aerospace forming demands hardened tool steel dies with precisely ground radii; worn tooling introduces dimensional variations that compound across production runs

- Heat treatment effects: Solution treatment and aging schedules affect formability dramatically—some alloys must be formed in softer conditions then heat-treated to final temper

- Surface finish preservation: Protective films, specialized lubricants, and careful handling prevent scratches and tool marks that could become stress concentrators in service

- Minimum bend radii: Each alloy-temper combination has specific limits; violating them causes cracking, orange peel texture, or hidden micro-fractures

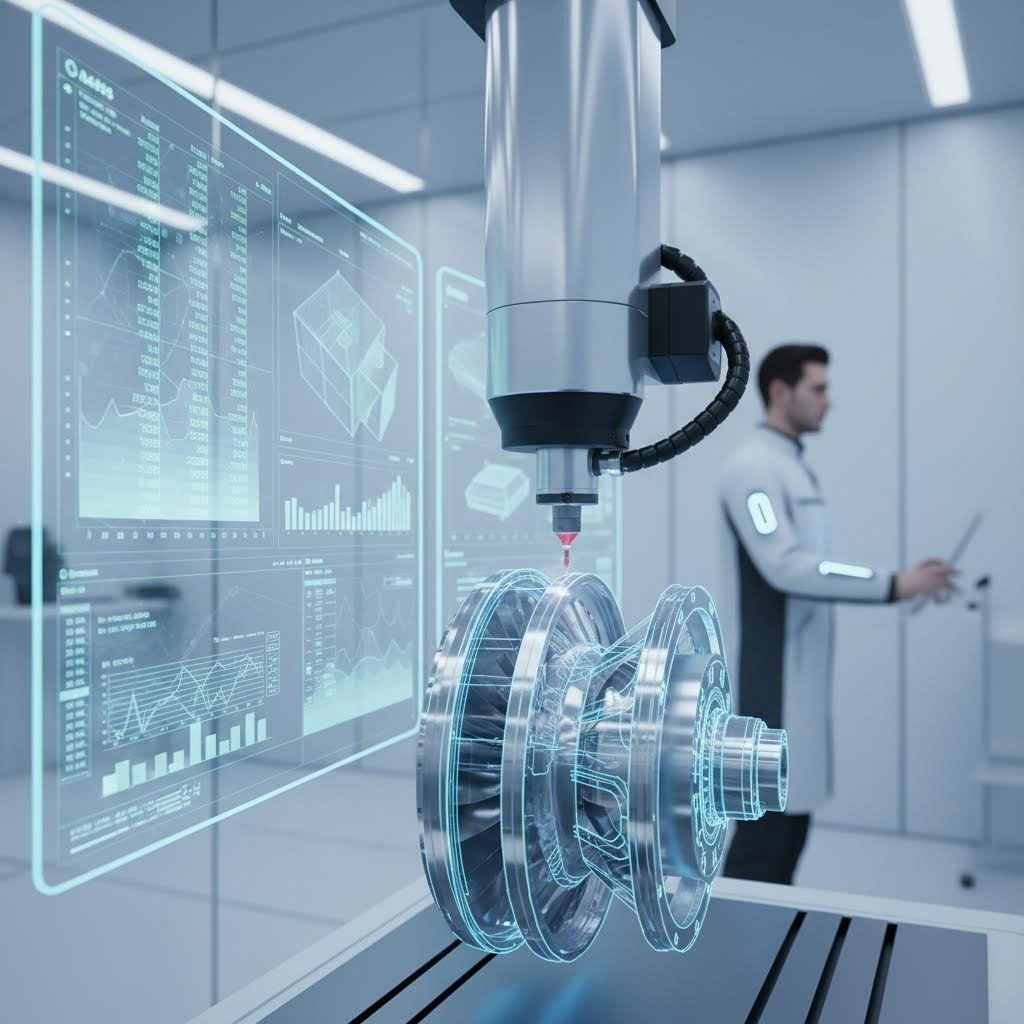

Achieving and Verifying Aerospace Tolerances

Aerospace components typically require tolerances of ±0.005" or tighter for critical dimensions. How do fabricators consistently hit these marks—and prove they've done so?

Modern verification starts during the process itself. CNC forming equipment with integrated sensors monitors bend angle, force, and position in real-time. Any deviation triggers immediate correction or stops production before defective parts accumulate.

Post-forming inspection employs coordinate measuring machines (CMMs), optical comparators, and laser scanning systems. According to Approved Sheet Metal's inspection guidance, each tight tolerance requires careful measurement using calibrated, high-precision equipment—a ±0.002" tolerance takes significantly more inspection time than a ±0.010" feature.

First article inspections (FAIs) validate that production processes can consistently meet specifications before full runs begin. Smart fabricators focus FAI efforts on forming dimensions rather than laser-cut features, since forming introduces the greatest variation potential. This targeted approach cuts inspection time while maintaining quality assurance where it matters most.

With forming processes mastered, fabricators face another challenge: scaling precision across high-volume production. That's where stamping operations enter the picture, offering repeatable accuracy for structural aircraft parts manufactured in quantity.

Aircraft Components Stamping and Production Methods

When aerospace manufacturers need thousands of identical brackets, terminals, or structural fittings—each meeting the same exacting specifications—forming processes alone can't deliver the required consistency and throughput. That's where aircraft components stamping becomes indispensable. This high-volume production method transforms flat sheet stock into complex three-dimensional parts through precisely engineered dies, achieving repeatability that manual forming simply cannot match.

Sounds straightforward? Consider this: a single progressive die might execute blanking, punching, forming, and trimming operations in rapid sequence—sometimes reaching 1,500 strokes per minute according to Wiegel Manufacturing. At those speeds, even microscopic variations in tooling or material properties can cascade into serious quality problems. That's why aircraft components metal stamping demands specialized approaches that go far beyond standard industrial practices.

High-Volume Stamping for Structural Aircraft Parts

Why choose stamping over other forming methods? The answer comes down to three factors: volume, consistency, and cost-per-part economics. When production requirements reach thousands or millions of pieces annually, stamping's automated precision delivers advantages that manual or low-volume processes cannot replicate.

Progressive Die Stamping: Imagine a metal strip advancing through a series of stations, each performing a specific operation—blanking the outline, punching holes, forming flanges, and trimming excess material. By the time the strip exits, a completed part drops free. According to Wiegel's aerospace capabilities, progressive die high-speed stamping incorporates state-of-the-art vision systems and sensor technology to ensure 100% quality control at speeds reaching 1,500 strokes per minute.

Deep Drawing: When components require depth—cups, housings, shields, or enclosures—deep drawing pulls material into die cavities through controlled plastic deformation. As Aerostar Manufacturing explains, this process places blanks over die cavities, uses lubricants to reduce friction and tearing, and controls blank holder pressure to prevent wrinkling. Multi-stage deep drawing handles complex geometries that single operations cannot achieve.

Precision Blanking: Every stamping operation begins with accurate blanks—flat cutouts that establish the part's perimeter before subsequent forming. Aerospace blanking optimizes nesting patterns to maximize material yield while maintaining the tight dimensional control that downstream operations require. Even a few thousandths of variation at this stage compounds through every subsequent step.

Airplane sheet metal components produced through these methods include busbars, compression limiters, fasteners, engine components, lead frames, shields, terminals, contacts, and connectors—essentially the electrical and structural elements that integrate into larger aircraft systems.

Precision Die Design for Aerospace Tolerances

What separates aerospace stamping from automotive or industrial applications? The differences appear at every level—from tooling materials to inspection frequency to documentation requirements.

Tighter tolerances: While automotive stamping might accept ±0.010" variations on non-critical dimensions, aerospace components often demand ±0.005" or tighter. According to Jennison Corporation's industry analysis, aerospace metal stamping applications require not only technical excellence but also complete traceability and compliance with FAA, NASA, and DOD requirements.

Specialized tooling materials: Dies for aerospace stamping are machined from hardened tool steels and undergo heat treatment to maintain edge sharpness through extended production runs. As Aerostar's process documentation notes, CAD/CAM software designs dies accounting for springback, clearance, and tool wear—factors that directly impact dimensional consistency over time.

Enhanced quality verification: Camera vision systems inspect critical dimensions at production speeds, flagging deviations before defective parts accumulate. Wiegel's aerospace operations utilize Zeiss CMMs, OGP smart scopes, and dedicated sensor technology to monitor stamping parts both in-line and off production lines.

The material selection for aerospace stamping extends beyond common aluminum to include copper, brass, phosphor bronze, beryllium copper, stainless steel, titanium, and even exotic alloys like Inconel and Hastelloy. Each material demands specific die clearances, lubrication strategies, and forming speeds to achieve consistent results.

When Stamping Makes Sense: Design and Volume Considerations

How do engineers decide between stamping and other fabrication methods? The decision matrix weighs several interconnected factors:

- Production volume: Stamping's tooling investment typically requires annual quantities in the thousands to achieve cost-effectiveness; low-volume runs favor laser cutting, forming, or machining

- Part complexity: Progressive dies excel at parts requiring multiple operations—holes, bends, cutouts, and formed features—executed in sequence

- Material considerations: Formable alloys with predictable springback characteristics respond well to stamping; brittle or work-hardening materials may require alternative approaches

- Dimensional criticality: When tolerances demand consistency across thousands of parts, stamping's repeatability outperforms manual methods

- Secondary operation requirements: Parts needing plating, heat treatment, or assembly integrate efficiently with stamping production flows

The Stamping Process Sequence

From raw material to inspected component, aerospace stamping follows a structured sequence that builds quality into every stage:

- Design and planning: Engineers create CAD models, run finite element analysis to simulate stresses, and plan production methods—progressive, transfer, or line die—based on volume requirements

- Material selection and verification: Raw material is verified against ASTM/ISO specifications, with full documentation of tensile strength, ductility, and chemical composition

- Die design and fabrication: CAD/CAM software generates die geometry accounting for springback and clearance; hardened tool steels are machined and heat-treated

- Blanking: Sheet or coil stock feeds into the press; dies shear material into pre-cut shapes with optimized nesting to reduce scrap

- Punching: Holes, slots, and cutouts are created with maintained punch/die clearance to avoid burrs or deformation

- Forming: Bending, curling, and stretching operations create three-dimensional shapes; springback is controlled through optimized tooling design

- Drawing: For depth-requiring components, material is pulled into die cavities with controlled blank holder pressure

- Trimming: Excess material and flash are removed to achieve final edge dimensions within tolerance limits

- Secondary operations: Deburring, plating, tapping, welding, or coating operations prepare parts for final assembly

- Quality control and inspection: CMM measurements, visual inspections, and destructive/non-destructive testing validate compliance with specifications

This systematic approach—refined through decades of aerospace manufacturing experience—ensures that every stamped component meets the stringent requirements that airworthiness demands. But producing quality parts is only part of the equation. Fabricators must also demonstrate compliance through documented quality systems and certifications that aerospace customers require.

Quality Certifications and Compliance Standards

You've seen how aerospace fabricators achieve tight tolerances through specialized forming and stamping processes. But here's the question that keeps procurement managers up at night: how do you know a fabricator can consistently deliver that quality? The answer lies in certifications—documented proof that a supplier has implemented rigorous quality management systems capable of meeting aerospace's unforgiving standards.

Aviation sheet metal fabrication operates under one of the most demanding regulatory frameworks in manufacturing. According to the Americas Aerospace Quality Group (AAQG) Spring 2024 meeting statistics, 96% of AS9100 series certified companies have fewer than 500 employees. This isn't just a standard for aerospace giants—it's essential for suppliers at every level of the supply chain.

AS9100D Requirements for Fabrication Facilities

What exactly does AS9100D certification demand from aircraft sheet metal fabrication shops? Released on September 20, 2016, this standard builds upon ISO 9001:2015 foundations while adding numerous aerospace-specific requirements that address the industry's unique safety, reliability, and regulatory demands.

Think of AS9100D as ISO 9001 with aerospace teeth. While both require documented quality management systems, AS9100D goes further with mandatory components including:

- Operational risk management: Systematic approaches to identifying, assessing, and mitigating risks throughout product lifecycles—not optional, but required

- Configuration management: Ensuring product integrity and traceability from design through disposal, with documented verification at every stage

- Counterfeit parts prevention: Comprehensive systems to prevent, detect, and respond to unauthorized or fraudulent components entering the supply chain

- Product safety requirements: Systematic identification and control of safety risks where failures could result in loss of life or mission failure

- Human factors consideration: Addressing how human performance affects quality outcomes in manufacturing processes

Major aerospace manufacturers—Boeing, Airbus, Lockheed Martin, and Northrop Grumman—require AS9100 compliance as a condition of doing business. Certified organizations gain access to aerospace supply chains through the IAQG OASIS database, where potential customers can easily identify qualified suppliers.

Building a Compliant Quality Management System

Imagine every component in your shop having a complete biography—where the raw material originated, what tests it passed, who performed each operation, and what inspections verified conformance. That's the level of traceability aerospace metal fabrication services must maintain.

A compliant quality management system connects safety requirements directly to specific fabrication practices:

Material certification verification: Before fabrication begins, incoming materials undergo inspection to verify they meet required quality standards. According to AMREP Mexico's quality control analysis, this includes checks for material composition, strength, and durability. Materials failing to meet specifications are rejected—no exceptions.

In-process inspection protocols: Quality control doesn't end with incoming materials. Throughout manufacturing, regular inspections check for deviations from specifications. These include visual checks, dimensional measurements, and verification against engineering drawings at defined checkpoints.

Non-destructive testing requirements: NDT plays a crucial role in aerospace component inspection. Common methods include:

- Ultrasonic testing: Detecting internal flaws through sound wave reflection

- X-ray inspection: Revealing porosity, cracks, or inclusions invisible to surface examination

- Eddy current testing: Identifying surface and near-surface defects in conductive materials

- Dye penetrant inspection: Exposing surface-breaking cracks and discontinuities

Documentation standards: Every component must be tracked through every production stage. This includes documenting raw materials, manufacturing processes, inspections, and test results. As noted in aerospace quality control best practices, traceability ensures that if a defect is discovered later, it can be traced back to its source—whether a specific material batch or particular manufacturing process.

The standard emphasizes defect prevention, variation reduction, and waste elimination throughout aerospace supply chains, directly supporting the industry's zero-tolerance approach to quality failures.

Comparing Quality Certifications Across Industries

How do different quality certifications stack up? Understanding the relationships between AS9100D, ISO 9001:2015, and IATF 16949 helps manufacturers serving multiple industries leverage their existing quality systems.

| Requirement Category | ISO 9001:2015 | IATF 16949 (Automotive) | AS9100D (Aerospace) |

|---|---|---|---|

| Base Standard | Foundation standard | Builds on ISO 9001 | Builds on ISO 9001 |

| Industry Focus | General manufacturing | Automotive supply chain | Aviation, space, defense |

| Risk Management | Risk-based thinking required | FMEA mandatory | Operational risk management mandatory |

| Product Safety | General requirements | Product safety emphasis | Critical safety requirements with life/mission implications |

| Configuration Management | Not specifically required | Change management focus | Mandatory throughout product lifecycle |

| Counterfeit Prevention | Not addressed | Not specifically addressed | Comprehensive prevention protocols required |

| Supplier Quality | Supplier evaluation required | Supplier development emphasis | Rigorous supplier qualification and monitoring |

| Traceability | Where appropriate | Full traceability required | Complete traceability mandatory |

| Customer Requirements | Customer focus | Customer-specific requirements | Regulatory compliance (FAA, EASA, DOD) |

| Certification Database | Various registrars | IATF database | OASIS database |

According to TUV Nord's industry comparison, both IATF 16949 and AS9100 build upon ISO 9001, with each sector adding specific requirements critical to their applications. Automotive emphasizes extremely high consistency with high volumes and process improvements. Aerospace focuses primarily on making flight-worthy parts with controls needed to accomplish that mission.

Here's why this matters for aerospace fabrication: organizations already certified to IATF 16949 possess quality systems with significant overlap to aerospace requirements. The precision stamping, statistical process control, and supplier management disciplines transfer directly. What they must add are aerospace-specific elements—configuration management, counterfeit prevention, and the heightened product safety protocols that aviation demands.

The certification process itself requires substantial commitment. AS9100D certification typically takes 6-18 months, depending on organizational size, complexity, and existing quality system maturity. Multi-stage audits conducted by IAQG-accredited certification bodies evaluate documentation, implementation, and effectiveness across all quality management system elements.

With certification establishing foundational quality capabilities, fabricators must then translate these systems into practical workflows that carry components from initial design through production qualification—the complete fabrication lifecycle that determines whether parts ultimately achieve flight-ready status.

The Complete Fabrication Lifecycle and DFM Principles

You've established quality systems that meet aerospace standards. Now comes the real test: transforming a CAD model into a flight-qualified component that passes every inspection and performs flawlessly in service. This aerospace fabrication lifecycle demands more than manufacturing skill—it requires integrating engineering decisions, compliance requirements, and production realities from the very first design concept.

Here's what separates successful aerospace programs from costly failures: design choices made in the first week often determine 80% of manufacturing costs. Get those early decisions right, and fabrication flows smoothly. Miss critical design for manufacturability aerospace principles, and you'll face rework, delays, and budget overruns that compound through every subsequent phase.

From CAD to Flight-Ready Parts

Imagine tracing a single bracket from initial concept to installed hardware. The aerospace fabrication lifecycle encompasses every step of that journey—each phase building on the previous while laying groundwork for what follows.

- Concept and requirements definition: Engineers establish functional requirements, load conditions, environmental exposures, and interface constraints. Material candidates are identified based on strength-to-weight ratios, temperature tolerance, and corrosion resistance needs. Critical tolerances are flagged for downstream attention.

- Preliminary design and DFM analysis: CAD models take shape while fabricators evaluate manufacturability. According to Jiga's DFM principles guide, this phase optimizes designs for specific sheet metal fabrication processes—laser cutting, punching, bending, and welding—ensuring the design can be manufactured using available equipment and tooling.

- Material selection validation: Candidate alloys undergo formal evaluation against specifications. Mill certifications are reviewed, test coupons may be fabricated, and material traceability documentation begins. This step prevents costly discoveries later when production materials don't behave as expected.

- Aerospace prototype development: Physical prototypes validate design assumptions before committing to production tooling. According to 3ERP's aerospace prototyping analysis, this "fail-fast" approach catches design issues early, potentially saving up to 20% off production costs by identifying problems before they become expensive fixes.

- First article inspection aerospace: The initial production part undergoes comprehensive dimensional verification, material testing, and documentation review. This first article inspection validates that production processes can consistently meet all specifications—serving as the gateway to full production authorization.

- Production qualification and ramp-up: With first article approval, production scales while maintaining the quality systems and process controls validated during earlier phases. Statistical process control monitors key characteristics, and periodic audits verify ongoing compliance.

Design Decisions That Drive Fabrication Success

Why do some aerospace programs sail through fabrication while others stumble? The difference often traces back to DFM principles applied—or ignored—during initial design. Smart design choices ripple through the entire lifecycle, reducing costs and accelerating schedules.

Consider bend radii. According to Jiga's DFM guidelines, maintaining consistent bend radii ideally greater than the material thickness prevents cracking and ensures uniformity. Specify a radius too tight for your chosen alloy, and you'll face forming failures, material waste, and schedule delays. Design it correctly from the start, and parts flow through production without drama.

Key DFM principles for aerospace sheet metal include:

- Simplify geometry: Avoid complex shapes requiring multiple forming operations or specialized tooling—each additional operation adds cost, time, and potential failure points

- Standardize features: Use standard hole sizes and shapes to reduce tooling costs; position holes at least one material thickness away from edges and other holes to prevent distortion

- Consider grain direction: Align tabs at least 45° to sheet grain to avoid fracture risk; bending perpendicular to rolling direction typically produces better results

- Tolerance appropriately: Apply tolerances achievable with sheet metal fabrication processes—overly tight tolerances increase manufacturing costs and complexity without adding functional value

- Design for assembly: Include self-locating tabs, slots, and features that simplify assembly; minimize fastener count and use standard fastener types

As emphasized in DFM best practices, the relevance of this process is highly significant in punch/press and die work. Adherence to basic rules guiding feature details and placement enables relatively easier manufacture and creates fewer quality challenges in volume production.

Rapid Prototyping: Accelerating Design Iteration

What if you could test five design variations in the time traditional methods allow for one? Rapid prototyping capabilities—including 5-day turnaround services from qualified fabricators—enable exactly this kind of accelerated iteration before committing to expensive production tooling.

According to 3ERP's industry research, rapid prototyping in aerospace isn't just about building things faster—it's about making smarter decisions early. Techniques like CNC machining and both subtractive and additive manufacturing allow aerospace companies to quickly figure out what works and what doesn't. Despite the speed, turning a new concept into a fully tested prototype typically takes a couple of months, highlighting the need for these fast, iterative techniques in the high-stakes world of aerospace.

Different prototype types serve different purposes:

- Visual prototypes: Confirm shape, dimensions, and aesthetics during early stakeholder reviews—typically crafted from less expensive materials

- Functional prototypes: Evaluate operational performance using materials closely mimicking final specifications to identify potential design flaws

- Scale models: Support aerodynamic evaluations and spatial fit checks efficiently without full-sized fabrication

- Full-scale models: Replicate exact dimensions for advanced simulations and maintenance procedure validation

The investment in aerospace prototype development pays dividends throughout production. Components that emerge from thorough prototyping rarely surprise fabricators with hidden manufacturability problems. Issues get resolved in prototype quantities—where mistakes cost hundreds of dollars—rather than production runs where they cost thousands.

Engineering and Compliance Integration

Throughout this lifecycle, engineering decisions and compliance requirements interweave continuously. Material selection must satisfy both performance engineering and regulatory traceability. Forming methods must achieve dimensional targets while generating the documentation quality systems demand.

First article inspection aerospace serves as the culmination of this integration. Every material certification, process parameter, and inspection result feeds into a comprehensive package demonstrating that production processes consistently meet all requirements. Only with first article approval does production receive authorization to proceed at scale.

This systematic approach—refined through decades of aerospace experience—ensures that fabricated components arrive at assembly not just dimensionally correct, but fully documented and traceable from raw material through final inspection. It's the foundation that enables the industry's remarkable safety record, one carefully validated part at a time.

As fabrication methods and quality systems mature, emerging technologies continue reshaping what's possible—from hybrid manufacturing processes to AI-driven inspection systems that promise even greater precision and efficiency.

Emerging Technologies and Future Developments

What happens when you combine the geometric freedom of 3D printing with the precision of CNC machining—all in a single machine? You get hybrid additive-subtractive manufacturing, one of several aerospace manufacturing technology breakthroughs reshaping how fabricators approach complex components. The industry has evolved dramatically over decades, moving from manual craftsmanship to CNC-controlled precision, and now toward full aerospace industry 4.0 integration where machines communicate, adapt, and optimize in real time.

This transformation isn't just about speed or cost savings. It's fundamentally changing what's possible in aerospace fabrication—enabling geometries that couldn't exist before, materials engineered at the atomic level, and quality systems that catch defects invisible to human inspectors.

Next-Generation Materials Entering Aerospace Production

Imagine an aluminum alloy that's 5-10% lighter than conventional aerospace grades while maintaining comparable strength. That's what advanced aerospace alloys like aluminum-lithium (Al-Li) compositions deliver—and fabricators are learning to work with these demanding materials.

According to research published in Advanced Engineering Materials, powder bed fusion laser beam (PBF-LB) processing of Al-Li alloys has achieved relative densities above 99% using ultrashort pulse laser systems. The study demonstrated that optimized processing parameters—150W laser power, scanning speeds between 500-1000 mm/s, and 70% line overlap—produce nearly fully dense parts suitable for aerospace applications.

The challenge? Lithium's reactivity and tendency to evaporate during high-temperature processing demands precise control. Researchers found that slower scanning velocities result in higher lithium loss due to increased energy input and elevated temperatures during melting. This requires fabricators to balance density optimization against composition control—a delicate equilibrium that defines cutting-edge material processing.

Beyond Al-Li alloys, other material developments reshaping aerospace fabrication include:

- Titanium aluminides: Intermetallic compounds offering exceptional high-temperature performance for turbine applications at half the density of nickel superalloys

- Metal matrix composites: Aluminum or titanium matrices reinforced with ceramic particles or fibers, delivering tailored stiffness-to-weight ratios

- High-entropy alloys: Multi-principal element compositions exhibiting unique combinations of strength, ductility, and corrosion resistance

Automation and Digital Integration in Modern Fabrication

Picture a forming cell where robots load blanks, sensors monitor every press stroke, and AI algorithms adjust parameters in real time based on material behavior. This isn't science fiction—it's automated aerospace fabrication becoming reality across production floors.

According to Dessia Technologies' aerospace industry analysis, AI-powered automation is stepping in not just to speed up processes, but to rethink how aerospace systems are designed, tested, validated, and produced. The shift moves from static, linear workflows to adaptive, AI-augmented environments where engineers co-design with intelligent systems.

Hybrid additive-subtractive manufacturing exemplifies this integration. As documented in a systematic review published in Applied Sciences, this approach alternates additive and subtractive subprocesses on the same machine to overcome individual process limitations while generating new synergies. The aerospace sector is identified as the leading field for application and development, particularly for high-value parts manufactured from titanium and nickel superalloys.

The research confirms that hybrid manufacturing reduces material waste—especially critical for expensive aerospace alloys—while achieving the geometric, dimensional, and surface quality that flight-critical components demand. Companies like Mazak and DMG Mori have developed hybrid machines combining laser metal deposition with multi-axis milling, enabling near-net-shape additive production followed by precision finishing.

AI-driven quality inspection represents another leap forward. Modern systems combine:

- Machine vision systems: High-resolution cameras detecting surface defects at production speeds, flagging anomalies invisible to human inspectors

- Digital twins: Real-time digital replicas simulating performance under various conditions, predicting failures before they occur in physical components

- Predictive analytics: Algorithms analyzing sensor data to identify wear patterns and schedule maintenance before quality degrades

- Closed-loop process control: Systems that automatically adjust forming parameters based on real-time measurements, maintaining tolerances without operator intervention

Sustainability and Efficiency Driving Innovation

Environmental considerations increasingly influence aerospace fabrication decisions. Material efficiency—maximizing usable parts from raw stock—directly impacts both cost and sustainability. Hybrid manufacturing addresses this by producing near-net-shape components that require minimal material removal, dramatically reducing the expensive scrap generated when machining aerospace alloys from solid billets.

Recycling aerospace-grade scrap presents both challenges and opportunities. Alloy segregation, contamination prevention, and maintaining material certifications through reprocessing require sophisticated systems. Yet the economic incentive is substantial—titanium and nickel superalloy scrap commands premium prices, and closed-loop recycling reduces dependence on primary metal production.

Energy-efficient forming processes complement material conservation efforts. Servo-driven presses replacing traditional mechanical systems offer precise force control while reducing energy consumption. Induction heating for localized forming operations minimizes thermal input compared to furnace-based approaches. These incremental improvements accumulate across production volumes, meaningfully reducing aerospace manufacturing's environmental footprint.

Key Technology Trends Transforming Aerospace Fabrication

- Hybrid additive-subtractive machines: Single-setup production combining laser metal deposition or powder bed fusion with multi-axis CNC machining for complex, high-value components

- Advanced aluminum-lithium alloys: Lighter aerospace structures through optimized Al-Li compositions processed via powder metallurgy and additive manufacturing

- Automated forming cells: Robotic loading, real-time sensing, and adaptive process control enabling consistent high-volume production with minimal operator intervention

- AI-powered inspection: Machine learning algorithms analyzing visual, dimensional, and NDT data to detect defects faster and more reliably than manual methods

- Digital thread integration: Seamless data flow from design through production, inspection, and service—enabling full traceability and continuous improvement

- Sustainable manufacturing practices: Closed-loop material recycling, energy-efficient processes, and waste reduction strategies aligned with environmental regulations

These developments don't replace fundamental fabrication expertise—they amplify it. Engineers still must understand material behavior, tooling requirements, and quality standards. But increasingly, they work alongside intelligent systems that handle complexity beyond human processing capacity while freeing skilled professionals to focus on decisions requiring judgment and experience.

As these technologies mature, selecting fabrication partners who embrace innovation while maintaining proven quality systems becomes increasingly important for aerospace manufacturers navigating an evolving production landscape.

Selecting the Right Fabrication Partner for Your Project

You've invested months developing a component design that meets every aerospace requirement. Your quality systems are ready. Emerging technologies promise enhanced capabilities. But here's the question that ultimately determines program success: who actually fabricates your parts? Aerospace fabrication partner selection can make or break production outcomes—the wrong choice leads to missed deadlines, quality escapes, and budget overruns that compound through every program phase.

According to Lasso Supply Chain's vendor evaluation research, choosing the right fabrication vendor is critical for ensuring your project's success, whether you're developing a prototype or scaling up for production. A reliable vendor can deliver high-quality parts, meet deadlines, and align with your technical requirements. The challenge? Knowing which criteria matter most—and how to verify capabilities before committing.

Critical Factors When Evaluating Fabrication Partners

What separates qualified aerospace suppliers from those who merely claim capability? Metal fabrication supplier evaluation requires systematic assessment across multiple dimensions—not just pricing comparisons that ignore the quality and delivery risks lurking beneath attractive quotes.

Certification status: Start with non-negotiables. According to QSTRAT's supplier qualification analysis, aerospace supplier qualification revolves around three key standards: AS9100 Rev D, AS9120B, and AS9133A. Each addresses specific supply chain elements—manufacturing quality systems, distribution controls, and product qualification protocols respectively. Gate criteria for supplier qualification include valid AS9100 or NADCAP certifications, compliance with ITAR/EAR regulations, adherence to cybersecurity protocols, and alignment with ESG standards.

Technical capabilities: Does the fabricator's equipment match your requirements? As noted by Die-Matic's supplier selection guide, press tonnage, material range, and part size capacity all determine whether a supplier can meet your production requirements. Equally important is in-house tooling and the ability to maintain progressive stamping dies—capabilities that improve part repeatability, reduce setup times, and enable faster production runs.

Quality track record: Past performance predicts future results. Request defect rate data, on-time delivery statistics, and corrective action history. Suppliers already approved by major OEMs often maintain performance scorecards tracking these metrics. QSTRAT's research indicates that aerospace supplier scorecards typically weight quality metrics at 35% or higher—the single largest category in evaluation frameworks.

Engineering support depth: A capable certified aerospace manufacturer should be more than a supplier—they should act as an engineering partner. According to Die-Matic's analysis, early-stage collaboration through Design for Manufacturability (DFM) can identify opportunities to reduce scrap, streamline tooling, and improve product performance before production begins. Suppliers who provide prototyping and simulation support can test part geometry and material behavior under real-world conditions.

Maximizing Value Through Strategic Supplier Relationships

Once you've identified qualified candidates, how do you build partnerships that deliver sustained value? The answer lies in recognizing that precision stamping services and fabrication relationships function best as collaborative engagements rather than transactional exchanges.

Responsiveness signals commitment. Consider this: a fabricator offering 12-hour quote turnaround demonstrates operational efficiency and customer focus that translates to production responsiveness. Similarly, rapid prototyping capabilities—like 5-day turnaround services—enable design iteration before committing to production tooling, catching issues when fixes cost hundreds rather than thousands.

For example, Shaoyi (Ningbo) Metal Technology demonstrates how precision stamping expertise for automotive applications translates to aerospace-adjacent work requiring similar tolerances and quality systems. Their IATF 16949 certification, comprehensive DFM support, and automated mass production capabilities exemplify the qualities aerospace programs demand. While primarily serving automotive chassis, suspension, and structural component markets, their quality systems and precision capabilities align with the rigorous standards aerospace fabrication requires.

Strategic supplier relationships deliver benefits beyond individual transactions:

- Qualified precision stamping partners: Look for IATF 16949 or AS9100 certification, rapid prototyping capabilities (5-day turnaround), automated mass production, comprehensive DFM support, and responsive quote turnaround (12 hours or less)—capabilities exemplified by manufacturers like Shaoyi

- Technical capability verification: Confirm press tonnage range, material processing experience, in-house tooling design and maintenance, and inspection equipment (CMM, vision systems, NDT capabilities)

- Quality system maturity: Evaluate documented quality management systems, traceability protocols, supplier qualification processes, and continuous improvement programs

- Production scalability: Assess capacity planning approaches, tooling changeover efficiency, and ability to handle both prototype and high-volume orders without quality degradation

- Communication and responsiveness: Gauge quote turnaround times, engineering accessibility, and proactive issue communication—early indicators of production partnership quality

- Geographic and logistical considerations: Evaluate shipping distances, domestic versus international sourcing implications, and alignment with just-in-time delivery requirements

According to Lasso Supply Chain's research, once you've selected a vendor, aim to build a collaborative relationship. Regular communication, clear expectations, and mutual trust lead to better outcomes. Share your roadmap to help the vendor plan for future needs, and provide constructive feedback to improve their performance.

Risk-Based Supplier Qualification

Not all components carry equal risk—and your supplier qualification approach should reflect this reality. QSTRAT's aerospace supplier qualification framework recommends organizing suppliers into risk tiers based on component criticality:

| Risk Tier | Component Criticality | Qualification Activities | Review Frequency |

|---|---|---|---|

| Tier 1 (Critical) | Flight safety, structural integrity | On-site audits, extensive documentation, sample testing | Monthly reviews |

| Tier 2 (Significant) | Performance-affecting components | Desktop audits, certification verification, performance monitoring | Quarterly reviews |

| Tier 3 (Standard) | Non-critical parts | Certification checks, periodic sampling | Annual reviews |

This tiered approach ensures resources focus where they matter most—particularly in areas affecting product safety and regulatory compliance. Digital tools increasingly support this process, centralizing ERP and quality data, automating scorecard calculations, and providing real-time performance visibility across supplier networks.

Evaluating fabrication vendors requires thorough analysis of their quality, lead time, and technical capabilities. By asking the right questions, reviewing their processes, and aligning their strengths with your project's needs, you can find a partner that delivers reliable results. The investment in careful vetting pays dividends through smoother programs, better products, and supply chain resilience that supports long-term aerospace manufacturing success.

Frequently Asked Questions About Aerospace Sheet Metal Fabrication

1. What is aerospace sheet metal fabrication and how does it differ from industrial metalwork?

Aerospace sheet metal fabrication is the specialized process of transforming flat metal sheets into precision components for aircraft and spacecraft. Unlike industrial metalwork that may tolerate variations of 1/16 inch, aerospace fabrication requires tolerances of ±0.005 inches or tighter. The key differences include stringent material specifications with full traceability from mill to finished part, mandatory regulatory oversight including FAA regulations and AS9100D certification, and comprehensive quality verification through non-destructive testing and in-process inspections.

2. What materials are commonly used in aerospace sheet metal fabrication?

The most common materials include aluminum alloys such as 2024 for fatigue-critical structures, 6061 for weldability, and 7075 for high-strength applications. Titanium alloys like Ti-6Al-4V are used for high-temperature zones near engines, maintaining strength up to 600°F. Inconel superalloys handle extreme conditions in turbine blades and combustion chambers at temperatures reaching 2000°F. Stainless steel grades like 316 provide corrosion resistance for hydraulic fittings and fasteners.

3. What certifications are required for aerospace sheet metal fabrication?

AS9100D certification is the primary requirement, building on ISO 9001:2015 with aerospace-specific additions including operational risk management, configuration management, counterfeit parts prevention, and product safety requirements. Major manufacturers like Boeing, Airbus, and Lockheed Martin require AS9100 compliance. NADCAP certification validates special processes, while facilities serving automotive-aerospace crossover work often hold IATF 16949 certification, which shares significant quality system overlap with aerospace standards.

4. How do fabricators control springback when forming high-strength aerospace alloys?

Springback occurs when part of the deformation remains elastic during bending. Fabricators combat this through overbending past the target angle so springback brings parts to specification, using mandrels and wiper dies to maintain shape control, applying controlled localized heating to soften materials, and utilizing CNC systems that correct angles in real-time. Different alloys require different approaches—7075-T6 is often formed in softer tempers then heat-treated, while 5xxx series alloys naturally bend well with minimal rebound.

5. What should I look for when selecting an aerospace fabrication partner?

Essential evaluation criteria include valid AS9100 or IATF 16949 certification status, technical capabilities matching your requirements such as press tonnage and material range, documented quality track records with defect rate and delivery statistics, and engineering support depth including DFM analysis and prototyping capabilities. Response indicators like 12-hour quote turnaround and 5-day rapid prototyping demonstrate operational commitment. Manufacturers like Shaoyi demonstrate how precision stamping expertise with comprehensive DFM support translates effectively to aerospace-adjacent applications requiring similar tolerances.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —