Nitrogen Gas Springs in Stamping Dies: The Engineer's Guide to Force & Precision

TL;DR

Nitrogen gas springs in stamping dies are high-pressure hydraulic components that use inert nitrogen gas to deliver substantial force in a compact cylinder, far exceeding the capabilities of traditional mechanical coil springs. By maintaining consistent pressure throughout the stroke, they significantly improve part quality and reduce the physical footprint of the die.

For automotive and industrial manufacturers, the primary advantage lies in their force density and longevity. Unlike coil springs that fatigue and lose preload, nitrogen springs provide immediate contact force and can be adjusted to meet precise tonnage requirements, making them the standard for modern high-volume metal stamping.

Fundamentals: Mechanism & Function in Stamping Dies

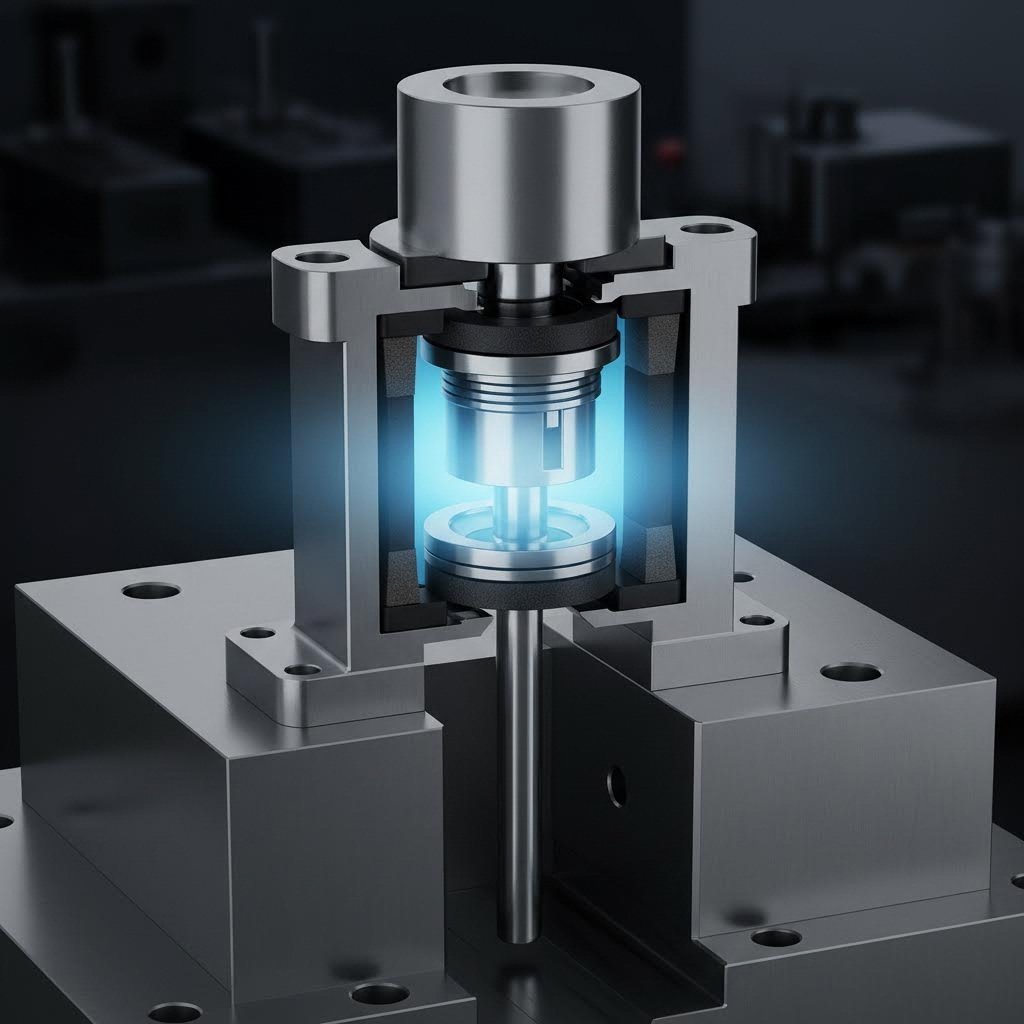

At its core, a nitrogen gas spring operates as a sealed system containing pressurized nitrogen gas, a piston rod, and a specialized cylinder. When the press closes, the piston compresses the gas, storing potential energy that is released as the press opens. This mechanism allows for a much higher force density than mechanical alternatives, meaning a small gas spring can exert the same force as a much larger coil spring.

The choice of nitrogen is not arbitrary; it is an inert gas, which is critical for the component's longevity. As noted by Special Springs, the inert nature of nitrogen prevents oxidation and corrosion inside the cylinder, ensuring the internal seals and lubrication oils remain stable even under the intense heat generated by rapid stamping cycles. If oxygen or compressed air were used, the combination of oil and heat could lead to combustion or rapid seal degradation.

In a typical stamping die setup, these springs are positioned between the die plates—often in the binder or stripper plate—to hold the sheet metal firmly in place before the forming punch contacts the material. This "pad hold-down" function is vital. It prevents the metal from wrinkling or tearing during the draw process. Because nitrogen springs offer adjustable pressure, engineers can fine-tune the holding force by simply adjusting the gas charge, a flexibility that mechanical springs cannot offer.

Critical Comparison: Nitrogen Gas Springs vs. Mechanical Coil Springs

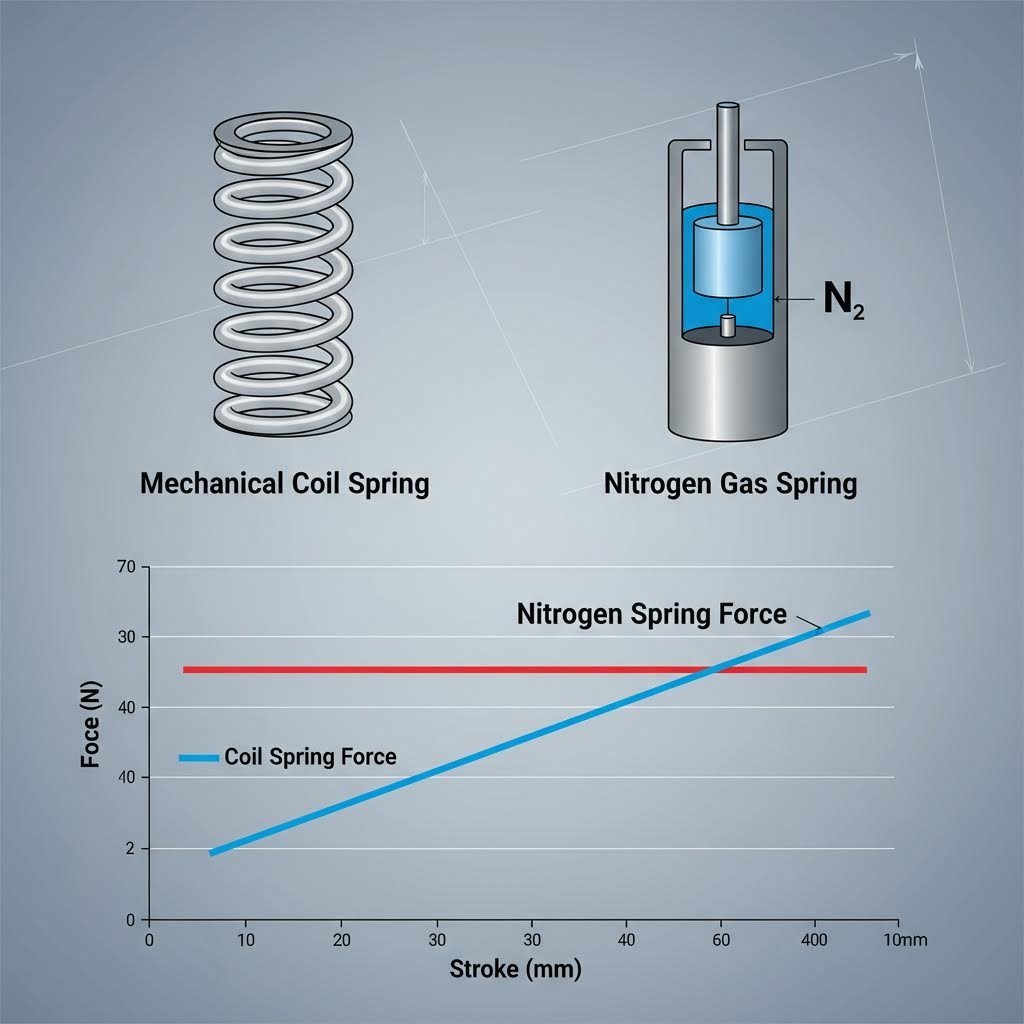

The transition from mechanical coil springs to nitrogen gas springs is often driven by the need for higher precision and space efficiency. While coil springs are inexpensive and simple, they suffer from a linear force curve—they provide very little force at initial contact (preload) and peak force only at full compression. Nitrogen springs, conversely, deliver near-peak force immediately upon contact.

| Feature | Mechanical Coil Springs | Nitrogen Gas Springs |

|---|---|---|

| Force Curve | Linear (Low initial, high final) | Flatter (High initial force, consistent rise) |

| Space Efficiency | Low (Requires large pockets/many springs) | High (Compact, high force density) |

| Service Life | Limited (Prone to fatigue/breakage) | Extended (Millions of cycles with maintenance) |

| Adjustability | None (Must replace spring) | High (Adjust gas pressure) |

| Initial Cost | Low | Moderate to High |

Space constraints are often the deciding factor. In complex automotive dies, "shut height" (the space available when the die is closed) is at a premium. A single nitrogen cylinder can often replace a cluster of 5–10 coil springs, drastically reducing the volume of the die. This allows for more stations in a progressive die or simply a smaller, lighter tool that is cheaper to handle and store.

Furthermore, reliability is a major differentiator. Coil springs can break unpredictably, sending metal fragments into the tool and causing catastrophic damage. Nitrogen springs, when properly maintained, wear gradually. Modern designs from manufacturers like Ready Technology feature "bore sealed" systems and floating guide stems that resist side-load damage, ensuring millions of strokes before a rebuild is necessary.

Selection Guide: Calculating Force & Stroke Requirements

Selecting the correct nitrogen gas spring requires precise engineering math. The goal is to balance the required holding force with the available space and press capacity. A common approach for determining the quantity of springs needed is to divide the total required force by the maximum force available for a chosen spring diameter.

Calculating Stroke Length

According to application guidelines from Harslepress, you should never select a spring with a stroke length exactly equal to the die travel. A safety margin is essential to prevent the piston from bottoming out, which causes immediate failure.

- Formula: Minimum Stroke = Die Travel + 10% Safety Margin.

- Example: If your die travel is 50mm, do not use a 50mm spring. Select a spring with at least 55mm of stroke (often rounding up to a standard 60mm or 63mm model).

Force Distribution

It is not enough to just meet the total force requirement; the force must be distributed evenly across the pressure pad to prevent tipping or binding. Engineers typically adhere to ISO or VDI standards (such as VDI 3003) to ensure compatibility. When retrofitting, you may need to choose a "compact" or "super compact" series if the die height is restricted, though these often come with shorter maximum stroke limits compared to ISO standard models.

Installation, Maintenance & Safety Standards

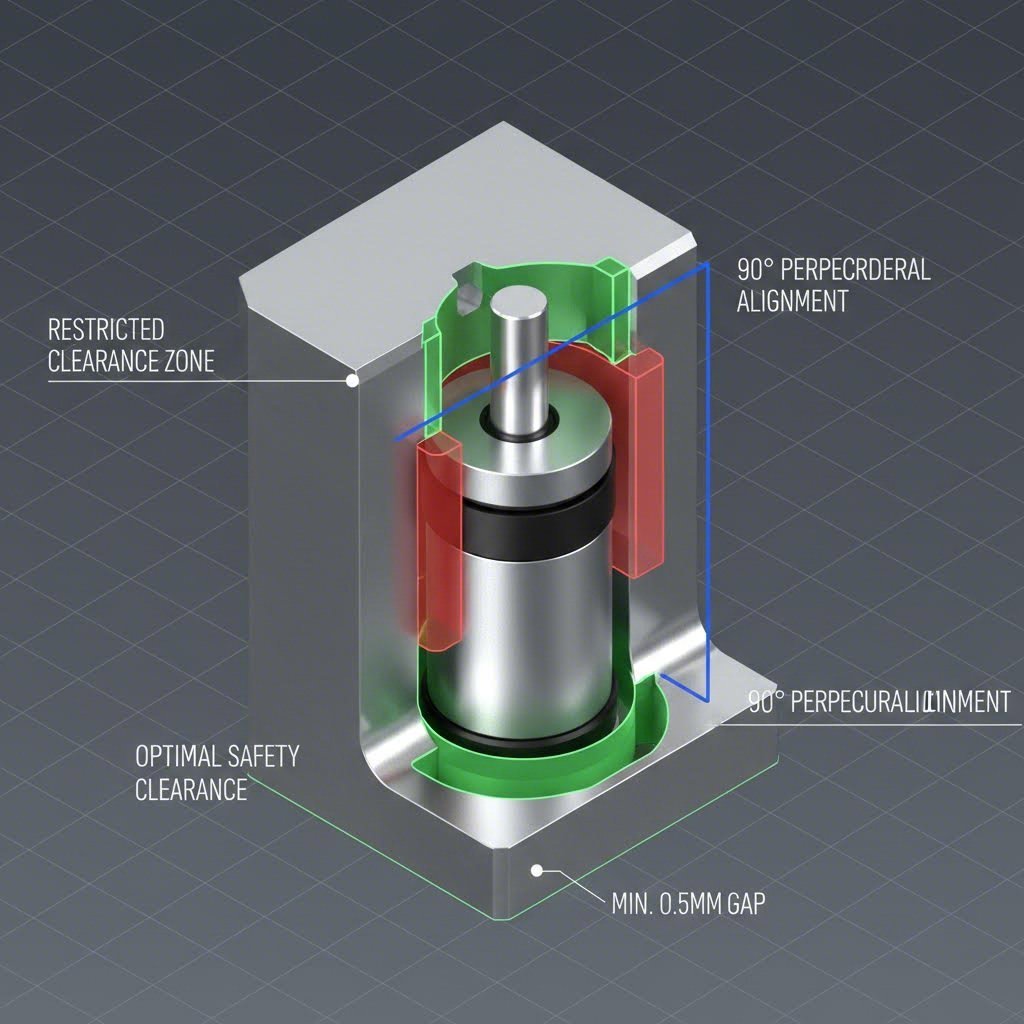

Safety is paramount when working with high-pressure cylinders. A nitrogen spring is effectively a pressure vessel, and improper handling can be dangerous. The most critical installation rule is ensuring the pocket depth is sufficient to support the cylinder body. Generally, the pocket depth should be at least 50% of the canister length to ensure stability and perpendicularity.

Installation Best Practices

- Perpendicularity: The spring must be mounted 90 degrees to the contact surface. Even a slight angle can cause side-loading, wearing out the seals prematurely.

- Clearance: Maintain a pocket clearance of 0.5mm to 1.0mm. A tight fit can cause the cylinder to bind if thermal expansion occurs during operation.

- Drainage: If the die uses heavy lubricants, ensure the pockets have drainage channels. Hydrostatic pressure from trapped fluids can crush the cylinder.

Disassembly poses the highest risk. Never attempt to open a gas spring without first fully venting the nitrogen gas. Most manufacturers include a specific deflation valve or screw. As Harslepress advises, use a hex key to slowly depress the valve core (pointing it away from you) until all hissing stops before removing any retaining rings.

Leading Manufacturers & Interchangeability

The market is served by several established manufacturers, including DADCO, Hyson, Kaller, and Special Springs. Many of these brands adhere to the ISO 11901 standard, which allows for a degree of interchangeability. For instance, a DADCO ISO series spring can often be swapped with an equivalent model from Kaller or Hyson without modifying the die pocket, simplifying maintenance for global stamping programs.

However, while the external dimensions may be identical, internal technologies like sealing systems and rod guidance vary. DADCO’s UltraPak cartridges and Ready Technology’s Design-Tite systems are proprietary features intended to extend service life in dirty stamping environments. Procurement teams should balance the initial cost against the "cost per stroke"—a cheaper spring that fails every 500,000 cycles is far more expensive than a premium one lasting 2 million cycles when you factor in the downtime.

Once the tooling and components are finalized, the focus shifts to production. For manufacturers scaling from prototyping to mass production, partnering with an experienced stamping provider is crucial to leveraging these technologies effectively. Accelerate your automotive production with Shaoyi Metal Technology’s comprehensive stamping solutions, which utilize advanced tooling standards to deliver precision components like control arms and subframes. Their expertise bridges the gap between component selection and high-volume IATF 16949-certified manufacturing.

Conclusion

Nitrogen gas springs have revolutionized the metal stamping industry by decoupling force from volume. They allow engineers to design compact, high-performance dies that produce superior parts with less scrap. By understanding the fundamentals of force density, adhering to strict installation safety protocols, and selecting reputable ISO-compliant brands, manufacturers can significantly reduce downtime and extend the lifecycle of their tooling.

The initial investment in nitrogen technology pays dividends through consistent part quality and reduced maintenance. Whether retrofitting an old mechanical die or designing a new progressive tool, the nitrogen gas spring is an indispensable asset in modern manufacturing.

Frequently Asked Questions

1. Can I replace coil springs with nitrogen gas springs directly?

Yes, but it requires calculation. You cannot simply swap them one-for-one based on size alone. You must calculate the total force provided by the coil springs and select nitrogen springs that match that force. Often, fewer nitrogen springs are needed to do the work of many coil springs, which may require modifying the die's pressure pad to distribute the force evenly.

2. How often do nitrogen gas springs need to be recharged?

In a well-maintained die, nitrogen springs can last millions of cycles without needing a recharge. However, a small amount of pressure loss (approx. 10% per year) is normal. It is recommended to check the pressure during routine die maintenance intervals, typically every 6 to 12 months, depending on usage volume.

3. What is the difference between self-contained and linked systems?

A self-contained spring functions independently with its own internal gas charge. A linked system connects multiple springs via hoses to a control panel and external tank. Linked systems allow you to monitor and adjust the pressure of all springs simultaneously from outside the press, which is ideal for large automotive dies requiring frequent pressure adjustments.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —