Why Roll Forging Automotive Applications Matters for Your Business

Understanding Roll Forging and Its Mechanical Principles

When you picture metal forming, you might imagine a blacksmith hammering glowing steel on an anvil. But what if there was a way to shape metal with greater precision, consistency, and efficiency? That is exactly what roll forging delivers. This specialized manufacturing process has become indispensable for producing high-strength automotive components that keep vehicles running safely and reliably.

Roll forging is a precision metal forming process where a preheated billet passes through grooved cylindrical or semi-cylindrical rolls, progressively shaping the metal through compressive forces to produce elongated components with superior grain flow and mechanical properties.

Unlike traditional hammer forging where impact forces deform metal in discrete blows, roll forging uses continuous rotational compression. This fundamental difference changes everything about how the finished component performs under stress. The result? Parts with exceptional tensile strength, uniform density, and smooth surface finishes that automotive engineers demand.

How Roll Forging Shapes Metal Through Progressive Compression

Imagine inserting a heated metal bar between two powerful rotating cylinders, each containing specially designed grooves. As the bar passes through, the rolls compress and elongate it with each rotation. This process continues through multiple passes until the metal achieves its desired profile and dimensions.

The magic happens at the molecular level. During this progressive compression, the metal's internal grain structure aligns along the component's length. This alignment follows the natural stress paths the part will experience during service. For automotive applications like axle shafts and connecting rods, this means dramatically improved fatigue resistance compared to machined or cast alternatives.

The forging process typically heats billets to temperatures between 1050-1150°C, ensuring optimal plasticity and grain flow. At these temperatures, the metal becomes malleable enough to reshape without cracking, while still maintaining the structural integrity needed for demanding applications. This careful temperature control distinguishes quality roll forging operations from less sophisticated methods practiced in traditional traditional smithy and forging workshops of earlier eras.

The Fundamental Difference Between Roll Forging and Traditional Forging Methods

Understanding what is the forging method best suited for your application requires knowing how roll forging compares to alternatives. Here is how the main types of forging stack up:

- Open-die forging: Metal flows freely except where it contacts flat dies. Best for large, simple parts but offers less precision.

- Closed-die forging: Metal fills precision die cavities under high pressure. Excellent for complex shapes but requires significant tooling investment.

- Roll forging: Heated billets pass through grooved rotating rolls. Ideal for elongated components requiring uniform cross-sections and superior grain alignment.

- Press forging: Uses slow, continuous pressure rather than impact. Creates deeper, more uniform deformation but typically at lower speeds.

Roll forging bridges the gap between open-die flexibility and closed-die precision. It requires less tooling investment than impression die methods while delivering greater efficiency and consistency than hammer-based approaches. This balance makes it particularly valuable for automotive manufacturers who need high volumes of drivetrain and suspension components with predictable mechanical properties.

The evolution from traditional smithy and forging techniques to modern roll forging represents more than just technological advancement. It reflects the automotive industry's relentless pursuit of components that are stronger, lighter, and more reliable. When your transmission shaft or steering component originates from a roll forging operation, you benefit from centuries of metallurgical knowledge refined through contemporary engineering precision.

Why Automotive Engineers Prefer Roll Forging

Why do automotive manufacturers consistently choose this process over casting, machining, or other forming methods? The answer lies in a combination of metallurgical advantages, weight optimization capabilities, and material efficiency that competitors simply cannot match. When safety-critical components are on the line, engineers need manufacturing methods that deliver predictable, superior performance every single time.

Grain Flow Optimization for Maximum Fatigue Resistance

Picture the internal structure of metal as millions of tiny crystals packed together. When you machine a component from solid bar stock, you cut through these grain boundaries randomly. But when you forge metal, something remarkable happens. The grains align along the direction of deformation, creating continuous flow lines that follow the part's contours.

This grain flow optimization is critical for automotive forging applications. Components like axle shafts and connecting rods experience repeated stress cycles throughout their service life. A steering knuckle might endure millions of load reversals over a vehicle's lifetime. When grain structure aligns along these stress paths, the component resists fatigue cracking far more effectively than cast or machined alternatives.

The metallurgical advantages of forged materials extend beyond fatigue resistance:

- Enhanced tensile strength: Continuous grain flow eliminates weak points where cracks typically initiate.

- Superior impact resistance: Aligned grain boundaries absorb shock loads more effectively.

- Consistent mechanical properties: Unlike casting, forging eliminates porosity and internal defects that compromise performance.

- Improved ductility: Proper forging design ensures components can deform slightly under extreme loads rather than fracturing suddenly.

According to industry research, forged parts demonstrate significantly higher impact and fatigue resistance compared to cast alternatives. This makes forging the preferred process for safety-critical automotive components where failure is not an option.

How Roll Forging Supports Automotive Lightweighting Goals

Vehicles have been getting larger and heavier every year due to consumer demand and safety regulations. Simultaneously, governments have implemented fuel efficiency and emission reduction mandates that push manufacturers to remove as much mass as possible. This creates a challenging engineering paradox that roll forging helps solve.

The strength-to-weight optimization advantage works like this: because forged components are inherently stronger than cast or machined parts, engineers can specify thinner cross-sections while maintaining required safety factors. A roll-forged transmission shaft might weigh 15-20% less than a cast equivalent designed for the same application, all while delivering superior durability.

This lightweighting imperative becomes even more critical for battery electric vehicles. Since battery energy density remains far lower than gasoline, EVs tend to be significantly heavier than equivalent internal combustion vehicles. Every gram saved in drivetrain components extends range and improves efficiency. The forging material selection process allows engineers to specify high-strength alloys like high-strength chrome-moly steels such as 42CrMo, 4140, or SCM440 that maximize this strength-to-weight advantage.

Beyond component weight, roll forging delivers exceptional material efficiency. The progressive deformation process achieves up to 90% material utilization, compared to machining operations where cutting away metal creates expensive waste. When working with premium alloy steels, the volume of metal removed during machining can sometimes cost more than the material content of the finished part. Roll forging eliminates this wasteful equation entirely.

The sustainability benefits compound these advantages. Less material waste means reduced environmental impact. Lower energy consumption compared to alternative processes further supports corporate sustainability initiatives. For automotive manufacturers facing increasing pressure from regulators and consumers alike, these considerations increasingly influence supplier selection and manufacturing process decisions.

Understanding these metallurgical and efficiency advantages explains why engineers specify roll forging for critical applications. But how does the actual manufacturing process work, and what considerations ensure optimal results for automotive components?

The Complete Roll Forging Process for Automotive Components

Sounds complex? The roll forging procedure actually follows a logical sequence that automotive manufacturers have refined over decades. Each stage builds upon the previous one, transforming raw metal billets into precisely shaped preforms ready for final processing. Understanding this forged manufacturing process helps procurement professionals and engineers make informed decisions about component specifications and supplier capabilities.

From Billet to Preform Through Progressive Shaping Stages

The forge process begins long before metal touches the rotating dies. Here is how automotive components move through each critical production phase:

- Billet preparation and inspection: Raw material arrives as cylindrical bar stock, typically cut to precise lengths. Quality control teams verify material certification, check for surface defects, and confirm dimensional accuracy before proceeding. For automotive applications, common steel grades include 42CrMo, 4140, SCM440, and various carbon steels depending on end-use requirements.

- Heating to forging temperature: Billets enter induction or gas-fired furnaces where they reach optimal forming temperatures. Steel alloys typically require heating to 1050-1150°C, while aluminum grades used in lightweight automotive applications heat to 360-520°C. Precise temperature control prevents overheating that could damage grain structure or underheating that causes cracking during deformation.

- Initial roll pass: The heated billet enters between semi-cylindrical rolls containing specially machined grooves. As the rolls rotate through half a revolution, they squeeze and elongate the metal. Each roll contains multiple groove profiles of progressively smaller dimensions.

- Progressive shaping: After the initial pass, operators reposition the workpiece into the next set of smaller grooves. This sequence repeats until the metal achieves the desired cross-sectional profile and length. The forging line may include three to eight reduction passes depending on the complexity of the final shape.

- Intermediate reheating (if required): For components requiring extensive deformation, the workpiece may need reheating between passes to maintain optimal plasticity and prevent work hardening.

- Final forming and ejection: The last pass establishes precise dimensions and surface geometry. The shaped preform exits the roll dies ready for subsequent operations.

This progressive approach differs fundamentally from 3d roll forming processes used for sheet metal. While 3d roll forming creates complex profiles from flat sheets through continuous bending, roll forging works hot billets through compressive deformation. Both processes share the concept of incremental shaping, but their applications and metallurgical outcomes differ significantly.

Temperature Control and Material Selection for Automotive Grades

Temperature management throughout the forge process directly impacts component quality. When you work steel above its recrystallization temperature, new strain-free crystals form continuously during deformation. This hot working eliminates internal stresses and produces favorable grain sizes that enhance mechanical properties.

According to metallurgical research, hot forging temperatures for common automotive materials follow these guidelines:

| Material Type | Forging Temperature Range | Common Automotive Applications |

|---|---|---|

| Carbon and alloy steels | 1050-1150°C | Crankshafts, axle shafts, connecting rods |

| Aluminum alloys | 360-520°C | Suspension arms, lightweight drivetrain components |

| Copper alloys | 700-800°C | Electrical connectors, specialized fittings |

Die design considerations become particularly critical for automotive tolerances. The grooves machined into roll dies must account for material springback, thermal expansion, and the precise dimensional requirements of downstream operations. Automotive components often demand tolerances of ±0.5mm or tighter, requiring careful engineering of die profiles and process parameters.

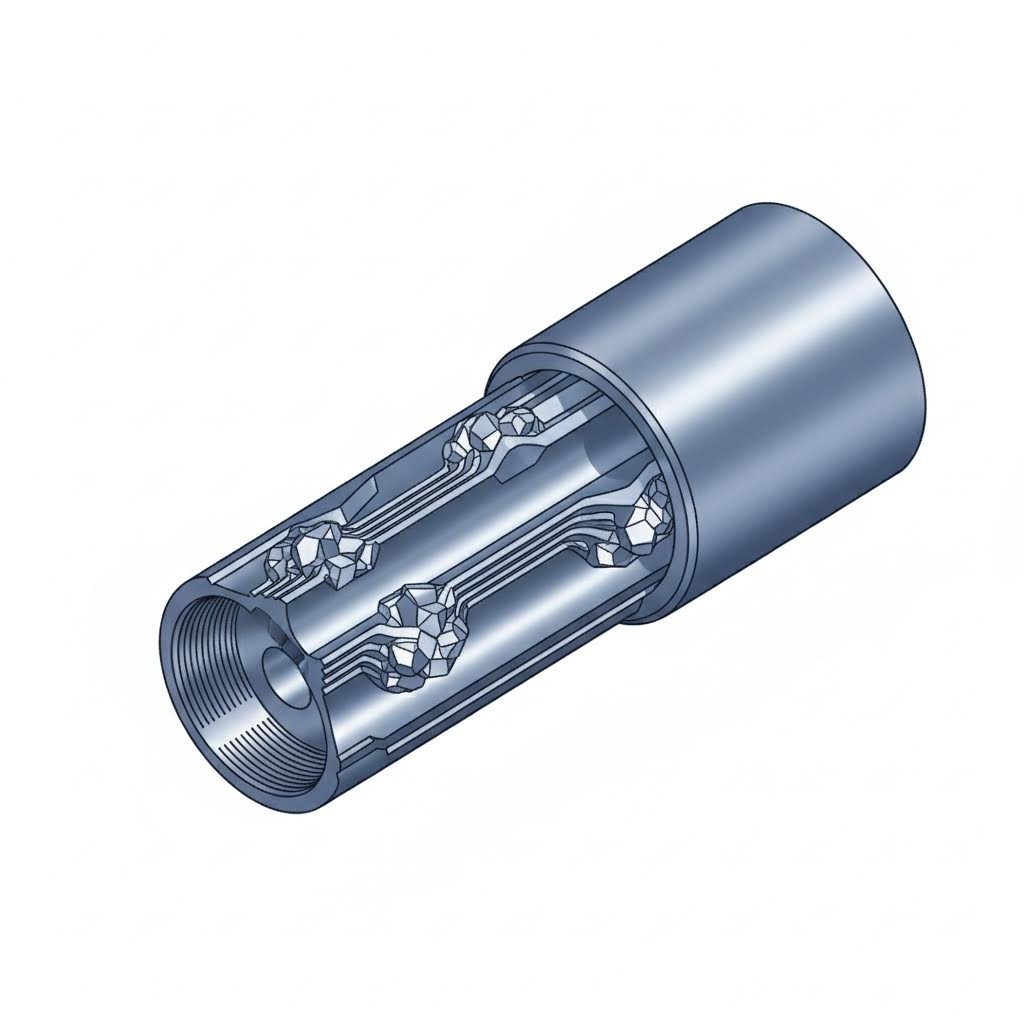

What many competitors fail to explain is how roll forging frequently serves as a preforming operation rather than a standalone process. In automotive manufacturing, roll-forged preforms commonly proceed to closed-die forging for final shaping. This hybrid approach combines the material distribution advantages of roll forging with the geometric precision of impression die work.

Imagine producing a crankshaft. The initial roll forging operation redistributes metal mass along the length of the billet, creating thicker sections where counterweights will form and thinner sections for journals. This preform then transfers to a closed-die forging press for final shaping. The result? Optimal grain flow throughout the component, minimal material waste, and superior mechanical properties compared to machining from solid bar stock.

Post-forging operations complete the manufacturing sequence. These typically include:

- Controlled cooling: Gradual temperature reduction prevents thermal stresses and warping.

- Heat treatment: Normalizing, quenching, and tempering establish final hardness and mechanical properties.

- Surface finishing: Shot blasting removes scale, while machining achieves critical tolerance dimensions.

- Quality inspection: Dimensional verification, metallurgical testing, and non-destructive examination confirm specifications.

This complete forging procedure ensures automotive components meet the demanding specifications required for safety-critical applications. But which specific parts benefit most from this manufacturing approach, and why does each component require the unique advantages roll forging provides?

Critical Automotive Components Made Through Roll Forging

When you open the hood of any modern vehicle, you are looking at dozens of forging components working together in perfect harmony. But which parts specifically benefit from roll forging, and why? Understanding these applications helps engineers and procurement professionals specify the right manufacturing process for each critical component. The answer comes down to geometry, stress requirements, and the unique metallurgical advantages this process delivers.

Roll forging excels at producing parts that share specific geometric characteristics: elongated shapes, varying cross-sections along their length, and rotational symmetry. These features align perfectly with how the rotating dies progressively shape metal during the forming process. When a forging component exhibits these traits while also demanding exceptional mechanical properties, roll forging becomes the manufacturing method of choice.

Drivetrain Components That Benefit from Roll Forged Grain Structure

Imagine the forces transmitted through your vehicle's drivetrain every time you accelerate, brake, or navigate a sharp turn. These forging products must withstand tremendous torsional loads, bending moments, and cyclic stresses throughout millions of operational cycles. Here is why specific drivetrain components demand the superior grain alignment that only roll forging delivers:

Crankshafts represent perhaps the most demanding forging application in any internal combustion engine. This component converts linear piston motion into rotational energy while enduring explosive combustion forces thousands of times per minute. The crankshaft's complex geometry features main journals, rod journals, and counterweights arranged along an elongated axis. Roll forging creates preforms with ideal mass distribution before closed-die finishing, ensuring grain flow follows the stress paths through each critical section. According to industry experts, this grain flow optimization makes forged crankshafts significantly stronger than cast alternatives, enabling lighter designs without sacrificing durability.

Axle shafts transmit torque from the differential to the wheels while supporting a portion of vehicle weight. These components experience constant torsional loading combined with bending stresses during cornering. The elongated, cylindrical geometry with varying diameters makes axle shafts ideal candidates for roll forging. The process aligns grain structure along the shaft's rotational axis, maximizing torsional strength exactly where the component needs it most.

Connecting rods link pistons to the crankshaft, converting reciprocating motion to rotation. These components endure alternating tensile and compressive loads at frequencies exceeding 100 cycles per second in high-performance engines. Fatigue resistance becomes absolutely critical. The elongated I-beam or H-beam cross-section, combined with round bearing surfaces at each end, suits roll forging perfectly. Grain flow through the length of the rod ensures maximum fatigue life under these punishing conditions.

Transmission shafts require consistent mechanical properties along their entire length to transfer power reliably between gear sets. Any weak point or inconsistency could lead to catastrophic failure. Roll forging produces homogeneous material without the porosity or segregation defects that can plague cast alternatives. This uniformity ensures predictable performance throughout the component's service life.

Suspension and Steering Parts Requiring Roll Forging Precision

Beyond the drivetrain, suspension and steering systems rely on roll-forged components to maintain vehicle control and passenger safety. These forging applications demand precise geometry combined with exceptional strength:

Steering knuckles and tie rod ends must maintain exact alignment under varying loads while resisting fatigue from road impacts. The combination of cylindrical sections with varying diameters makes these components suitable for roll forging as a preforming operation. Dimensional control during roll forging, as noted by industry manufacturers, reduces deformation and surface defects while keeping tolerances tight throughout the process.

Suspension arms and control arms connect wheels to the vehicle body while allowing controlled movement. These components must absorb road shocks without permanent deformation. The elongated shapes with varying cross-sections benefit from roll forging's ability to distribute material precisely where stress concentrations occur.

Stabilizer bar components resist body roll during cornering by connecting opposite wheels through a torsion bar. The cylindrical geometry with varying diameters along the length matches roll forging capabilities perfectly, while the grain alignment enhances torsional fatigue resistance.

| Component Type | Critical Performance Requirements | Why Roll Forging Addresses Each Requirement |

|---|---|---|

| Crankshafts | High torsional strength, fatigue resistance under cyclic combustion loads, precise balance | Grain flow aligns with stress paths; preforming optimizes mass distribution for counterweights and journals |

| Axle Shafts | Torsional strength, bending resistance, consistent properties along length | Elongated cylindrical geometry suits progressive shaping; grain alignment maximizes torsional capacity |

| Connecting Rods | Exceptional fatigue resistance, high strength-to-weight ratio, dimensional precision | Grain flow through I-beam section prevents fatigue crack initiation; material efficiency reduces weight |

| Transmission Shafts | Uniform mechanical properties, torque transmission capability, rotational balance | Homogeneous material without porosity; consistent cross-section achieved through progressive passes |

| Steering Components | Precise geometry, impact resistance, long-term dimensional stability | Tight tolerance control during forming; grain structure resists deformation under repeated loads |

| Suspension Arms | Shock absorption, fatigue resistance, lightweight design | Material distribution optimized for stress concentrations; strength-to-weight advantages enable mass reduction |

The geometric characteristics shared by these forging components explain their suitability for roll forging. Elongated shapes allow progressive shaping through multiple roll passes. Varying cross-sections benefit from the process's ability to redistribute material along the workpiece length. Rotational symmetry matches the cylindrical die geometry, ensuring uniform deformation around the part's axis.

These forging products represent just a portion of roll forging's automotive applications. As vehicle powertrains evolve toward electrification, new component requirements are emerging that leverage the same fundamental advantages in different ways.

Roll Forging in Electric Vehicle Manufacturing

What happens when the automotive industry's most reliable metal forming process meets its most disruptive technology shift? Electric vehicles are rewriting the rulebook for component design, yet roll forging remains remarkably relevant. While EVs eliminate many traditional drivetrain parts, they introduce new components with demanding requirements that this proven manufacturing method addresses exceptionally well.

The transition from internal combustion engines to electric powertrains creates fundamentally different engineering challenges. Battery packs add substantial weight, electric motors deliver instant maximum torque, and thermal management operates under entirely new parameters. These factors reshape which components manufacturers need and how those parts must perform. According to industry analysis, forged components have become essential for EV production precisely because they satisfy both the strength and weight optimization demands these vehicles require.

Roll Forging Applications for Electric Vehicle Drivetrains

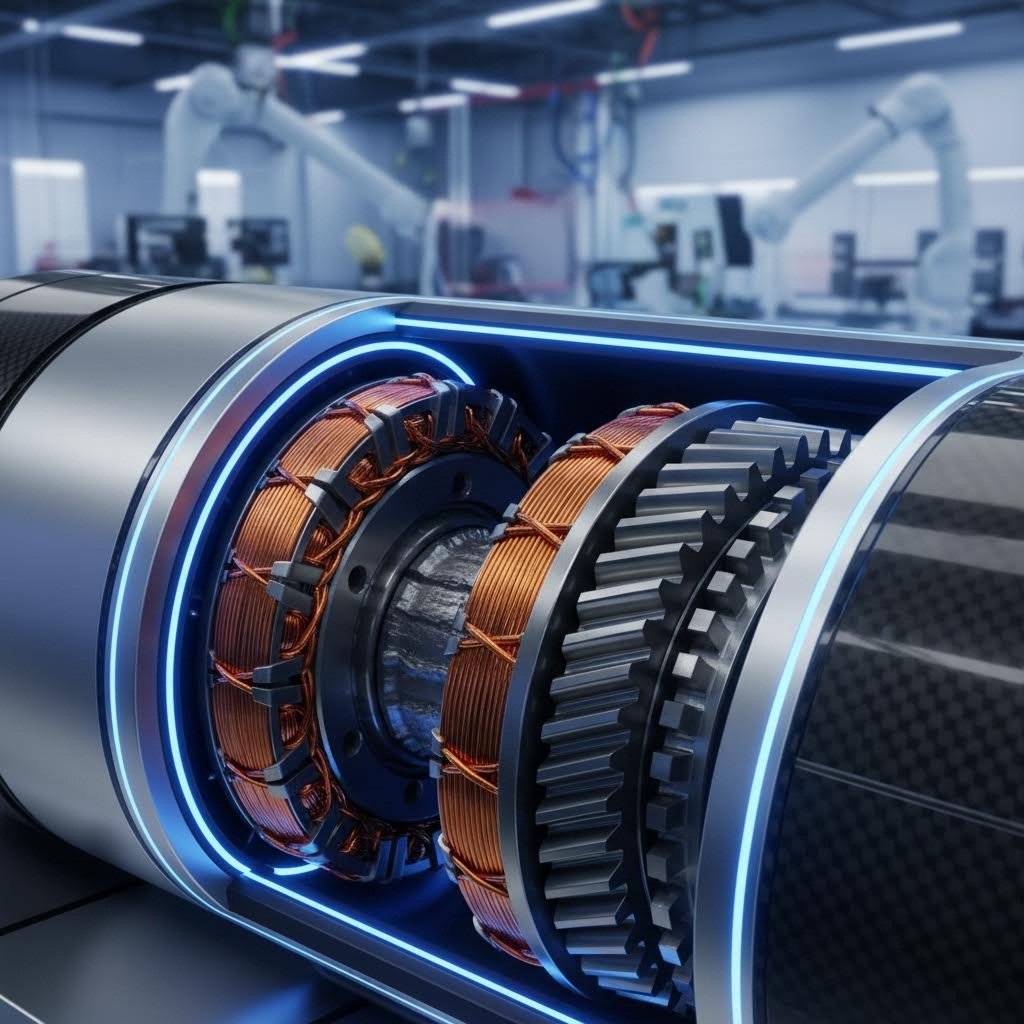

Imagine an electric motor spinning at 15,000 RPM while delivering peak torque from zero speed. The motor shaft connecting this power source to the reduction gears experiences stress profiles that differ dramatically from traditional transmission components. Roll forging produces these critical EV drivetrain elements with the grain structure alignment necessary to handle these unique demands.

Motor shafts represent a prime example of evolved forging engineering requirements. Research from Shimadzu Corporation demonstrates that radial forging processes, closely related to roll forging techniques, significantly improve both tensile strength and elastic modulus in hollow shaft applications. Their testing revealed that forged motor shafts show clear yield point improvements, with mechanical property enhancements extending approximately 16mm from the surface into the material interior. This creates components that satisfy both strength requirements and weight reduction goals critical for extending EV driving range.

Reduction gear components in EV drivetrains face higher torque density than traditional automotive gears. Since electric motors deliver maximum torque instantly, these components cannot rely on the gradual torque buildup that internal combustion engines provide. Roll forging creates gear blanks with optimal grain flow orientation, ensuring teeth resist the instantaneous high-load conditions characteristic of electric propulsion systems.

Structural battery enclosure elements must protect heavy battery packs while contributing to overall vehicle rigidity. The automotive roll forming of these components requires materials that combine crashworthiness with weight efficiency. Forged mounting brackets, cross-members, and structural reinforcements deliver the mechanical properties necessary for battery protection without adding excessive mass that would reduce vehicle range.

The forging industry continues adapting to these evolving requirements. New material specifications for EV components often demand aluminum alloys and specialty steels that maintain strength at elevated operating temperatures while minimizing weight. Roll forging accommodates these materials effectively, producing components with superior properties compared to cast or machined alternatives.

Sustainability Advantages in Modern Automotive Manufacturing

Beyond component performance, roll forging aligns with the sustainability initiatives driving the entire EV movement. When your manufacturing process inherently reduces waste and energy consumption, you support the same environmental goals that make electric vehicles attractive in the first place.

Material efficiency stands out as a primary sustainability advantage. Roll forging achieves material utilization rates approaching 90%, dramatically outperforming subtractive manufacturing methods. When producing EV motor shafts or gear blanks, nearly all input material becomes finished product rather than machining chips destined for recycling. This efficiency reduces raw material demand, lowers procurement costs, and minimizes the environmental footprint of component production.

Energy consumption comparisons favor forging over alternative processes as well. While the initial heating of billets requires significant energy input, the rapid forming process and high material utilization offset this consumption. Casting processes require melting entire batches of metal and maintaining molten temperatures throughout extended production cycles. Machining operations consume energy continuously while removing material that has already absorbed manufacturing energy. Roll forging concentrates energy investment into material that becomes the final product.

The sustainability benefits extend through the entire vehicle lifecycle:

- Reduced material waste: Less scrap means lower raw material extraction and processing impacts.

- Lighter components: Weight-optimized forged parts improve EV efficiency throughout operational life.

- Extended durability: Superior fatigue resistance reduces replacement frequency and associated manufacturing cycles.

- Recyclability: Forged steel and aluminum components maintain material properties through recycling processes.

As EV adoption accelerates globally, manufacturers increasingly evaluate suppliers based on sustainability credentials alongside traditional quality and cost metrics. Roll forging operations that minimize waste, optimize energy consumption, and produce durable components position themselves favorably in this evolving competitive landscape.

The shift toward electric mobility does not diminish roll forging's relevance. Instead, it redirects applications toward new component categories while preserving the fundamental advantages that made this process essential for automotive manufacturing. But selecting the right forging approach for specific EV applications requires understanding the differences between hot and cold processing methods.

Hot Versus Cold Roll Forging for Automotive Applications

Choosing between hot and cold roll forging might sound like a purely technical decision, but it directly impacts component performance, production costs, and manufacturing timelines. Both processes shape metal through progressive compression, yet they produce dramatically different results. Understanding when each approach delivers optimal outcomes helps automotive engineers and procurement professionals specify the right manufacturing method for every application.

The fundamental distinction comes down to temperature. Hot roll forging heats metal above its recrystallization point, typically between 1050-1200°C for steel alloys. Cold roll forging works material at or near room temperature. This seemingly simple difference cascades into significant variations in achievable tolerances, surface quality, material properties, and component size capabilities.

Selecting Hot Roll Forging for High-Deformation Automotive Parts

When your component requires substantial shape changes or features complex geometry, hot roll forging becomes the logical choice. The elevated temperatures make metal significantly more malleable, reducing the forces needed for deformation while enabling greater shape complexity in each pass.

Think about crankshafts, axle shafts, and large connecting rods. These components require extensive material redistribution along their length, with dramatic cross-section variations between journals, counterweights, and bearing surfaces. According to manufacturing research, hot forging delivers improved ductility that makes shaping these complex geometries practical, while the recrystallization process refines grain structure for enhanced mechanical properties.

The metallurgical advantages of hot roll forging metal extend beyond formability:

- Reduced work hardening: Elevated temperatures prevent the strain hardening that can make cold-worked material brittle.

- Enhanced grain refinement: Recrystallization during deformation produces fine, uniform grain structures that improve toughness.

- Lower forming forces: Reduced material resistance means less powerful equipment can shape larger components.

- Stress relief: Hot working relieves internal stresses that could otherwise cause distortion or premature failure.

Automotive applications favoring hot roll forging typically involve safety-critical drivetrain and suspension components where fatigue resistance and impact toughness outweigh precision requirements. Research from industry sources indicates that hot-forged components exhibit up to 20% higher fatigue resistance compared to their cold-forged counterparts, making this process essential for parts that endure millions of stress cycles throughout vehicle life.

The process does have trade-offs. Surface oxidation at elevated temperatures creates scale that requires removal through shot blasting or pickling. Dimensional tolerances typically range wider than cold forging achieves, often necessitating secondary machining for critical features. Tool steel forging of die components must withstand extreme thermal cycling, increasing tooling costs compared to cold-working dies.

When Cold Roll Forging Delivers Superior Precision

What if your application demands tight tolerances and exceptional surface finish without extensive secondary processing? Cold roll forging excels precisely in these scenarios. By working metal at ambient temperatures, this process eliminates thermal expansion variables and surface oxidation concerns.

Steel forging at room temperature produces components with dimensional accuracies that hot processes cannot match. According to comparative analysis, cold forging achieves tight tolerances and excellent dimensional accuracy, reducing the need for secondary machining. This precision advantage translates directly into cost savings for high-volume automotive production where eliminating machining operations improves profitability.

Automotive components ideally suited for cold roll forging include:

- Transmission gears and pinions: Require precise tooth geometry and smooth surface finish for quiet operation.

- High-precision fasteners: Demand consistent dimensions across millions of production units.

- Bearing races: Need tight tolerances and superior surface quality for reliable rolling contact.

- Small shafts and spindles: Benefit from strain hardening that increases surface hardness.

The roll forming process at ambient temperatures offers distinct advantages for appropriate applications. Material waste decreases by up to 25% compared to hot forming, according to industry data, since no scale forms on component surfaces. Energy consumption drops significantly without heating requirements. Strain hardening during cold deformation actually increases material strength, particularly at the surface where wear resistance matters most.

However, press forging at room temperature requires substantially higher forming forces than hot working. This limits component size and the degree of deformation achievable in each pass. Materials must possess sufficient room-temperature ductility, restricting cold forging to aluminum, copper alloys, and lower-carbon steels. Harder alloys and larger components typically require hot processing regardless of precision requirements.

Tool steel forging considerations differ significantly between hot and cold processes. Cold forging dies experience extreme pressures without thermal relief, demanding premium tool materials with exceptional hardness and wear resistance. While individual die sets cost more, they often last longer than hot-forging tooling subjected to thermal cycling and oxidation.

| Decision Factor | Hot Roll Forging | Cold Roll Forging |

|---|---|---|

| Typical Components | Crankshafts, axle shafts, connecting rods, large suspension arms | Gears, precision fasteners, bearing races, small shafts |

| Achievable Tolerances | ±0.5mm to ±1.0mm typical; secondary machining often required | ±0.1mm to ±0.3mm achievable; minimal secondary operations |

| Surface Finish | Scale formation requires removal; rougher initial finish | Superior finish; often eliminates polishing requirements |

| Production Volume Suitability | Medium to high volumes; setup costs amortized over production runs | High volumes preferred; maximizes tooling investment returns |

| Material Considerations | All steel alloys, titanium, superalloys; materials difficult to cold work | Aluminum, copper, low-carbon steels; materials with room-temperature ductility |

| Tooling Costs | Moderate initial cost; thermal cycling reduces die life | Higher initial cost; extended die life offsets investment |

| Component Size Range | Large components feasible; less force required per unit deformation | Limited to smaller parts; forming forces restrict size |

| Material Properties Achieved | Refined grain structure, stress-relieved, enhanced toughness | Strain-hardened surface, improved strength, work-hardened properties |

The decision between hot and cold roll forging ultimately depends on balancing component requirements against manufacturing constraints. Large drivetrain parts demanding extensive deformation clearly favor hot processing. Precision components requiring tight tolerances and smooth surfaces benefit from cold forming. Many automotive applications fall between these extremes, requiring careful analysis of all relevant factors before committing to a manufacturing approach.

Regardless of which temperature range suits your components, ensuring consistent quality throughout production depends on robust quality management systems and supplier evaluation processes.

Quality Standards and Supplier Evaluation for Automotive Roll Forging

How do you know if a roll forging supplier can actually deliver the quality your automotive components demand? Certifications, testing protocols, and documentation requirements separate world-class suppliers from those that simply cannot meet OEM expectations. Understanding these quality standards helps procurement professionals and engineers evaluate potential partners before committing to production relationships that directly impact vehicle safety and reliability.

The automotive industry operates under some of the most stringent quality requirements of any manufacturing sector. When a forging hub fails or a suspension component cracks, the consequences extend far beyond warranty claims. Lives depend on every component performing exactly as designed throughout the vehicle's service life. This reality drives the comprehensive quality management systems and testing protocols that define automotive forging suppliers.

IATF 16949 Certification and What It Means for Component Quality

Imagine walking into a forging facility and immediately understanding whether they can meet your automotive specifications. IATF 16949 certification provides exactly this assurance. This globally recognized quality management standard, developed specifically for the automotive industry, establishes requirements that go far beyond basic manufacturing competence.

According to industry certification experts, IATF 16949 builds upon ISO 9001:2015 foundations while adding automotive-specific requirements that ensure consistent, reliable component production. The certification demonstrates that a supplier has implemented systems addressing the forgings meaning behind quality - not just meeting specifications, but continuously improving processes to exceed expectations.

The major IATF 16949 requirements that impact roll forging suppliers include:

- Quality Management System (QMS): A robust framework built on customer focus, leadership engagement, process approach, and evidence-based decision-making. Suppliers must demonstrate that quality permeates every operational aspect.

- Planning and Risk Analysis: Systematic identification and mitigation of potential risks throughout manufacturing processes, including supply chain considerations that could affect component quality.

- Process Management: Documented procedures ensuring consistent quality with measurable effectiveness monitored regularly. Every forging terms and parameter must be controlled and verified.

- Product Design and Development: Robust development processes accounting for customer requirements, safety regulations, and legal obligations with managed change control.

- Monitoring and Measurement: Continuous operational monitoring including regular audits, inspections, and performance evaluations verifying QMS effectiveness.

For procurement professionals, IATF 16949 certification serves as a baseline qualification filter. Suppliers without this certification typically cannot participate in OEM supply chains for safety-critical components. However, certification alone does not guarantee excellence. The depth and maturity of a supplier's quality systems matter as much as the certificate itself.

Essential Testing Protocols for Automotive Forged Parts

What happens after a roll-forged component leaves the production line? Comprehensive testing protocols verify that each part meets the demanding specifications automotive applications require. Understanding these forging terms and testing methods helps engineers specify appropriate quality requirements and evaluate supplier capabilities.

According to quality control specialists, testing for automotive forged components spans multiple categories:

Dimensional Inspection: Verification that components meet geometric specifications within required tolerances. Modern suppliers employ coordinate measuring machines (CMM) that capture precise dimensional data across hundreds of measurement points. This documentation provides traceability throughout production runs and supports continuous improvement initiatives.

Metallurgical Testing for Grain Structure: The entire advantage of roll forging depends on proper grain flow alignment. Metallurgical testing confirms that internal structure meets design expectations. Techniques include:

- Microscopic examination: Sectioned samples reveal grain size, flow patterns, and structural uniformity.

- Hardness testing: Rockwell, Brinell, or Vickers methods verify material resistance to deformation meets specifications.

- Tensile testing: Destructive tests measure strength, ductility, and elongation properties.

- Impact testing: Charpy or Izod methods assess toughness under sudden loading conditions.

Non-Destructive Testing (NDT): These methods detect defects without damaging components, enabling 100% inspection of critical parts:

- Ultrasonic testing (UT): High-frequency sound waves detect internal flaws like voids, inclusions, or cracks invisible to visual inspection.

- Magnetic particle inspection (MPI): Reveals surface and near-surface defects in ferromagnetic materials by detecting magnetic field disruptions.

- Radiographic testing: X-ray or gamma-ray imaging exposes internal defect conditions for detailed analysis.

OEM specification compliance requires documented verification at each production stage. Pre-forging quality control validates incoming material certifications and billet dimensions. During-forging monitoring tracks temperature, force, and timing parameters in real-time. Post-forging inspection confirms final dimensions, surface quality, and material properties before shipment.

When evaluating roll forging suppliers for automotive applications, procurement professionals should verify:

- Certification status: Current IATF 16949 certification with recent audit results demonstrating continuous compliance.

- Quality management systems: Documented procedures covering every production stage with evidence of consistent implementation.

- Traceability capabilities: Systems tracking each component from raw material through finished product, enabling rapid identification if quality issues emerge.

- Testing documentation: Comprehensive records including PPAP (Production Part Approval Process), FMEA (Failure Mode and Effects Analysis), and CMM reports.

- Inspection equipment: Modern testing capabilities matching the precision requirements of specified components.

- Corrective action processes: Demonstrated ability to identify root causes and implement lasting solutions when defects occur.

Suppliers like Shaoyi (Ningbo) Metal Technology exemplify these quality standards with their IATF 16949 certification and rigorous quality control protocols. Their precision hot forging solutions demonstrate how proper quality systems translate into reliable automotive components, from suspension arms to drive shafts, all backed by the documentation and traceability automotive OEMs require.

Quality standards and testing protocols establish the foundation for supplier relationships, but successful automotive forging partnerships require additional considerations around production capabilities, engineering support, and supply chain logistics.

Partnering with Roll Forging Suppliers for Automotive Success

You have identified the perfect component design, specified the right materials, and confirmed that roll forging delivers the mechanical properties your application demands. Now comes the critical question: how do you find a supplier capable of translating those specifications into consistently excellent production? The difference between a successful automotive forging partnership and a frustrating procurement experience often comes down to evaluating supplier capabilities against your specific project requirements.

Whether you are sourcing millions of drivetrain components annually for a major OEM or developing specialty parts for performance vehicles and heavy-duty commercial applications, the fundamentals of supplier selection remain remarkably consistent. Understanding how to forging supplier relationships effectively means matching production capabilities with volume requirements, engineering support with design complexity, and geographic positioning with supply chain efficiency goals.

Balancing Volume Requirements with Supplier Capabilities

Imagine launching a new vehicle platform requiring 500,000 axle shafts annually versus developing a limited-production performance variant needing just 2,000 units. These scenarios demand fundamentally different supplier capabilities, yet both require the same attention to quality and precision. Understanding where your project falls on this spectrum helps narrow supplier candidates quickly.

For high-volume OEM production, suppliers must demonstrate:

- Proven capacity scalability: Equipment and workforce capable of ramping from development quantities to full production without quality degradation.

- Consistent process control: Statistical process monitoring ensuring every component meets specifications regardless of production shift or equipment condition.

- Supply chain resilience: Multiple raw material sources and contingency planning protecting against disruptions that could halt your assembly lines.

- Competitive cost structures: Manufacturing efficiency enabling pricing that supports your vehicle program margins.

According to industry sourcing experts, suppliers with at least 10-15 years of experience across multiple sectors demonstrate the reliability and versatility needed for demanding automotive programs. Their established processes, trained workforces, and proven equipment reduce the risks inherent in high-volume production commitments.

Lower-volume specialty applications present different challenges. Performance vehicles, heavy-duty commercial trucks, and defence forging applications often require custom forging solutions with unique geometries, specialized materials, or enhanced mechanical properties. These projects prioritize:

- Engineering flexibility: Willingness to collaborate on unique specifications rather than forcing designs into standard production parameters.

- Material expertise: Experience with specialty alloys and heat treatments that mainstream automotive suppliers may not routinely handle.

- Forging mold development: Capability to design and manufacture custom tooling economically for smaller production runs.

- Quality documentation: Comprehensive traceability and testing records that specialty applications often demand.

The distinction between high-volume and specialty suppliers is not always binary. Some manufacturers excel at bridging this gap, offering the engineering flexibility of custom shops with the process discipline of volume producers. These partners prove particularly valuable when developing components that may start as limited-production items before scaling to mainstream applications.

From Rapid Prototyping to Mass Production Partnerships

What if you need functional prototypes in weeks rather than months? The gap between design concept and production-ready components often determines competitive advantage in automotive development. Suppliers offering integrated prototyping capabilities compress this timeline dramatically while ensuring prototype performance accurately predicts production results.

According to manufacturing research, traditional prototyping processes requiring 12-20 weeks for tooling preparation create significant innovation barriers. Modern rapid prototyping approaches combining additive manufacturing for die creation with conventional forging techniques reduce these timelines by up to 60%. This acceleration enables design iterations that would otherwise be economically impractical.

The design-for-manufacturability phase represents perhaps the most critical period in any automotive forging project. During this stage, supplier engineering teams analyze component designs, identify potential manufacturing challenges, and recommend modifications that improve both quality and cost-effectiveness. Key considerations include:

- Draft angles and radii: Ensuring geometry allows clean material flow and die release without defects.

- Cross-section transitions: Gradual changes preventing stress concentrations during forming and in service.

- Material distribution: Optimizing preform design to minimize waste while ensuring complete die fill.

- Tolerance allocation: Balancing specification requirements against achievable manufacturing precision.

Suppliers with in-house engineering capabilities add tremendous value during this phase. Their manufacturing experience translates directly into practical design recommendations that academic analysis might miss. When your supplier can simulate forging processes, predict potential issues, and suggest proven solutions, you avoid the costly iterations that plague less collaborative relationships.

For example, Shaoyi (Ningbo) Metal Technology demonstrates how integrated capabilities streamline automotive procurement. Their precision hot forging solutions, backed by IATF 16949 certification and rigorous quality control, span from rapid prototyping in as little as 10 days to high-volume mass production. In-house engineering ensures robust components like suspension arms and drive shafts meet exact specifications, while their location near Ningbo Port enables fast, globally compliant manufacturing that supports tight supply chain timelines.

Lead time considerations extend beyond initial prototyping into ongoing production planning. Understanding realistic expectations helps avoid the scheduling conflicts that strain supplier relationships:

| Project Phase | Typical Lead Time Range | Key Variables Affecting Timeline |

|---|---|---|

| Tooling Development | 4-12 weeks | Component complexity, die material requirements, design iterations |

| Prototype Production | 10 days - 6 weeks | Supplier capabilities, quantity required, testing scope |

| Production Ramp-Up | 4-8 weeks | Volume targets, quality validation requirements, capacity availability |

| Ongoing Production | 2-6 weeks per order | Order quantity, material availability, production scheduling |

Supply chain considerations increasingly influence supplier selection decisions. Geographic positioning affects logistics efficiency, lead times, and total landed costs. Suppliers located near major shipping ports enable faster international delivery while reducing transportation expenses. Global compliance requirements add complexity, particularly when components must meet specifications from multiple regional standards bodies simultaneously.

The oil and gas forging sector shares many supplier evaluation criteria with automotive applications, including demanding material specifications, rigorous testing requirements, and zero tolerance for quality deviations. Suppliers experienced in these adjacent industries often bring valuable process discipline and documentation practices that translate directly into automotive program success.

When structuring supplier relationships for long-term success, consider these strategic elements:

- Transparent communication: Regular updates on production status, capacity constraints, and potential issues before they become crises.

- Continuous improvement commitment: Suppliers who proactively suggest cost reduction opportunities and quality enhancements demonstrate true partnership mentality.

- Flexibility for urgent requirements: Willingness to accommodate unexpected volume changes or expedited orders when your business needs demand responsiveness.

- Technical collaboration: Ongoing engineering support for design updates, material substitutions, and process refinements throughout the program lifecycle.

According to supply chain research, forged components from qualified suppliers reduce overall supply chain risk by providing consistent quality, reliable delivery, and predictable performance. A well-structured forging partnership becomes an extension of your engineering and manufacturing capabilities rather than simply a transactional vendor relationship.

The automotive industry's evolution toward electrification, lightweighting, and sustainability creates ongoing opportunities for roll forging suppliers who invest in capabilities matching these emerging requirements. Selecting partners positioned to support both current production needs and future technology directions protects your supply chain investment over the long term.

Frequently Asked Questions About Roll Forging Automotive Applications

1. What is roll forging and how does it work in automotive manufacturing?

Roll forging is a precision metal forming process where preheated billets pass through grooved rotating cylindrical dies, progressively shaping the metal through compressive forces. Unlike hammer forging that uses discrete impact blows, roll forging applies continuous rotational compression that aligns the metal's grain structure along the component's length. This creates elongated automotive parts like axle shafts, crankshafts, and connecting rods with superior mechanical properties and fatigue resistance essential for safety-critical vehicle applications.

2. What is the forging process in the automotive industry?

The automotive forging process involves shaping heated metal using compressive forces to create high-strength components. Roll forging specifically heats billets to 1050-1150°C for steel alloys, then passes them through multiple roll die stations for progressive shaping. This process often serves as a preforming operation before closed-die finishing, optimizing material distribution for complex parts like crankshafts. The result is components with aligned grain flow, enhanced fatigue resistance, and superior strength-to-weight ratios compared to cast or machined alternatives.

3. What are the main applications of roll forging in vehicles?

Roll forging produces critical automotive drivetrain and suspension components including crankshafts requiring aligned grain structure for torsional strength, axle shafts needing exceptional fatigue resistance, connecting rods demanding high-cycle durability, transmission shafts requiring uniform mechanical properties, and steering components needing precise geometry. The process excels at creating elongated parts with varying cross-sections and rotational symmetry. Electric vehicles also benefit from roll-forged motor shafts and reduction gear components designed for instant torque delivery.

4. What are the disadvantages of roll forging compared to other methods?

Roll forging has limitations including higher initial tooling costs for die development, the requirement for specialized equipment, and constraints on component geometry to elongated shapes with rotational symmetry. Hot roll forging produces surface scale requiring removal and achieves wider tolerances (±0.5mm to ±1.0mm) than cold processes, often necessitating secondary machining. Component size is limited by equipment capacity, and complex geometries may require hybrid approaches combining roll forging preforms with closed-die finishing operations.

5. How do I choose between hot and cold roll forging for automotive parts?

Select hot roll forging for larger components requiring significant deformation like crankshafts and axle shafts, where enhanced ductility and grain refinement outweigh precision requirements. Hot forging at 1050-1200°C delivers up to 20% higher fatigue resistance. Choose cold roll forging for precision parts like gears, fasteners, and bearing races needing tight tolerances (±0.1mm to ±0.3mm) and superior surface finish. Cold processing offers 25% less material waste and strain-hardened surfaces but limits component size and material options to ductile alloys.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —