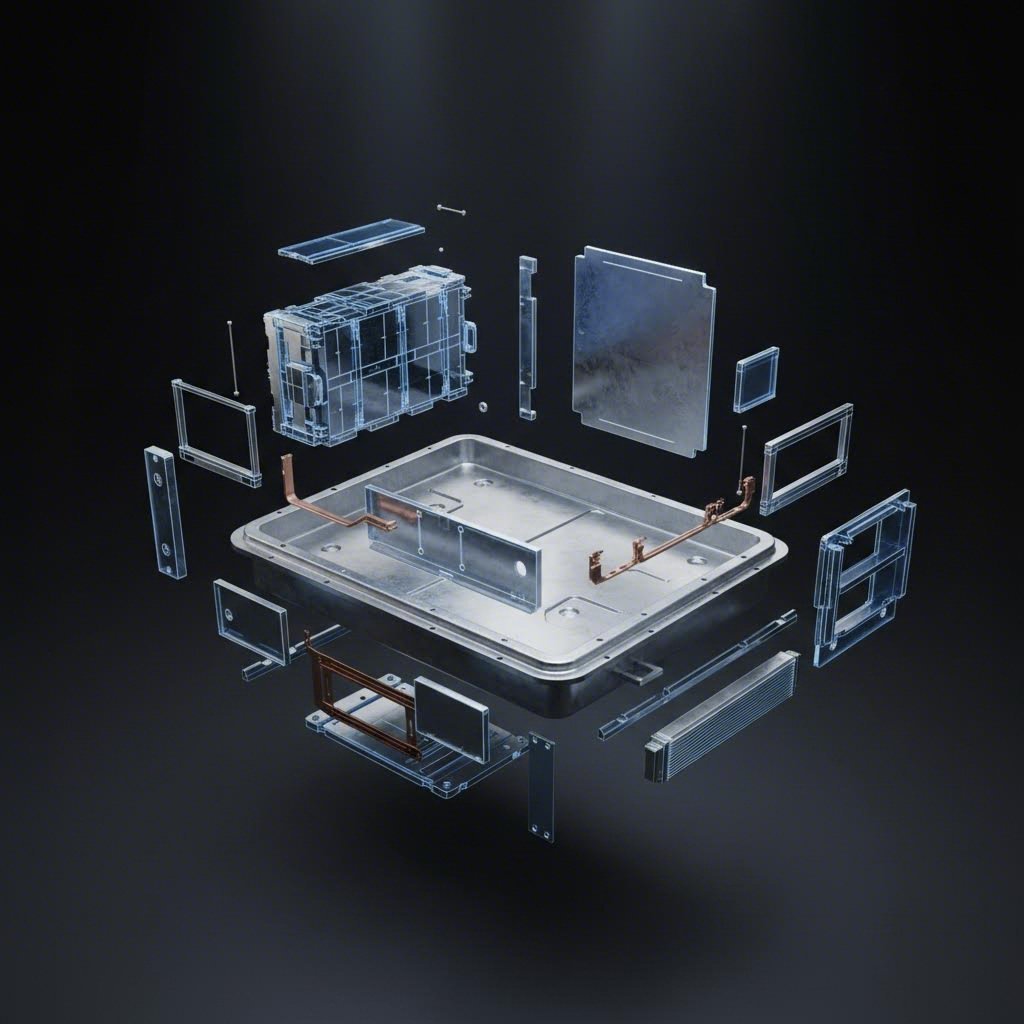

Stamping Electric Vehicle Battery Enclosures: Advanced Design Guide

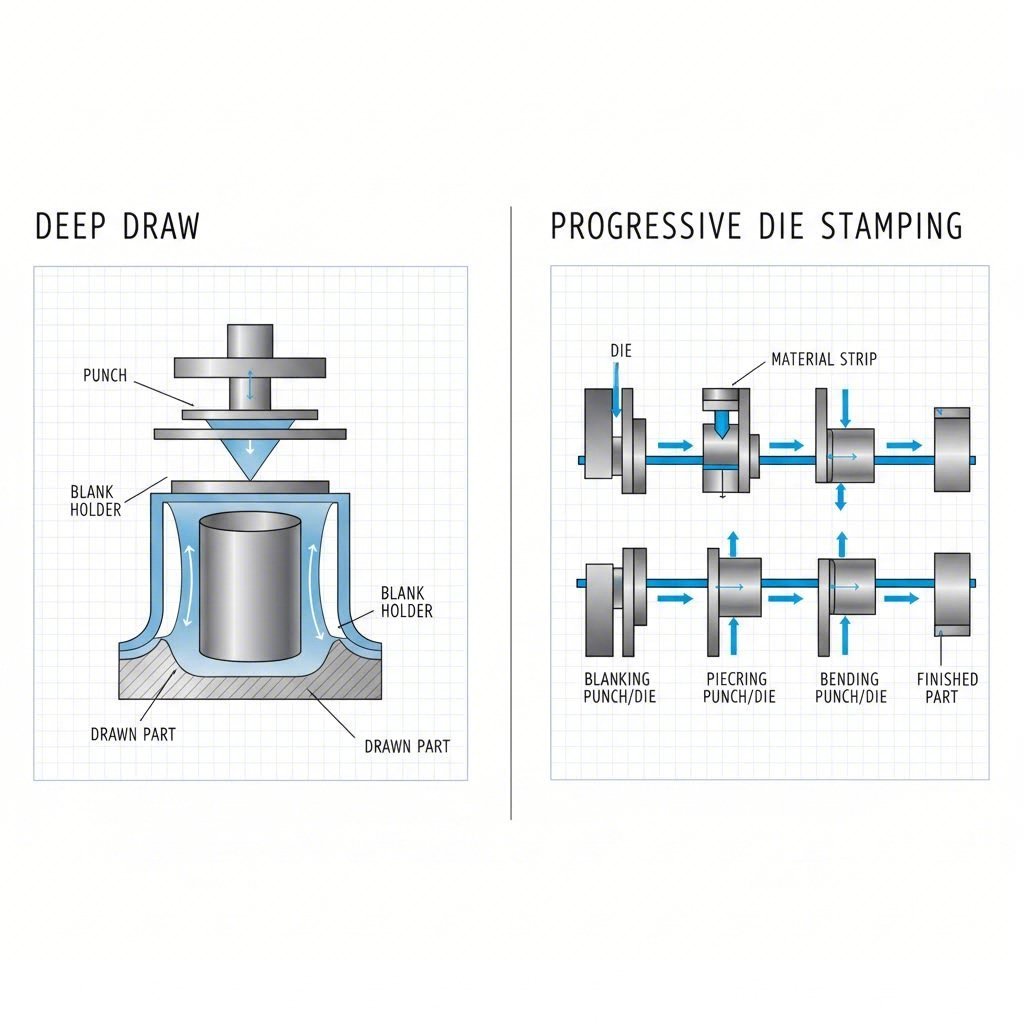

<h2>TL;DR</h2><p>Stamping electric vehicle battery enclosures has evolved from simple metal forming into a high-precision science critical for EV range and safety. As of 2025, the industry is shifting toward <strong>one-piece deep draw designs</strong> and <strong>Tailor-Welded Blanks (TWB)</strong> to eliminate leak paths and reduce weight. While aluminum currently dominates roughly 80% of the market due to its lightness, Advanced High-Strength Steel (AHSS) is making a resurgence with innovative "hashtag" blank designs that offer superior underbody impact protection at a lower cost. For engineers, the core challenge lies in balancing these material properties with tight tolerance requirements (often ±1.5mm for flange flatness) to ensure IP67 sealing and thermal runaway containment.</p><h2>Fundamentals of EV Battery Enclosure Stamping</h2><p>The battery enclosure is the structural spine of an electric vehicle, tasked with supporting up to 50% of the vehicle's value while protecting volatile chemistry from road debris and crash forces. Stamping these components requires a move beyond traditional sheet metal fabrication into advanced deep draw and progressive die methodologies.</p><h3>Deep Draw vs. Progressive Die Applications</h3><p>For the main battery tray (the "tub"), <strong>deep draw stamping</strong> is the preferred method. This process involves pulling a metal blank into a die cavity to create a seamless, box-like shape with depth. The primary advantage here is the elimination of welded seams along the corners, which are notorious failure points for moisture intrusion. Manufacturers like Hudson Technologies and Magna utilize deep draw capabilities to achieve near-rectangular corners and maximize internal volume for battery cells—Magna’s OptiForm process, for instance, reportedly increases usable battery space by 10% compared to traditional multi-piece assemblies.</p><p>Conversely, <strong>progressive die stamping</strong> is utilized for high-volume production of smaller, intricate internal components such as busbars, connectors, and structural ribs. In this process, a metal coil feeds through a series of stations that cut, bend, and form the part in sequence. This method ensures exceptional repeatability for parts that require millions of units annually.</p><h3>Scalability and Partner Selection</h3><p>The transition from prototyping to mass production is a critical phase in EV program development. OEMs require partners who can validate geometry with soft tooling before investing in hard production dies. Suppliers like <a href="https://www.shao-yi.com/auto-stamping-parts/">Shaoyi Metal Technology</a> bridge this gap by offering IATF 16949-certified precision stamping with press capabilities up to 600 tons, enabling the production of everything from rapid prototypes to high-volume control arms and subframes that meet rigorous global standards.</p><h2>Material Strategy: Aluminum vs. Advanced High-Strength Steel (AHSS)</h2><p>The choice between aluminum and steel remains the most significant design decision for battery enclosures, with each material offering distinct trade-offs in weight, cost, and thermal performance.</p><h3>Aluminum: The Lightweight Incumbent</h3><p>Aluminum currently holds approximately 80% of the EV battery enclosure market. Its primary advantage is density—aluminum is roughly one-third the weight of steel, which directly translates to extended vehicle range. Alloys in the 6000 series are commonly used for their favorable strength-to-weight ratio and high thermal conductivity, which assists in dissipating heat generated by the battery modules. However, aluminum enclosures often require thicker gauges to match the crash protection of steel, and the material is significantly more expensive per kilogram.</p><h3>Steel: The Cost-Effective Challenger</h3><p>Steel is fighting back with Advanced High-Strength Steel (AHSS) grades like Martensitic steel (M1500/M1700). These materials offer ultra-high tensile strength, allowing for thinner gauges that rival aluminum in weight while providing superior protection against underbody impacts (e.g., hitting a bollard or road debris). Steel also has a much higher melting point (approx. 1370°C vs. 660°C for aluminum), offering better inherent containment during a thermal runaway event. Recent industry analyses suggest that steel enclosures can be up to 50% cheaper to fabricate than their aluminum counterparts.</p><table><thead><tr><th>Feature</th><th>Aluminum (6000 Series)</th><th>AHSS (Martensitic)</th></tr></thead><tbody><tr><td><strong>Market Share</strong></td><td>~80%</td><td>~20% (Growing)</td></tr><tr><td><strong>Primary Benefit</strong></td><td>Weight reduction (Range)</td><td>Impact strength & Cost</td></tr><tr><td><strong>Thermal Conductivity</strong></td><td>High (Good for cooling)</td><td>Low (Good for fire insulation)</td></tr><tr><td><strong>Manufacturing</strong></td><td>Extrusion/Casting/Stamping</td><td>Cold/Hot Stamping, Roll Forming</td></tr></tbody></table><h2>Innovation Spotlight: The "Hashtag" Tailor-Welded Blank</h2><p>One of the most promising developments in 2025 is the application of Tailor-Welded Blanks (TWB) to solve the "springback" issues inherent in stamping large steel trays. A notable case study involving Cleveland-Cliffs and AutoForm demonstrated a novel approach to stamping a one-piece battery tray using a "hashtag-shaped (#)" blank design.</p><p>In this configuration, ultra-high-strength AHSS is used for the flat bottom of the tray to ensure maximum protection against road hazards. This central panel is laser-welded to a perimeter of milder, more formable steel. The milder steel forms the sidewalls and corners—areas that undergo severe deformation during the deep draw process.</p><p>This hybrid material approach solves two critical problems:</p><ul><li><strong>Springback Control:</strong> Stamping a tray entirely from AHSS often results in severe warping (springback) when removed from the die, making it impossible to achieve the required flatness for sealing. The mild steel perimeter absorbs the forming stress, stabilizing the part.</li><li><strong>Process Efficiency:</strong> It allows for a one-hit stamping process that eliminates the need for separate underbody shields, reducing part count and assembly complexity.</li></ul><h2>Engineering for Failure: Sealing, Thermal & Safety</h2><p>Stamping electric vehicle battery enclosures is not just about shaping metal; it is about meeting rigorous functional performance standards. The enclosure must effectively be a survival cell for the battery modules.</p><h3>Sealing and Flange Flatness</h3><p>The most critical quality metric for a stamped battery tray is flange flatness. To meet IP67 or IP68 ingress protection ratings (ensuring the pack is watertight even when submerged), the mating surface where the lid seals to the tray must be perfectly flat. Industry standards typically demand a flatness variation of no more than <strong>±1.5 mm</strong> over the entire length of the tray. Achieving this requires advanced simulation software to predict and compensate for metal springback during the die design phase.</p><h3>Thermal Runaway Containment</h3><p>Safety regulations are driving new material requirements. Organizations like UL Solutions have introduced tests such as <strong>UL 2596</strong>, which evaluates enclosure materials under thermal runaway conditions. While steel naturally withstands high temperatures, aluminum enclosures often require additional thermal blankets or mica sheets to prevent burn-through. Interestingly, thermoplastic composites are emerging as a competitor here, with some materials forming a protective char layer (intumescence) that acts as a heat shield during fire events.</p><h3>Crash Safety Integration</h3><p>Finally, the stamped enclosure contributes to the vehicle’s overall crashworthiness. In side-pole impact tests, the battery tray must transfer loads through stamped cross-members and ribs to prevent intrusion into the cell modules. Deep draw stamping allows engineers to integrate these stiffening features directly into the tray geometry, reducing the need for welded reinforcements and lowering the total weight.</p><h2>Conclusion</h2><p>The stamping of EV battery enclosures represents a convergence of metallurgy, simulation, and precision manufacturing. Whether utilizing deep-drawn aluminum for maximum range or tailor-welded steel for cost-effective safety, the goal remains the same: a lightweight, leak-proof, and crash-resistant housing. As automakers push for higher volumes and lower costs in 2025, the ability to stamp complex, one-piece trays with hybrid materials will define the next generation of electric vehicle architecture.</p><section><h2>Frequently Asked Questions</h2><h3>1. What is the difference between deep draw and progressive stamping for EV parts?</h3><p>Deep draw stamping is used for large, seamless components with significant depth, such as the main battery tray or "tub," because it eliminates welded corners and leak paths. Progressive stamping is better suited for high-volume production of smaller, complex parts like connectors, busbars, and brackets, where a strip of metal is formed in sequential steps for maximum speed and efficiency.</p><h3>2. Which material is better for battery enclosures: aluminum or steel?</h3><p>It depends on the vehicle's priorities. Aluminum is preferred for premium and long-range vehicles because it is significantly lighter (up to 40% weight savings), which improves range. Steel (specifically AHSS) is favored for mass-market vehicles where cost reduction and superior underbody impact protection are the primary goals. Steel is also naturally more resistant to fire breakthrough during thermal runaway events.</p><h3>3. Why is flange flatness so critical in stamped battery trays?</h3><p>Flange flatness is essential for creating a hermetic seal between the battery tray and the cover. If the flange varies by more than the allowable tolerance (typically ±1.5 mm), the gasket may not seal properly, leading to water or dust ingress (failing IP67 standards), which can cause catastrophic short circuits or battery failure.</p></section>

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —