Blanking vs Piercing in Automotive Stamping: Process Mechanics & Die Design

TL;DR

In the high-precision world of automotive manufacturing, the fundamental difference between these two shearing processes lies in the objective: blanking produces the final component (the cut-out piece is the product), whereas piercing creates internal features like holes (the cut-out slug is scrap). While they utilize similar hydraulic or mechanical press mechanics, their tooling designs differ significantly to manage material flow. In automotive progressive dies, these operations typically function in tandem—piercing internal geometries first, followed by blanking the final chassis or body part from the metal strip.

The Core Difference: Product vs. Scrap

For automotive engineers and procurement specialists, distinguishing between blanking and piercing is not merely a semantic exercise; it dictates tool design, material usage, and cost estimation. Both are shearing processes that stress sheet metal beyond its ultimate tensile strength until fracture occurs, but the desired outcome defines the terminology.

Blanking is the operation where the material removed from the primary sheet or strip is the useful part. The remaining metal strip is referred to as the skeleton or scrap. For example, when producing a door latch bracket, the bracket itself is "blanked" out of the coil.

Piercing (often used interchangeably with punching in general contexts, though distinct in precision stamping) reverses this logic. In piercing, the material removed—the slug—is scrap, and the hole left in the sheet is the desired feature. This is critical for creating mounting points, lightening holes, or pilot holes for subsequent operations.

The "Master" Tooling Rule

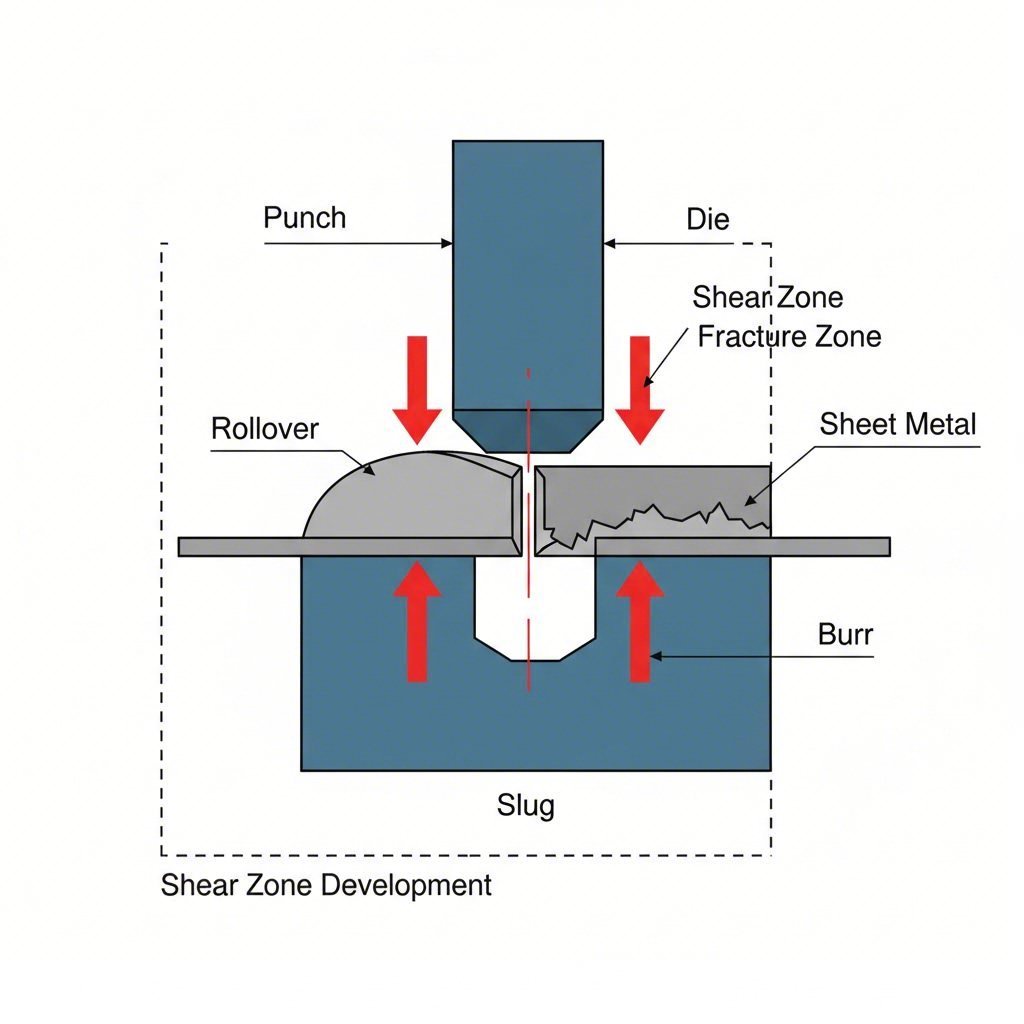

The most technical distinction arises in the die design phase. To ensure the final component meets tolerance specifications, engineers apply clearance rules differently:

- In Blanking: The die cavity size determines the final part size. The clearance is applied to the punch, making it smaller than the nominal dimension.

- In Piercing: The punch size determines the final hole size. The clearance is applied to the die, making the opening larger than the nominal dimension.

Automotive Specifics: Fine Blanking vs. Standard Blanking

Standard blanking often leaves a rough edge with a "fracture zone" covering nearly two-thirds of the material thickness. For general structural parts, this is acceptable. However, automotive applications frequently demand higher precision for functional components like transmission gears, seatbelt mechanisms, and brake calipers. This is where Fine Blanking becomes essential.

Fine blanking is a specialized variation that utilizes a V-ring (impingement ring) to hold the sheet metal firmly against the die before the punch engages. This counter-pressure prevents the material from flowing away from the cutting edge, resulting in a 100% sheared edge that is smooth and perpendicular to the sheet surface. Unlike standard blanking, which may require secondary machining to clean up rough edges, fine blanking produces net-shape parts ready for assembly.

For sourcing managers, understanding this distinction is vital. Specifying "fine blanking" for a part that only requires standard blanking needlessly inflates costs, while failing to specify it for a high-wear gear tooth can lead to premature component failure.

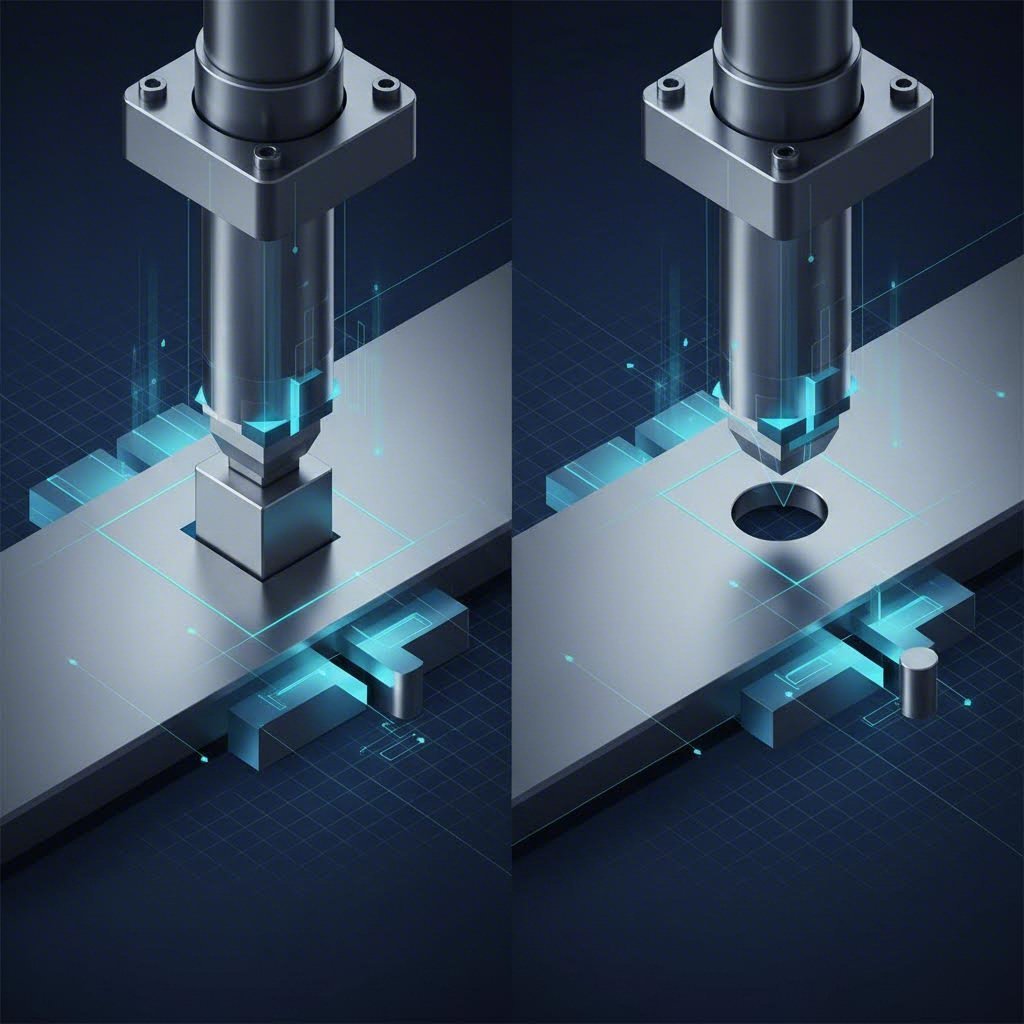

Process Engineering: Progressive Dies & Sequencing

In high-volume automotive stamping, blanking and piercing rarely happen in isolation. They are integrated into progressive dies—complex tools where a metal strip moves through multiple stations with each press stroke. The sequencing of these operations is critical for part integrity and dimensional accuracy.

Typically, the process follows a strict order:

- Pilot Piercing: The first operation often pierces pilot holes. These are not for the final function of the car part but are used to locate and guide the strip precisely through subsequent stations.

- Internal Piercing: Functional holes and cutouts are created while the part is still attached to the main strip. This ensures that the relative position of internal features is held to tight tolerances.

- Final Blanking: The last station cuts the external profile, separating the finished component from the scrap skeleton.

Efficient sequencing minimizes "tolerance stack-up." If a part were blanked first and then pierced in a secondary operation, locating the part precisely would be difficult and slow. By piercing first in the strip, the material acts as its own fixture. For manufacturers bridging the gap from rapid prototyping to high-volume production, partners like Shaoyi Metal Technology offer critical support in optimizing these progressive die layouts to meet strict OEM standards.

Comparison of Die Design & Clearances

The clearance—the gap between the punch and the die—is the single most critical variable in determining edge quality and tool life. Insufficient clearance causes secondary shearing (double break), creating debris that can damage the die. Excessive clearance creates large burrs and deformation.

The table below summarizes the technical configurations for automotive tooling:

| Feature | Blanking Operation | Piercing Operation |

|---|---|---|

| Primary Objective | Produce a solid part (Plug) | Produce a hole (Opening) |

| Scrap Material | Remaining sheet (Skeleton) | Removed slug |

| Controlling Dimension | Die Size = Part Size | Punch Size = Hole Size |

| Clearance Applied To | Punch (Undersized) | Die (Oversized) |

| Critical Defect Risk | Dishing (Part curvature) | Slug Pulling (Scrap rising up) |

Correctly calculating these clearances based on material tensile strength and thickness is what separates industrial-grade stamping from lower-tier fabrication.

Common Defects & Troubleshooting

Even with precise tooling, defects occur. In automotive stamping, where "Class A" surfaces and safety-critical geometries are standard, identifying the root cause is mandatory.

Burrs and Rollover

Die roll (a rounded edge on the entry side) and burrs (sharp ridges on the exit side) are natural byproducts of shearing. However, excessive burr height indicates dull tooling or incorrect clearance. In blanking, a large burr on the part suggests the punch clearance is too large. In piercing, a burr around the hole suggests the die clearance is excessive.

Slug Pulling

A specific issue in piercing operations is slug pulling, where the scrap slug sticks to the punch face and is pulled out of the die cavity on the return stroke. If this slug falls onto the strip, it can damage the part or the die in the next stroke—a catastrophic event in high-speed automated lines. Engineers mitigate this by adding spring-loaded ejector pins to the punch or using special vacuum die blocks.

Conclusion

While blanking and piercing share the physics of shearing metal, their roles in automotive stamping are distinct and complementary. Blanking defines the perimeter and yields the final component, while piercing creates the functional internal geometry. Mastering the interplay between these processes—specifically regarding tool clearances, sequencing in progressive dies, and the application of fine blanking for precision parts—is essential for achieving the efficiency and quality required by modern vehicle manufacturing.

Frequently Asked Questions

1. What is the difference between piercing and blanking?

The primary difference is the desired product. In blanking, the piece cut out from the sheet is the final product, and the remaining sheet is scrap. In piercing, the hole created in the sheet is the desired feature, and the piece cut out (the slug) is scrap.

2. Why is fine blanking used in automotive parts?

Fine blanking is used for high-precision automotive components like gears, brake parts, and seatbelt mechanisms because it produces a fully sheared, smooth edge without the fracture zone typical of standard blanking. This eliminates the need for secondary machining operations to smooth the edges.

3. How do blanking and piercing work in a progressive die?

In a progressive die, piercing usually occurs at earlier stations to create pilot holes and internal features while the metal strip is stable. Blanking typically happens at the final station to cut the completed part out of the strip, ensuring all internal features are precisely located relative to the outer edge.

4. How is die clearance calculated differently for blanking and piercing?

For blanking, the die opening is sized to the required part dimension, and clearance is deducted from the punch size. For piercing, the punch is sized to the required hole dimension, and clearance is added to the die opening size.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —