Automotive Stamping Die Storage: Heavy-Duty Racks & AS/RS Solutions

TL;DR

Automotive stamping die storage presents a unique engineering challenge due to the extreme weight (20,000 to over 100,000 lbs) and high value of Class A surface dies. Standard warehouse racking is structurally inadequate and dangerous for this application. The three primary industrial solutions are Structural I-Beam Racks (for high-density vertical storage of dies up to 80,000 lbs), Automated Storage and Retrieval Systems (AS/RS) (for maximizing vertical space and reducing retrieval time), and codified Floor Stacking using certified safety blocks for ultra-heavy tools. Facility managers must prioritize systems that resist point-loading failure and comply with OSHA lockout/tagout regulations to prevent catastrophic equipment damage or injury.

Structural I-Beam Racks: The Industry Standard

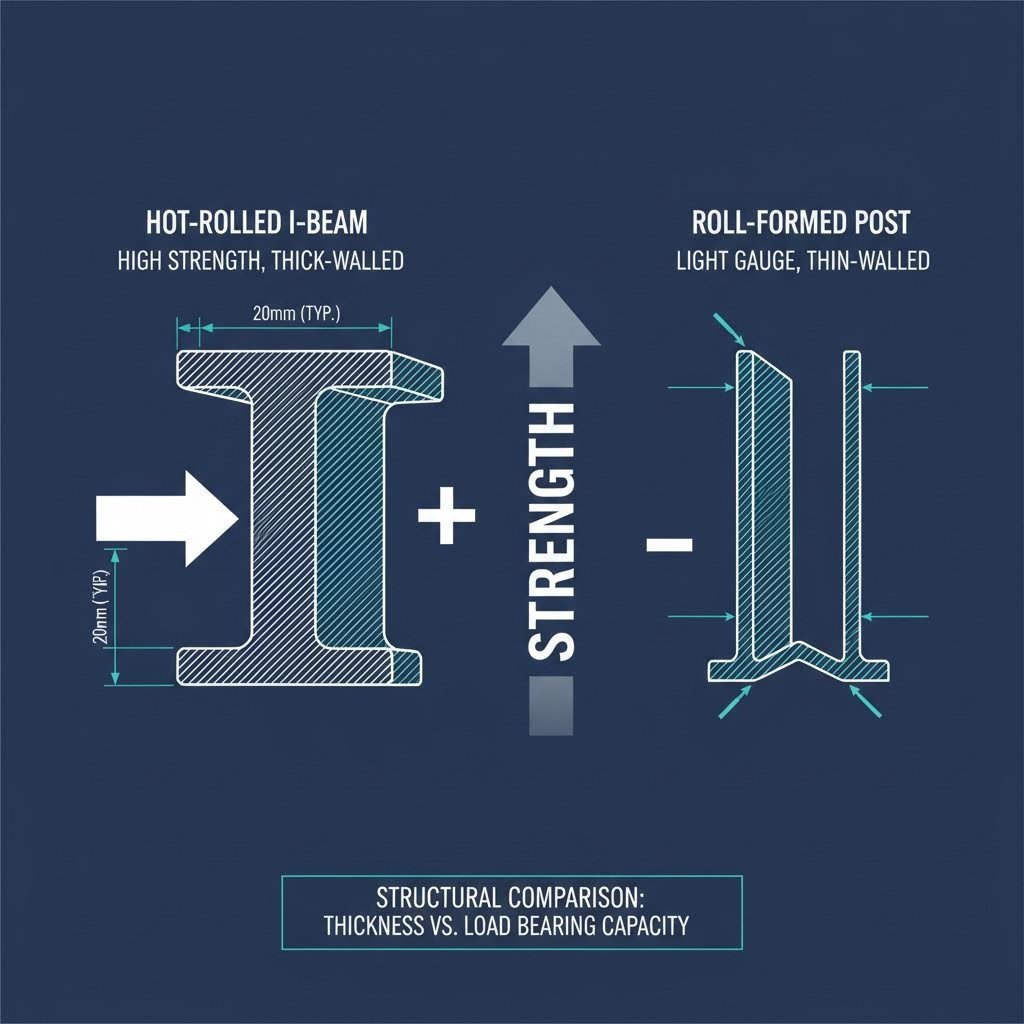

For the vast majority of automotive stamping facilities, structural I-beam racking represents the optimal balance between storage density, accessibility, and capital expenditure. Unlike roll-formed steel commonly found in light-duty warehousing, structural racking is fabricated from hot-rolled structural steel channel, offering superior resistance to impact and massive point loads.

Why Roll-Formed Racking Fails

A critical error in facility planning is attempting to repurpose standard pallet racking for heavy die storage. Roll-formed columns are susceptible to buckling under the specific stress patterns of stamping dies, which often exert intense "point loads" rather than the uniformly distributed loads pallet racks are designed to handle. Furthermore, the inevitable forklift impacts in a fast-paced press room can compromise the structural integrity of roll-formed steel, leading to catastrophic collapse.

Structural I-beam systems, such as those engineered by Dexco, use heavy-duty bolted connections and ship channel construction. These systems can support shelf capacities exceeding 80,000 pounds per tier. When specifying these racks, engineers should look for features like solid steel decks (to prevent dies from slipping between beams) and forklift entry bars, which elevate the die slightly to allow forks to slide underneath without damaging the rack beams.

Automated Die Storage & Retrieval Systems (AS/RS)

As land costs rise and "Just-in-Time" manufacturing demands tighter schedules, many OEMs are shifting toward automation. Automated Die Storage and Retrieval Systems (AS/RS) replace the chaotic forklift traffic of the press room with precision-controlled cranes or Vertical Lift Modules (VLMs).

Maximizing Cube Utilization

Traditional floor storage wastes up to 70% of available vertical space. AS/RS solutions utilize the full height of the facility—often up to 40 or 50 feet—storing dies in high-density vertical banks. Providers like Southwest Solutions Group highlight that VLMs can recover up to 85% of floor space compared to static racking. This recovered footage allows manufacturers to expand production lines without acquiring new real estate.

Operational Efficiency and Safety

Beyond space savings, AS/RS systems integrate directly with warehouse management systems (WMS) to track die locations instantly. Retrieval times drop from 20+ minutes of forklift hunting to under 5 minutes of automated delivery. Solutions from Macrodyne often include integrated transfer carts that move the die directly from the storage rack to the press bolster, eliminating the dangerous overhead crane maneuvers typically required to flip and position heavy tooling.

For manufacturers scaling their operations, preserving the quality of these dies is paramount. Whether you are moving from rapid prototyping to mass production, ensuring your tooling remains pristine is critical for partners delivering comprehensive stamping solutions. Automated systems significantly reduce the risk of accidental collision damage during transport, protecting the investment in high-precision tooling.

Safety Die Blocks & Floor Storage Compliance

For dies exceeding 50 tons—or in facilities where vertical racking is not feasible—floor storage remains a common practice. However, this method is often plagued by the "Industrial Jenga" risk, where disorganized stacking creates severe safety hazards.

The Role of Die Safety Blocks

Simply placing a die on the concrete floor is acceptable, but stacking requires strict adherence to safety protocols. A critical component in this ecosystem is the usage of die safety blocks. Unlike makeshift wooden blocks which can splinter or compress, engineered die blocks are designed to mechanically prevent the release of kinetic energy during storage or maintenance.

According to Dynamic Die Supply, using proper static storage blocks elevates the die, protecting critical components from floor moisture and corrosion while allowing forklift access. OSHA regulations (referenced in 29 CFR 1910.147) emphasize that stored energy must be controlled; ensuring dies are blocked and interlocked prevents gravity-induced slides or falls.

Floor Layout Best Practices

To maintain compliance, floor storage zones must be clearly marked with high-visibility paint. Aisles must be wide enough to accommodate the turning radius of the largest capacity forklift or the travel path of the overhead crane. Never stack dies of different footprints directly on top of one another without an intermediate load-bearing plate or frame, as this creates unstable centers of gravity.

Comparison: Structural vs. AS/RS vs. Floor Storage

Selecting the right storage method depends on die weight, throughput frequency, and budget. The following matrix compares the three dominant strategies.

| Feature | Structural I-Beam Racks | Automated (AS/RS) | Floor Storage (with Blocks) |

|---|---|---|---|

| Primary Benefit | High durability & density | Max space efficiency & speed | Zero capacity limit |

| Typical Load Limit | Up to 80,000 lbs / tier | Up to 50 tons / location | Unlimited (floor load dependent) |

| Space Efficiency | High (Vertical storage) | Maximum (Vertical + Compact) | Low (Horizontal sprawl) |

| Initial Cost | Moderate | High (Significant CapEx) | Low |

| Retrieval Speed | Medium (Forklift dependent) | Fast (<5 mins) | Slow (Crane/Forklift maneuvering) |

| Risk Profile | Low (if impacts are managed) | Lowest (Human removed from loop) | Moderate (Trip hazards, corrosion) |

While AS/RS systems offer the highest performance, the high initial capital expenditure makes them best suited for high-volume Tier 1 suppliers. Structural racking remains the workhorse for most mid-sized stamping houses, providing safe verticality without the complexity of automation.

Conclusion: Engineered Confidence

The decision on how to store automotive stamping dies is not merely logistical; it is a fundamental safety and financial calculation. A single dropped die can cost hundreds of thousands of dollars in repairs and weeks of downtime. By transitioning from chaotic floor stacking to engineered solutions—whether structural I-beam racks or sophisticated AS/RS units—facility managers gain control over their inventory. The goal is a "press-ready" environment where tooling is protected, accessible, and compliant, ensuring that the production rhythm is never broken by preventable storage failures.

Frequently Asked Questions

1. What is the difference between structural and roll-formed racking?

Structural racking is made from hot-rolled steel channels (like I-beams) and uses bolted connections, making it capable of withstanding massive loads and forklift impacts. Roll-formed racking is made from lighter gauge steel bent into shape; it is generally unsuitable for heavy die storage because it can buckle under point loads and lacks impact resistance.

2. Do we really need die safety blocks for storage?

Yes. While often associated with die setting and maintenance (to prevent the press from closing), safety blocks or spacers in storage prevent damage to the die's internal components and allow for safe forklift access. They also ensure stability if dies are stacked, preventing dangerous slides.

3. What are the OSHA regulations for stacking dies?

OSHA does not have a single standard named "die stacking," but general materials handling standards apply. Materials stored in tiers must be stacked, blocked, interlocked, and limited in height so that they are stable and secure against sliding or collapse. Additionally, aisles and passageways must be kept clear, and floor load limits must not be exceeded.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —