Choosing Forged Wheels For Track Use Without Expensive Mistakes

Understanding Forged Wheels and Their Track Performance Edge

Imagine shaving seconds off your lap time without changing your driving technique. Sounds impossible? The secret might be spinning right beneath you. When you're pushing your car to its limits on track, every component matters—but few have as direct an impact on performance as your wheels. They're the crucial link between your suspension and the asphalt, affecting acceleration, braking response, and cornering grip in ways that can make or break your personal best.

Why Your Wheel Choice Matters on Track

Track wheels endure punishment that street driving simply cannot replicate. High-speed cornering generates immense lateral forces, while aggressive braking creates intense heat cycles that stress materials to their limits. The wrong wheel choice doesn't just cost you time—it compromises safety and erodes the confidence you need to push hard through every corner.

So what are forged wheels, and why do serious track enthusiasts swear by them? Unlike cast alternatives that pour molten metal into molds, forged wheels begin as solid aluminum billets subjected to extreme pressure—often exceeding 10,000 tons. This intense compression fundamentally transforms the metal's internal structure, creating a denser grain pattern with superior mechanical properties.

The Forged Advantage for Serious Drivers

The forging process does something remarkable to aluminum. When that billet gets pressed under massive force, the metal's grain structure condenses dramatically. Think of it like compacting loose sand into solid stone—the result is a material that's both stronger and more resilient under repeated stress.

Because forged material is inherently stronger, less of it is needed to maintain structural integrity under load. This means you get a lighter and stronger product simultaneously—the holy grail of motorsport engineering.

A forged aluminum 6061 wheel delivers an exceptional strength-to-weight ratio that directly translates to track performance. According to manufacturing specifications, this aerospace-grade alloy combined with the forging process creates wheels that can handle repetitive stress cycles far longer before showing fatigue. For track use, this durability isn't just convenient—it's essential for both performance and safety.

The benefits of rotary forged wheels and fully forged options extend beyond raw strength. The precision manufacturing process allows for thinner spokes and finer details without sacrificing integrity. This means better brake cooling, reduced unsprung mass, and the ability to clear larger brake packages—all critical considerations when choosing track wheels.

Throughout this guide, you'll discover how to match wheel construction to your specific motorsport discipline, navigate the complexities of sizing and fitment, and build a buying framework that protects your investment. Whether you're preparing for your first HPDE event or chasing competitive lap times, understanding these fundamentals will help you make decisions you won't regret when the flag drops.

Comparing Wheel Construction Methods for Motorsport

Now that you understand why forged wheels command respect in motorsport circles, let's dig into how they stack up against the alternatives. When you're comparing forged wheels vs alloy wheels—or more specifically, cast versus flow-formed versus fully forged—the differences go far deeper than price tags. Each construction method creates fundamentally different products with distinct performance characteristics that matter enormously on track.

Cast vs Forged vs Flow-Formed for Track Days

So what is the difference between forged wheels and alloy wheels you'll find at your local tire shop? It all comes down to manufacturing. Cast wheels start as molten aluminum poured into molds and allowed to cool. This process is straightforward and cost-effective, but it has a critical weakness: as the liquid metal solidifies, inconsistencies like porosity and air pockets can form within the structure. These microscopic imperfections become potential failure points under the repeated stress of track use.

Flow-formed wheels—sometimes marketed as "rotary forged" or "spun forged"—represent a middle-ground approach. They begin life as cast wheels, but after leaving the mold, they're placed on a rotary machine that applies heat and pressure to stretch and compress the barrel section. This process increases tensile strength and reduces weight compared to pure casting, though the center section remains cast.

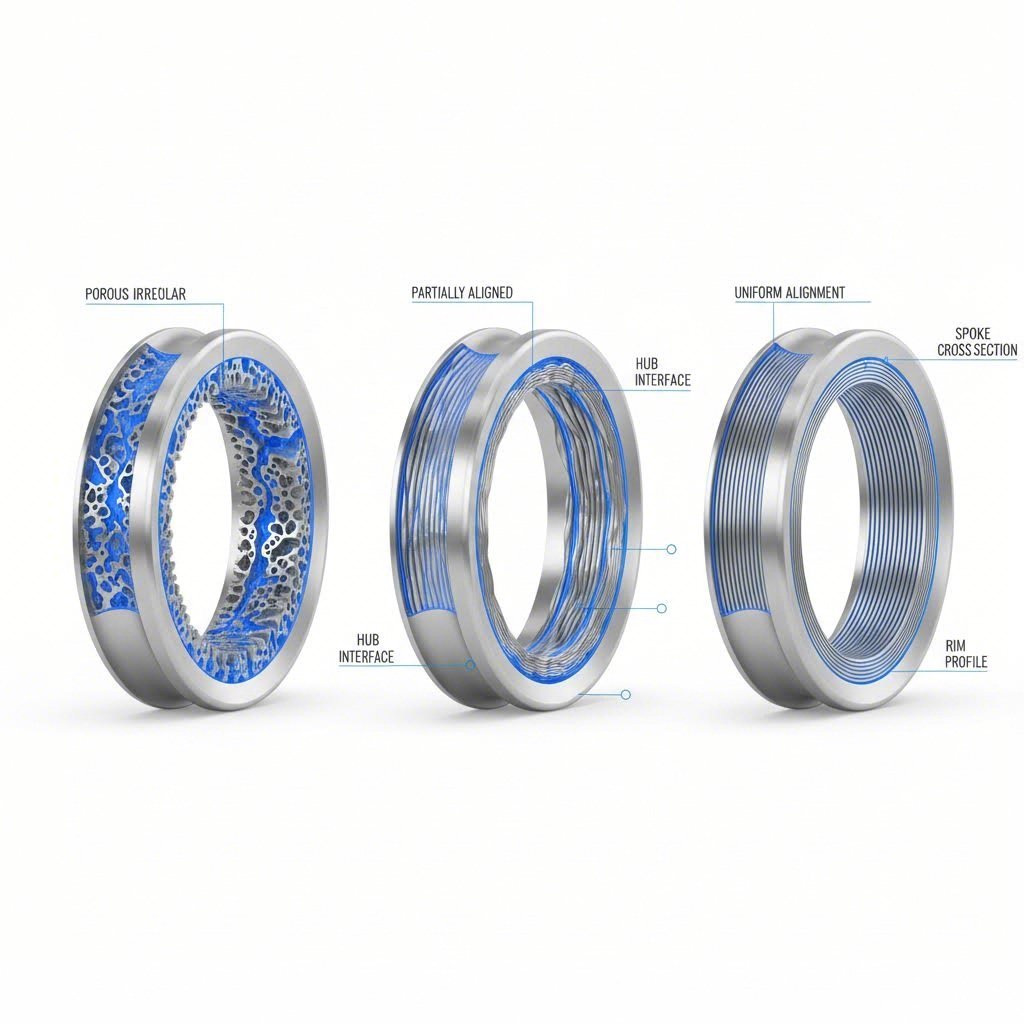

Fully forged wheels take an entirely different path. Starting from a solid aluminum billet, extreme pressure literally reshapes the metal's grain structure. The result? A wheel where the internal grain follows the contours of the design, creating uniform strength throughout. There's no porosity, no hidden weak spots—just dense, consistent material engineered to handle punishment.

| Characteristic | Cast Wheels | Flow-Formed Wheels | Forged Wheels |

|---|---|---|---|

| Construction Method | Molten aluminum poured into molds | Cast center with pressure-formed barrel | Solid billet compressed under extreme pressure |

| Typical Weight Difference | Baseline (heaviest) | 15-25% lighter than cast | 25-35% lighter than cast |

| Impact Resistance | Prone to cracking under stress | Improved over cast; good resilience | Excellent; bends before cracking |

| Heat Dissipation | Adequate for street use | Good; handles moderate track heat | Superior; dense structure manages heat cycles |

| Price Range | $150-$400 per wheel | $300-$700 per wheel | $800-$2,500+ per wheel |

| Best Use Case | Street driving; occasional beginner HPDE | Regular HPDE; light competition | Competitive racing; frequent track use |

Finding the Right Balance of Cost and Performance

Here's a question worth considering: what is better, alloy or forged wheels for your specific situation? The honest answer depends on where you are in your motorsport journey and how you'll use them.

For beginners attending their first few HPDE events, quality cast wheels from reputable manufacturers can be perfectly acceptable. You're learning car control, building confidence, and not yet generating the consistent high loads that stress wheels to their limits. Spending less on wheels initially means more budget for instruction, tires, and brake pads—investments that will accelerate your development faster.

However, as your skills progress and your pace increases, the calculus changes. The difference between cast and forged wheels weight becomes increasingly significant because of something called unsprung mass—the weight of components not supported by your suspension springs.

Unsprung mass directly affects how quickly your suspension can respond to surface changes. Every pound saved at the wheels has a multiplicative effect on handling, braking, and acceleration response.

Think about it this way: your suspension must control wheel movement constantly. Lighter wheels accelerate and decelerate faster, allowing tires to maintain better contact with the pavement. This translates to:

- Faster acceleration as the drivetrain works against less rotational inertia

- Shorter braking distances with reduced mass to slow down

- Sharper turn-in response as less weight resists direction changes

- Improved bump absorption as the suspension controls lighter components more easily

The grain structure differences between construction methods also matter for longevity under track stress. Cast wheels experience repeated thermal cycling and load stress that can propagate those internal inconsistencies into cracks over time. Flow-formed wheels handle this better in the barrel section, but their cast centers remain vulnerable. Forged wheels, with their aligned grain structure and absence of porosity, maintain structural integrity through hundreds of track sessions.

What does forged wheels mean for your wallet long-term? Consider this: a quality forged wheel that survives years of track abuse may actually cost less per session than cheaper alternatives that need replacement after a few seasons. Add in the safety margin that comes with superior impact resistance—the ability to bend rather than shatter when you clip a curb—and the investment starts making serious sense.

Understanding these construction differences is essential groundwork, but the next critical step is matching your wheel choice to your specific motorsport discipline. Different racing styles create vastly different demands on your equipment.

Selecting Wheels by Motorsport Discipline

Here's something many enthusiasts overlook: the perfect track wheel for autocross might be completely wrong for wheel-to-wheel racing. Each motorsport discipline creates unique demands on your equipment, and understanding these differences prevents costly mismatches between your wheels and your racing goals.

Matching Wheels to Your Racing Style

Think about what happens when you throw your car into a tight autocross cone course versus holding a sweeping line at triple-digit speeds during a time attack session. The forces, heat cycles, and potential hazards differ dramatically. Your wheel selection should reflect these realities rather than defaulting to a one-size-fits-all approach.

Let's break down what each discipline truly demands from your race car wheel setup:

Autocross: Where Every Ounce Counts

Autocross rewards responsiveness above almost everything else. You're making rapid direction changes, often transitioning from full left lock to full right lock within seconds. This creates tremendous stress on wheel mounting points and spoke bases as lateral loads reverse repeatedly throughout a run.

- Lightweight priority: With runs lasting under two minutes, weight savings translate directly to quicker transitions and faster times—aim for the lightest true forged rims your budget allows

- Tight turning stress resistance: Repeated full-lock maneuvers generate unique fatigue patterns different from high-speed track use

- Modest heat cycling: Short runs mean less thermal stress, so extreme heat dissipation becomes less critical

- Curb strike risk: Cone courses set in parking lots often feature unexpected surface transitions and occasional cone strikes

HPDE: Building Skills Without Breaking the Bank

High Performance Driving Events serve as the entry point for most track enthusiasts. Here, durability and forgiveness matter more than shaving every possible gram. You're learning proper lines, developing car control, and occasionally making mistakes—your wheels need to survive that learning curve.

- Durability for the learning phase: Expect occasional off-track excursions and curb contact as you develop your skills

- Curb strike resistance: HPDE tracks feature aggressive kerbing that punishes poor apex timing—wheels that bend rather than crack provide crucial safety margin

- Reasonable cost replacement: Budget for potential damage without catastrophic financial consequences

- Heat management: Longer sessions mean more thermal cycling than autocross—your track wheel choice should handle sustained heat buildup

Time Attack: Chasing Ultimate Performance

When every hundredth of a second matters, time attack competitors obsess over details that casual drivers ignore. This discipline demands wheels optimized for outright speed, often pushing the boundaries of what's practical for other uses.

- Ultimate weight savings: Serious competitors run the lightest wheels structurally capable of surviving their power and grip levels

- Aerodynamic spoke designs: At sustained high speeds, spoke patterns can create measurable drag differences

- Brake clearance for massive packages: Time attack builds often feature oversized brake systems requiring careful wheel fitment

- Single-session focus: Wheels may be inspected and replaced more frequently, prioritizing performance over longevity

Wheel-to-Wheel Racing: When Contact Happens

Competitive door-to-door racing introduces variables that other disciplines avoid: potential contact with other cars, debris from incidents, and the stress of race-pace laps for extended durations.

- Regulations compliance: Many racing series specify wheel sizes, widths, or even approved manufacturers—verify rules before purchasing

- Impact resistance: Contact with other vehicles or debris is virtually inevitable over a season of racing

- Consistent performance under stress: Wheels must maintain integrity through race-length stints at maximum attack

- Spare availability: Popular Apex Wheels and established brands offer easier replacement when damage occurs mid-season

Discipline-Specific Requirements You Cannot Ignore

As drivers progress from beginner HPDE to competitive racing, their wheel requirements evolve significantly. That forgiving flow-formed wheel that served you well during your first track days may become inadequate when you're consistently generating 1.4g lateral loads on sticky tires.

Consider how dramatically loads increase with skill development. According to 949 Racing's engineering analysis, street driving rarely exceeds 0.85g lateral force, while a well-prepared track car on performance tires can sustain 1.4g or higher. Add aerodynamic downforce and you might see 1.6g sustained cornering loads—forces that were virtually unimaginable when most wheel testing standards were established.

The JWL standard's cornering fatigue test simulates barely 1g of lateral force. Your high-performance track car generates loads 40-60% higher than what many wheels are specifically tested to handle.

This reality makes load rating understanding essential. A wheel rated for 620kg load capacity might seem adequate until you calculate what happens during aggressive track driving. That rating assumes conditions far gentler than what your car experiences when you're attacking apexes at the limit of adhesion.

Impact resistance specifications become particularly relevant when discussing curb strikes—an inevitability for anyone pushing hard on track. The difference between a wheel that bends and one that shatters can mean the difference between limping back to the paddock and a much more serious situation. Forged wheels excel here precisely because their grain structure allows controlled deformation rather than catastrophic failure.

Street driving simply cannot replicate the sustained stress cycles that track use generates. An HPDE weekend might subject your wheels to more fatigue than months of daily commuting. Understanding this disparity helps explain why wheels that seem "perfectly fine" on the street can develop cracks or fail during their first serious track outing.

With discipline-specific requirements clarified, the next crucial step involves getting your wheel dimensions right. Width, diameter, and offset choices directly determine whether your carefully selected wheels actually deliver the handling benefits you're seeking.

Wheel Sizing Strategy for Optimal Track Handling

You've selected the right construction method and matched your wheel choice to your motorsport discipline. Now comes the decision that actually determines whether those wheels transform your handling or create new problems: sizing. Getting width, diameter, and offset wrong doesn't just cost performance—it can damage suspension components, destroy tires prematurely, and fundamentally alter how your car responds to inputs.

Getting Width, Diameter, and Offset Right

Think of wheel sizing as a three-dimensional puzzle where each variable affects the others. Change one dimension and you'll likely need to reconsider the rest. Let's break down each element and understand what it actually does on track.

Width: The Foundation of Grip

Wheel width directly determines your tire's contact patch—the only thing connecting your car to the asphalt. According to IPG Parts' technical analysis, wider wheels create a broader contact patch that increases the tire's surface area in contact with the road. This larger patch improves traction, which proves crucial for high-speed cornering and accelerating out of turns.

But width does more than just expand your grip footprint. A wider wheel stretches the tire sidewall, making it stiffer. This reduced sidewall flex enhances steering precision and response—key factors when you need quick and accurate steering inputs through complex corner sequences. Less flex also means the tire maintains its shape better under high loads, ensuring consistent contact with the road and preventing unpredictable handling.

There's a balance to strike, however. Excessively wide wheels can create:

- Increased steering effort and reduced feedback

- Potential fender clearance issues, especially with suspension travel

- Heavier rotating mass if you're stretching beyond optimal tire pairings

- Uneven wear patterns if the tire profile becomes too aggressive

Diameter: The Unsprung Mass Trade-Off

Smaller diameter wheels reduce unsprung mass—that multiplicative performance factor we discussed earlier. A 17-inch wheel typically weighs less than an 18-inch equivalent of the same construction quality, and the shorter sidewall tire also contributes less rotating weight. For pure performance on smooth circuits, going smaller often makes sense.

However, diameter isn't just about weight. Your brake package dictates minimum wheel size. Those impressive 6-piston calipers and 380mm rotors you're eyeing? They won't fit behind 15-inch wheels regardless of how light they are. Many serious track builds end up at 17 or 18 inches as the sweet spot—large enough for substantial brake upgrades while still managing weight effectively.

Consider tire availability too. Popular NT03 wheels and similar track favorites often work best with specific diameter and width combinations where tire manufacturers concentrate their performance offerings. Going exotic with sizing might leave you with limited rubber choices.

The Geometry That Makes or Breaks Handling

Offset: More Complex Than It Appears

Offset measures the distance from the wheel's mounting surface to its centerline, expressed in millimeters. Positive offset means the mounting surface sits toward the outside face; negative offset pushes it toward the inside. This seemingly simple measurement has profound effects on how your car drives.

According to Drivingline's technical breakdown, offset directly determines your scrub radius—the distance between the tire centerline and the steering axis where it meets the ground. A positive scrub radius means your tires don't pivot on their center but instead arc front and back as you steer. The result? More steering effort, increased feedback from bumps, and potential handling unpredictability.

Most OEM vehicles engineer scrub radius close to zero for predictable behavior. When you swap to wheels with significantly different offset—especially more negative offset for that aggressive track stance—you're increasing scrub radius and changing fundamental steering characteristics. This isn't necessarily bad, but you need to understand the trade-off.

Offset also affects wheel bearing loads. Moving the wheel further outboard creates longer lever arms that stress hub bearings and suspension components. Track driving already generates forces far beyond street use; adding offset-induced stress compounds the issue. Parallel forged wheels with moderate offsets often provide the best balance between aesthetics and mechanical longevity.

| Vehicle Type | Typical Width Range | Common Diameter | Offset Considerations | Primary Track Style |

|---|---|---|---|---|

| Lightweight Sports Cars (Miata, BRZ, Lotus) | 7.5" - 9" | 15" - 17" | +35 to +45mm; preserve factory geometry | Autocross, Time Attack |

| Sport Compacts (Civic, Golf, Focus) | 8" - 9.5" | 17" - 18" | +35 to +45mm; watch for inner fender clearance | HPDE, Time Attack |

| Sports Sedans (M3, C63, IS-F) | 9" - 10.5" | 18" - 19" | +22 to +35mm; accommodate wider tires | HPDE, Wheel-to-Wheel |

| High-Power GT Cars (Corvette, 911, GT-R) | 10" - 12" (rear) | 18" - 20" | Varies widely; match to brake package | Time Attack, Endurance |

| Dedicated Race Cars | Per regulations | Per regulations | Optimized for specific chassis; often custom | Series-specific |

Brake Package Compatibility: The Hidden Constraint

Here's where many enthusiasts make expensive mistakes. You've found the perfect Fikse FM10 or other premium forged rims at a great price, but will they actually clear your brake setup? As brake fitment specialists note, big brake kits expand both caliper dimensions and rotor diameter, directly affecting wheel fitment.

Larger calipers extend outward toward the wheel spokes, while bigger rotors reduce available inner barrel space. Many performance setups require offsets between +30mm and +45mm depending on vehicle width, suspension design, and wheel size. But offset alone doesn't solve the equation—spoke design matters enormously.

Concave spoke patterns and thinner wheel barrels can accommodate higher offsets while maintaining brake clearance. What are forged rims doing differently here? Their superior strength allows thinner spoke designs without sacrificing structural integrity, creating more room for massive brake packages. A well-designed 18-inch forged wheel might clear brakes that a poorly designed 19-inch cast wheel cannot.

Before purchasing, always verify:

- Minimum wheel diameter for your brake rotor size

- Required spoke-to-caliper clearance (typically 3-5mm minimum)

- Inner barrel depth and caliper body positioning

- Whether manufacturer-provided brake clearance templates exist

Suspension Geometry Interactions

Your wheel specs don't exist in isolation—they interact with your suspension geometry in ways that affect handling balance. Width and offset changes alter your effective track width, which influences weight transfer characteristics during cornering. Diameter changes affect your tire's sidewall height, which impacts how suspension geometry changes through travel.

Consider camber curve effects: as your suspension compresses and extends, wheel camber changes based on control arm geometry. A taller sidewall tire provides more compliance to absorb these changes smoothly, while a shorter sidewall (from larger diameter wheels) makes those geometry changes more immediate and potentially unsettling.

For most track applications, maintaining suspension geometry close to the manufacturer's intended design yields the most predictable results. Dramatic offset or width changes might look aggressive, but they often require suspension modifications to restore proper handling balance.

With sizing strategy clarified, the next critical consideration involves how your carefully selected wheels interact with the tires that actually grip the track surface.

Tire Fitment Considerations for Track Applications

You've nailed down the perfect wheel size and construction—but here's where many track enthusiasts stumble. The relationship between your wheels and tires isn't just about making the numbers match. On track, where lateral forces routinely exceed 1.4g and temperatures swing wildly between sessions, the wheel-tire interface becomes a critical performance factor that separates confident drivers from those chasing handling gremlins all day.

Pairing Wheels with Track-Ready Rubber

When you're selecting tires for your fully forged wheels, forget about matching the numbers printed on the sidewall. What actually matters is tread width—the real-world measurement of rubber contacting pavement. According to MotoIQ's performance tire guide, tire manufacturers often produce multiple versions of the same marked size with significantly different actual widths.

Here's a practical rule that experienced track drivers follow: target your wheel width to match the tire's tread width, or go approximately 0.5 inches wider. This creates a slight "stretch" or preload on the sidewall that improves response and break-away characteristics. Too narrow a wheel and the sidewall becomes overly stressed with compromised ride quality and unpredictable grip loss. Too wide and you'll experience sloppy handling, vague steering feel, and excessive tread squirm.

- 7.5" wheel width: Ideal for 205-225mm tread width tires

- 8.0" wheel width: Best matches 215-235mm tread width tires

- 8.5" wheel width: Optimal for 225-245mm tread width tires

- 9.0" wheel width: Suits 235-255mm tread width tires

- 9.5" wheel width: Accommodates 245-265mm tread width tires

- 10.0" wheel width: Designed for 255-285mm tread width tires

- 10.5"+ wheel width: Supports 275mm+ tread width applications

Remember that for every 0.5-inch change in rim width, a tire's section width typically changes by approximately 0.2 inches. This relationship helps you predict how a given tire will behave when mounted on wheels slightly different from its design specification.

Sidewall and Bead Seat Compatibility Essentials

Under track conditions, your tire beads experience forces that street driving never approaches. When you're carrying maximum speed through a sweeping corner, those beads must maintain an absolutely secure seal against the wheel's bead seat. Any compromise here doesn't just cause slow air leaks—it can lead to sudden pressure loss at the worst possible moment.

The Tire and Rim Association establishes global engineering standards ensuring tire bead diameters and profiles exactly match specified wheel bead seat dimensions. Standard passenger car wheels feature an ISO J contour with a 5-degree bead seat taper, safety humps to retain beads during pressure loss, and tall flanges to laterally support tire sidewalls. These specifications exist because the tire-wheel interface must perform flawlessly under extreme conditions.

Every tire and the wheel upon which it is mounted must fit together better than a hand in a glove. Tire bead diameters and profiles must exactly match their specified wheel's bead seat dimensions and contours.

Are forged wheels aluminium? Yes—and their manufacturing precision creates measurably better bead seating than cast alternatives. VT forged wheels and similar quality manufacturers machine their bead seats to tighter tolerances, ensuring consistent contact around the entire circumference. This precision matters because any high or low spots in a cast wheel's bead seat can create uneven sealing pressure, potentially allowing the tire to unseat under extreme lateral loads.

According to Bridgestone's mounting guidelines, concentric mounting—where the wheel center aligns precisely with the tire center—is essential for performance and safety. Non-concentric mounting causes ride disturbances and irregular wear that compounds over time. Quality rock forged wheels and other precision-manufactured options maintain the dimensional accuracy needed for perfect concentricity, reducing vibration at high speeds and ensuring even tire wear through countless heat cycles.

The relationship between wheel construction quality and bead seating extends beyond initial fitment. Track use subjects wheels to repeated thermal cycling and mechanical stress. Lower-quality wheels can develop slight warping or surface irregularities over time that compromise bead sealing. Fully forged wheels resist these deformations, maintaining their precise geometry session after session.

Heat Cycling and Temperature Management

Track tires live a demanding thermal life. They heat rapidly under aggressive driving, then cool during pit stops, only to heat again when you return to the circuit. This repeated cycling affects both tire compound performance and the wheel-tire interface itself.

Forged aluminum's denser molecular structure conducts heat more efficiently than cast alternatives. This characteristic helps manage tire temperatures in two important ways: heat transfers away from the tire bead area more effectively, and the wheel itself maintains more consistent temperatures throughout a session. Consistent wheel temperature means consistent bead seat dimensions—critical for maintaining that perfect seal.

Heat management also affects tire performance directly. A wheel that absorbs and retains excessive heat can push tire temperatures beyond optimal ranges, accelerating wear and potentially causing thermal degradation. The superior heat dissipation of forged construction helps keep your expensive track rubber in its ideal operating window longer.

Consider too how tire pressure changes with temperature. As your tires heat during a session, internal pressure rises. Starting with the correct cold pressures requires understanding how your specific wheel-tire combination behaves through its heat cycle. Higher-quality wheels with better thermal properties tend to produce more predictable pressure curves, making setup decisions more consistent from session to session.

With your wheel and tire pairing optimized, the next consideration becomes how to protect and maintain this investment through race weekends and beyond.

Track Day Wheel Strategy and Backup Planning

You've invested in quality forged wheels, paired them with the right tires, and dialed in your sizing. But here's a question that separates prepared drivers from those who end up watching from the paddock: what happens when something goes wrong? A single curb strike, an unexpected pothole, or debris on the racing line can end your day instantly—unless you've built a complete track wheel strategy that accounts for reality rather than hoping for perfection.

Building Your Complete Track Wheel Arsenal

Should you run your track wheels on the street, or maintain completely separate setups? This decision affects everything from convenience to long-term costs. Many drivers start with dual-purpose wheels—driving to the track, running sessions, then driving home. It's simpler and requires less equipment. But simplicity comes with trade-offs.

Dedicated track wheels offer significant advantages worth considering:

- Optimized sizing: You can run more aggressive widths and offsets without worrying about daily driving clearance issues or ride quality

- Tire preservation: Track tires mounted on dedicated wheels avoid the heat cycling damage that comes from street miles between events

- Faster pit turnaround: Swap complete wheel-tire packages rather than changing tires at the track

- Reduced street tire wear: Your commuter rubber stays fresh while your track rubber handles the abuse

- Easier inspection: Wheels used exclusively for track duty can be inspected systematically without the confusion of street-induced wear patterns

The convenience of dual-purpose setups fades quickly when you consider the logistics. Street miles accumulate heat cycles on expensive track tires, degrading their performance before they ever see a circuit. And running track-optimized wheel specs on daily roads can accelerate suspension wear and create unpredictable handling in everyday situations.

Transport and Storage Protection

Your forged wheels represent a substantial investment—treating them casually during transport invites damage that compromises both performance and safety. According to Road & Track's tech inspection guidance, organizers scrutinize wheel condition carefully because they understand how easily transport damage goes unnoticed until it matters most.

Proper wheel storage between events means:

- Individual wheel bags or padded separators to prevent surface contact

- Vertical storage when possible to avoid flat-spotting tires

- Climate-controlled environments to prevent rubber degradation and potential corrosion

- Securing wheels during vehicle transport so they cannot shift, roll, or impact each other

Many experienced track enthusiasts invest in wheel carts or dedicated trailers specifically to protect their equipment. The cost seems excessive until you've scratched a $2,000 forged wheel against another one during a hasty load-in.

Backup Plans That Save Your Track Day

Imagine you're three sessions into a perfect track day. Your times are dropping, the car feels dialed, and then—contact with an apex curb that didn't seem that aggressive. Now you're sitting in the paddock with a damaged wheel and no way to continue. This scenario plays out constantly at tracks worldwide, and the drivers who keep running are those who planned ahead.

Before every track event, work through this pre-track wheel preparation checklist:

- Visual inspection: Check each wheel for cracks, especially around spoke bases, lug holes, and the inner barrel where stress concentrates

- Bead seat examination: Look for corrosion, damage, or irregularities that could compromise tire sealing

- Lug hole condition: Verify threads are clean and lug seats show no elongation or damage

- Runout check: Spin each wheel and watch for wobble indicating bends or damage

- Tire pressure verification: Confirm cold pressures match your documented baseline for this wheel-tire combination

- Torque specification: Re-torque all lug nuts to manufacturer specs—heat cycling can loosen hardware

- Valve stem condition: Replace aging rubber stems and verify metal stems are tight

Spare Wheel Strategies

Your backup approach should match your event type. Single-day HPDE events and endurance racing create fundamentally different spare requirements.

For typical track days, carrying at least one complete spare wheel-tire assembly makes sense. If you're running a staggered setup with different front and rear sizes, you'll need to decide whether to carry spares for both—or accept that damage to certain corners might end your day. Many drivers prioritize front spares since front wheels typically contact curbs more frequently during corner entry.

Endurance events demand more comprehensive preparation. Multi-hour races can consume equipment at rates that single-day events never approach. Serious endurance competitors often bring:

- Complete spare sets for both axles

- Pre-mounted tires in multiple compounds for changing conditions

- Backup wheels already balanced and ready for immediate installation

- Spare hardware including lug nuts, valve stems, and pressure sensors

Track wheels for trucks and heavier vehicles face additional considerations. Higher vehicle weights generate greater forces during curb strikes, and the larger wheel sizes common on these platforms make spares bulkier to transport and store.

The Cost-Benefit Reality

Here's where the math gets interesting. Quality forged wheels cost significantly more upfront than budget alternatives. But track use creates cumulative stress that reveals the true value of superior construction over time.

Consider two scenarios: Driver A purchases budget cast wheels at $300 each, while Driver B invests in quality forged wheels at $1,000 each. After two seasons of aggressive track use, Driver A has replaced three wheels due to cracking and has one showing stress fractures that require retirement. Driver B's forged wheels show minor cosmetic wear but remain structurally sound.

Driver A's actual cost: $1,200 initial + $900 replacements = $2,100 and counting. Driver B's cost: $4,000 initial investment that continues providing reliable service. The forged wheels that seemed expensive suddenly look like the economical choice—and that calculation doesn't even factor in the track days Driver A missed while waiting for replacement wheels to arrive.

As noted by industry experts, quality forged wheels maintain structural integrity through hundreds of track sessions where cheaper alternatives fail. The dense grain structure created during forging resists the fatigue that causes cast wheels to develop cracks over repeated stress cycles.

This durability advantage extends beyond simple longevity. Variant wheels review discussions and similar community feedback consistently highlight how forged construction provides peace of mind that lets drivers push harder. Knowing your wheels can handle the abuse creates confidence that translates directly to faster lap times and more enjoyable track experiences.

With your track day wheel strategy established, the next essential skill involves maintaining and inspecting your investment to catch problems before they become failures.

Maintenance and Inspection for Track Wheel Longevity

Your forged wheels just survived another intense track session. But here's what separates drivers who enjoy years of reliable service from those facing unexpected failures: what happens in the hours and days after you pull off the circuit matters as much as what happens on it. Understanding what is a forged wheel's maintenance needs—and following through consistently—protects both your investment and your safety.

Keeping Your Forged Wheels Track-Ready

Track sessions coat your wheels with aggressive brake dust, rubber particles, and road grime that's far more damaging than typical street accumulation. Left untreated, this contamination doesn't just look bad—it actively attacks your wheel's finish and can accelerate corrosion around critical stress points.

According to Custom Wheel Offset's maintenance guide, proper cleaning requires specific approaches:

- Start with a thorough water rinse: Knock off the top layer of brake dust and debris before touching the wheel with anything

- Use pH-balanced wheel cleaner: Avoid harsh degreasers that can damage finishes—especially on polished forged rims without clear coat protection

- Clean with soft brushes only: Focus on tight areas around lug holes and spoke bases where contamination accumulates

- Dry completely: Air drying creates water spots that dull finishes over time—use clean microfiber towels

- Apply wheel sealant: Creates a protective barrier that repels brake dust and makes subsequent cleaning easier

What is forged rims' biggest maintenance enemy? Neglect. The forged wheels meaning superior strength doesn't mean they're immune to environmental damage. Brake dust contains metal particles that embed in surfaces and cause pitting if left too long. A quick wipe-down weekly and thorough cleaning every 2-3 weeks keeps contamination from becoming permanent damage.

Inspection Points That Prevent Failures

Visual inspection after every track session isn't optional—it's essential. Unlike street driving, track use generates forces that can initiate damage invisible to casual observation. Knowing where to look and what to look for catches problems while they're still manageable.

Focus your post-track inspection on these critical areas:

- Spoke bases: Where spokes meet the hub face experiences maximum stress during cornering—look for hairline cracks radiating from these junctions

- Lug hole surroundings: Repeated torque cycling and high loads concentrate stress here—check for elongation, cracking, or surface irregularities

- Inner barrel: Often overlooked but critical—inspect for dents, cracks, or deformation from curb contact

- Bead seat area: Damage here compromises tire sealing under load—look for gouges, corrosion, or surface irregularities

Unlike metal fatigue that develops gradually, wheel failures under track stress can progress rapidly once initiated. A crack that seems minor today can become catastrophic within a few more sessions.

Warning signs that demand immediate attention include:

- Any visible crack, no matter how small—especially around spoke bases or lug holes

- New vibrations at speed that weren't present before

- Unusual sounds like creaking or clicking during hard cornering

- Visible bends or deformation in the rim profile

- Air pressure loss that can't be attributed to valve or tire issues

- Discoloration or surface changes around stress concentration points

Torque Specifications and Longevity

Proper lug nut torque isn't just about keeping wheels attached—it directly affects how long your wheels survive track abuse. Under-torqued lugs allow micro-movement that wallows out lug holes over time. Over-torqued hardware creates stress concentrations that can initiate cracking.

Always use a calibrated torque wrench and follow manufacturer specifications exactly. Re-check torque after the first heat cycle of each track day, as thermal expansion and contraction can alter clamping force. Legacy forged wheels and other quality manufacturers provide specific torque recommendations—follow them precisely rather than defaulting to generic values.

When Wheels Should Retire from Track Duty

Quality forged wheels from certified manufacturers maintain structural integrity through years of track abuse—but nothing lasts forever. Consider retirement when:

- Any structural crack has been identified, regardless of repair attempts

- Multiple curb strikes have accumulated visible damage

- The wheel has been bent and straightened more than once

- Refinishing has removed significant material from stress-critical areas

- The wheel is over 5-6 years old with heavy track use in demanding conditions

The dense grain structure created during forging allows quality wheels to survive stress cycles that would crack lesser alternatives. But this durability advantage only applies when combined with proper maintenance and honest assessment of accumulated wear. A retired track wheel can still serve street duty where demands are far lower—giving you continued value while keeping your track sessions safe.

With your maintenance and inspection protocols established, the final piece of the puzzle involves building a systematic buying framework that ensures your next wheel purchase matches your actual needs and progression plans.

Building Your Track Wheel Buying Framework

You've absorbed the technical knowledge—construction methods, sizing strategy, tire fitment, and maintenance protocols. Now comes the moment of truth: actually purchasing wheels that match your specific situation rather than following generic advice or falling for marketing hype. The difference between a satisfying investment and an expensive regret often comes down to asking yourself the right questions before opening your wallet.

Your Track Wheel Buying Checklist

Think about how you'd approach buying a house or choosing a career path. You wouldn't rely on gut feeling alone—you'd create a systematic framework for evaluating options against your actual needs. Wheel purchases deserve the same disciplined approach, especially when you're investing in equipment that directly affects both performance and safety.

Follow this step-by-step evaluation process before committing to any purchase:

- Honestly assess your current skill level: Are you still learning proper racing lines and threshold braking, or consistently pushing at the limit of adhesion? Beginners benefit more from durable, forgiving wheels while developing skills. Advanced drivers extracting maximum performance need construction quality that matches their pace.

- Define your primary discipline: Autocross, HPDE, time attack, and wheel-to-wheel racing each create different demands. A wheel optimized for one discipline may underperform or wear prematurely in another. Match your purchase to what you'll actually do most often.

- Calculate your realistic budget: Include not just wheel cost but tires, mounting, balancing, potential spare wheels, and replacement hardware. A $4,000 forged wheel investment means little if you can't afford appropriate tires to mount on them.

- Consider your progression timeline: Planning to move from HPDE to competitive racing within a year? Factor that evolution into your purchase. Buying wheels that serve your current level but become inadequate within 12 months wastes money.

- Verify brake package compatibility: Measure your current setup—or planned upgrades—and confirm spoke clearance, inner barrel depth, and diameter requirements before falling in love with a specific wheel design.

- Research manufacturer reputation: Look beyond marketing claims to actual track community feedback. How do wheels from this manufacturer hold up after seasons of abuse? What's the warranty and support like when problems occur?

- Confirm certification and quality standards: Does the manufacturer hold relevant certifications that demonstrate consistent quality control? This matters more than aesthetics when your safety depends on structural integrity.

Making the Investment That Matches Your Goals

Budget reality forces difficult trade-offs, but understanding where to compromise—and where you absolutely shouldn't—prevents regrettable decisions. Here's an honest cost-benefit analysis for track wheel purchases:

| Investment Level | Typical Per-Wheel Cost | Best Suited For | Trade-offs |

|---|---|---|---|

| Entry Track | $250-$450 | Beginner HPDE; learning phase; limited events per year | Heavier weight; shorter lifespan; less impact resistance |

| Enthusiast | $450-$800 | Regular HPDE; light autocross; developing drivers | Flow-formed construction; good value but cast center remains |

| Performance | $800-$1,500 | Frequent track use; time attack; competitive autocross | Fully forged; excellent durability; significant weight savings |

| Professional | $1,500-$2,500+ | Wheel-to-wheel racing; sponsored programs; ultimate performance | Maximum optimization; custom specifications; highest strength |

Notice something interesting? The performance tier often delivers the best value for serious track enthusiasts. Entry-level wheels require more frequent replacement, while professional-tier products offer diminishing returns unless you're competing at the highest levels. That $800-$1,500 sweet spot provides forged construction durability without features most amateur drivers will never exploit.

Why Manufacturer Certifications Matter

When you're evaluating wheel manufacturers, certifications tell you more than any marketing brochure. According to industry certification standards, key certifications demonstrate systematic commitment to quality rather than occasional good batches.

IATF 16949 certification deserves particular attention for track wheels. This automotive industry standard covers the entire production process, ensuring high-quality standards at every manufacturing stage. It focuses on continuous improvement and defect prevention—exactly what you need when your wheels will experience forces that exceed standard testing parameters by 40-60%.

As referenced in wheel rating explanations, standards like SAE J2530, JWL, and VIA establish baseline safety requirements. SAE ratings ensure wheels handle minimum load capacity through radial fatigue, cornering fatigue, impact, and torsion testing. JWL adds roundness testing and mandates third-party inspection. VIA certification goes further, testing wheels across different tire sizes and vehicles through deformation, durability, and tensile evaluations.

But here's what many buyers miss: these standards establish minimums for street use. Track driving exceeds those parameters significantly. That's why manufacturer quality systems matter as much as individual product certifications—they indicate whether every wheel leaving the factory meets specifications, not just the samples submitted for testing.

The Forging Quality Connection

Quality forging processes directly impact wheel performance and safety under extreme track conditions. The precision of hot forging operations determines grain structure consistency, which in turn determines how wheels respond to repeated stress cycles. Inconsistent forging creates weak points that may pass initial testing but develop problems under accumulated track abuse.

This is where choosing manufacturers with proven automotive industry credentials becomes critical. Precision hot forging solutions from certified manufacturers like Shaoyi Metal Technology demonstrate the quality control systems that ensure structural integrity for demanding applications. Their IATF 16949 certification and rapid prototyping capabilities—delivering custom specifications in as little as 10 days—represent the manufacturing sophistication that serious track components require.

Some enthusiasts have compared the difference between quality forging and lesser processes to the art wheel forged soda can demonstrations you might find online—where properly forged aluminum resists crushing forces that would instantly collapse cast material. While those demonstrations oversimplify metallurgy, they illustrate a fundamental truth: manufacturing process quality determines real-world performance under stress.

The forging process isn't just about shaping metal—it's about creating consistent molecular structure that performs predictably under extreme conditions. Quality control at every manufacturing stage separates wheels that survive seasons of track abuse from those that fail when you need them most.

Final Decision Framework

Before finalizing any wheel purchase for track use, verify these critical elements:

- Construction method matches your use intensity: Flow-formed for occasional track days; fully forged for regular competitive use

- Sizing accommodates your brake package: Current setup and planned upgrades within the next 2-3 years

- Manufacturer holds relevant certifications: ISO 9001 at minimum; IATF 16949 for serious track applications

- Community track record exists: Real-world feedback from drivers in your discipline and at your pace

- Spare availability is reasonable: Can you source replacements quickly if damage occurs mid-season?

- Warranty terms are clear: What's covered, what voids coverage, and how are claims processed?

Whether you're considering established brands like 3SDM wheels for their European styling, exploring Variant Maxim wheels for aggressive fitments, or looking at larger JTX forged wheels 22x12 for truck applications, this framework applies universally. The specific brand matters less than ensuring your choice aligns with your actual needs, skill level, and budget reality.

Choosing forged wheels for track use doesn't require guesswork or hoping you got lucky. Armed with the technical understanding from this guide and a systematic evaluation approach, you can invest confidently in equipment that enhances your track experience for years to come. The drivers who avoid expensive mistakes aren't necessarily the ones with the biggest budgets—they're the ones who asked the right questions before committing their money.

Frequently Asked Questions About Choosing Forged Wheels for Track Use

1. Does wheel choice matter for the track?

Absolutely. Wheel choice directly impacts lap times, safety, and driving confidence on track. Track driving generates lateral forces exceeding 1.4g—far beyond street driving's typical 0.85g. Forged wheels offer superior strength-to-weight ratios, reducing unsprung mass for faster acceleration, shorter braking distances, and sharper turn-in response. Quality forged wheels from certified manufacturers like those with IATF 16949 certification also provide better impact resistance, bending rather than cracking during curb strikes—a critical safety advantage when pushing limits.

2. Would I need forged wheels as a track noob?

Not necessarily at first. For beginners attending initial HPDE events, quality cast or flow-formed wheels from reputable manufacturers can be perfectly acceptable. You're still developing car control and not generating the consistent high loads that stress wheels to their limits. However, as your skills progress and pace increases, upgrading to forged wheels becomes increasingly beneficial. Flow-formed wheels offer a cost-effective middle ground—approximately 15-25% lighter than cast with improved durability—before investing in fully forged options.

3. What is the difference between forged wheels and alloy wheels?

All forged wheels are alloy wheels, but not all alloy wheels are forged. The key difference lies in manufacturing. Cast alloy wheels pour molten aluminum into molds, creating potential porosity and air pockets. Forged wheels compress solid aluminum billets under extreme pressure (often exceeding 10,000 tons), creating denser grain structures without internal weak points. This results in wheels that are 25-35% lighter than cast equivalents while offering superior impact resistance and durability under repeated track stress cycles.

4. Are forged wheels worth the money for track use?

For regular track enthusiasts, forged wheels often prove more economical long-term. While initial costs run $800-$1,500 per wheel versus $150-$400 for cast options, the math changes over time. Cast wheels may need replacement after a few seasons of track abuse due to cracking, while quality forged wheels maintain structural integrity through hundreds of sessions. When you factor in replacement costs, missed track days, and the safety margin of wheels that bend rather than shatter, the investment makes financial sense for anyone tracking regularly.

5. What should I consider when choosing track wheels?

Focus on five key factors: construction method (forged for competitive use, flow-formed for regular HPDE), proper sizing (width for tire contact patch, diameter for brake clearance, offset for steering geometry), discipline-specific requirements (autocross prioritizes lightweight, wheel-to-wheel racing needs impact resistance), brake package compatibility (verify spoke and inner barrel clearance), and manufacturer certifications (IATF 16949 indicates consistent quality control). Always inspect wheels after each track session and maintain proper torque specifications to ensure longevity.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —