Tandem Press vs Transfer Press Stamping: Efficiency vs Agility

TL;DR

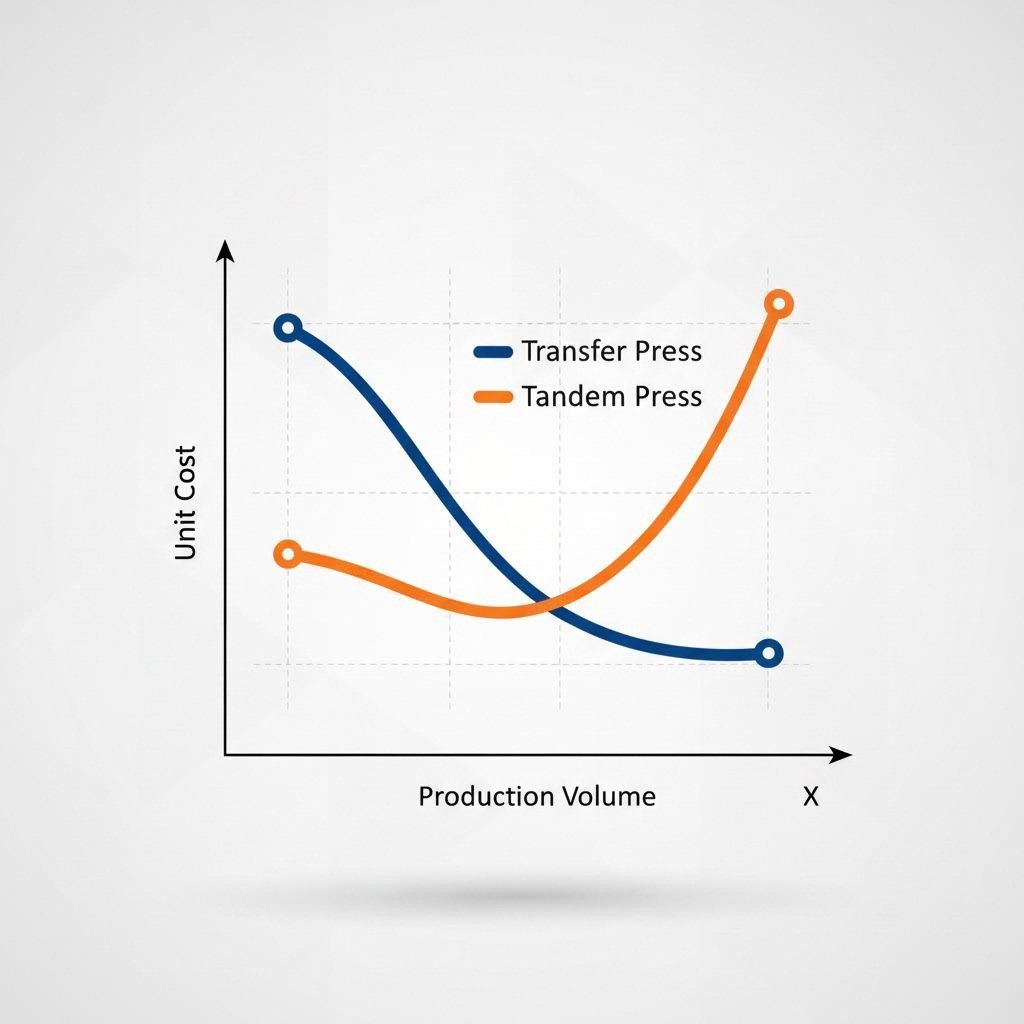

The choice between tandem press vs transfer press stamping represents the fundamental manufacturing trade-off between speed and flexibility. Transfer presses are monolithic high-speed beasts, integrating multiple stations into a single bed to deliver unmatched efficiency (15–30+ SPM) for dedicated high-volume parts. In contrast, tandem press lines consist of individual presses linked by robotic automation, offering superior modularity and adaptability for high-mix production, albeit at historically lower speeds (8–15 SPM). Ultimately, choose transfer for maximum volume and lowest per-part cost; choose tandem for operational versatility and diverse part families.

1. Core Definitions & Operational Mechanics

To understand the strategic value of these technologies, we must first distinguish their physical architecture. A transfer press is essentially a single, massive machine containing a long bed where multiple die stations are mounted side-by-side. The workpiece is moved between these stations by an internal, mechanically synchronized transfer system—typically rails or grippers that operate in perfect harmony with the press slide. This integration creates a closed ecosystem where the part is always under positive control, allowing for aggressive acceleration and deceleration.

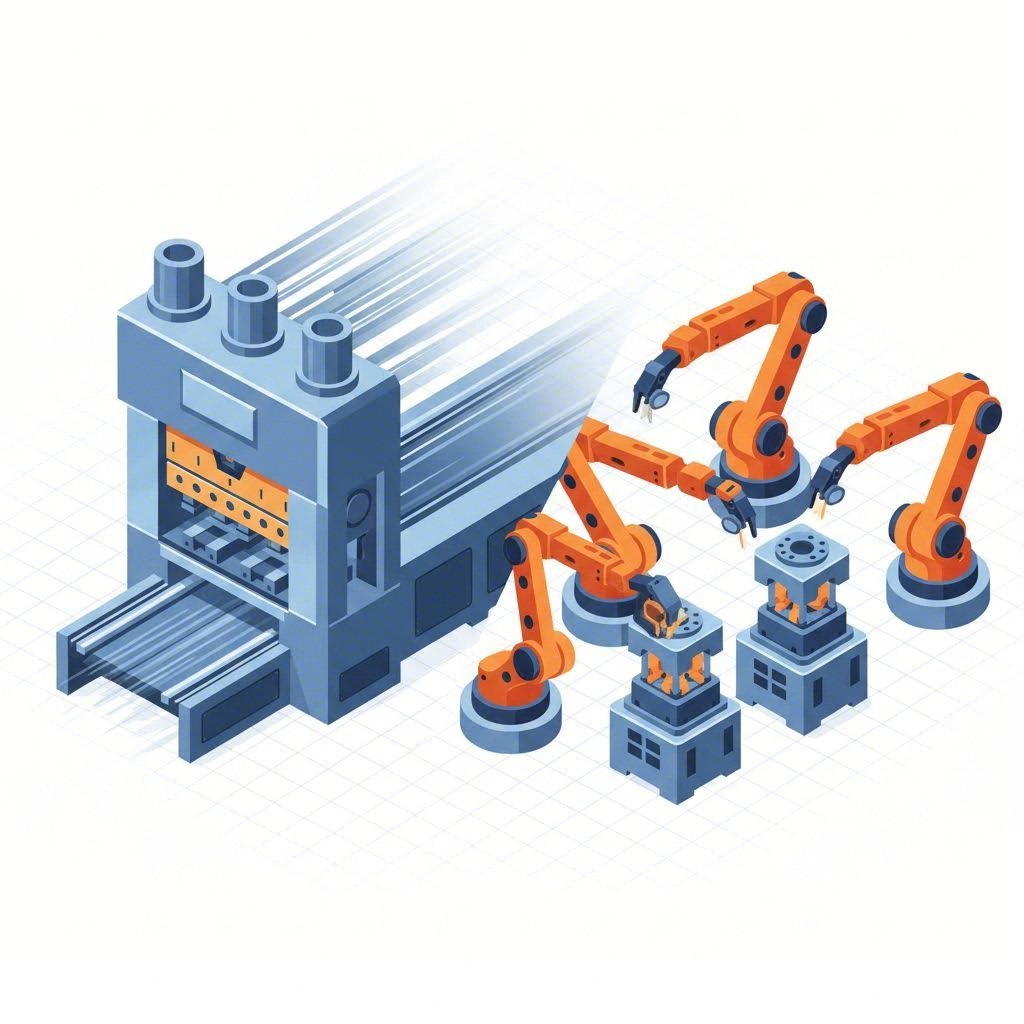

Conversely, a tandem press line is a sequence of independent presses (typically 4 to 6 units) arranged in a line. The first press, known as the lead or head press, often handles the heavy drawing operation, while subsequent "follower" presses perform trimming, piercing, and flanging. The critical distinction lies in the automation: parts are moved between presses by external robotic arms or crossbar transfer systems. This separation defines the tandem line's character—it is a modular chain of machines rather than a single monolithic unit.

Visually, the difference is striking. A transfer press is compact but requires a deep, heavy foundation to support its concentrated tonnage. A tandem line sprawls across the factory floor, requiring more square footage but offering easier access to individual stations for maintenance. While a transfer press functions like a synchronized watch mechanism, a tandem line operates like a bucket brigade—efficient, but dependent on the handoff between independent actors.

2. Speed & Efficiency Showdown (SPM Analysis)

In the high-stakes world of automotive stamping, Strokes Per Minute (SPM) is the currency of profitability. Historically, the transfer press has been the undisputed champion of speed. Because the transfer mechanism is mechanically linked to the press drive, it moves in exact synchronization with the slide. This allows transfer presses to run continuously at 15 to 30 SPM, with some high-speed systems for smaller parts exceeding 60 SPM. For a manufacturer producing millions of identical cross-members or suspension arms, this velocity is unbeatable.

Tandem lines have traditionally lagged behind, operating in the 8 to 15 SPM range. The bottleneck is the "handshake"—the time required for a robot to enter the press, grip the part, extract it, and place it in the next press. However, the gap is closing. Modern servo-driven tandem lines utilize programmable slide motion to optimize the stroke, allowing the press to open faster for the robots. When paired with high-speed carbon fiber crossbar feeds, these advanced tandem lines can now achieve 18–21 SPM, challenging the transfer press's dominance in the medium-high volume segment.

| Feature | Transfer Press | Traditional Tandem Line | Servo Tandem Line |

|---|---|---|---|

| Typical Speed | 15–30+ SPM | 8–12 SPM | 15–21 SPM |

| Part Control | Continuous / Mechanical | Intermittent / Robotic | Synchronized Servo |

| Best For | Mass Production (Volume) | Heavy Parts / Low Speed | High Mix / High Speed |

3. Flexibility & Adaptability: The Strategic Pivot

If speed is the transfer press's superpower, flexibility is the tandem line's fortress. A transfer press is a "dedicated specialist." Changing production from one part family to another often requires swapping massive tri-axis rails and re-calibrating the entire internal transfer pitch—a complex engineering feat. It thrives on "Economies of Scale," where the machine runs the same part for weeks or months. It is rigid, powerful, and intolerant of frequent disruption.

The tandem line, however, offers "Economies of Scope." Because the presses and robots are independent, the line is infinitely reconfigurable. Need to skip a station for a simpler part? Just reprogram the robots to bypass Press #3. Handling a massive body side panel today and a smaller fender tomorrow? The robots can adapt their gripper paths instantly. This modularity allows manufacturers to run diverse product mixes on a single asset, making tandem lines the preferred choice for Tier 1 suppliers who must serve multiple OEM platforms.

Operational resilience also favors the tandem approach. In a transfer press, a failure in the main drive or transfer rail stops the entire line—"one down, all down." In a tandem line, if a single press goes down for maintenance, it is sometimes possible to run a partial process or bypass the faulty unit (depending on the die process), offering a layer of redundancy that protects delivery schedules.

4. Economic Analysis: CAPEX vs. TCO

The financial decision involves more than just the sticker price. A high-tonnage transfer press demands a colossal upfront Capital Expenditure (CAPEX), not just for the machine but for the massive pit foundation and specialized heavy-lift cranes required for installation. It is a "bet the company" asset that must run constantly to amortize its cost.

Tandem lines offer a more flexible investment model. A manufacturer might start with a line of three presses and add a fourth or fifth unit two years later as business grows. This "phased investment" strategy improves cash flow and reduces risk. However, the Total Cost of Ownership (TCO) tells a nuanced story. While transfer presses cost more upfront, their centralized operation often results in lower energy consumption per part and reduced labor (one operator vs. potentially multiple for a large tandem line). Conversely, tandem lines incur higher "soft costs" for maintaining multiple hydraulic systems, robot controllers, and safety interlocks.

For manufacturers where the capital outlay for a full transfer or tandem line is prohibitive, or where volume fluctuates unpredictably, partnering with a specialized contract manufacturer becomes the strategic bridge. Companies like Shaoyi Metal Technology leverage high-tonnage precision presses (up to 600 tons) to deliver IATF 16949-certified components, offering a scalable path from rapid prototyping to high-volume mass production without the fixed asset risk.

5. Decision Matrix: Which One is Right for You?

Selecting the right technology requires mapping your production reality against the machine's strengths. Use this decision matrix to guide your investment strategy:

-

Choose a Transfer Press If:

- Volume is King: You require 1M+ parts annually of the same component.

- Space is Limited: You need maximum output per square meter of factory floor.

- Part Geometry is Consistent: You are producing a family of parts with similar sizes and transfer pitches.

- Material Efficiency: You need deep drawing capabilities with precise control to minimize scrap.

-

Choose a Tandem Line If:

- Mix is High: You produce small batches of widely varying parts (e.g., doors, hoods, and pillars on the same line).

- Parts are Massive: The component dimensions exceed the bed size of standard transfer presses (e.g., full body sides).

- Budget is Phased: You need to spread capital investment over several years.

- Resilience is Critical: You cannot afford total line stoppages from a single component failure.

Conclusion

The debate between tandem press vs transfer press stamping is not about which technology is superior, but which aligns with your business model. The transfer press remains the undisputed king of efficiency for stable, high-volume mass production. The tandem line, particularly with modern servo integration, stands as the agile master of high-mix manufacturing, ready to pivot with shifting market demands. By analyzing your volume, part complexity, and long-term flexibility needs, you can deploy the system that turns your press shop into a competitive advantage.

Frequently Asked Questions

1. What is the main difference between tandem and transfer presses?

The primary difference lies in the transfer mechanism and machine structure. A transfer press is a single monolithic machine where parts move between stations via internal rails. A tandem press is a line of individual, separate presses where parts are moved between machines by robotic arms or crossbar automation.

2. Which press type is faster?

Transfer presses are generally faster, capable of speeds between 15 and 30+ strokes per minute (SPM) due to their synchronized mechanical transfer. Traditional tandem lines run slower (8–15 SPM), though modern servo-driven tandem lines are narrowing this gap, reaching speeds of up to 21 SPM.

3. Can a tandem line produce the same parts as a transfer press?

Yes, both systems can perform similar operations like drawing, trimming, and piercing. However, transfer presses are limited by their bed size and transfer pitch, making tandem lines better suited for extremely large parts like automotive body sides that require more space between stations.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —