Sheet Metal Shearing Service Secrets: What Suppliers Won't Tell You

What Is Sheet Metal Shearing and How Does It Work

Ever watched a pair of scissors slice through paper? Now imagine that same principle scaled up to industrial proportions, cutting through metal with surgical precision. That's essentially what sheet metal shearing delivers, and understanding this process could save you thousands on your next fabrication project.

A sheet metal shearing service uses a cold mechanical cutting process where material is positioned between two sharp blades. The lower blade remains stationary while the upper blade descends with controlled force, creating intense localized stress that exceeds the metal's shear strength. According to Fractory, this shearing force subjects the sheet metal to stress until the material's ultimate shear strength is overcome, resulting in a clean separation along the cutting line.

The Mechanics Behind Clean Metal Separation

The shearing process unfolds in three distinct phases. First, the blade makes contact and begins applying pressure. Next, the material undergoes plastic deformation as stress builds along the cutting line. Finally, controlled fracture occurs when the accumulated force exceeds the metal's resistance.

What makes this process remarkable is its precision. A 5-10% clearance of the metal thickness allows the sheet to plastically deform between the upper and lower blades, creating that characteristic clean edge. The blades, typically made from tool steel or carbide, work in tandem to slice through materials up to 6mm thick without generating chips, burning, or heat-affected zones.

You'll notice that shearing in sheet metal differs fundamentally from thermal cutting methods. There's no melting, no sparks, and no material lost to kerf width. The metal simply separates along a predetermined straight line, much like how scissors work but with industrial-grade power behind every cut.

Why Manufacturers Still Rely on Shearing Technology

With laser cutting and waterjet technology readily available, you might wonder why metal shearing services remain so popular. The answer comes down to practical economics and efficiency.

Shearing delivers unmatched speed for straight-line cuts, with modern equipment achieving production rates exceeding 60 cuts per minute on thin materials. The process generates virtually zero material waste since there's no kerf, maximizing material yield and reducing raw material costs. Additionally, the cold cutting nature preserves the metal's mechanical properties and surface finish, eliminating concerns about heat distortion.

Throughout this guide, you'll discover the different shearing techniques available, which materials perform best, how this process compares to alternatives, and what separates exceptional service providers from the rest. Whether you're sourcing your first metal shearing services or looking to optimize existing supplier relationships, the insights ahead will transform how you approach these critical fabrication decisions.

Types of Shearing Techniques Every Buyer Should Understand

Sounds complex? Here's the reality most suppliers won't share: not all sheet shearing methods are created equal, and choosing the wrong technique for your application can mean wasted time, poor edge quality, and inflated costs. Understanding the distinct capabilities of each shearing method puts you in the driver's seat when negotiating with providers.

The shearing sheet metal landscape includes several specialized techniques, each engineered to solve specific manufacturing challenges. Whether you're processing high-volume production runs or handling specialty applications, matching the right method to your needs is where smart buyers gain their advantage.

Guillotine Shearing for Production Efficiency

When speed and volume matter most, guillotine shearing dominates the production floor. According to ACRA Machinery, these machines work by first clamping the material with a ram, then moving a metal blade down across a fixed blade to make the cut. The moving blade can be straight or set at an angle to decrease the force required for larger pieces.

What makes guillotine shears the workhorse of sheet metal shearing capabilities? Consider these characteristics:

- High-speed processing: Modern hydraulic guillotines achieve 7-8 strokes per minute, making them ideal for continuous production environments

- Adjustable rake angles: A 5-degree shear angle decreases cutting force by approximately 20%, enabling efficient processing of thicker materials

- Wide capacity range: Industrial models handle material thicknesses from thin gauge up to 40mm and sheet lengths exceeding 20 feet

- CNC integration: Advanced systems feature automated blade gap adjustments and programmable back gauges for repeatable precision

The trade-off? Guillotine shears can produce slightly rougher edges compared to precision methods, making them best suited for parts destined for welding or further processing where edge aesthetics aren't critical.

Specialized Shearing Methods for Different Applications

Beyond guillotine shearing, several specialized techniques address unique manufacturing requirements. Understanding when each method shines helps you request exactly what your project demands.

Alligator Shearing

Imagine a mechanical jaw powered by hydraulic force, and you've pictured an alligator shear. These robust machines feature hinged jaws ranging from 4 to 36 inches long, according to Rajesh CNC. They excel at cutting ferrous materials like rebar, pipe, I-beams, and angle iron.

- Primary use case: Scrap metal processing and preparation for shredding

- Material thickness range: Handles heavy structural sections that other shears cannot accommodate

- Key strength: Cost-effectiveness, exceptional strength, and durability for rough processing

- Limitation: Produces rough edges unsuitable for precision applications

Bench Shearing

For smaller operations requiring precision without industrial-scale equipment, bench shears offer a compelling solution. These bench-mounted units use a compound mechanism to increase mechanical advantage, delivering clean cuts free of burrs on medium-sized sheet metal pieces.

- Primary use case: Rough shaping and cutting 90-degree angles, T-sections, round bars, and square bars

- Material thickness range: Light to medium gauge materials, typically under 3mm

- Key strength: Efficiency and burr-free edge quality for prototype work and small batches

- Limitation: Cannot handle high-volume production or heavy plate materials

Power Shearing

When your project requires cutting straight lines or large radius curves with flexibility, power shears step up to the challenge. These electrically or pneumatically powered hand-operated tools work with an upper blade moving toward a fixed lower blade, applying tension to the cutting material.

- Primary use case: Blanking large pieces of sheet metal and cutting curved profiles

- Material thickness range: Thin to medium gauge sheets, excellent for materials up to 2.5mm

- Key strength: Flexibility in cutting curves, portability, accuracy, and quality finish

- Limitation: Slower than stationary equipment for straight production cuts

Throatless Shearing

Need intricate curved or irregular cuts? Throatless shears differ from other models because their open design allows cutting material to be freely moved around during the operation. This unique characteristic makes them perfect for artistic metalwork and custom fabrication requiring complex shapes.

Choosing the right technique isn't just about what's available; it's about matching equipment capabilities to your specific material, thickness, volume, and edge quality requirements. With this knowledge, you're now prepared to evaluate how different metals behave under these shearing processes and what that means for your project outcomes.

Material Considerations for Optimal Shearing Results

When you request a quote from a sheet metal shearing service, do they ask detailed questions about your material? If not, that's a red flag. Here's what experienced buyers know: the metal you're cutting fundamentally changes everything about the shearing process, from blade selection to achievable tolerances and even pricing.

Different metals respond to shearing force in dramatically different ways. According to SHEN-CHONG, material properties like shear strength, ductility, and hardness directly determine cutting behavior and the force required. Understanding these differences helps you communicate effectively with providers and avoid costly surprises.

How Steel and Aluminum Respond Differently to Shearing

Imagine cutting through butter versus cutting through cheese. That's essentially the difference between aluminium shearing and steel shearing, though both require precision to achieve quality results.

Steel Shearing Characteristics

Low carbon steel, with a shear strength around 250-300 MPa, represents the industry standard that most shearing equipment is designed to handle. The material provides predictable cutting behavior and clean edge separation. High-strength steel and alloy steel present greater challenges, with shear strengths reaching 400-600 MPa. These materials demand more powerful equipment, sharper blades, and often slower cutting speeds to prevent blade damage.

Aluminum Shearing Characteristics

Aluminum alloys typically exhibit shear strengths of 150-250 MPa, making them easier to cut than steel. However, their higher ductility creates unique challenges. The material tends to flow rather than fracture cleanly, which can produce burrs if blade clearances aren't properly adjusted. Aluminum also work-hardens during cutting, so blade condition becomes especially critical for maintaining edge quality across production runs.

Stainless Steel Shearing Considerations

Stainless steel shearing requires special attention due to the material's combination of high shear strength (300-450 MPa) and work-hardening tendencies. The chromium content that gives stainless its corrosion resistance also makes it tougher on blades. Experienced providers use specific blade clearances and may reduce cutting speeds to achieve clean edges without excessive tool wear.

Copper and Brass Behavior

With shear strengths around 150 MPa, copper and its alloys cut easily but present their own quirks. These soft, highly ductile materials can smear or deform if blade clearances are too tight. The crystalline structure of copper also means grain direction affects edge quality more noticeably than with other metals.

Thickness Ranges and Material Constraints

Every material has an optimal thickness window for shearing operations. Push beyond these limits, and you'll encounter diminished edge quality, increased defects, or equipment strain. As noted in DIMAKIN's equipment guide, not all metals behave the same under pressure, and machine capacity ratings typically reference mild steel as the baseline.

| Material Type | Typical Thickness Range | Shearing Considerations | Common Applications |

|---|---|---|---|

| Low Carbon Steel | 0.5mm - 25mm | Industry baseline; predictable cutting behavior; standard blade clearances apply | Automotive panels, enclosures, structural components |

| High-Strength Steel | 0.5mm - 12mm | Requires 40-50% more cutting force; increased blade wear; slower speeds recommended | Structural applications, heavy equipment, safety components |

| Aluminum Alloys | 0.5mm - 12mm | Tighter blade clearances typically needed (5-8% of thickness); watch for burr formation | Aerospace panels, electronics enclosures, decorative trim |

| Stainless Steel | 0.5mm - 10mm | Work-hardens rapidly; requires sharp blades and reduced clearances; may need lubrication | Food equipment, medical devices, architectural elements |

| Copper/Brass | 0.3mm - 6mm | Very ductile; prone to smearing; grain direction affects edge quality | Electrical components, decorative applications, heat exchangers |

Material pretreatment also plays a significant role in shearing outcomes. Annealed metals cut more easily with reduced shear force requirements, while hardened materials demand greater force and experience accelerated blade wear. When specifying your project, always communicate the material's condition, not just its grade.

The grain structure of your metal affects more than you might expect. Finer grain structures typically exhibit higher shear strength, requiring greater cutting force. Additionally, cutting perpendicular to the grain direction often produces cleaner edges than cutting parallel to it. For critical applications, discussing grain orientation with your provider can prevent edge quality issues before they occur.

Understanding these material-specific behaviors positions you to have informed conversations with service providers. But how does shearing compare when you're weighing it against laser cutting, plasma, or waterjet alternatives? The answer depends on factors that go beyond just the material itself.

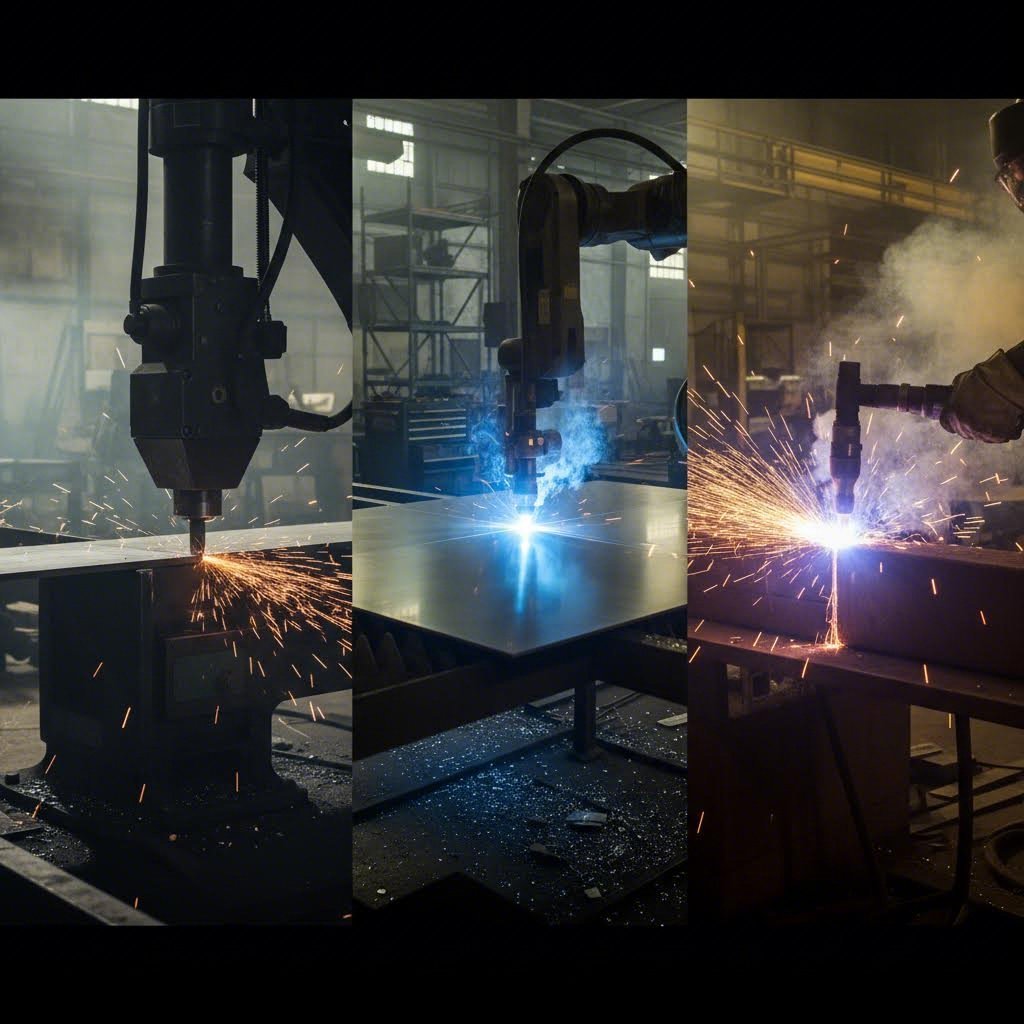

Shearing Versus Alternative Cutting Methods

Here's a question that separates informed buyers from everyone else: when should you insist on shearing, and when does laser or plasma cutting actually make more sense? The answer isn't as straightforward as most suppliers suggest, and understanding these trade-offs could dramatically impact both your project costs and final part quality.

Each cutting technology brings distinct advantages to the table. According to Saky Steel's industry analysis, while many cutting methods exist, metal shearing remains one of the most widely used techniques due to its efficiency and cost-effectiveness. But that doesn't mean it's always the right choice for every application.

When Shearing Outperforms Laser and Plasma Cutting

Imagine you need 5,000 rectangular blanks cut from mild steel sheets. You could choose laser cutting for its precision, but you'd pay premium prices and wait longer for delivery. Shearing stainless steel or carbon steel in high volumes? That's where traditional shearing technology truly shines.

Shearing dominates in specific scenarios:

- Straight-line cuts only: When your parts require simple linear cuts without curves or internal features, shearing delivers faster results at lower costs

- High-volume production: Large sheets can be cut into smaller blanks quickly with minimal setup, making shearing ideal for production runs exceeding hundreds of pieces

- Heat-sensitive applications: Unlike thermal methods, shearing creates no heat-affected zones that could alter material properties or cause warping

- Maximum material utilization: Zero kerf width means no material lost to the cutting process itself, improving yield rates

As noted in Ursviken's technical comparison, for high-volume straight-line cutting of medium to thick materials, hydraulic shears offer the most cost-effective solution. Their combination of productivity, reliability, and low operating costs makes them ideal for steel service centers and manufacturing operations focused on standardized components.

Cost and Speed Advantages of Traditional Shearing

Let's talk numbers that actually matter to your bottom line. The economic advantages of shearing extend beyond the per-cut price tag.

Initial Investment: Shearing machines require moderate capital investment while offering low ongoing operational expenses. They consume less energy than thermal cutting methods and have fewer consumable parts, resulting in lower maintenance costs overall.

Operational Expenses: No expensive consumables like assist gases, abrasives, or electrodes are required. The primary maintenance involves blade sharpening and alignment, keeping recurring costs predictable and manageable.

Production Speed: For straight cuts, shearing is one of the fastest methods available. A hydraulic shearing machine can process thousands of straight cuts per shift with minimal downtime, particularly when integrated into automated feeding systems.

| Cutting Method | Speed Rating | Cost Per Cut | Edge Quality | Thickness Range | Best Applications |

|---|---|---|---|---|---|

| Shearing | Very High | Low | Good (square, clean edges) | Up to 25mm mild steel | High-volume blanks, straight cuts, cost-sensitive production |

| Laser Cutting | Medium | High | Excellent (precise, smooth) | Up to 20mm mild steel | Complex shapes, tight tolerances, intricate designs |

| Plasma Cutting | Medium-High | Moderate | Good (may need finishing) | 3mm to 50mm | Medium to thick plate, moderate complexity |

| Waterjet Cutting | Low | Very High | Excellent (no thermal impact) | Virtually unlimited | Heat-sensitive materials, precision work, exotic metals |

Precision Considerations: According to industry specifications, hydraulic shearing machines typically provide precision tolerances of ±0.1 mm to ±0.2 mm, which is suitable for many industrial applications. Laser cutting achieves tolerances as fine as ±0.05 mm, while plasma cutting ranges from ±0.1 mm to ±0.5 mm depending on system quality and material thickness.

When to Choose Alternative Methods:

Shearing isn't always the answer. Consider laser cutting when your project involves complex geometries, tight tolerances, or frequent design changes. Plasma cutting offers a balanced solution for operations needing both straight cuts and moderately complex shapes in thicker materials. Waterjet excels for heat-sensitive materials or when cutting exotic alloys that would damage conventional tooling.

The optimal choice depends on your specific production requirements, material types, and budget constraints. Each technology has evolved to address particular metalworking needs, making them complementary rather than competing solutions in many manufacturing environments.

One often-overlooked advantage of shearing involves sustainability. The process produces little waste compared to thermal methods, requires no harmful gases or high-energy beams, and consumes relatively low energy. For manufacturers prioritizing greener production practices, these factors add meaningful value beyond pure economics.

Understanding when shearing makes sense versus when alternatives perform better positions you to make informed decisions. But even when shearing is the right choice, quality outcomes depend heavily on preventing common defects and maintaining tight tolerances throughout production.

Quality Standards and Defect Prevention in Shearing

Ever received a batch of sheared parts only to discover rough edges, twisted profiles, or dimensions that don't match your specifications? You're not alone. What most suppliers won't tell you is that these quality issues are entirely preventable when proper metal shearing quality control protocols are followed. The difference between acceptable parts and rejected scrap often comes down to factors that experienced providers monitor constantly but rarely discuss with customers.

Understanding common shearing defects empowers you to ask the right questions, evaluate provider capabilities more effectively, and specify requirements that ensure precision metal shearing results. Let's pull back the curtain on what causes these problems and how professional services prevent them.

Common Defects and Their Root Causes

According to New Mexico Metals, shearing defects can be avoided or at the very least minimized if the right preventative measures are taken. Here's what you should watch for and what causes each issue:

- Burr Formation: Those rough, raised edges along the cut line signal a drop in shear edge quality. Burrs typically form when blades become dull, when clearance between upper and lower blades is improperly set, or when the wrong blade material is used for the application. Prevention requires maintaining sharp blades and adjusting clearance to match material type and thickness.

- Edge Deformation: When sheet metal wobbles or shifts during cutting, the result is a distorted, uneven edge. This happens when hold-down clamps fail to secure the material firmly throughout the shearing cycle. Proper clamp pressure and blade condition are essential for clean edge separation.

- Bowing: This defect curves the cut edge, making it look like an archer's bow. Bowing occurs frequently when shearing long, narrow strips and results from stresses inherent in the metal itself rather than equipment malfunction. Taking a trim cut to release grain stress from the edge or shearing across the grain instead of along it minimizes this issue.

- Twisting: When fabricated metal curls into a spiral after shearing, excessive rake angle is typically the culprit. Like bowing, twisting can be reduced through trim cuts and cross-grain shearing when possible.

- Camber: Material that doesn't remain straight when sheared, even when lying flat, exhibits camber. This results from varying thickness across the sheet width (called crown) or excessive internal grain stress. Trim cutting and cross-grain shearing help minimize camber when material properties allow.

As noted in MaxTor Metal's troubleshooting guide, burr formation is one of the most common defects in metal shearing, and these burrs can lower the quality of your finished product while making further processing difficult. Catching these issues early through proper shearing defect prevention protocols saves significant rework costs downstream.

Tolerance Standards in Professional Shearing

What separates adequate shearing from precision metal shearing? It comes down to the tolerances a provider can consistently achieve and the factors they control to maintain those standards.

Blade clearance, expressed as a percentage of material thickness, is the single most critical factor determining edge quality. According to industry standards, this clearance typically ranges from 2% to 10% of sheet thickness depending on the material's mechanical properties. Proper clearance ensures efficient cutting while promoting plastic deformation without damaging the material.

Professional shearing services targeting precision applications typically achieve dimensional tolerances of ±0.1 mm to ±0.2 mm. Several interconnected factors affect whether these standards are consistently met:

- Blade Condition: Sharp blades produce clean cuts with minimal burr formation. Studies indicate that blades cleaned daily last 25-35% longer than those cleaned less often, maintaining edge quality throughout their service life.

- Clearance Settings: Too little clearance causes excessive blade wear and requires more cutting force. Too much clearance produces larger burrs and rougher edges. Experienced operators adjust clearance for each material type and thickness.

- Hold-Down Pressure: Adequate clamping force prevents material movement during the cut. Insufficient pressure leads to edge deformation, while excessive pressure can mark or distort thin materials.

- Rake Angle: The angle of the upper blade relative to the lower blade affects both required cutting force and edge quality. A 5-degree shear angle decreases cutting force by approximately 20% but must be balanced against potential twist in narrow strips.

- Machine Calibration: Regular alignment checks and calibration ensure the blade gap remains consistent across the full cutting length. Misalignment causes uneven cuts and dimensional errors.

When evaluating providers, ask specific questions about their quality control procedures. How often do they inspect and sharpen blades? What clearance settings do they use for your material type? How do they verify dimensional accuracy during production runs? Providers committed to quality will have clear answers and documented procedures for each of these factors.

Quality outcomes depend not just on equipment capabilities but on the expertise of operators who understand how material properties, machine settings, and environmental factors interact. This brings us to an equally important consideration: understanding what drives shearing service pricing and how to optimize your orders for cost efficiency.

Understanding Pricing Factors and Cost Optimization

Here's what most shearing service providers won't volunteer: their pricing isn't arbitrary, and understanding the underlying cost drivers gives you significant leverage to reduce expenses without sacrificing quality. Metal shearing cost factors follow predictable patterns, and buyers who understand these patterns consistently negotiate better deals and avoid surprise charges.

According to Zintilon's cost analysis, shearing equipment generally requires lower initial capital than advanced cutting methods, and operating costs remain typically lower due to minimal energy consumption and simpler mechanical processes. But that doesn't mean all quotes are created equal. Let's break down exactly what drives shearing service pricing and how you can optimize your orders for maximum value.

Key Factors That Drive Shearing Service Pricing

When you receive a quote for affordable sheet metal shearing, several variables determine that final number. Understanding their relative impact helps you prioritize where to focus your cost-reduction efforts.

- Material Type and Grade: This factor carries the highest pricing impact. Mild steel represents the baseline cost, while stainless steel, aluminum alloys, and specialty metals command premium pricing. As noted in industry research, specialized alloys like stainless steel are pricier than mild steel due to increased blade wear and more demanding processing requirements.

- Material Thickness: Thicker materials require more cutting force, slower processing speeds, and accelerate blade wear. Equipment capacity limitations may also restrict which providers can handle your project, potentially limiting competitive options.

- Quantity and Batch Size: Higher volumes distribute fixed setup costs across more pieces, significantly reducing per-part pricing. Shearing proves most cost-effective for high-volume production of simple parts where setup time becomes negligible relative to cutting time.

- Tolerance Requirements: Tighter tolerances demand more careful setup, slower cutting speeds, and increased inspection time. Standard industrial tolerances of ±0.2 mm cost less than precision requirements of ±0.1 mm or tighter.

- Edge Finish Specifications: If your application requires minimal burr or specific edge quality, additional blade maintenance, slower speeds, or secondary deburring operations add cost. Parts destined for welding typically accept rougher edges than visible architectural components.

- Turnaround Time: Rush orders incur premium pricing due to schedule disruption and expedited material sourcing. According to Cutting Edge Steel, last-minute projects often come with premium pricing due to expedited labor and material sourcing.

How to Optimize Your Order for Cost Efficiency

Smart buyers don't just accept quotes passively. They structure their requests to minimize costs while still achieving project requirements. Here's what you need to provide when requesting services, and how preparation directly reduces your final price.

Provide Complete Specifications Upfront: Incomplete requests lead to conservative pricing as providers build in contingencies for unknown variables. Your specification package should include material type and grade, exact thickness, quantity required, dimensional tolerances, edge finish requirements, and delivery timeline. Clear documentation eliminates guesswork and enables accurate, competitive quoting.

Optimize Design for Shearing: Simplifying your design reduces costs significantly. Avoid overly complex cuts and unnecessary features that require extensive labor. Using standard material sizes and designing parts that nest efficiently on standard sheet dimensions minimizes waste and processing time.

Consolidate Orders for Volume Pricing: Rather than placing multiple small orders, consolidate requirements into larger batches when inventory permits. This spreads setup costs across more pieces and often qualifies for volume discounts. Planning ahead allows you to combine orders that would otherwise be processed separately.

Select Appropriate Tolerance Levels: Request only the precision your application genuinely requires. Over-specifying tolerances wastes money on capabilities you don't need. Parts that undergo further machining or welding rarely require the tightest shearing tolerances.

Allow Realistic Lead Times: Building adequate time into your schedule avoids rush premiums. Standard lead times typically cost 15-25% less than expedited processing for equivalent work.

The most cost-effective shearing projects share common characteristics: clear specifications, appropriate tolerance requirements, consolidated volumes, and realistic timelines. Investing time in preparation consistently delivers measurable savings.

Understanding these pricing dynamics positions you to evaluate quotes intelligently and identify opportunities for optimization. But cost efficiency means nothing if you select a provider whose capabilities don't match your requirements. Next, we'll explore how to evaluate and select a shearing service provider that delivers both value and quality.

How to Evaluate and Select a Shearing Service Provider

Finding a metal shearing service provider is easy. Finding the right one? That's where most buyers stumble. What separates exceptional providers from mediocre ones rarely shows up on their websites, and the questions you should be asking probably aren't the ones you're currently asking. Let's change that.

The difference between a certified shearing services provider and a generic metal shop extends far beyond equipment. It encompasses quality systems, technical expertise, industry-specific knowledge, and the support infrastructure that determines whether your project succeeds or becomes an expensive lesson. Understanding what to look for transforms you from a passive buyer into an informed partner who commands better outcomes.

Certification and Quality Indicators to Verify

When evaluating an industrial shearing company, certifications provide objective evidence of quality commitment. But not all certifications carry equal weight, and understanding what each one actually means helps you separate genuine capability from marketing noise.

According to Xometry's certification guide, IATF 16949 is a quality management system that doubles down on creating consistency, safety, and quality across automotive products. This certification differs from general quality systems because it specifically addresses automotive industry requirements for defect prevention, waste reduction, and continuous improvement.

Why does this matter for your shearing project? IATF 16949-certified manufacturers like Shaoyi demonstrate commitment to automotive-grade quality standards that exceed typical fabrication shop capabilities. Even if you're not in the automotive industry, these certifications indicate rigorous process controls that benefit any precision application.

- IATF 16949: Automotive-specific quality management system based on ISO 9001. Signifies the organization has met stringent requirements for limiting defects and reducing waste. Essential for automotive supply chain participation.

- ISO 9001: General quality management system certification. Establishes baseline quality controls but lacks industry-specific rigor. Good starting point but insufficient alone for demanding applications.

- AS9100: Aerospace quality management standard. Required for aerospace supply chain participation and indicates capability for high-precision, documented processes.

- Equipment Certifications: Verify that shearing equipment undergoes regular calibration and maintenance. Ask for calibration records and preventive maintenance schedules.

- Material Traceability: Quality providers maintain complete material certification documentation, enabling you to verify material properties and origin for each batch.

Beyond certifications, investigate the provider's quality control procedures. How do they verify dimensional accuracy during production? What inspection equipment do they use? How are non-conforming parts identified and segregated? Providers with robust quality systems will have clear, documented answers to these questions.

Matching Provider Capabilities to Your Industry Needs

Different industries impose different requirements on metal shearing service providers. What works perfectly for construction applications may fall short for aerospace components. Understanding these distinctions helps you match provider capabilities to your specific needs.

Automotive Industry Requirements:

The automotive sector demands IATF 16949 certification as a baseline expectation. Beyond certification, automotive projects require rapid prototyping capabilities to validate designs before production commitment, comprehensive DFM (Design for Manufacturability) support to optimize parts for efficient production, and consistent quality across high-volume runs. Providers offering 12-hour quote turnaround and rapid prototyping, such as Shaoyi's automotive stamping services, demonstrate the responsiveness automotive supply chains demand.

Aerospace Industry Requirements:

Aerospace applications prioritize material traceability, tight tolerances, and comprehensive documentation. Expect providers to maintain detailed records of material certifications, processing parameters, and inspection results for every part. AS9100 certification is typically mandatory for supply chain participation.

Construction Industry Requirements:

Construction projects often prioritize volume capacity, competitive pricing, and reliable delivery over ultra-tight tolerances. Structural steel applications may accept standard tolerances while emphasizing on-time delivery and the ability to handle large, heavy plates.

Use this evaluation checklist when assessing potential providers:

- Equipment Capabilities: Can they handle your material type, thickness range, and sheet dimensions? What is their maximum shearing capacity?

- Quality Certifications: Do they hold certifications relevant to your industry (IATF 16949 for automotive, AS9100 for aerospace)?

- Material Handling Capacity: Can they process your required volumes within acceptable timeframes? Do they have material storage and handling capabilities for your sheet sizes?

- Turnaround Times: What are standard and expedited lead times? Can they support rapid prototyping for design validation?

- DFM Support: Do they offer design feedback to optimize parts for shearing? Can they identify cost-saving opportunities in your designs?

- Communication Responsiveness: How quickly do they respond to quote requests? According to Accio's supplier screening guidance, response times of 4 hours or less indicate strong operational efficiency.

- References and Track Record: Can they provide references from similar projects? What is their on-time delivery rate?

- Secondary Operations: Do they offer deburring, forming, or other value-added services that could simplify your supply chain?

The best provider isn't necessarily the cheapest or the most certified. It's the one whose capabilities, quality systems, and service model align precisely with your project requirements and industry expectations.

According to New Mexico Metals, most industries, especially smaller ones, rely on local metal shearing service providers to do the shearing job. However, for demanding applications, geographic proximity matters less than capability alignment. A certified provider with comprehensive DFM support located across the country may deliver better outcomes than an uncertified local shop without technical expertise.

When you've identified promising providers, the next step involves navigating the quote-to-delivery process effectively. Understanding how to prepare specifications, communicate requirements, and verify quality upon receipt ensures your carefully selected provider delivers the results you expect.

Working With Shearing Services From Quote to Delivery

You've identified the right provider. Now what? The shearing service workflow between your initial inquiry and receiving finished parts is where projects either run smoothly or derail into frustrating delays and quality disputes. What most buyers don't realize is that their own preparation and communication practices directly influence outcomes as much as the provider's capabilities.

Working with shearing providers effectively isn't complicated, but it does require understanding what information matters, when to provide it, and how to verify results. Let's walk through the complete metal shearing quote process so you can navigate each stage with confidence.

Preparing Your Specifications for Accurate Quotes

Imagine submitting a quote request with incomplete information. The provider either asks follow-up questions, delaying your timeline, or makes assumptions that inflate pricing to cover unknowns. Neither outcome serves your interests. According to Approved Sheet Metal, having access to complete specification information at the start of a project can expedite the precision fabrication process and ensure requirements are met that might not be listed on the RFQ.

Your specification package should answer every question the provider might ask before they need to ask it. Here's the complete workflow from request to delivery:

- Compile Complete Technical Documentation: Provide CAD drawings or detailed dimensioned sketches showing all critical measurements, tolerances, and features. Include material specifications with alloy or grade designations, not just generic descriptions like "stainless steel."

- Specify Material Conditions: Note whether material should be annealed, hardened, or in a specific temper condition. As we covered earlier, material properties significantly affect shearing behavior and blade selection.

- Define Edge Requirements: State whether edges should be sharp, deburred, or meet specific finish standards. Internal specification documents frequently define expectations around edge breaks, surface grain direction, and burr removal that rarely appear on basic drawings but are often expected.

- Declare Quantity and Timeline: Provide exact quantities needed and realistic delivery dates. Distinguish between prototype quantities and production volumes, as pricing structures differ significantly.

- Submit Through Appropriate Channels: Use the provider's preferred submission method, whether online portal, email, or direct contact. Manufacturers offering 12-hour quote turnaround, like Shaoyi, typically have streamlined intake processes that accelerate response times when you provide complete information upfront.

- Review Quote Details Carefully: When you receive the quote, verify it addresses all your specifications. Check for line-item breakdowns covering material, processing, finishing, and delivery. According to LTJ Industrial, a well-structured quote makes it easy to compare vendors and understand the full scope of work.

- Confirm Production and Track Progress: After approving the quote, confirm material availability and production scheduling. Establish communication checkpoints for longer projects.

- Verify Quality Upon Receipt: Inspect parts against your original specifications before accepting delivery. Check dimensional accuracy, edge quality, and material condition.

Providers with comprehensive DFM support can identify cost-saving opportunities you might have missed. Shaoyi's rapid prototyping capabilities enable faster project validation by allowing you to test designs before committing to full production runs, catching potential issues early when corrections cost less.

Quality Verification and Issue Resolution

What happens when parts arrive and something isn't right? How you handle quality verification and issue resolution determines whether problems become minor inconveniences or major project setbacks.

Establish inspection criteria before parts arrive. Know exactly what you'll measure, what tolerances are acceptable, and what constitutes a rejectable defect. This preparation prevents disputes about whether parts meet specifications.

- Dimensional Verification: Measure critical dimensions against your original specifications. Use appropriate measuring tools calibrated to the precision your tolerances require.

- Edge Quality Assessment: Inspect cut edges for burrs, deformation, or roughness exceeding your requirements. Compare against any reference samples or finish standards you specified.

- Visual Inspection: Check for surface scratches, handling damage, or material defects that occurred during processing or shipping.

- Documentation Review: For regulated industries, verify material certifications and any required inspection documentation accompany the shipment.

When issues arise, document them thoroughly with photographs and measurements before contacting the provider. Clear documentation facilitates faster resolution and prevents miscommunication about the nature of the problem.

The most successful customer-provider relationships treat quality issues as opportunities for process improvement rather than adversarial disputes. Providers committed to quality appreciate specific feedback that helps them prevent recurrence.

Common issues customers encounter often trace back to specification gaps rather than provider errors. If edge quality doesn't meet expectations but wasn't explicitly specified, responsibility becomes ambiguous. If tolerances weren't stated, the provider likely defaulted to standard commercial tolerances that may not match your assumptions. Prevention through thorough upfront specification beats resolution after the fact.

Effective communication throughout the shearing service workflow builds relationships that benefit future projects. Providers who understand your requirements, quality expectations, and industry context deliver better results with each successive order. That accumulated knowledge becomes a competitive advantage you won't easily replicate with new suppliers.

Frequently Asked Questions About Sheet Metal Shearing Services

1. What does a sheet metal shear do?

A sheet metal shear uses two sharp blades working together to cut metal along straight lines. The lower blade stays fixed while the upper blade descends with controlled force, creating stress that exceeds the metal's shear strength. This cold mechanical process separates material cleanly without generating heat, chips, or material loss. Unlike thermal cutting methods, shearing preserves the metal's original properties and surface finish, making it ideal for high-volume production of blanks and straight-cut components.

2. How much does sheet metal shearing work cost?

Sheet metal shearing costs vary based on material type, thickness, quantity, tolerance requirements, and turnaround time. Mild steel represents the baseline cost, while stainless steel and specialty metals command premium pricing due to increased blade wear. Higher volumes reduce per-part costs by distributing setup expenses. Standard tolerances cost less than precision requirements. Rushing orders typically adds 15-25% to pricing. Providing complete specifications upfront helps secure accurate, competitive quotes from providers.

3. What is the process of sheet shearing?

Sheet shearing unfolds in three phases: blade contact and pressure application, plastic deformation along the cutting line, and controlled fracture when force exceeds material resistance. Material is positioned between upper and lower blades with proper clearance (typically 2-10% of thickness). Hold-down clamps secure the sheet while the moving blade descends. The process produces clean cuts quickly without thermal effects, making it cost-effective for straight-line cuts in materials up to 25mm thick.

4. What certifications should a shearing service provider have?

Quality shearing providers should hold certifications relevant to your industry. IATF 16949 certification demonstrates automotive-grade quality standards with rigorous defect prevention protocols. ISO 9001 establishes baseline quality controls. AS9100 is essential for aerospace applications requiring documented processes. Beyond certifications, verify equipment calibration records, material traceability documentation, and inspection procedures. Providers like Shaoyi offering IATF 16949 certification with rapid prototyping and DFM support indicate comprehensive manufacturing capabilities.

5. When should I choose shearing over laser or plasma cutting?

Choose shearing for high-volume straight-line cuts where cost efficiency matters most. Shearing excels when processing simple rectangular blanks, requiring no heat-affected zones, or maximizing material yield. The process achieves faster speeds and lower per-cut costs than thermal methods for suitable applications. Select laser cutting for complex geometries and tight tolerances. Use plasma for thicker materials needing moderate complexity. Waterjet suits heat-sensitive materials and exotic alloys requiring precision without thermal impact.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —