Aluminium Sheet Metal Fabrication: 9 Costly Mistakes Your Supplier Won't Mention

What Is Aluminium Sheet Metal Fabrication

Ever wondered how those lightweight aircraft panels, sleek electronic enclosures, or corrosion-resistant marine components come to life? The answer lies in aluminium sheet metal fabrication - a specialized manufacturing process that transforms flat aluminium sheets into precision-engineered parts and assemblies.

Aluminium sheet metal fabrication is the process of cutting, bending, forming, joining, and finishing aluminium sheets - typically less than 6mm thick - to create functional components for industries ranging from aerospace to consumer electronics.

But here's the thing: working with aluminium isn't the same as working with steel or other metals. This distinction trips up many buyers and even some suppliers. Understanding what is a sheet metal fabrication process specifically for aluminium can save you from costly mistakes down the road.

What Makes Aluminium Fabrication Unique

When you compare aluminium to steel, the differences become immediately apparent. Aluminium weighs roughly one-third as much as steel, making it ideal for applications where weight reduction matters. But that lightweight advantage comes with fabrication challenges that require specialized expertise.

Consider these aluminium-specific properties that affect every stage of the sheet metal fabrication process:

- High thermal conductivity: Aluminium dissipates heat quickly during cutting and welding, requiring adjusted speeds and techniques

- Naturally forming oxide layer: This protective coating melts at approximately 3700°F - far higher than the 1221°F melting point of the aluminium beneath it

- Greater springback: Aluminium tends to return toward its original shape after bending more than steel does

- Softer material: While easier to machine, aluminium is more prone to scratching and requires careful handling

These characteristics explain why experienced fabricators treat aluminum sheets metal differently than their steel counterparts. The natural corrosion resistance that makes aluminium valuable - thanks to that oxide layer - actually complicates welding operations. Without proper surface preparation, you'll end up with weak joints and porosity issues.

Core Processes in Sheet Metal Work

Aluminium fabrication encompasses several interconnected operations, each requiring material-specific adjustments:

- Cutting: Laser cutting, waterjet cutting, and plasma cutting all work with aluminium, though laser cutting offers the precision most applications demand. The material's excellent thermal conductivity helps prevent heat buildup in the cutting zone.

- Bending and Forming: Press brakes and specialized dies shape flat sheets into angles, curves, and complex geometries. Aluminium's malleability makes it excellent for intricate designs, but operators must account for increased springback.

- Joining: TIG and MIG welding connect aluminium components, though the process demands cleaner surfaces and more precise heat control than steel welding.

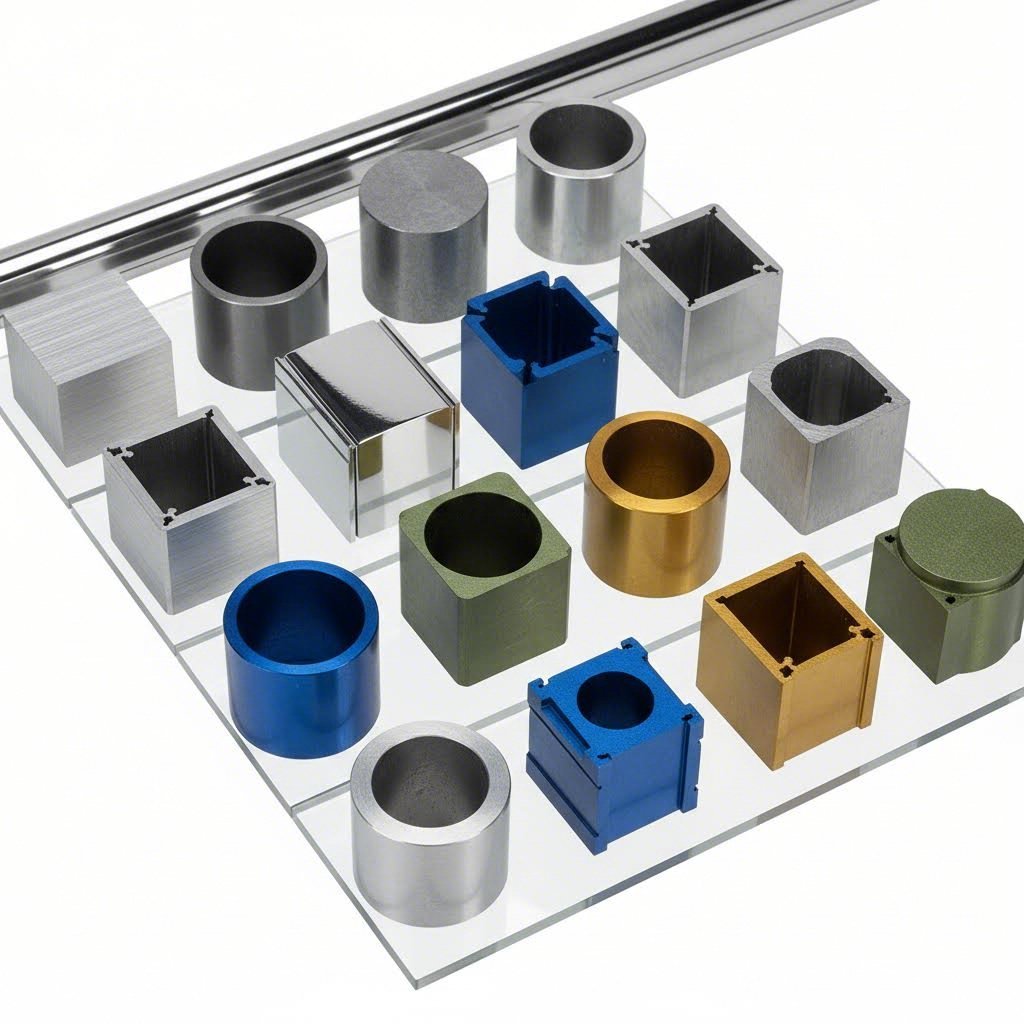

- Finishing: Anodizing, powder coating, and polishing enhance both appearance and durability of aluminum things we encounter daily - from smartphone cases to architectural panels.

Why has aluminium become the go-to material for so many applications? The answer combines practical and economic factors. Things that are made out of aluminum benefit from natural corrosion resistance, recyclability, and that crucial weight savings. Industries like aerospace, automotive, and electronics rely on aluminium fabrication to meet performance requirements that steel simply cannot achieve.

Understanding these fundamentals sets the stage for making informed decisions about alloy selection, thickness specifications, and fabrication methods - topics we'll explore in the sections ahead.

Aluminium Alloy Selection for Fabrication Success

Choosing the wrong alloy is one of the most expensive mistakes in aluminium sheet metal fabrication - and unfortunately, it's one your supplier might not catch until it's too late. Each aluminium alloy behaves differently during cutting, bending, and welding operations. Select the right one, and your parts perform flawlessly. Pick the wrong one, and you'll face cracking, poor weld quality, or premature failure in the field.

So how do you navigate the alphabet soup of alloy designations? Let's break down the most common options and their fabrication-specific characteristics.

Popular Alloys and Their Fabrication Characteristics

When evaluating aluminum alloy sheet metal for your project, you'll encounter alloys from several series - each engineered with different alloying elements that dramatically affect workability. Here's what you need to know about the alloys most frequently specified for sheet metal work:

| Alloy | Formability | Weldability | Corrosion Resistance | Strength | Typical Applications |

|---|---|---|---|---|---|

| 1100 | Excellent | Excellent | Excellent | Low | Chemical processing, heat exchangers, cooking utensils |

| 3003 | Excellent | Excellent | Excellent | Good | Roofing, siding, storage tanks, general fabrication |

| 5052 | Excellent | Excellent | Excellent (saltwater) | Good | Marine components, pressure vessels, medical devices |

| 6061 | Excellent | Excellent | Good | Excellent | Structural components, pipelines, recreational equipment |

| 7075 | Low | Low (prone to cracking) | Excellent | Excellent (highest) | Aerospace, military, high-stress automotive parts |

Notice how the relationship between strength and formability isn't always straightforward? The 7075 alloy offers approximately 1.5 times the strength of 6061, but its hardness makes it difficult to form and prone to cracking after welding. This is precisely why aerospace manufacturers often join 7075 components with rivets rather than welds.

For general 5052 aluminum sheet metal applications, you're looking at one of the strongest alloys in the non-heat-treatable category. The 5052 aluminium alloy contains no copper, which explains its exceptional resistance to saltwater corrosion - making it the default choice for marine environments. However, the material's softness makes it challenging to machine precisely.

When welding 5052 or 6061 aluminum alloy sheets, you'll achieve excellent results with proper surface preparation. Both alloys respond well to TIG and MIG processes. The 7075 series, however, requires extreme caution - the metal tends to crack during and after welding, severely limiting its suitability for welded assemblies.

Matching Alloys to Application Requirements

Understanding temper designations is just as critical as selecting the right alloy. The designation following the alloy number tells you how the material was processed - and this directly affects how aluminium malleable the sheet will be during fabrication.

Consider the popular alum 5052 H32 temper specification. The "H" indicates strain-hardening through cold working, while "32" specifies a quarter-hard condition that balances formability with strength. This temper is ideal for marine applications where you need to form complex shapes while maintaining structural integrity in harsh saltwater environments.

Compare this to 6061-T6, where "T6" indicates the alloy has been solution heat-treated and artificially aged. This temper delivers maximum strength - making it perfect for structural components - but reduces formability compared to softer tempers like T4. If your design requires extensive bending after the material arrives, specifying T4 temper and heat-treating afterward might be the smarter approach.

Here's a practical decision framework for alloy selection:

- Need maximum corrosion resistance in marine environments? Specify 5052-H32 aluminium alloy sheet for optimal performance

- Building structural components requiring good strength and weldability? Choose 6061-T6 for the best balance of properties

- Processing chemicals or food products? The 1100 series offers excellent corrosion resistance and high thermal conductivity

- General-purpose fabrication with good formability? 3003 provides an excellent cost-to-performance ratio

- Aerospace or military applications demanding highest strength-to-weight ratio? 7075 delivers - but plan for mechanical fastening rather than welding

One factor many buyers overlook: availability affects both lead time and cost. According to Approved Sheet Metal's 2025 guide, 5052, 6061, and 7075 are commonly stocked alloys, while more specialized grades may require extended lead times. When budget and timeline matter, choosing a readily available alloy can significantly streamline your project.

With your alloy selected, the next consideration is thickness - a decision that affects everything from forming complexity to structural performance.

Gauge and Thickness Selection Guide

Here's a question that trips up even experienced engineers: how many mm is a 6 gauge aluminium sheet? If you guessed the same thickness as 6 gauge steel, you'd be wrong - and that mistake could derail your entire project. Unlike standard metric measurements, gauge numbers work in reverse and vary between materials. Understanding this quirk is essential for specifying the right sheet metal thickness aluminum for your application.

Understanding Gauge Measurements

The gauge system dates back to before standardized units became universal, and it operates counterintuitively. A lower gauge number means thicker material, while higher numbers indicate thinner sheets. For example, 10 gauge aluminum measures approximately 2.588mm (0.1019 inches), while 22 gauge comes in at just 0.643mm (0.0253 inches).

But here's where it gets tricky: gauge sheet metal measurements aren't universal across materials. The same gauge number produces different thicknesses for steel, stainless steel, and aluminium. According to Tri-State Metals, a 10ga aluminum thickness measures 2.588mm, while 10 gauge carbon steel measures 3.416mm - nearly a millimeter thicker.

| Gauge | Aluminium Thickness (mm) | Aluminium Thickness (inches) | Typical Applications | Fabrication Compatibility |

|---|---|---|---|---|

| 10 | 2.588 | 0.1019 | Structural panels, heavy-duty enclosures | Laser, waterjet, press brake bending |

| 12 | 2.052 | 0.0808 | Industrial equipment, chassis components | All cutting methods, standard bending |

| 14 | 1.628 | 0.0641 | Custom fabrication, automotive panels | All methods with excellent formability |

| 16 | 1.290 | 0.0505 | Electronic enclosures, general fabrication | Highly versatile across all processes |

| 18 | 1.024 | 0.0403 | Roofing, architectural panels | Easy forming, all cutting methods |

| 20 | 0.813 | 0.0320 | HVAC ductwork, decorative elements | Excellent for complex bends |

| 22 | 0.643 | 0.0253 | Thin aluminum sheeting for crafts, light covers | May require support during processing |

Most sheet metals have practical limits: the lower threshold sits around 0.5mm, while anything exceeding 6mm is typically classified as plate rather than sheet. When specifying 1 4 aluminum sheet metal (approximately 6.35mm or 1/4 inch), you're actually ordering plate stock - which may affect pricing and available fabrication methods.

Thickness Selection by Application Type

Choosing the right thickness involves balancing several competing factors. Thicker gauges provide greater structural strength and rigidity, but they increase material costs, require more energy to form, and limit the complexity of bends you can achieve.

Imagine you're designing a structural bracket versus a decorative panel. The bracket needs to withstand significant loads, making 10-14 gauge thin aluminum sheet metal the appropriate choice. The decorative panel, however, only needs to maintain its shape and appearance - 18-22 gauge provides sufficient rigidity while reducing weight and cost.

Here's what you should consider for each gauge range:

- Heavy gauges (10-14): Ideal for structural components, load-bearing applications, and parts requiring exceptional durability. These thicknesses handle welding well but require larger minimum bend radii

- Medium gauges (16-18): The sweet spot for general fabrication, offering good strength with excellent formability. Most custom enclosures and industrial components fall into this range

- Light gauges (20-24): Perfect for applications where weight savings matter or complex forming is required. Common in HVAC, signage, and decorative applications

The relationship between thickness and minimum bend radius is critical for achieving accurate parts. According to Xometry's bending guide, a 10 gauge aluminium sheet requires a minimum bend radius of approximately 0.102 inches, while 20 gauge can achieve a tighter 0.032-inch radius. Specifying a bend radius smaller than these minimums risks cracking or distortion.

Pro tip: when your design requires tight bends in thicker material, consider specifying a softer temper designation. As discussed in the alloy section, a T4 temper offers better formability than T6 - allowing tighter radii without compromising the part during bending operations.

The thickness you select also affects which fabrication methods work best. Laser cutting handles thin aluminum sheet metal beautifully, delivering clean edges with minimal heat-affected zones. For thicker gauges approaching 1/4 inch, waterjet cutting may produce better results by eliminating thermal effects entirely. Understanding these relationships helps you design parts that are not only functional but also cost-effective to manufacture.

The Complete Fabrication Process Explained

You've selected your alloy and specified the right thickness - now what happens when your aluminium sheets arrive at the fabrication shop? Understanding each stage of the sheet metal fabrication processes helps you communicate effectively with suppliers, catch potential issues early, and make design decisions that reduce costs. Let's walk through the complete sequence from raw material to finished component.

Here's the fundamental truth about fabricating aluminum: every operation builds on the previous one. Skip a preparation step or rush through surface cleaning, and you'll pay for it later with weak welds or rejected parts. The fabricators who consistently deliver quality parts treat this as an interconnected system - not a series of isolated tasks.

- Material preparation and inspection

- Cutting and shaping operations

- Forming and bending

- Joining and assembly

- Surface finishing and treatment

Cutting and Shaping Operations

Before any cutting begins, experienced fabricators inspect incoming aluminium sheets for surface defects, proper alloy certification, and dimensional accuracy. This step catches problems before they become expensive - imagine discovering your 5052 shipment is actually 3003 after you've already cut and formed fifty brackets.

When it comes to actually separating material, you'll encounter two categories of methods: thermal (non-shearing) and mechanical (shearing). Each has distinct advantages when you fabricate sheet metal from aluminium.

Thermal Cutting Methods:

- Laser cutting: The precision champion for aluminium work. Focused laser beams melt material at specific locations, delivering tolerances as tight as ±0.003 inches. Aluminium's high thermal conductivity actually helps here - the material dissipates heat quickly, reducing the heat-affected zone

- Waterjet cutting: Uses high-pressure water (typically exceeding 50,000 psi) mixed with abrasive particles. Since there's no heat involved, you eliminate thermal distortion entirely - making this ideal for heat-sensitive alloys like 7075

- Plasma cutting: Ionized gas melts and blows away material. While faster than laser for thicker gauges, plasma produces rougher edges that may require secondary finishing

Mechanical Cutting Methods:

- Shearing: A straight-line cutting process that applies shear force to separate material. Fast and economical for simple cuts, but limited to straight edges

- Blanking: A punch and die extract shaped pieces from larger sheets - the extracted piece becomes your workpiece

- Punching: Similar setup to blanking, but here the punched-out portion is scrap while the remaining sheet becomes the product

Here's something your supplier might not mention: aluminium's softness compared to steel means cutting tools wear differently. Dull tooling doesn't just slow production - it creates burrs and rough edges that affect downstream operations. Quality fabricators maintain strict tool replacement schedules specifically calibrated for aluminium work.

Forming and Joining Techniques

Once your parts are cut to shape, forming metal sheet into three-dimensional geometries requires understanding aluminium's unique behavior. The material's excellent formability makes it ideal for complex shapes, but that advantage comes with a catch: springback.

Springback occurs because aluminium tends to partially return toward its original flat state after bending forces are released. A 90-degree bend might spring back to 87 degrees if you don't compensate. Experienced fabricators address this by:

- Over-bending slightly beyond the target angle

- Using bottoming dies that compress material at the bend line

- Adjusting tooling based on specific alloy and temper characteristics

Common forming techniques for aluminium include:

- V-bending: A punch forces the sheet into a V-shaped die - the workhorse of press brake operations

- Roll bending: Three rollers progressively curve sheets into cylindrical or curved shapes. Aluminum roll forming produces consistent results for applications like curved panels and tubes

- Hydroforming: High-pressure fluid stretches aluminium into complex die shapes - common in automotive body panels

- Curling: Rolls edges to eliminate sharp burrs and increase edge strength

Work hardening presents another aluminium-specific consideration during forming. As you bend and form the material, it becomes progressively harder and less ductile. Multiple forming operations on the same area can cause cracking if you don't anneal (heat treat to soften) between steps. Roll forming aluminum in continuous operations requires careful monitoring to prevent material failure.

Joining aluminium components demands more preparation than steel fabrication. That naturally-forming oxide layer we discussed earlier? It melts at approximately 3700°F - nearly three times higher than the aluminium beneath it (1221°F). If you attempt to weld without removing this layer, you'll trap oxides in the weld pool, creating porosity and weak joints.

Surface preparation before welding involves:

- Mechanical cleaning with stainless steel brushes (never use brushes previously used on steel)

- Chemical cleaning with solvents to remove oils and contaminants

- Removing oxide immediately before welding - the layer reforms within minutes of cleaning

For welding itself, TIG (Tungsten Inert Gas) welding delivers the cleanest results on aluminium. The process uses a non-consumable tungsten electrode and shielding gas to protect the weld zone from atmospheric contamination. MIG welding offers faster production speeds for thicker sections, using a continuously-fed wire electrode with shielding gas.

Aluminium's thermal conductivity creates welding challenges beyond surface preparation. The material pulls heat away from the weld zone rapidly, requiring higher heat input than comparable steel work. This heat dissipation also means you need to complete welds relatively quickly before the surrounding material absorbs too much energy.

Alternative joining methods bypass welding challenges entirely:

- Riveting: Mechanical fastening that's especially valuable for alloys like 7075 that crack when welded

- Adhesive bonding: Modern structural adhesives create strong joints without heat input

- Soldering: Heats only the filler metal, not the base aluminium - useful for electrical connections

The finishing stage - anodizing, powder coating, or mechanical surface treatments - completes the fabrication process. But finishing deserves its own detailed discussion, which brings us to surface treatment options and their specific requirements for aluminium components.

Overcoming Aluminium Fabrication Challenges

Here's what your fabrication supplier might not tell you upfront: aluminium's desirable properties - lightweight, corrosion-resistant, highly formable - create genuine manufacturing headaches that require specialized expertise to solve. Skip these considerations, and you'll end up with warped parts, failed welds, or components that don't meet dimensional specifications. Understanding these challenges before you place an order helps you ask the right questions and avoid costly surprises.

Let's examine the four major fabrication challenges specific to aluminium and the proven solutions for each.

- Thermal conductivity effects: Aluminium conducts heat approximately five times faster than steel, pulling thermal energy away from cutting and welding zones rapidly

- Oxide layer complications: The naturally-forming aluminum oxide layer melts at 3700°F - nearly three times higher than the base metal beneath it

- Springback during bending: Aluminium's aluminum flexibility causes it to partially return toward its original shape after forming forces release

- Work hardening accumulation: Repeated aluminum forming operations progressively harden the material, reducing ductility and increasing crack risk

Managing Springback in Aluminium Bending

Is 5052 aluminum bendable? Absolutely - it's one of the most formable alloys available. But that formability comes with a catch that affects every bent component you'll ever order.

Springback happens because aluminium stores elastic energy during bending. Once the press brake releases, that stored energy pushes the metal back slightly toward its original flat state. According to Inductaflex's technical guide, aluminum has a relatively high ratio between its elasticity and yield strength, meaning it can return farther than many other metals once forming force is removed.

The amount of 5052 aluminum bending springback you'll encounter depends on several factors:

- Alloy type and temper: 6000-series alloys bend well but show moderate springback, while 7000-series alloys resist bending more and spring back farther. T5 and T6 tempers increase springback due to their higher strength

- Wall thickness: Thin sheets spring back more than thick ones - a critical consideration when specifying gauge for custom aluminum bending projects

- Bend radius: Tighter radii usually cause more springback, especially on thicker or stiffer material

So how do experienced fabricators compensate? The solutions range from simple to sophisticated:

| Compensation Strategy | Effectiveness | Best Application |

|---|---|---|

| Over-bending past target angle | High | Standard press brake operations |

| Applying tension during bend (stretch forming) | Very High | Complex curves and tight tolerances |

| Mandrel and die optimization | High | Tube and profile bending |

| Lowering bend speed | High | Precision work with tight angles |

| Using larger radii | Moderate | When design flexibility allows |

Modern CNC machines can correct for springback automatically. These systems rely on real-time sensors that track radius changes and adaptive software that adjusts during the bend. When paired with test cycles, these adjustments remove most of the guesswork from achieving accurate angles on the first production run.

What's the purpose of bypass notches in sheet metal forming? These relief cuts reduce stress concentration at bend intersections, preventing cracking and allowing material to flow more predictably during complex forming operations - particularly valuable when working with aluminium's tendency to work-harden.

Oxide Layer Preparation for Welding

Why does aluminium welding require specialized expertise compared to steel? The answer lies in that protective oxide layer we keep mentioning. While this layer provides excellent corrosion resistance, it creates serious complications during joining operations.

The oxide layer melts at approximately 3700°F, while the aluminium beneath it melts at just 1221°F. Attempt to weld without removing this barrier, and you'll trap oxides in the weld pool - creating porosity, inclusions, and joints that fail under stress.

According to Lincoln Electric's welding guide, preweld cleaning requires two operations in a specific sequence - and reversing the order causes problems:

- Remove oil, grease, and water vapor using an organic solvent such as acetone or a mild alkaline solution. Citrus-based degreasers work but require thorough rinsing and drying before welding

- Clean aluminum oxidation from the surface with a stainless steel wire brush (used only for aluminum) or specialized oxide-removal solutions. Exercise extreme care when handling chemical solutions, and rinse thoroughly

- Assemble the joint and cover with brown Kraft paper if welding won't occur immediately - this prevents airborne contaminants from settling into the joint

- Weld within a few days of cleaning. The oxide layer reforms within minutes of exposure to air, so clean again if the joint sits longer than planned

Beyond surface preparation, aluminium's thermal conductivity demands different welding techniques than steel. The material pulls heat away from the weld zone so rapidly that welders must use higher heat input and complete passes more quickly. This isn't simply a matter of turning up the amperage - it requires genuine expertise in managing heat distribution across the workpiece.

Equipment differences matter too. Aluminium TIG welding typically uses AC (alternating current) power rather than the DC commonly used for steel. The AC cycle helps break up the oxide layer during welding. MIG welding aluminium requires push-type wire feeders and specialized contact tips to prevent the softer aluminium wire from bird-nesting in the gun.

Here are practical tips for achieving consistent welding results on aluminium components:

- Never use wire brushes previously used on steel - iron contamination causes corrosion in aluminium welds

- Preheat thicker sections (above 1/4 inch) to reduce the thermal gradient and improve penetration

- Use backing bars or fixtures to control heat distribution and prevent distortion

- Store filler materials in dry conditions - moisture contamination causes porosity

- Consider tack welding in multiple locations to minimize warping as the full weld progresses

Work hardening adds another layer of complexity to multi-step fabrication sequences. Each forming operation increases material hardness while decreasing ductility. If your part requires multiple bends in the same area, discuss annealing (heat treatment to restore softness) between operations with your fabricator. Skipping this step on complex parts often leads to cracking that only becomes visible after finishing - the most expensive time to discover a problem.

Understanding these challenges doesn't mean aluminium is difficult to work with - it means you need partners who understand the material's behavior. The fabricators who produce consistent, high-quality aluminium components have invested in specialized equipment, trained their welders specifically for aluminium work, and developed process controls that account for these unique material properties.

With fabrication challenges addressed, the next consideration is how your surface finishing choices affect both appearance and long-term performance of aluminium components.

Surface Finishing and Treatment Options

You've invested in quality aluminum sheet material, navigated alloy selection, and worked through fabrication challenges - but here's where many projects stumble at the finish line. The surface treatment you choose affects everything from corrosion resistance to aesthetic appeal, and getting it wrong means rejected parts or premature failure in the field.

Think of surface finishing as the final protective layer between your aluminium component and the environment it'll face. Whether you're working with thin sheet aluminium for decorative panels or heavy-gauge structural components, the preparation steps and finish selection directly determine how long your parts will perform.

Preparing Surfaces for Coating

Here's what experienced finishers know that many fabricators overlook: surface preparation accounts for approximately 80% of coating success. Skip steps or rush through cleaning, and even premium coatings will fail prematurely.

According to SAF Anodizing & Finishing, the pretreatment chemicals used for both anodizing and painting are so harsh they can destroy non-aluminum parts. This means any hardware, accessories, or dissimilar metal components must be removed before sending assemblies for finishing.

Cleaning aluminum oxide from fabricated parts follows a specific sequence:

- Degrease thoroughly - Remove oils, lubricants, and handling residues using alkaline cleaners or solvents

- De-oxidize the surface - Chemical de-oxidation removes the existing oxide layer and contamination

- Apply conversion coating - Chrome or non-chrome pretreatments prevent new oxidation and promote adhesion

- Rinse and dry completely - Residual chemicals trapped in assemblies will damage final finishes

Assemblies require special attention. Drainage holes are essential - top holes admit air while bottom holes drain. Without proper drainage, pretreatment chemicals become trapped and leak later, ruining your finish. Even tightly welded joints can allow chemical entrapment over time.

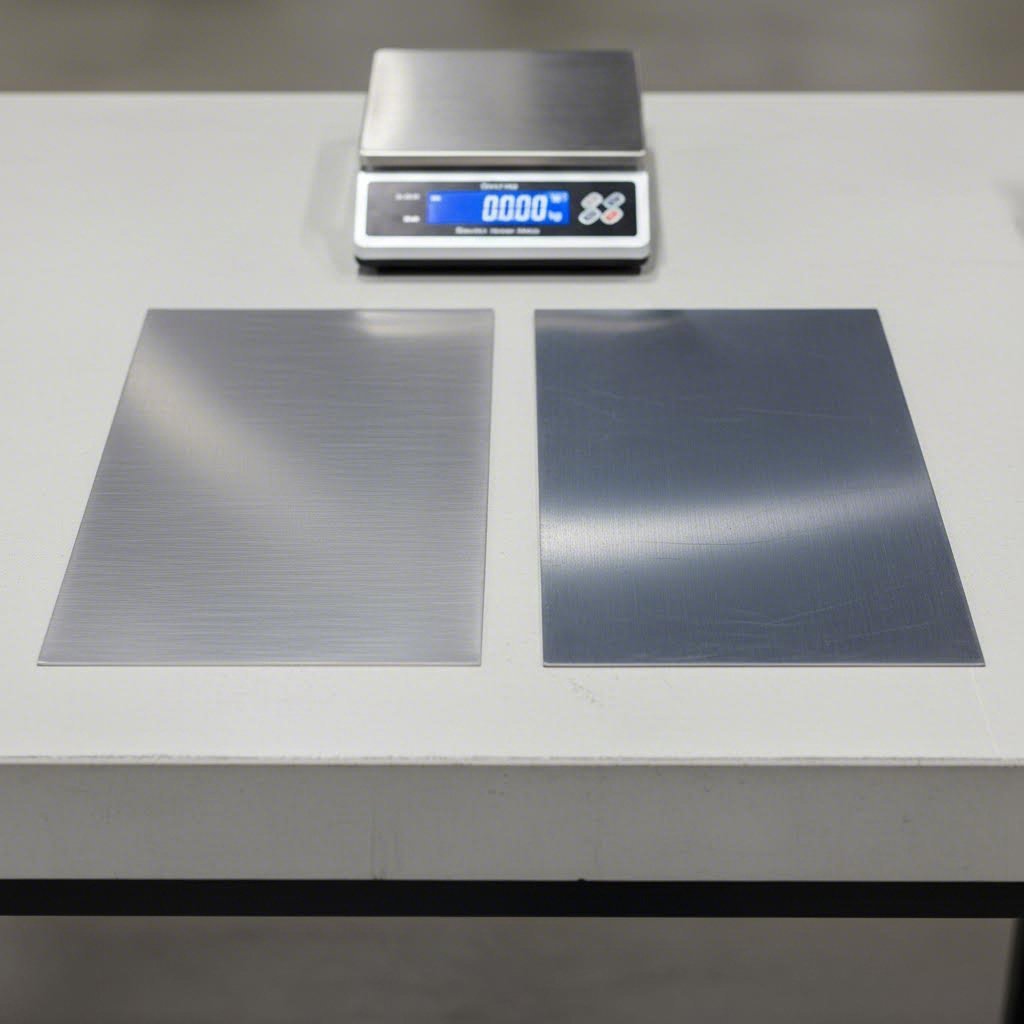

For aluminum sheet craft metal projects or large aluminum sheet metal panels, flatness becomes a concern during finishing. According to SAF's guidance, flat aluminium sheets may warp in curing ovens as the metal expands and contracts at temperatures reaching 475°F. If flatness is critical, consider finishing after fabrication rather than before.

Finish Options and Their Benefits

Each surface finish offers distinct advantages depending on your application requirements. Here's what you need to know about the most common options:

- Mill finish: The as-received surface from the rolling mill. Cost-effective for hidden components but offers minimal corrosion protection and shows scratches easily. Not suitable for outdoor exposure

- Anodizing: An electrochemical process that creates a protective aluminum oxide layer. Type II anodizing offers good corrosion resistance and accepts dyes for color. Hardcoat (Type III) provides exceptional wear resistance for high-traffic applications like door entrances

- Powder coating: Electrostatically applied dry powder cured under heat. Provides excellent corrosion resistance and comes in virtually unlimited colors and textures. Ideal for outdoor products when properly pretreated

- Brushed finish: Mechanical abrasion creates uniform directional lines. Offers a matte sheen with good corrosion protection and hides fingerprints better than polished surfaces

- Polished finish: Progressive grinding and buffing creates a mirror-like appearance. Visually striking but requires more maintenance and shows handling marks readily

Choosing between anodizing and painting depends heavily on application. According to SAF's specifications, anodizing is not recommended for coastal locations due to salt corrosion - painting is preferred in marine environments. However, paint lacks the abrasion resistance needed for entryways, where anodizing remains the safer choice.

For powder coating aluminium specifically, PF Online recommends a de-oxidation step followed by chrome or non-chrome pretreatment for outdoor products. This combination prevents oxidation formation and provides superior long-term adhesion - especially critical in harsh environments.

Your fabrication method choices affect achievable surface quality. Laser cutting produces clean edges with minimal heat-affected zones, while plasma cutting may require edge grinding before finishing. Welded areas need particular attention - filler material must match the base alloy to ensure consistent appearance after anodizing. Using 5356 filler rod is recommended; never use 4043, which turns smutty black during the anodizing process.

One final consideration: order all anodizing material from the same lot to reduce color variation caused by metallurgical composition differences. Even slight alloy variations between production runs can create noticeable color differences after anodizing - a detail that's easy to overlook until parts arrive side by side.

Surface finishing represents your last opportunity to enhance component performance and appearance. The investment in proper preparation and appropriate finish selection pays dividends throughout the product's service life - making it one of the most cost-effective decisions in the entire fabrication process.

Cost Factors and Budget Optimization

So you've specified the right alloy, selected appropriate thickness, and chosen your surface finish - now comes the question everyone wants answered: what will this actually cost? Understanding the factors that drive aluminum fabrication pricing helps you make design decisions that balance performance requirements with budget realities. More importantly, it helps you avoid expensive surprises when quotes arrive.

Here's what many buyers don't realize: small changes in design specifications can create large price fluctuations. According to Austgen's fabrication cost analysis, factors like alloy selection, material thickness, and finishing requirements interact in ways that significantly impact final pricing. Let's break down what actually drives the cost of aluminum fabricated products and how you can optimize without sacrificing quality.

Primary Cost Drivers in Aluminium Fabrication

Every aluminum fab project involves multiple cost components that combine to determine your final price. Understanding these drivers helps you have informed conversations with fabricators and make smarter tradeoffs.

- Raw material costs: Aluminum pricing fluctuates based on global supply, demand, and energy costs. Different alloys carry different premiums - 7075 costs approximately $5.00-$6.50 per kilogram compared to $2.50-$3.00 for 3003, according to TBK Metal's 2025 cost guide

- Material thickness: Thicker materials demand more processing time and energy. A 10mm sheet requires higher machine intensity and longer processing times than a 2mm sheet, directly increasing costs

- Design complexity: Intricate shapes, tight tolerances, and multiple forming operations require slower machining speeds, closer monitoring, and greater handling. Aerospace components demanding ±0.05mm tolerances can cost 40% more than simpler designs

- Labor and expertise: Skilled machinists, welders, and engineers command premium wages. Performance aluminum fabrication requiring CAD/CAM proficiency and specialized welding techniques increases labor costs significantly

- Machine time: CNC machines, laser cutters, and press brakes represent significant capital investments. Complex parts consuming extended machine time absorb more of these fixed costs

- Finishing requirements: Anodizing, powder coating, and specialized surface treatments add 15-25% to base fabrication costs. Marine-grade anodizing for durability in coastal conditions commands additional premiums

- Order volume: Larger quantities reduce per-unit costs through economies of scale. Setup costs, programming, and machine preparation spread across more units

- Lead time pressures: Rush orders requiring expedited processing typically carry premium charges of 15-50% depending on urgency

Consider a real example from Austgen's case studies: a Brisbane fabricator working on high-performance vehicle components found that machine time accounted for 30% of total project cost due to tight tolerance requirements, while skilled labor wages added another 25%. Understanding this breakdown helps you see where cost reduction opportunities exist.

Strategies for Cost Optimization

Sounds expensive? Here's the good news - smart design decisions can significantly reduce metal for fabrication costs without compromising functionality. The key is making these choices early, before specifications are locked in.

Optimize designs to reduce waste: Careful layout planning and standard dimensions minimize offcuts and scrap material. Nesting parts efficiently on sheet stock reduces material consumption - a straightforward way to lower costs on any aluminum fabrication project.

Choose the right alloy for the job: Don't specify 6061-T6 when 3003 meets your requirements. Premium alloys cost more and may complicate fabrication. Match alloy properties to actual performance needs rather than over-engineering.

Select appropriate thickness early: Specifying heavier gauge than necessary wastes material and increases forming difficulty. Determine minimum acceptable thickness based on structural requirements, not habit or assumption.

Simplify tolerance specifications: Tight tolerances require slower machining, more inspection, and greater handling care. According to Protolabs' cost reduction guide, specifying tighter tolerances than actually needed drives up costs unnecessarily. Apply precision where it matters, not everywhere.

Use standard bend radii: Custom tooling for non-standard bends adds setup time and cost. Designing around common press brake tooling streamlines production and reduces per-part pricing.

Consider alternative finishes: Evaluate whether premium finishes justify their cost for your application. Powder coating may achieve similar durability at lower cost than hardcoat anodizing in many environments.

Order in bulk when possible: According to Austgen's analysis, a Sydney fabricator reduced cladding panel unit costs by 25% through a bulk order - saving on material, labor, and machine time simultaneously.

Use readily available fasteners: Protolabs recommends sticking with standard PEM hardware that's readily stocked. Specialty aluminum or 400 Series stainless steel fasteners often require 10,000-piece minimum orders and six to eight weeks of additional lead time.

One often-overlooked opportunity: request design feedback from your fabricator before finalizing specifications. Quality aluminum fabrication partners will identify cost-saving modifications - perhaps a slightly larger bend radius that eliminates special tooling, or a finish change that reduces preparation steps. This collaborative approach frequently uncovers savings that aren't obvious from the design side alone.

Balancing quality requirements with budget constraints isn't about cutting corners - it's about investing resources where they matter most. A component that's over-engineered in non-critical areas wastes money that could improve performance where it actually counts. Understanding cost drivers gives you the knowledge to make those tradeoffs intelligently.

Aluminium Versus Steel Fabrication Comparison

Now that you understand the cost factors driving aluminium projects, here's a question that surfaces in nearly every fabrication decision: should you use aluminium or steel? The answer isn't as straightforward as comparing price tags. Each material demands different fabrication approaches, and choosing incorrectly can result in failed parts, blown budgets, or components that simply don't perform in the intended application.

When comparing sheet metal steel to aluminium, the most obvious difference is weight. According to Weerg's material comparison guide, aluminium weighs approximately one-third as much as steel - a difference that becomes crucial in sectors like aerospace, automotive, and marine applications where every kilogram matters.

Weight and Strength Considerations

Is aluminum as strong as steel? In absolute terms, no - steel holds a clear strength advantage. However, this question misses the bigger picture. When you factor in weight, aluminium's strength-to-weight ratio often makes it the smarter engineering choice.

| Property | Aluminium | Steel | Fabrication Impact |

|---|---|---|---|

| Density | ~2.7 g/cm³ | ~7.85 g/cm³ | Aluminium weighs roughly one-third as much, reducing shipping and handling costs |

| Tensile Strength | 90-690 MPa (varies by alloy) | 400-2000 MPa (varies by grade) | Steel handles heavier loads in absolute terms |

| Strength-to-Weight Ratio | Excellent | Good | Aluminium delivers more strength per unit weight |

| Corrosion Resistance | Excellent (natural oxide layer) | Poor to Good (requires treatment except stainless) | Aluminium needs no protective coating for most environments |

| Machinability | Excellent - faster cutting, less tool wear | Good - harder on tooling | Aluminium typically machines faster with lower tooling costs |

| Material Cost | Higher per kilogram | Lower per kilogram (except stainless) | Steel is generally more budget-friendly for raw material |

Here's what many buyers overlook: aluminum malleable properties far exceed steel's. According to Eagle Aluminum's comparison, aluminium can be shaped and formed into customized configurations without fractures or fissures. This malleability, combined with excellent ductility, makes aluminium ideal for complex geometries that would crack steel during forming.

Malleable aluminium also performs better in cold-weather applications - its strength actually increases as temperatures drop. Steel, by contrast, can become brittle in extreme cold, creating potential failure points in arctic or refrigeration applications.

When to Choose Aluminium Over Steel

Forming steel sheet requires different approaches than working with alu sheet metal. Steel's higher hardness means slower cutting speeds, more aggressive tooling, and greater machine wear. Aluminium's softness allows faster processing but demands careful handling to prevent scratches and surface damage.

When welding, the differences become even more pronounced. Steel welding is relatively straightforward - clean the surface, set your parameters, and weld. Aluminium requires removing the oxide layer immediately before welding, using AC power for TIG processes, and managing heat input carefully due to the material's rapid thermal conductivity.

So when does aluminium make the most sense? Consider these application scenarios:

- Automotive applications: Weight reduction directly improves fuel efficiency and performance. Electric vehicles particularly benefit from aluminium's lightweight properties, extending battery range

- Aerospace components: Every pound saved means more payload capacity or reduced fuel consumption. The 7075 alloy delivers strength comparable to many steels at a fraction of the weight

- Marine environments: Aluminium's natural corrosion resistance eliminates the need for protective coatings that wear away in saltwater. The 5052 alloy specifically resists saltwater corrosion without supplementary treatment

- Architectural applications: Building facades, window frames, and structural elements benefit from aluminium's corrosion resistance and aesthetic versatility

- Electronic enclosures: Aluminium's excellent thermal conductivity helps dissipate heat from electronic components while its lightweight nature simplifies installation

According to Endura Steel's analysis, aluminium remains impervious to rust and avoids the need for coatings or paints susceptible to wearing or chipping. Its inherent safeguard lies in a naturally occurring oxide film enveloping the surface - the same layer that complicates welding but provides lifelong protection.

Steel remains the better choice when:

- Maximum absolute strength matters more than weight savings

- Budget constraints are severe and volume is high

- Operating temperatures exceed aluminium's practical limits (above 400°F for most alloys)

- The application involves heavy impact or abrasion resistance

The fabrication complexity comparison often tips toward aluminium for smaller production runs. While material costs per kilogram are higher, aluminium's faster machining speeds, reduced tooling wear, and elimination of rust-prevention coatings can offset the raw material premium - especially for complex parts requiring extensive machine time.

Making the right material choice requires evaluating your specific application requirements against these tradeoffs. When weight reduction, corrosion resistance, or complex forming are priorities, aluminium typically delivers better overall value. When raw strength, high-temperature performance, or minimum material cost drive the decision, steel often wins.

With material selection clarified, the final consideration is finding a fabrication partner who understands these nuances and can deliver consistent quality for your aluminium components.

Selecting the Right Fabrication Partner

You've done the homework - specified the right alloy, optimized your design for cost efficiency, and determined that aluminium best meets your application requirements. Now comes a decision that can make or break your entire project: choosing who actually fabricates your parts. The wrong partner delivers headaches, delays, and components that don't meet specifications. The right one becomes a long-term asset that improves your products over time.

Here's what many buyers learn the hard way: sending RFQs to multiple shops and selecting the lowest bidder rarely produces the best outcome. According to Dr. Shahrukh Irani's fabricator selection guide, too often businesses treat job shops as interchangeable - and countless projects get derailed by partnerships with shops that weren't thoroughly evaluated. What sounded good in the quote often turns out to be overpromising, leading to delays and reworks due to poor quality.

Whether you're sourcing aluminum sheet fabrication for prototypes or scaling to production volumes, evaluating potential partners against consistent criteria helps you identify fabricators who can actually deliver what they promise.

Evaluating Fabricator Capabilities

Not all aluminium fabrication services are created equal. A shop that excels at steel work may struggle with aluminium's unique characteristics - the oxide layer management, springback compensation, and thermal conductivity challenges we've discussed throughout this guide. Look for partners who demonstrate genuine expertise with aluminium specifically.

Here are the key criteria for evaluating any aluminum fabricator:

- Experience and industry expertise: Look for a proven track record specifically in aluminium projects. According to TMCO's fabricator selection guide, experience translates to deep understanding of aluminum grades, properties, and how they behave during cutting, forming, and welding. Teams experienced across diverse industries can anticipate challenges and recommend smarter solutions

- Technical capabilities and equipment: Advanced aluminum fabrication tools are essential for accuracy and repeatability. Leading fabricators invest in CNC press brakes for consistent bending, high-precision laser cutting systems, TIG and MIG welding stations configured for aluminium, and in-house machining centers

- Engineering and design support: The right fabricator doesn't just follow drawings - they help improve them. Look for partners offering CAD/CAM modeling and Design for Manufacturability (DFM) reviews before fabrication begins. This collaboration ensures manufacturability and cost efficiency

- Material knowledge: A capable aluminium fabricator understands which alloy grade best suits your application - whether you need weldability, formability, or high strength. They should advise on appropriate temper designations and their effects on fabrication

- Quality certifications: Certifications demonstrate commitment to consistent quality. ISO certification indicates documented inspection and testing processes. For automotive applications, IATF 16949 certification represents the gold standard - this automotive-specific certification includes requirements for product traceability, change control, and validation of production processes that exceed general ISO 9001 standards

- Scalability and turnaround: Choose a fabricator who can scale production as your needs grow. The ability to handle both prototype and high-volume runs under one roof saves time and avoids production bottlenecks

- In-house finishing capabilities: Vertically integrated operations that combine fabrication, machining, and finishing under one roof reduce handoffs, shorten lead times, and ensure consistent quality protocols throughout the process

Quality control deserves particular attention. According to TMCO's guidance, reliable aluminium fabrication services employ multi-stage inspection systems - checking dimensions, weld integrity, and surface finish at each stage. Advanced inspection tools such as coordinate measuring machines (CMMs) verify accuracy within microns, catching problems before they become expensive.

For automotive components specifically, IATF 16949 certification indicates a fabricator meets the highest standards of quality management in the automotive industry. According to DeKalb Metal Finishing's certification analysis, this standard places strong emphasis on defect prevention, continuous improvement, and supply chain management - requirements that help ensure the entire production process delivers consistent results.

Preparing Your Project for Quotation

Once you've identified potential aluminium sheet fabrication partners, preparing a complete quotation package accelerates the evaluation process and produces more accurate pricing. Incomplete information leads to placeholder quotes that change once fabricators see actual requirements.

Gather these elements before requesting quotes:

- Complete CAD files: Provide 3D models and 2D drawings with all dimensions, tolerances, and bend specifications clearly marked

- Material specifications: Include alloy designation, temper, and thickness requirements. Specify acceptable alternatives if flexibility exists

- Quantity requirements: Indicate both initial order quantities and anticipated annual volumes. This helps fabricators offer appropriate pricing tiers

- Surface finish requirements: Specify anodizing type, powder coating colors, or other finish requirements with applicable standards

- Tolerance specifications: Clearly communicate which dimensions are critical versus standard tolerance

- Timeline expectations: Include both prototype delivery needs and production schedule requirements

- Quality documentation needs: Specify required certifications, inspection reports, or traceability documentation

Don't overlook the value of rapid prototyping capabilities when evaluating partners. Fabricators offering quick-turn prototypes - some deliver within 5 days - allow you to validate designs before committing to production tooling. Combined with comprehensive DFM support, this approach catches design issues early when changes cost the least.

Communication style matters as much as technical capability. The best aluminium fabrication services provide progress updates, timeline reviews, and engineering feedback throughout the project lifecycle. This partnership approach ensures alignment from design through delivery - and often uncovers cost-saving opportunities that weren't obvious from drawings alone.

For readers seeking automotive-grade aluminium sheet metal fabrication with rapid turnaround, Shaoyi (Ningbo) Metal Technology offers IATF 16949-certified quality combined with 5-day rapid prototyping and 12-hour quote turnaround - capabilities that accelerate automotive supply chains from prototype through automated mass production.

Selecting the right fabrication partner isn't just about finding someone who can make your parts - it's about building a relationship that improves your products over time. The investment in thorough evaluation pays dividends in consistent quality, on-time delivery, and the confidence that comes from working with genuine aluminium fabrication experts.

Frequently Asked Questions About Aluminium Sheet Metal Fabrication

1. Is aluminium fabrication expensive?

While aluminium's raw material cost per kilogram exceeds steel, the total project cost often balances out. Aluminium machines faster with less tool wear, requires no rust-prevention coatings, and its lighter weight reduces shipping costs. For IATF 16949-certified automotive applications, partners like Shaoyi Metal Technology offer DFM support and 12-hour quote turnaround to help optimize manufacturing costs without sacrificing quality.

2. What is a 5052 aluminum sheet used for?

5052 aluminum is the go-to alloy for marine environments, pressure vessels, and medical devices due to its exceptional saltwater corrosion resistance. The 5052-H32 temper specifically balances formability with strength, making it ideal for components requiring complex forming while maintaining structural integrity in harsh conditions. It contains no copper, which explains its superior corrosion performance.

3. What alloy is best for aluminium sheet metal fabrication?

The best alloy depends on your application. 5052 excels in marine and chemical environments with excellent formability and weldability. 6061-T6 delivers superior strength for structural components. 3003 offers the best cost-to-performance ratio for general fabrication. 7075 provides highest strength-to-weight for aerospace but resists welding. Consult with experienced fabricators offering comprehensive DFM support to match alloy properties to your specific requirements.

4. Why is aluminium harder to weld than steel?

Aluminium's naturally-forming oxide layer melts at approximately 3700°F - nearly three times higher than the 1221°F melting point of the base metal. Without proper oxide removal immediately before welding, oxides become trapped in the weld pool, creating porosity and weak joints. Additionally, aluminium's high thermal conductivity pulls heat away rapidly, requiring higher heat input and faster weld completion than comparable steel work.

5. How do I choose the right aluminium fabrication partner?

Evaluate partners based on aluminium-specific experience, advanced equipment like CNC press brakes and laser cutters configured for aluminium, and quality certifications. For automotive components, IATF 16949 certification indicates highest quality standards. Look for fabricators offering rapid prototyping capabilities, comprehensive DFM reviews, and scalability from prototype to production volumes under one roof.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —