Laser Blanking vs. Mechanical Blanking: The Cost & Performance Break-Even Analysis

TL;DR

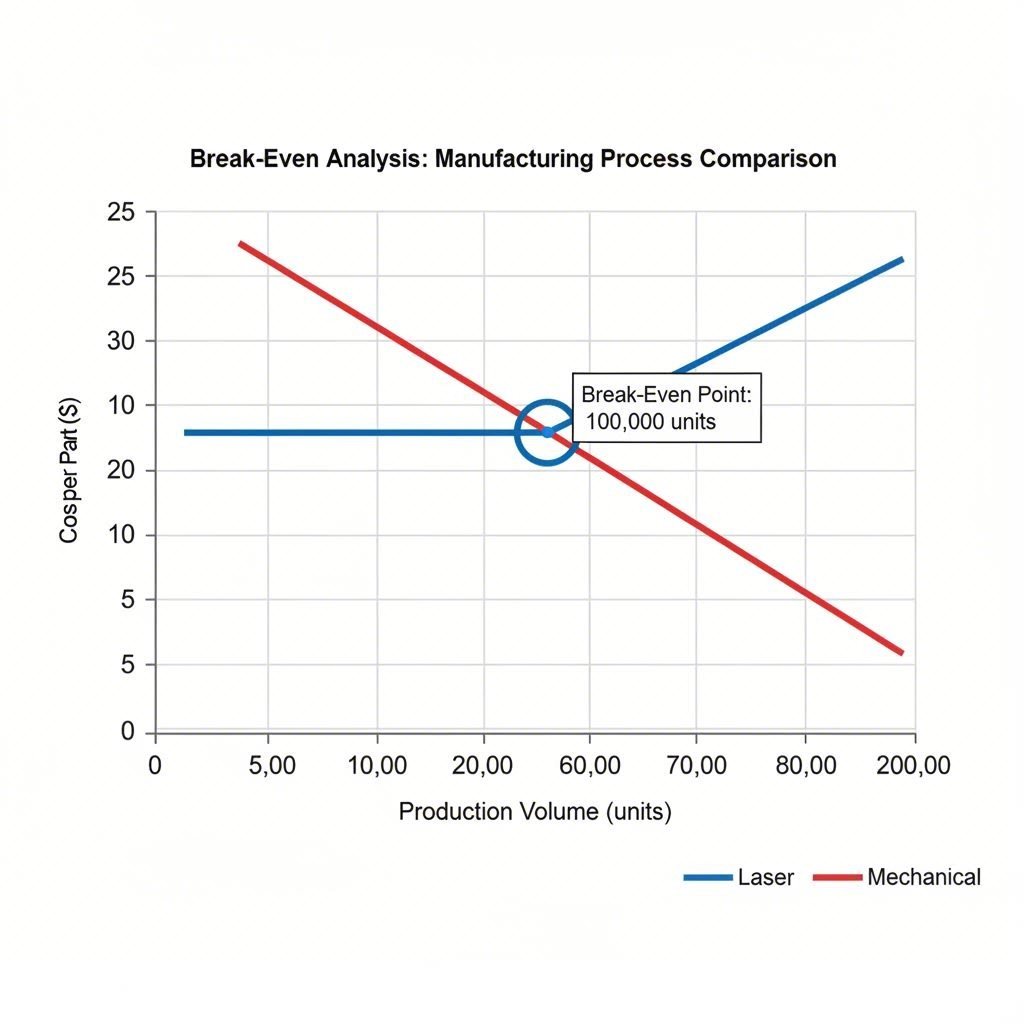

For modern manufacturers, the choice between laser blanking vs mechanical blanking is no longer just about speed—it is a calculation of total cost of ownership (TCO) and agility. Industry data consistently places the break-even point between 60,000 and 100,000 parts per year; below this threshold, laser blanking's zero-tooling model typically offers superior ROI. While mechanical blanking remains the undisputed leader for high-speed, stable mass production, laser blanking has become the preferred solution for processing Advanced High-Strength Steel (AHSS) and high-mix, low-volume components due to its superior material utilization and edge quality.

The Fundamental Shift: Hard Tooling vs. Soft Tooling

The core operational difference between these two technologies lies in how they define "tooling." Mechanical blanking relies on Hard Tooling—physical dies machined from tool steel that can weigh several tons. These dies require months to design, fabricate, and test before a single production part is stamped. Once in operation, changing between parts requires heavy overhead cranes and significant downtime (often 30–60 minutes) to swap the physical die sets.

In contrast, laser blanking utilizes Soft Tooling. The "tool" is simply a CNC program derived from a CAD file. There is no physical impactor and no die to manufacture. A design change that would cost $50,000 and take six weeks in a mechanical setup can be implemented in a laser blanking line in minutes by uploading a new file. This shift from physical assets to digital assets dramatically reduces the "time-to-part," allowing manufacturers to move from design freeze to production almost instantly. For industries like automotive, where model years and facelifts drive constant geometry changes, this flexibility is often more valuable than raw throughput.

Cost Analysis & The Break-Even Volume

For CFOs and plant managers, the decision often comes down to the break-even volume. Industry analyses, including reports from MetalForming Magazine, suggest that the financial tipping point typically sits between 60,000 and 100,000 parts per year.

The CAPEX vs. OPEX Trade-off

- Mechanical Blanking (High CAPEX, Low Unit Cost): Requires a massive upfront investment in dies (ranging from $20,000 to over $100,000 per part) and deep pit foundations for the press. However, once running, the operational cost per part is incredibly low due to high speeds.

- Laser Blanking (Low CAPEX, Higher Variable Cost): Eliminates die costs entirely. The initial machine investment is significant, but it installs on a standard flat floor. The cost per part is higher due to energy and gas consumables, but the total cost of ownership remains lower for volumes under the 100k threshold because the heavy amortization of dies is removed.

Hidden costs also play a role. Mechanical blanking requires acres of expensive floor space for die storage and maintenance. Laser blanking frees up this capital, allowing facilities to utilize floor space for active production rather than warehousing heavy steel tools.

Material Utilization & Nesting Efficiency

In automotive manufacturing, material cost can represent up to 70% of a stamped part's total value. This is where laser blanking often outperforms mechanical methods, regardless of speed. Mechanical dies are constrained by the physics of shearing; they require "engineering scrap" or webbing between parts to maintain structural integrity during the stroke.

Laser blanking utilizes Free-Style Nesting and common-line cutting. Because there is no physical force applied to the sheet, parts can be nested within millimeters of each other, or even share a cut line. Irregular shapes, such as L-brackets or window cutouts, can be interlocked in ways that are impossible with hard tooling. Data from The Fabricator indicates that laser blanking can yield 3% to 20% material savings compared to mechanical stamping. On a high-volume run of expensive aluminum or high-strength steel, a 3% yield improvement can amount to millions of dollars in annual savings.

Edge Quality & Material Suitability (AHSS)

The rise of Advanced High-Strength Steel (AHSS) has complicated the case for mechanical blanking. When high-tonnage presses shear AHSS (materials with tensile strengths over 1000 MPa), the impact often causes microfractures along the cut edge. These microfractures can lead to splitting failures during subsequent forming operations, increasing scrap rates downstream.

Laser blanking is a non-contact thermal process. It is material agnostic—cutting 1500 MPa press-hardened steel as easily as mild steel. The resulting edge is free of microfractures, and the Heat-Affected Zone (HAZ) is typically negligible (less than 0.2mm). Furthermore, processing AHSS on mechanical presses accelerates die wear, leading to maintenance costs that are often four times higher than for mild steel. Laser cutting eliminates this wear factor entirely, ensuring consistent edge quality from the first part to the millionth.

Production Speed: The Gap is Closing

Historically, mechanical blanking was the undisputed king of speed, capable of delivering 60+ strokes per minute (SPM). While it still holds the advantage for massive runs of simple parts, laser technology is catching up. Modern coil-fed laser lines employ multi-head systems (often 2 to 4 laser heads working simultaneously) and "DynamicFlow" technology to achieve effective speeds of 30–40+ parts per minute.

When evaluating speed, one must calculate "net throughput" rather than just strokes per minute. A mechanical press might run faster, but if it requires 45 minutes of downtime for a die change every few hours, its net efficiency drops. A laser line changes over in 5–7 minutes. For high-mix production environments requiring multiple daily changeovers, the tortoise (laser) often beats the hare (mechanical).

Decision Matrix: When to Choose Which

To simplify the selection process, use this decision framework based on your production constraints:

| Decision Factor | Choose Laser Blanking | Choose Mechanical Blanking |

|---|---|---|

| Annual Volume | < 100,000 parts/year | > 100,000 parts/year |

| Design Maturity | New Product Introduction (NPI), frequent changes | Frozen design, mature product line |

| Material Cost | High (Aluminum, AHSS) – Needs nesting efficiency | Low (Mild Steel) – Material scrap is less critical |

| Lead Time | Urgent (Days) | Standard (Months for die build) |

| Capital Budget | OPEX-focused (Avoid die investment) | CAPEX-focused (Lowest unit cost prioritized) |

While laser blanking offers unmatched agility, the reality of automotive mass production often demands the sheer throughput of traditional stamping for mature product lines. For manufacturers scaling from prototype to millions of units, verified fabrication partners like Shaoyi Metal Technology bridge this gap, offering IATF 16949-certified precision stamping capabilities up to 600 tons to handle high-volume demands that exceed laser blanking's economical range.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —