Stamping Wheel Houses: The Automotive Manufacturing Guide

TL;DR

Stamping wheel houses is the automotive manufacturing process of forming metal wheel wells (also known as wheel arches) using high-tonnage hydraulic or mechanical presses. Unlike the tabletop "stamp wheels" used in paper crafting, this industrial technique involves deep drawing flat sheet metal—typically high-strength steel or aluminum—into complex, curved structural components that house a vehicle's suspension and tires.

This guide covers the engineering specifications, material challenges, and step-by-step production workflow for manufacturing automotive wheel houses, ensuring structural rigidity and precise OEM tolerances.

The Wheel House Component: Definition and Function

In automotive engineering, the wheel house (often referred to as the wheel well or wheel arch) is a critical body-in-white (BIW) component. It serves as the enclosure for the vehicle's wheels, separating the road environment from the chassis and passenger cabin. While often confused with the exterior "fender," the wheel house is the internal structural shell that manages road debris, water spray, and acoustic vibration.

The assembly typically consists of two primary stamped parts: the Inner Wheel House and the Outer Wheel House. The inner panel is welded directly to the vehicle's floor pan and side rails, contributing significantly to the chassis' torsional stiffness. The outer panel bonds to the quarter panel or fender, defining the vehicle's cosmetic wheel arch profile. Because these components must accommodate the dynamic movement of the suspension system—including shock absorbers and springs—they require deep, complex geometries that are challenging to manufacture without defects.

Designers must balance conflicting requirements: maximizing interior cabin space while ensuring sufficient clearance for tire travel and suspension articulation. This geometric complexity makes the stamping process the only viable method for mass-producing these parts with the necessary speed and repeatability.

The Metal Stamping Process: Step-by-Step

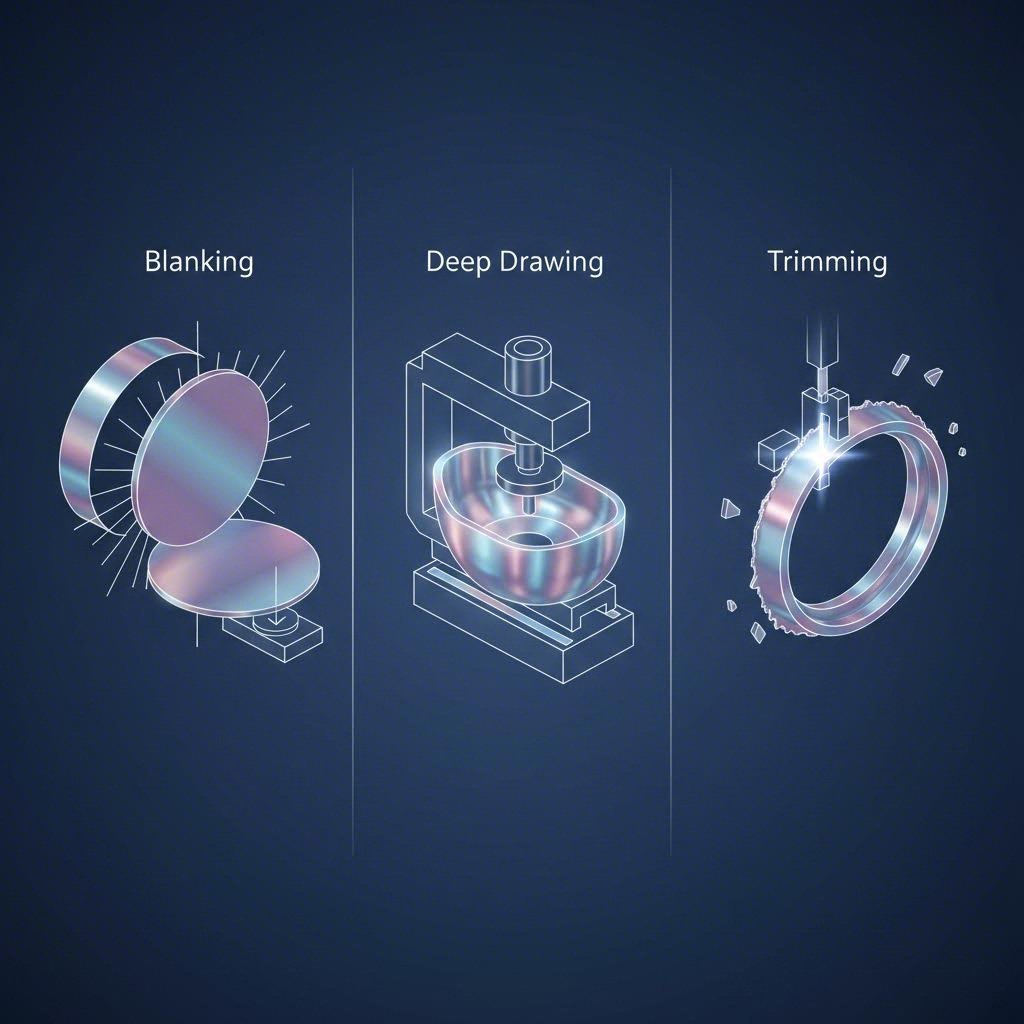

Manufacturing a wheel house involves a sequential die stamping workflow, typically performed on a transfer press line or a progressive die setup. According to industrial stamping specialists like Mursix, the process transforms flat metal coils into finished 3D components through a series of precise operations. The specific workflow for a wheel house generally includes four critical stages.

1. Blanking

The process begins with blanking, where a specific profile is cut from the master coil of sheet metal. For wheel houses, this blank is usually a large, roughly semi-circular or rectangular sheet calculated to provide enough material for the deep sides of the well without excessive waste. The quality of the blank's edge is crucial; burrs or micro-cracks at this stage can propagate into large splits during the forming phase.

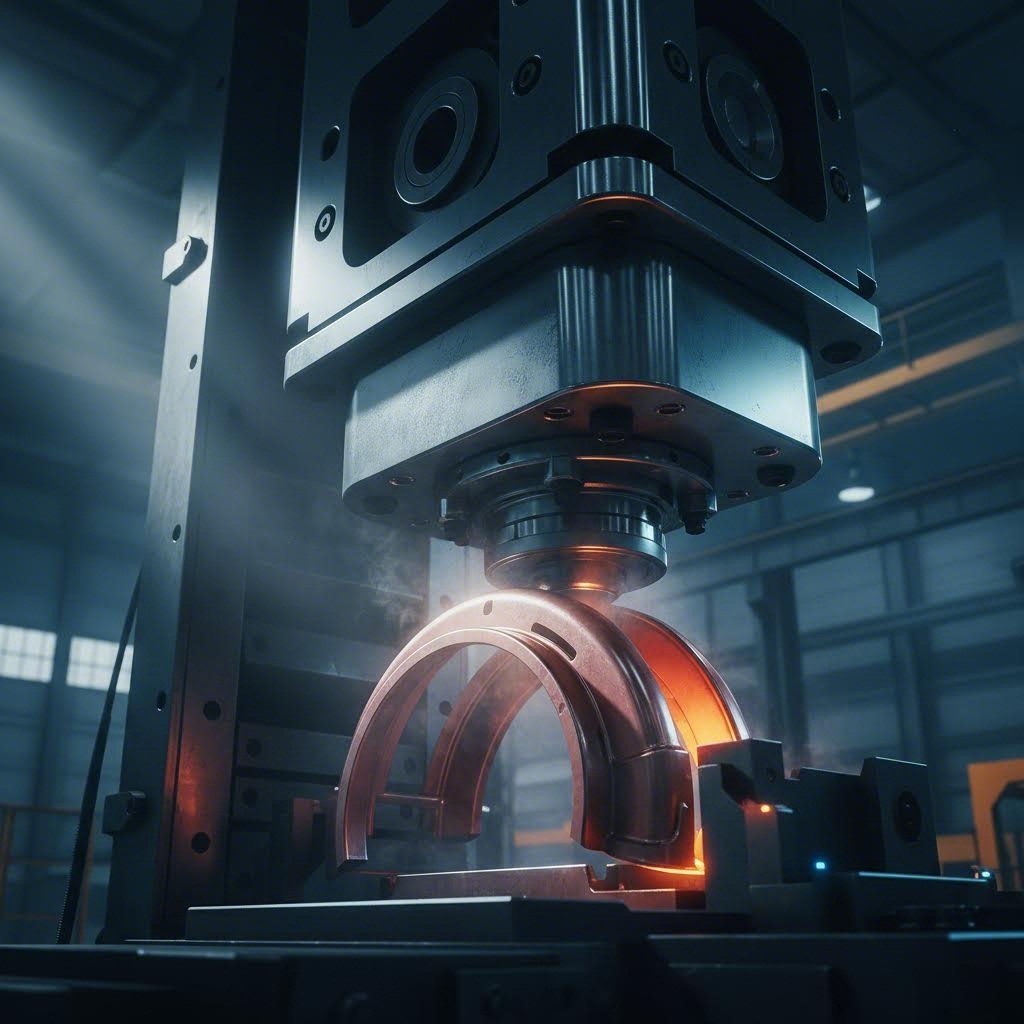

2. Deep Drawing

This is the most technically demanding phase. The flat blank is placed over a die cavity, and a punch forces the metal down to form the cup-like shape of the wheel house. Because wheel wells are deep (often 10–15 inches or more to accommodate suspension struts), the metal must flow plastically without tearing. Engineers monitor the draw ratio carefully, often using draw beads to control the flow of material and prevent wrinkling in the flange areas.

3. Trimming

Once the deep shape is formed, the excess material around the edges (binder scrap) must be removed. Trimming dies cut the final perimeter of the wheel house to exact CAD specifications, ensuring it will mate perfectly with the floor pan and quarter panel. Precision is non-negotiable here, as gaps in the wheel house assembly can lead to water leaks or structural weakness.

4. Piercing and Flanging

The final strokes of the press involve piercing holes for suspension mounting points, brake line clips, and sound-deadening liner attachments. Simultaneously, flanging operations may bend specific edges to create welding surfaces. In high-volume production, these steps occur in seconds, with automated transfer systems moving the part between die stations.

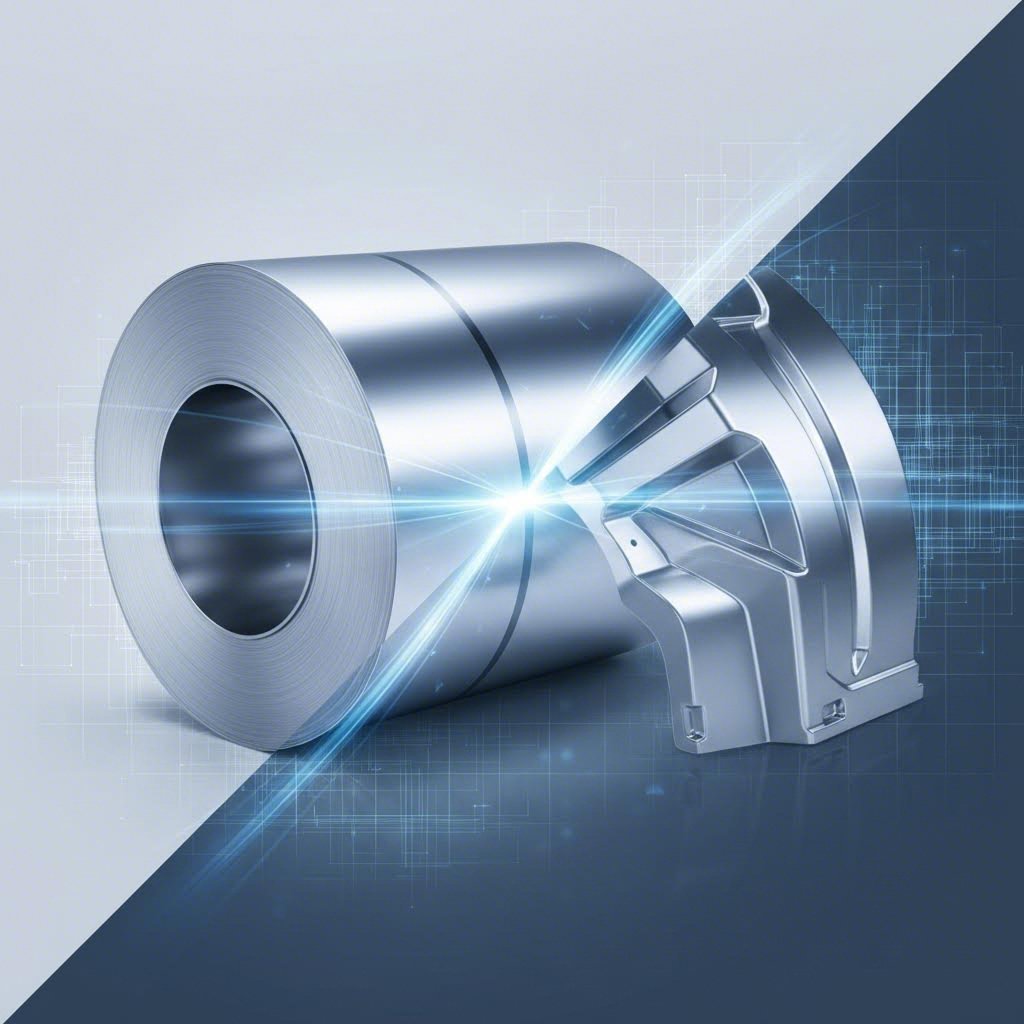

Material Selection: Steel vs. Aluminum

The choice of material for stamping wheel houses is dictated by the vehicle's weight targets and crash safety requirements. The material's formability—its ability to stretch without breaking—is the primary concern for manufacturing engineers.

- High-Strength Steel (HSS): traditionally the standard for wheel houses due to its durability and lower cost. It offers excellent protection against road debris impact. However, HSS requires significantly higher tonnage to stamp and causes more wear on the dies.

- Aluminum Alloys (5000/6000 Series): increasingly used in modern electric and luxury vehicles to reduce unsprung weight and improve range. Stamping aluminum wheel houses presents unique challenges, primarily springback—the tendency of the metal to return to its original shape after the press retracts. Die designers must compensate for this by over-bending the part or using advanced simulation software.

For manufacturers bridging the gap from prototype to mass production, selecting the right partner is as critical as selecting the right material. Shaoyi Metal Technology specializes in this transition, leveraging IATF 16949-certified precision to deliver complex components like wheel houses and subframes. Whether you need an initial run of 50 prototypes to validate your material choice or are ramping up to millions of units, their press capabilities up to 600 tons ensure consistent adherence to global OEM standards.

Mass Production Stamping vs. Manual Forming

A common point of confusion in this field is the difference between industrial stamping and the manual English Wheel method. While both techniques form metal into curves, they serve entirely different purposes in the automotive world.

| Feature | Industrial Stamping | English Wheel (Manual) |

|---|---|---|

| Mechanism | Hydraulic/Mechanical Press with matched Dies | Rolling metal between two steel wheels (anvils) |

| Volume | High Volume (Thousands per day) | Low Volume (One-off or prototype) |

| Consistency | Identical parts (Micron-level tolerance) | Dependent on operator skill; unique variations |

| Application | OEM Car Manufacturing | Classic Car Restoration, Hot Rods, Custom Fabrication |

If you are restoring a vintage vehicle and cannot find a replacement panel, a craftsman might use an English Wheel to hand-form a wheel house. However, for modern vehicle manufacturing, the stamping press is the only method capable of achieving the necessary structural integrity and production speed.

Quality Control and Common Defects

Stamping wheel houses is prone to specific defects due to the depth of the draw and the complexity of the shape. Quality control teams typically monitor for three primary failure modes:

- Splitting (Tearing): Occurs when the metal is stretched beyond its tensile limit, usually at the deepest corner of the wheel well. This often indicates poor lubrication or excessive hold-down pressure.

- Wrinkling: Happens when the metal compresses rather than flows, typically along the flange or side walls. This structural flaw compromises the part's ability to be welded correctly.

- Springback: As mentioned with aluminum, the part may distort after leaving the die. Advanced optical scanning systems are now used to verify that the final geometry matches the CAD model within strict tolerances.

Conclusion

Stamping wheel houses is a sophisticated intersection of material science and mechanical engineering. From the initial blanking of high-strength steel to the complex deep drawing that creates the protective arch, every step is calculated to ensure the vehicle's structural integrity. For automotive engineers and procurement specialists, understanding the nuances of this process—from material springback to press tonnage—is essential for sourcing components that meet the rigorous demands of modern transportation.

Frequently Asked Questions

1. What is the difference between a wheel house and a fender?

The wheel house (or wheel well) is the structural, internal enclosure that surrounds the tire and protects the chassis. The fender is the exterior cosmetic panel that covers the wheel house and blends into the car's body design. The wheel house provides structure; the fender provides style.

2. Why is deep drawing used for wheel houses?

Deep drawing is the only stamping technique capable of creating the deep, cup-like shape required to house a suspension system. Simple bending or folding cannot achieve the seamless, watertight depth needed for a functional wheel well.

3. Can aluminum be used for stamping wheel houses?

Yes, aluminum is widely used to reduce vehicle weight. However, it requires specialized stamping techniques to manage springback and prevents cracking, as aluminum is generally less formable than mild steel.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —