Automotive Stamping Quality Control Standards: IATF 16949 & Core Tools

TL;DR

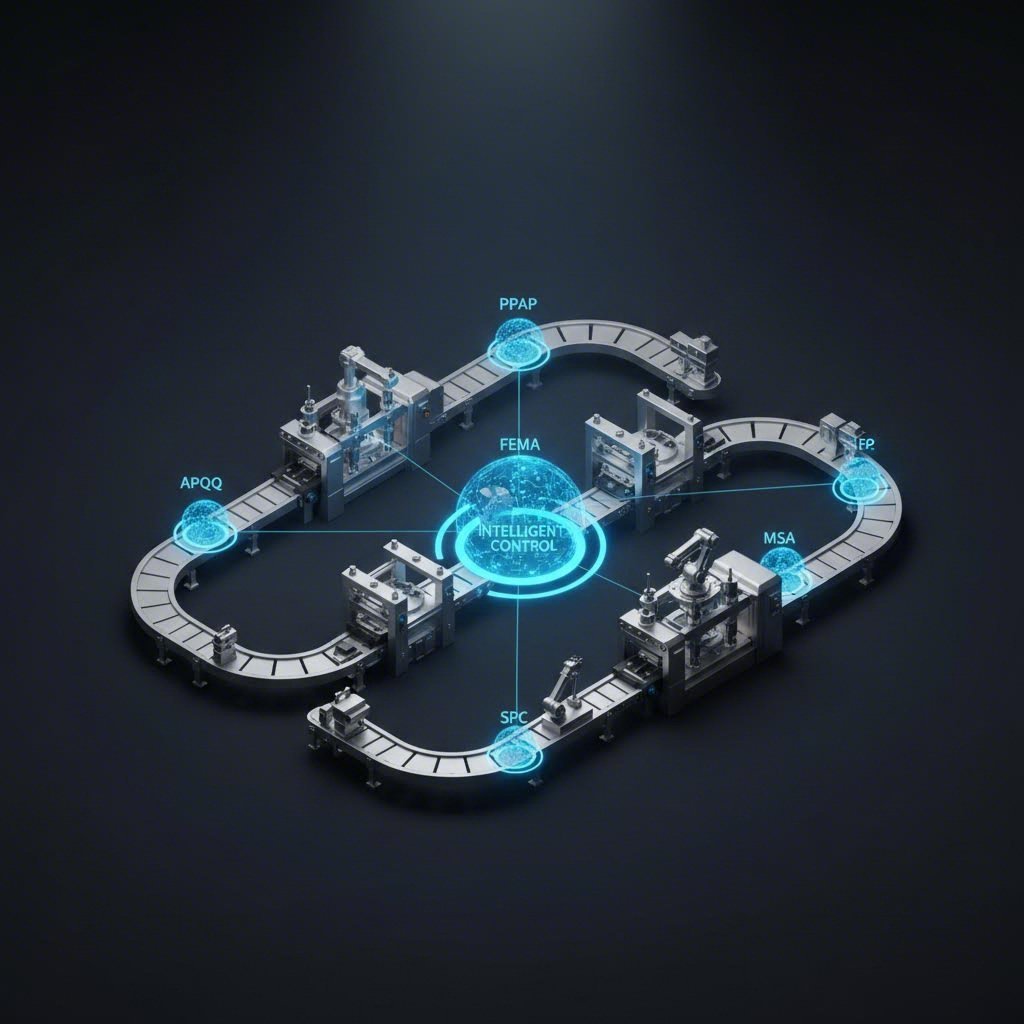

Automotive stamping quality control is rigorously governed by the IATF 16949 standard, which mandates a "zero-defect" mentality across the global supply chain. Unlike general manufacturing, automotive stamping requires defect prevention rather than just detection, achieved through the implementation of five mandatory core tools: APQP (planning), PPAP (approval), FMEA (risk mitigation), MSA (measurement accuracy), and SPC (statistical control).

To meet these standards, stamped parts—from body panels to safety-critical control arms—must undergo rigorous validation using advanced metrology like Coordinate Measuring Machines (CMM) and in-die sensing. For procurement officers and engineers, selecting a supplier means verifying not just their certification, but their proficiency in these methodologies to ensure consistent, safe, and durable components.

The Regulatory Landscape: IATF 16949 vs. ISO 9001

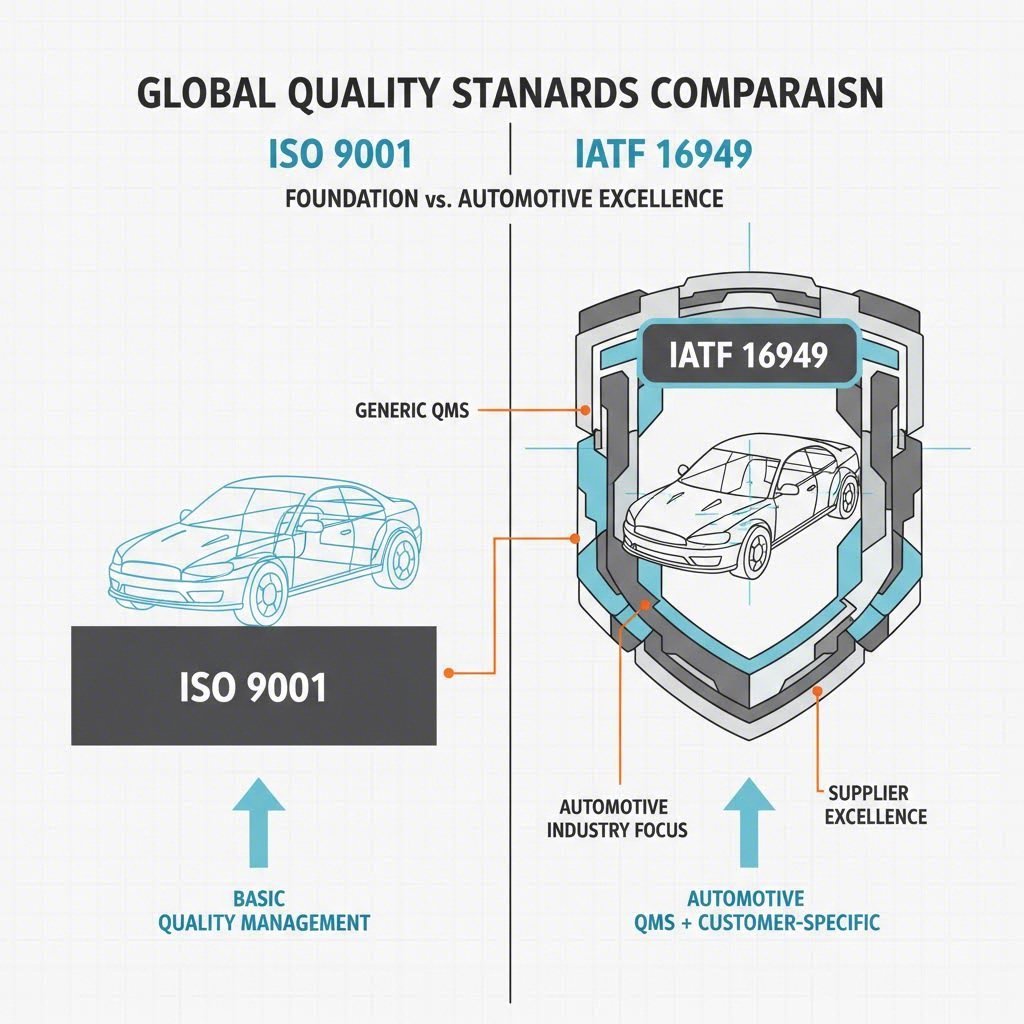

While ISO 9001 provides a baseline for general quality management systems (QMS), it is insufficient for the high-stakes demands of the automotive industry. The global gold standard for automotive stamping is IATF 16949, developed by the International Automotive Task Force. Understanding the distinction between these two is critical for evaluating supplier capability.

ISO 9001 focuses on customer satisfaction and consistent processes. It asks, "Did you make what you promised?" In contrast, IATF 16949 focuses on defect prevention, reduction of variation, and reduction of waste in the supply chain. It asks, "Is your process robust enough to prevent failures before they happen?" For automotive stampers, IATF 16949 requires compliance with customer-specific requirements (CSRs) and mandates the use of the "Core Tools," which are not explicitly required by ISO 9001.

| Feature | ISO 9001:2015 | IATF 16949:2016 |

|---|---|---|

| Primary Focus | General Customer Satisfaction | Defect Prevention & Variation Reduction |

| Scope | All Industries | Automotive Supply Chain Only |

| Core Tools | Recommended / Optional | Mandatory (APQP, PPAP, FMEA, SPC, MSA) |

| Calibration | Standard Traceability | Rigorous MSA (Gauge R&R) Studies |

For manufacturers, holding an IATF 16949 certification is the ticket to entry for Tier 1 and OEM supply chains. It signals that the stamper has a system in place to manage risk, ensure continuous improvement, and handle the rigorous documentation required for safety-critical parts.

The 5 Automotive Quality Core Tools (Critical Deep Dive)

The backbone of automotive stamping quality is the suite of five Core Tools established by the Automotive Industry Action Group (AIAG). These are not merely administrative hurdles; they are engineering methodologies designed to ensure that a stamped part—whether a simple bracket or a complex subframe—can be manufactured repeatedly at high volumes without deviation.

1. APQP (Advanced Product Quality Planning)

APQP is the project management framework that guides the launch of a new product. It begins before a single tool is cut. During this phase, stampers work with OEM engineers to define critical characteristics and feasibility. The goal is Design for Manufacturability (DFM)—ensuring the part geometry allows for robust stamping processes. APQP aligns the supply chain on timing, capacity, and quality targets.

2. PPAP (Production Part Approval Process)

PPAP is the "final exam" for the stamping process. Before mass production begins, the supplier must submit a PPAP package to the customer. This package provides evidence that the tooling produces parts that meet all engineering design records and specifications at the quoted production rate. A signed PPAP warrant confirms that the process is capable and validated.

3. FMEA (Failure Mode and Effects Analysis)

FMEA is a risk assessment tool used to identify potential failure points. In stamping, a Process FMEA (PFMEA) analyzes every step of the metal forming process. Engineers ask: "What happens if the slug is not ejected?" or "What if the lubrication fails?" Each risk is scored by Severity, Occurrence, and Detection. High-risk items require immediate corrective action, such as installing die protection sensors to stop the press before a crash occurs.

4. MSA (Measurement System Analysis)

You cannot control what you cannot measure accurately. MSA evaluates the reliability of the inspection equipment itself. The most common study is Gauge R&R (Repeatability and Reproducibility), which verifies that the measurement variation comes from the part, not the gauge or the operator. If a micrometer or vision system has poor R&R, the data it produces is useless for quality control.

5. SPC (Statistical Process Control)

SPC involves real-time monitoring of the manufacturing process. By plotting data points (such as the thickness of a drawn cup or the diameter of a pierced hole) on control charts, operators can detect trends. If a dimension starts drifting toward the control limit—perhaps due to tool wear—operators can stop the press and sharpen the punch before the part becomes a defect. This proactive approach is the essence of modern quality control.

Common Stamping Defects and Prevention Strategies

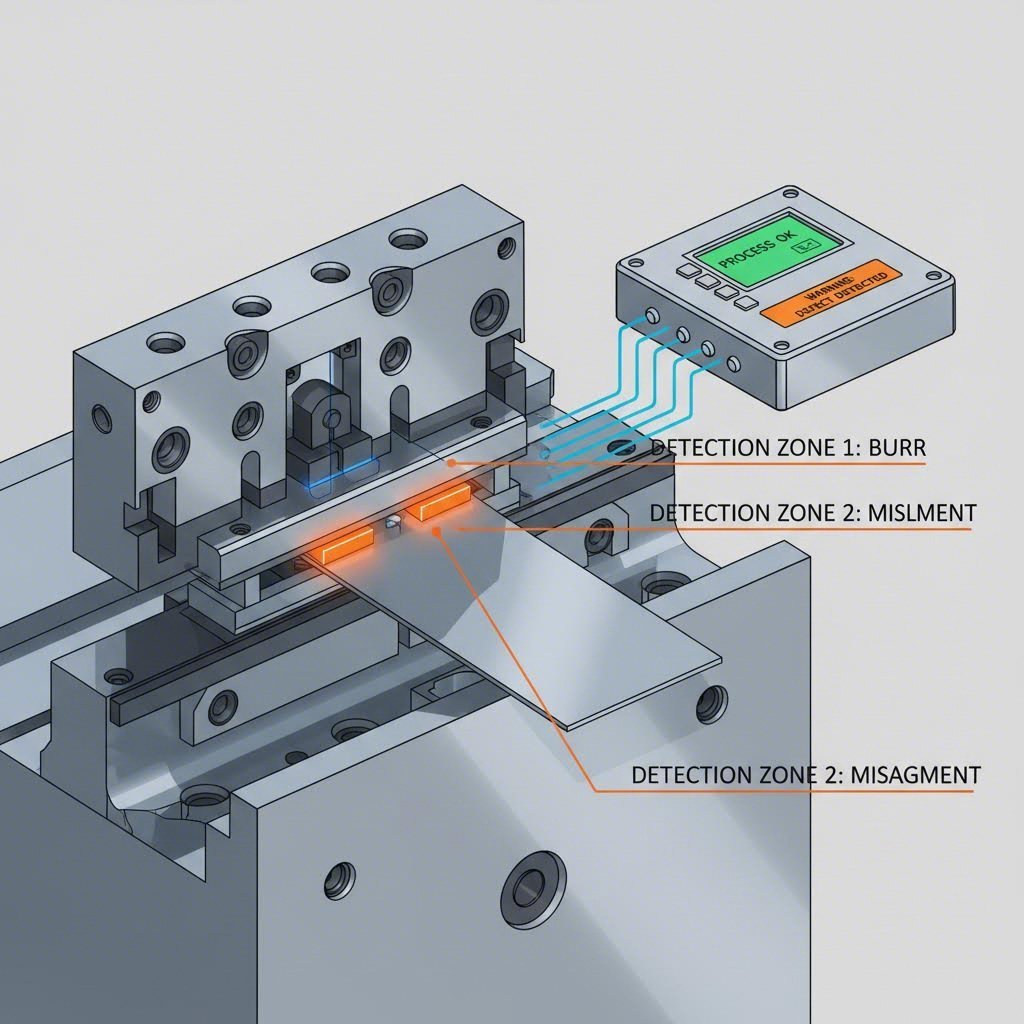

In the automotive sector, defects like burrs or splits can compromise vehicle safety or assembly line efficiency. The IATF standard demands a proactive approach to eliminating these issues through engineering controls rather than just final inspection.

| Defect Type | Mechanism & Cause | Prevention & Detection Strategy |

|---|---|---|

| Burrs | Rough edges caused by excessive clearance between the punch and die, or worn tooling edges. | Strict preventive maintenance schedules for tool sharpening; automated in-die monitoring to detect cutting force changes. |

| Springback | The metal's tendency to return to its original shape after bending, common in High-Strength Steel (HSS). | Advanced simulation software (AutoForm) during APQP to compensate for springback in the die design; over-bending techniques. |

| Splits / Cracks | Material failure where the metal thins excessively during deep drawing operations. | Lubrication management; using higher formability material grades; forming simulation analysis to optimize strain distribution. |

| Surface Defects | Scratches, slug marks, or pimples caused by debris (slugs) pulled back onto the die surface. | Slug retention features in the die; vacuum slug ejectors; vision systems to detect surface imperfections inline. |

Implementing In-Die Sensing is a critical prevention strategy. By embedding piezoelectric or acoustic sensors directly into the stamping die, manufacturers can detect a "double hit" or a missed feed in milliseconds, stopping the press instantly to prevent damage and defective parts.

Measurement Technology & Inspection Metrics

Verifying compliance requires advanced metrology hardware capable of handling complex geometries and tight tolerances. Modern automotive stampers utilize a mix of contact and non-contact inspection methods to generate the data required for PPAP and ongoing SPC.

- Coordinate Measuring Machines (CMM): The workhorse of the quality lab, CMMs use a touch probe to map the precise X, Y, and Z coordinates of a part’s features. They are essential for verifying complex 3D shapes and GD&T (Geometric Dimensioning and Tolerancing) requirements like flatness, parallelism, and true position.

- Optical Vision Systems & Comparators: For flat parts or 2D profiles, vision systems provide rapid pass/fail analysis. Automated systems can measure hundreds of dimensions in seconds, making them ideal for high-volume batch testing.

- Check Fixtures (Functional Gauges): These are custom-built physical tools that simulate the mating assembly. If the stamped part fits into the fixture and the "Go/No-Go" pins pass through the critical holes, the part is functionally acceptable. This provides immediate feedback to operators on the shop floor.

Key metrics tracked include Dimensional Accuracy (conformance to print), Material Properties (tensile and yield strength verification via lab testing), and Surface Finish (roughness average, Ra). Tracking these metrics ensures that every batch meets the strict reliability standards demanded by automotive OEMs.

Selecting a Supplier: The Quality Checklist

Choosing a metal stamping partner requires a deep audit of their quality maturity. Certification is just the starting point; the operational reality of how they apply standards is what determines long-term success. A robust supplier should demonstrate financial stability, a clean safety record, and a culture of continuous improvement.

When evaluating potential partners, look for vertically integrated capabilities. For example, manufacturers like Shaoyi Metal Technology demonstrate this balance by offering comprehensive stamping solutions that bridge the gap from rapid prototyping to high-volume manufacturing. With IATF 16949-certified precision and press capabilities up to 600 tons, they produce critical components like control arms and subframes with strict adherence to global OEM standards. Their ability to handle the entire lifecycle—from APQP design consultation to mass production—reduces the risk of quality fade during scaling.

Supplier Audit Checklist

- Certifications: Is the facility current with IATF 16949:2016? Do they have ISO 14001 (Environmental) if required?

- Core Tool Proficiency: Can they show real-world examples of their PFMEA and Control Plans? Do they actually use SPC data to drive decisions?

- Traceability: Can they trace a specific lot of parts back to the raw material mill heat number and the specific production shift?

- Maintenance: Is there a documented preventive maintenance program for both the presses and the dies?

FAQ: Automotive Stamping Standards

1. What are the 7 most common metal stamping steps?

The metal stamping process typically involves seven primary operations: Blanking (cutting the initial shape), Piercing (punching holes), Drawing (forming cup-like shapes), Bending (creating angles), Air Bending (forming without bottoming out), Bottoming/Coining (stamping under high pressure for precision), and Trimming (removing excess material). In progressive die stamping, many of these steps occur simultaneously as the metal strip moves through the press.

2. Which QMS standard is mandatory for automotive suppliers?

IATF 16949 is the mandatory Quality Management System (QMS) standard for the automotive supply chain. While it is based on the structure of ISO 9001, it includes extensive additional requirements specific to the automotive industry, such as competence in the 5 Core Tools, customer-specific requirements, and rigorous defect prevention protocols.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —