Sheet Metal Product Manufacturing: 9 Essential Points That Cut Costs

What Sheet Metal Product Manufacturing Really Means

Ever wondered how a flat piece of metal transforms into the precise bracket in your car or the sleek enclosure protecting your electronics? That's sheet metal product manufacturing at work—and understanding this process can save you significant costs on your next project.

Sheet metal fabrication is the industrial process of transforming flat metal sheets into functional components through cutting, forming, and joining operations—creating everything from simple brackets to complex enclosures with remarkable precision and efficiency.

From Flat Stock to Functional Parts

So, what is sheet metal exactly? It refers specifically to metal that's been formed into thin, flat pieces—typically ranging from 0.5mm to 6mm in thickness. Anything thicker than 6mm crosses into plate metal territory, which requires different equipment and techniques to process.

This thickness distinction matters more than you might think. Sheet metal's relative thinness makes it exceptionally malleable, allowing manufacturers to cut, bend, and shape it into virtually any geometry. You'll find sheet metal work behind countless everyday products—from the body panels on vehicles to HVAC ductwork, kitchen appliances, and electronic device housings.

What is metal fabrication in practical terms? It's taking these flat sheets and putting them through a carefully sequenced series of operations. First comes cutting—slicing the raw material into manageable blanks. Then forming operations like bending and stamping create the desired three-dimensional shapes. Finally, joining methods such as welding, riveting, or adhesive bonding assemble individual pieces into finished products.

The Manufacturing Method Behind Modern Products

Why does this manufacturing method dominate so many industries? The answer comes down to three key advantages:

- Material efficiency: Skilled fabricators can nest parts closely together on a sheet, minimizing waste. Most scrap is fully recyclable, further reducing material costs.

- Design flexibility: From simple flat panels to complex curved enclosures, the process accommodates an enormous range of geometries and specifications.

- Scalability: Whether you need one prototype or thousands of production parts, the same fundamental processes apply—just with different levels of automation.

When you look at all about sheet metal manufacturing, you'll discover it supports industries with vastly different requirements. Automotive manufacturers rely on it for body panels and structural components. Electronics companies need precise enclosures with tight tolerances. Aerospace applications demand lightweight yet incredibly strong assemblies. Construction projects use sheet metal for everything from roofing to decorative facades.

The versatility extends to material options as well. Manufacturers work with aluminum for lightweight applications, stainless steel where corrosion resistance matters, mild steel for cost-effective strength, and specialty alloys for demanding environments. Each material behaves differently during fabrication, requiring specific knowledge to define sheet metal processing parameters correctly.

Understanding these fundamentals puts you in a stronger position when specifying parts or evaluating manufacturing partners. The following sections will break down the specific processes, materials, and design considerations that directly impact your project costs and outcomes.

Core Manufacturing Processes Explained

Now that you understand what sheet metal fabrication involves, let's explore the specific processes that make it all happen. Think of the sheet metal fabrication process as a carefully orchestrated sequence—each operation builds on the previous one to transform flat stock into finished components.

Cutting Technologies That Shape Raw Material

Every sheet metal project starts with cutting. You're essentially carving out the blank shapes that will become your final parts. Four primary sheet metal cutting methods dominate modern fabrication shops, each with distinct strengths:

Laser cutting uses a focused beam of light—either from a CO2 or fiber laser source—to melt, burn, or vaporize material along a programmed path. The result? Extremely precise cuts with minimal heat-affected zones. Fiber lasers dominate thin material cutting, achieving exceptional speeds on sheets under 1/4" thick. However, cutting speed decreases significantly as material thickness increases.

Plasma cutting accelerates a jet of hot plasma—reaching temperatures up to 45,000°F—to cut through electrically conductive materials. Modern CNC plasma systems can cut 1/2" mild steel at speeds exceeding 100 inches per minute, making this the fastest option for medium to thick metal plates. High-definition plasma systems now rival laser quality on many applications while maintaining superior cutting speeds.

Waterjet cutting takes a completely different approach. It uses a high-pressure stream of water, often mixed with abrasive particles, operating at pressures up to 90,000 PSI. The key advantage? No heat generation whatsoever. This preserves material structural integrity—critical when working with heat-sensitive alloys or when you need absolutely no thermal distortion.

Shearing remains the workhorse for straight cuts on thinner materials. It's fast, economical, and requires minimal setup. When you simply need rectangular blanks or straight-edge cuts, shearing delivers the lowest cost per cut.

Forming Operations That Create Geometry

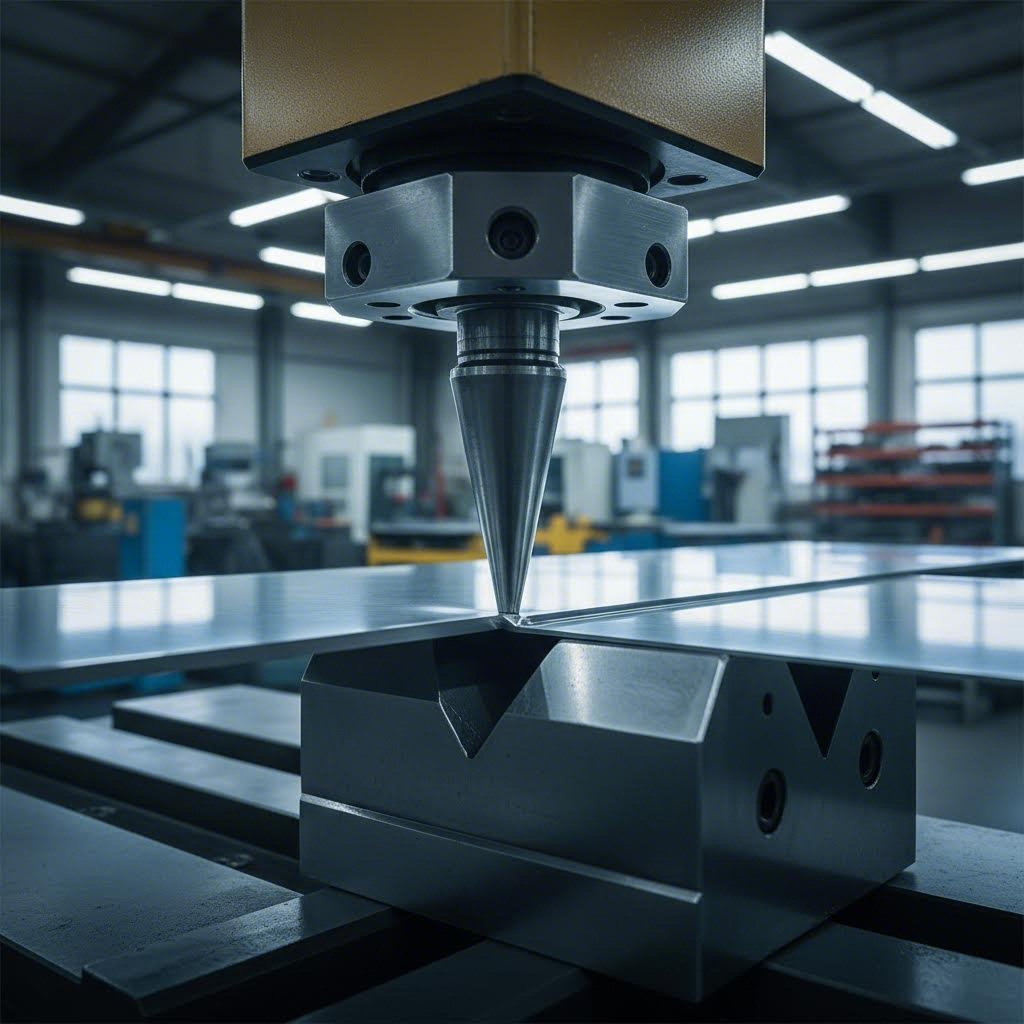

Once you have your cut blanks, forming sheet metal transforms those flat pieces into three-dimensional shapes. This is where the real magic happens in sheet metal forming.

Bending is the most common forming operation. Steel sheet bending uses press brakes with precision tooling to create angles, channels, and complex multi-bend geometries. The process relies on the material's ductility—its ability to deform without cracking.

Stamping uses dies to punch, form, or emboss features into sheet metal in a single stroke. High-volume production runs favor stamping because once you've invested in tooling, cycle times drop dramatically.

Deep drawing pulls sheet metal into a die cavity, creating seamless cup-shaped or box-shaped parts. Think beverage cans, kitchen sinks, or automotive fuel tanks—all products of deep drawing operations.

Roll forming continuously bends long strips of metal through a series of roller dies, producing consistent profiles like channels, angles, and custom cross-sections at high speed.

Joining Methods That Complete the Assembly

Individual formed components rarely stand alone. Sheet metal assembly brings multiple pieces together using various joining techniques:

- Welding: Creates permanent metallurgical bonds. MIG, TIG, and spot welding each serve different applications based on material type, joint configuration, and production volume.

- Riveting: Mechanical fastening that's ideal when welding isn't practical—such as joining dissimilar metals or when disassembly might be needed.

- Adhesive bonding: Distributes stress across larger surface areas and works well for joining thin materials that might distort under welding heat.

Process Capabilities Comparison

Choosing the right sheet metal fabrication techniques depends on your specific requirements. This comparison helps you match processes to your project needs:

| Process | Typical Tolerance | Thickness Range | Best Applications |

|---|---|---|---|

| Laser Cutting | ±0.005" (0.13mm) | 0.020" - 1.0" | Intricate designs, thin materials, precision parts |

| Plasma Cutting | ±0.015" (0.38mm) | 0.018" - 2.0" | Structural steel, heavy equipment, high-volume production |

| Waterjet Cutting | ±0.003" (0.08mm) | 0.020" - 12.0" | Heat-sensitive materials, thick plates, exotic alloys |

| Shearing | ±0.010" (0.25mm) | Up to 0.25" | Straight cuts, rectangular blanks, high-speed production |

| Press Brake Bending | ±0.5° angle | 0.020" - 0.5" | Brackets, enclosures, formed channels |

| Stamping | ±0.005" (0.13mm) | 0.010" - 0.25" | High-volume parts, complex features in single operation |

| Deep Drawing | ±0.010" (0.25mm) | 0.015" - 0.125" | Seamless containers, cups, enclosures |

Understanding how these processes interconnect helps you optimize your designs. A typical production sequence might flow like this: laser cutting creates precise blanks, forming operations add bends and features, secondary punching adds holes or slots, and finally welding or mechanical fastening completes the sheet metal assembly.

With these core processes understood, you'll want to know which materials work best with each technique—and how material selection directly impacts your manufacturing costs and part performance.

Material Selection and Thickness Guidelines

Choosing the right material isn't just about what looks good on a spec sheet—it directly impacts your manufacturing costs, production timeline, and part performance. Get this decision wrong, and you'll face cracking during forming, premature corrosion, or unnecessary expenses. Let's break down what actually matters when selecting materials for your sheet metal projects.

Steel Grades and Their Manufacturing Behavior

Steel remains the backbone of sheet metal product manufacturing, but not all steel grades behave the same way under a press brake or laser cutter.

Mild steel (low carbon steel) offers the most forgiving formability at the lowest cost. It bends easily, welds cleanly, and works with virtually any cutting method. The tradeoff? It requires protective coatings or paint to prevent rust in exposed environments.

Galvanized steel solves the corrosion problem by adding a zinc coating to mild steel. You'll pay a modest premium, but gain significant weather resistance. One consideration: welding galvanized material requires proper ventilation since the zinc coating produces harmful fumes when heated.

Stainless steel sheet metal commands higher prices but delivers exceptional corrosion resistance without additional coatings. The two most common grades you'll encounter are 304 and 316:

- 304 stainless: The workhorse grade—excellent for indoor applications, kitchen equipment, and mild outdoor exposure. It handles forming well and offers solid corrosion resistance in typical environments.

- 316 stainless: Contains 2-3% molybdenum, which significantly boosts performance in aggressive environments—especially those involving chlorides like saltwater or harsh chemicals. Expect to pay 20-30% more than 304, but this premium pays for itself in marine, medical, and chemical processing applications.

When working with sheet metal stainless steel, remember that it work-hardens during forming. This means your tooling experiences more wear, and you'll need larger bend radii compared to mild steel to prevent cracking.

Aluminum Alloys for Lightweight Applications

When weight matters—and it often does in automotive, aerospace, and portable equipment—aluminum sheets metal become the go-to choice. But here's where material selection gets nuanced.

5052-H32 aluminum is the fabricator's favorite. Because it's not heat-treated, it embodies high fatigue strength and elasticity, making it ideal for forming operations. You'll get crack-free bends and surprisingly smooth surface finishes. At approximately $2 less per pound than 6061, the cost savings add up quickly on larger projects.

6061-T6 aluminum offers superior strength after heat treatment, but that same treatment makes it prone to cracking during bending. If your design specifies tight radii with 6061, experienced fabricators will almost always recommend switching to 5052-H32. When you absolutely need 6061-T6, expect longer lead times and additional costs—you may need to start with T0 temper material and heat-treat the finished part.

Specialty Materials: Copper and Brass

For electrical conductivity, antimicrobial properties, or decorative applications, copper steel sheet alternatives like pure copper and brass enter the picture. Bronze sheet metal offers excellent wear resistance for specialized applications.

Copper forms beautifully but scratches easily and oxidizes over time (developing that characteristic green patina). Brass—an alloy of copper and zinc—machines and forms well while offering better corrosion resistance than pure copper.

How Thickness Affects Your Manufacturing Options

Material gauge doesn't just determine structural performance—it fundamentally changes which processes work and what tolerances you can achieve.

Thicker sheets require larger bend radii to avoid cracking because bending induces tensile and compressive stresses. The V-opening on your die must increase with material thickness, and bending force requirements climb accordingly. A 16-gauge sheet might bend easily on standard equipment, while 10-gauge material of the same alloy could require specialized heavy-duty presses.

Material Properties Comparison

| Material | Formability | Corrosion Resistance | Relative Cost | Typical Applications |

|---|---|---|---|---|

| Mild Steel | Excellent | Poor (requires coating) | $ | Brackets, enclosures, structural components |

| Galvanized Steel | Good | Good | $$ | Outdoor equipment, HVAC, automotive |

| 304 Stainless | Good | Excellent | $$$ | Kitchen equipment, indoor fixtures, general fabrication |

| 316 Stainless | Good | Superior (chloride resistant) | $$$$ | Marine, medical, chemical processing |

| 5052-H32 Aluminum | Excellent | Good | $$ | Enclosures, brackets, formed parts |

| 6061-T6 Aluminum | Fair (cracks easily) | Good | $$$ | Structural applications requiring strength |

| Copper | Excellent | Good (oxidizes) | $$$$ | Electrical components, decorative elements |

| Brass | Good | Good | $$$ | Hardware, decorative parts, low-friction applications |

The right material choice balances formability requirements against end-use performance needs and budget constraints. Selecting stainless sheet metal when galvanized steel would suffice wastes money. Choosing aluminium sheet when your design requires tight bend radii with 6061 causes manufacturing headaches. Understanding these tradeoffs positions you to make smarter decisions—and opens the door to the next critical topic: designing your parts so they actually manufacture efficiently.

Design for Manufacturing Essentials

You've selected the perfect material for your project. Now comes the step that separates costly redesigns from first-time success: designing your parts so they actually manufacture efficiently. Following proven sheet metal design guidelines doesn't just prevent failures—it directly reduces your production costs.

Here's the reality: most manufacturing delays and budget overruns trace back to design decisions made before the first cut. Let's explore the specific dimensions, clearances, and rules that keep your prototype sheet metal projects on track from the start.

Critical Dimensions That Prevent Manufacturing Failures

When working with sheet metal, certain dimensional relationships must be maintained—or you'll face distorted parts, cracked material, or features that simply can't be formed. These aren't arbitrary rules; they're based on how metal physically behaves during cutting and bending operations.

Hole-to-edge distances determine whether your cut features remain intact after bending. According to Protolabs' design guidelines, if your material is 0.036 in. (0.914mm) or thinner, holes should be at least 0.062 in. (1.574mm) from the material edge. For thicker materials, increase this to at least 0.125 in. (3.175mm) to avoid distortion.

Minimum flange length is equally critical. Your flanges must be at least 4 times the material thickness—anything shorter and the press brake simply can't grip the material properly. Working with 0.060" aluminum? Your minimum flange length is 0.240". Ignore this rule and you'll see inconsistent bends or material slipping during forming.

Hole and slot sizing follows a simple principle: minimum diameter should equal material thickness. For very thin materials (under 0.036"), maintain at least 0.062" diameter to prevent tooling damage and ensure clean cuts.

Feature-to-bend clearance follows what fabricators call the 4T rule. Keep all features—holes, tabs, slots—at least 4x material thickness away from bend lines. Using 0.050" copper? Give your features at least 0.200" clearance. Otherwise, the part will deform awkwardly during bending.

Bend Radius Rules for Different Materials

Perfectly perpendicular corners don't exist in sheet metal fabrication. Every bend creates a radius determined by the tooling used—and specifying the wrong radius leads to cracking or excessive springback.

Standard bend radius options typically include 0.030" (0.762mm), 0.060" (1.524mm), 0.090" (2.286mm), and 0.120" (3.048mm). The most common default is 0.030"—sufficient for most materials and thicknesses you'll encounter during sheet metal prototyping.

Here's a cost-saving tip many designers miss: use the same radius for all bends in a part. When your manufacturer doesn't have to change tooling between operations, you save on labor costs. Different radii for each bend might look elegant in CAD, but they add time and expense in production.

Remember that external bend radius equals material thickness plus internal bend radius. If you're using 0.060" material with a 0.030" internal radius, your external radius will be 0.090". This matters when your part must interface with other components.

Design Errors That Drive Up Manufacturing Costs

Sheet metal prototype fabrication reveals design problems quickly—usually through rejected parts or production delays. Avoid these common mistakes that experienced fabricators see repeatedly:

- Submitting solid 3D models without bend information: Your CAD file should show where bends occur. Sheet metal is flat and must be bent into shape—if you design it as a solid object, fabricators can't determine your intent.

- Varying material thickness within a single part: Since raw materials are single sheets, your entire part must maintain consistent thickness. You can't specify 0.125" in one area and 0.060" in another.

- Placing features too close to bends: Violating the 4T rule causes deformation during forming. This is the fastest way to create manufacturing difficulties.

- Specifying unnecessarily tight tolerances: This is where costs really escalate. Default CAD tolerances are designed for machining—far tighter than sheet metal processes require.

- Ignoring hem requirements: For hems, the minimum inside diameter should equal material thickness, with a return length of at least 6x material thickness.

Tolerance Specifications: When Precision Pays and When It Doesn't

Here's where many engineers unknowingly inflate their project costs. As Herold Precision Metals explains, "SolidWorks is designed for machining, where tolerances are much tighter than what is generally needed for sheet metal parts. This often leads to over-engineering and higher costs."

A typical tolerance for sheet metal might be ±0.010" across a bend—much looser than machining tolerances. Standard bend angle tolerance is ±1 degree. Specifying tighter requirements often means:

- Additional post-forming machining operations

- More complex quality control and inspection processes

- Reduced production yields

- Longer lead times

So when do tighter tolerances genuinely add value? Focus precision requirements on critical features that affect functionality—bolt holes, mounting points, or mating surfaces. For non-critical areas like general edges or decorative features, standard tolerances work perfectly fine.

The best approach when working with sheet metal? Collaborate with your fabricator early. Understanding manufacturing limitations upfront prevents costly redesigns and helps you specify realistic tolerances that balance precision with cost-effectiveness.

With your design optimized for manufacturing, the next question becomes: how do you verify that finished parts actually meet your specifications? That's where quality standards and inspection methods come into play.

Quality Standards and Inspection Methods

You've designed your parts with manufacturing in mind. But here's the critical question: how do you know the finished sheet metal components actually meet your specifications? Without robust quality control, even the best designs can result in parts that don't fit, fail prematurely, or require costly rework.

Precision sheet metal fabrication demands systematic inspection methods and adherence to recognized industry standards. Let's explore what separates consistently excellent metal fabrication parts from inconsistent production—and how to troubleshoot the quality issues that most manufacturers struggle to address.

Industry Standards That Define Quality

Quality in sheet metal engineering isn't subjective—it's defined by internationally recognized standards that establish clear requirements for processes, documentation, and performance.

ISO 9001 serves as the foundation for quality management across all manufacturing sectors. This standard ensures manufacturers maintain documented procedures, conduct regular audits, and implement continuous improvement processes. When evaluating precision sheet metal fabrication companies, ISO 9001 certification is the baseline expectation.

IATF 16949 builds on ISO 9001 with additional requirements specific to automotive supply chains. If your sheet metal components are destined for vehicles, this certification isn't optional—it's mandatory for most major automakers. IATF 16949 demands statistical process control (SPC), PPAP documentation, and failure mode analysis that general manufacturing standards don't require.

Beyond certifications, acceptable tolerances vary dramatically by application:

- General commercial parts: ±0.010" to ±0.015" dimensional tolerance; ±1° bend angle tolerance

- Precision assemblies: ±0.005" dimensional tolerance; ±0.5° bend angle tolerance

- Critical aerospace/medical components: ±0.002" or tighter, often requiring secondary machining operations

Understanding which tolerance class your application genuinely requires prevents over-specification costs while ensuring functional performance.

Inspection Methods for Critical Components

Modern inspection combines traditional measurement tools with advanced optical and coordinate-based systems. The right approach depends on your production volume, part complexity, and tolerance requirements.

Coordinate Measuring Machines (CMMs) remain the gold standard for precision sheet metal fabricator operations requiring micron-level accuracy. These systems use touch probes to collect 3D coordinate data, measuring complex geometries against CAD models. For critical sheet metal components with tight tolerances, CMM inspection provides the most reliable verification.

Optical measurement systems offer speed advantages for high-volume production. As modern optical inspection technology advances, vision systems can now "process hundreds of measurements in seconds, comparing them against CAD models with micron-level precision." These non-contact systems eliminate operator influence and enable 100% inspection on production lines.

Traditional gauge testing still plays an important role. Calipers, micrometers, height gauges, and radius gauges provide immediate feedback during production without complex setup procedures. Experienced operators use these tools for in-process checks that catch problems before they multiply across a production run.

Key Quality Checkpoints in Manufacturing Workflow

Effective quality control isn't just final inspection—it's integrated throughout the manufacturing process. Here's where precision sheet metal fabrication companies focus their quality efforts:

- Incoming material inspection: Verify thickness consistency, surface quality, and material certification before processing begins

- First article inspection: Comprehensive measurement of initial parts to validate setup before production runs

- In-process gauging: Real-time checks during cutting, forming, and assembly operations to catch drift before it creates scrap

- Bend angle verification: Digital angle finders or 3D measurement systems confirm bend accuracy after forming operations

- Surface quality analysis: Visual or automated optical inspection for scratches, dents, and surface finish requirements

- Final dimensional verification: Complete measurement against engineering drawings before packaging

- Assembly fit checks: Functional testing of mating components to verify real-world performance

Troubleshooting Springback and Material Distortion

Even with perfect designs and quality materials, two persistent challenges plague sheet metal manufacturing: springback and material distortion. Understanding how professionals overcome these issues helps you specify parts that stay in tolerance.

Springback occurs when metal attempts to return to its original flat state after bending. As industry experts explain, "The best way to deal with springback is to bend the metal beyond the required bending angle. It ensures that even after springback, the material's final bend aligns with the specifications."

The degree of springback varies by material. Higher-strength alloys and stainless steel fabrication projects experience more pronounced springback than mild steel or aluminum. Experienced fabricators compensate by:

- Overbending by calculated amounts based on material properties

- Using bottoming or coining techniques that exceed the material's yield strength

- Employing advanced press brakes with real-time angle measurement and automatic compensation

Dimensional variation from material inconsistency presents another challenge. Even within specification, thickness variations of a few thousandths affect bend angles and formed dimensions. The solution? Incoming material inspection that detects variations before processing, and SPC systems that adjust machine parameters in real time.

Surface defects including scratches, die marks, and orange peel texture typically trace to tooling condition, material handling, or lubrication problems. Quality-focused manufacturers maintain tooling schedules, use protective films during processing, and implement proper handling procedures to minimize these issues.

The integration of inspection data with manufacturing systems represents the future of quality control. Digital twin technology and cloud-based quality management systems now enable predictive quality control and virtual inspection before physical production begins—catching potential problems when they're cheapest to fix.

With quality systems in place to verify your specifications, the next consideration is understanding how requirements differ across industries—and what that means for your specific application.

Industry Applications and Requirements

Ever notice how the bracket holding your car's suspension system looks nothing like the enclosure protecting your laptop's motherboard? That's not coincidental—each industry demands fundamentally different specifications from sheet metal manufacturing. Understanding these sector-specific requirements helps you specify parts correctly the first time and find manufacturing partners with relevant expertise.

The sheet metal manufacturing industry serves remarkably diverse applications, yet each sector operates under distinct tolerance requirements, material specifications, and certification standards. Let's examine what separates automotive-grade production from aerospace precision—and why electronics enclosures demand capabilities that industrial equipment doesn't.

Automotive Component Requirements

Automotive applications represent one of the largest segments of sheet metal production worldwide. From chassis reinforcements to mounting brackets and structural components, vehicles contain hundreds of fabricated metal parts that must meet stringent quality and safety standards.

What sets automotive apart? IATF 16949 certification is essentially mandatory for Tier 1 and Tier 2 suppliers. This standard—built on ISO 9001—adds automotive-specific requirements including Advanced Product Quality Planning (APQP), Production Part Approval Process (PPAP), and statistical process control. If you're sourcing chassis, suspension, or structural components, your manufacturer needs this certification or you won't get approved by major automakers.

Tolerance requirements in automotive typically range from ±0.010" to ±0.015" for general structural parts, tightening to ±0.005" for critical mounting surfaces. Material selection favors high-strength low-alloy (HSLA) steels, galvanized steel for corrosion protection, and increasingly aluminum alloys for weight reduction initiatives.

When searching for metal fabrication companies for automotive projects, verify IATF certification status upfront—it's the fastest way to filter for qualified suppliers.

Aerospace Tolerance and Material Demands

Aerospace manufacturing operates in an entirely different league. According to industry specifications, precision machining of aerospace parts typically requires tolerances tighter than ±0.01 mm (approximately ±0.0004"), especially for load-bearing structures.

Why so stringent? Aerospace components endure extreme conditions—thermal cycling from -55°C to 200°C, high aerodynamic loads, and prolonged vibration exposure. Every dimension matters when structural failure isn't an option.

Material selection in aerospace centers on titanium alloys (Ti-6Al-4V), aluminum 7075-T6, and specialty alloys like Inconel 718. These materials offer exceptional strength-to-weight ratios but demand specialized processing knowledge. Titanium, for example, requires inert gas shielding during welding to prevent embrittlement—a capability not every fabrication shop possesses.

Certification requirements include AS9100 quality management and often NADCAP accreditation for special processes like heat treatment and non-destructive testing. Sheet metal companies near me without aerospace certifications simply cannot compete for this work, regardless of their general fabrication capabilities.

Electronics Enclosure Specifications

Electronics enclosures present unique challenges that differ markedly from structural applications. Precision fits ensure proper component mounting, while EMI/RFI shielding protects sensitive circuits from electromagnetic and radio frequency interference.

As EMI shielding experts explain, electromagnetic interference from power lines, radio transmitters, and other electronic devices can cause circuitry malfunctions or complete failure. Proper shielding uses conductive metals to create barriers that absorb or reflect electromagnetic waves.

Material selection for EMI shielding involves specific tradeoffs:

- Copper: Excellent conductivity and shielding effectiveness up to GHz frequencies, but higher cost and moderate corrosion resistance

- Aluminum: Very good conductivity with excellent formability and lightweight properties—often the best balance for commercial electronics

- Tin-plated steel: Good corrosion resistance at moderate cost, suitable for many industrial electronics applications

- Mu-metal: Exceptional low-frequency magnetic shielding, though poor formability and very high cost limit applications

Tolerances for electronics enclosures typically range from ±0.005" to ±0.010"—tight enough to ensure proper sealing and component alignment without the extreme precision aerospace demands. Surface finish requirements often specify powder coating or anodizing for both protection and aesthetics.

Industrial Equipment: Durability Meets Cost Efficiency

Industrial equipment manufacturing prioritizes different values: durability, ease of maintenance, and cost efficiency over absolute precision. Think machine guards, control panel enclosures, conveyor components, and structural frames.

These applications typically accept wider tolerances—±0.015" to ±0.030"—because functional performance doesn't require aerospace-level precision. This tolerance relaxation translates directly to lower manufacturing costs through faster production cycles and reduced inspection requirements.

Material selection in industrial applications favors mild steel for its excellent formability and low cost, galvanized steel for outdoor installations, and stainless steel where washdown environments or corrosive conditions exist. Weldability often matters more than weight, since industrial equipment rarely faces the mass constraints of aerospace or automotive applications.

Certification requirements vary widely based on end-use. General industrial equipment may only require ISO 9001, while food processing equipment demands FDA-compliant finishes and pharmaceutical applications require additional documentation.

Industry Requirements Comparison

| Industry Sector | Typical Tolerance | Common Materials | Required Certifications | Key Requirements |

|---|---|---|---|---|

| Automotive | ±0.005" to ±0.015" | HSLA steel, galvanized steel, aluminum alloys | IATF 16949, ISO 9001 | PPAP documentation, SPC, crash safety compliance |

| Aerospace | ±0.0004" to ±0.005" | Ti-6Al-4V, aluminum 7075, Inconel 718 | AS9100, NADCAP | Full traceability, fatigue testing, thermal cycling validation |

| Electronics | ±0.005" to ±0.010" | Aluminum, copper, tin-plated steel | ISO 9001, UL certification | EMI/RFI shielding, precision fits, surface finish |

| Industrial Equipment | ±0.015" to ±0.030" | Mild steel, galvanized steel, stainless steel | ISO 9001 | Durability, weldability, cost efficiency |

Understanding these sector-specific requirements positions you to make informed decisions when specifying parts or evaluating potential manufacturing partners. The sheet metal industry continues evolving to meet increasingly diverse application demands—but one trend affects all sectors: the growing importance of sustainable manufacturing practices.

Sustainability in Metal Manufacturing

Here's something most manufacturers won't discuss openly: the environmental impact of their operations. Yet sustainability in metal fabrication isn't just about corporate responsibility—it directly affects your bottom line through material costs, waste disposal expenses, and energy consumption.

The good news? Sheet metal ranks among the most sustainable manufacturing materials available. Understanding how modern metal processing approaches minimize environmental impact helps you make informed decisions that benefit both your budget and the planet.

Recyclability Advantages of Metal Manufacturing

Unlike plastics that degrade with each recycling cycle, steel and aluminum maintain their structural properties indefinitely. This creates a genuine circular economy where yesterday's scrap becomes tomorrow's precision components.

Consider this: recycling aluminum saves up to 95% of the energy required to produce it from raw materials. That's not a marginal improvement—it's a transformational efficiency gain that makes aluminium fabrication inherently more sustainable than many alternative materials.

Steel offers similar advantages. Both ferrous and non-ferrous metals can be melted down and reformed without losing essential properties. Companies like Tesla and GM have embraced this reality, incorporating significant amounts of recycled aluminum into their vehicle production processes and setting ambitious goals for renewable energy sourcing.

What does this mean for your projects? When you specify recyclable fabrication materials like steel or aluminum, you're choosing options that:

- Reduce dependence on virgin ore extraction and associated environmental impacts

- Lower embodied carbon in finished products—increasingly important for LEED certification and green building standards

- Create end-of-life value since scrap metal commands real market prices

- Support circular economy models where materials never truly become waste

Waste Reduction Through Smart Nesting

Material costs typically represent 50-75% of total sheet metal production expenses. Every percentage point of material utilization improvement translates directly to cost savings—and reduced environmental impact.

Modern nesting software has revolutionized how fabricators arrange parts on raw sheets. Instead of dedicating entire sheets to single part types, mixed-part nesting combines different components to fill odd-shaped spaces with smaller pieces. The results are measurable:

- 15-25% reduction in raw material costs with optimized nesting

- 30% less scrap requiring disposal

- 20% faster production through optimized cutting paths

Common-line cutting takes efficiency further by positioning parts so they share cutting lines. When parts share edges, you need only one cut instead of two—saving time, reducing kerf loss, and minimizing waste simultaneously.

Remnant management completes the waste reduction strategy. Rather than scrapping leftover material, digital inventory systems track, store, and match remnant pieces to future small jobs. According to industry data, most fabrication shops recover nesting software costs within 3-6 months through material savings alone.

Energy Efficiency in Modern Fabrication

Beyond material utilization, energy consumption represents another sustainability frontier. Different cutting and forming processes consume vastly different amounts of power—and energy-efficient machinery is being increasingly adopted across the industry.

Laser cutting and CNC machining offer precision that reduces excess material waste while consuming less energy per cut than older technologies. Fiber lasers, in particular, convert electrical energy to cutting power far more efficiently than CO2 systems—reducing both operating costs and carbon footprint.

For mild steel fabrication and general steel processing, manufacturers are also turning to water-based coatings and low-emission welding processes. These technologies minimize environmental footprint without sacrificing quality or production speed.

Many forward-thinking fabrication facilities now incorporate renewable energy sources—solar panels, wind power, or purchased renewable energy credits—to further reduce the carbon intensity of their operations. When evaluating manufacturing partners, asking about energy sourcing reveals their commitment to sustainable practices.

Practical Sustainability Practices

Implementing sustainable metal fabrication doesn't require revolutionary changes. These proven practices deliver measurable environmental and economic benefits:

- Specify recycled content: Many suppliers offer sheet metal with verified recycled content at competitive prices

- Design for material efficiency: Work with fabricators early to optimize part nesting and reduce scrap generation

- Choose appropriate tolerances: Over-specified tolerances increase scrap rates and energy consumption for marginal functional benefit

- Consider material recyclability: End-of-life recovery value should factor into material selection decisions

- Evaluate supplier sustainability programs: ISO 14001 environmental management certification indicates systematic commitment to reducing environmental impact

- Consolidate shipments: Fewer deliveries mean reduced transportation emissions and lower logistics costs

The construction sector exemplifies these principles in action. Buildings using metal siding or roofing benefit from material durability and recyclability while gaining improved energy efficiency through metal's reflectivity—reducing artificial cooling needs.

As industries continue prioritizing sustainability, sheet metal's inherent recyclability, combined with modern waste reduction technologies and energy-efficient equipment, positions it as a genuinely green manufacturing option. The environmental advantages align with economic benefits—a rare combination that makes sustainable practices genuinely attractive rather than merely obligatory.

With sustainability considerations addressed, the next practical question becomes: what actually drives the cost of your sheet metal projects, and where can you find optimization opportunities?

Understanding Manufacturing Cost Factors

Here's what most manufacturers won't tell you upfront: the quoted price for your sheet metal parts depends on far more than raw material costs. Understanding the actual cost drivers—and where optimization opportunities exist—puts you in control of your project budget before you commit to production.

Unlike vague estimates that leave you guessing, this breakdown reveals exactly what influences pricing in custom fabrication projects. Whether you're sourcing prototype quantities or planning high-volume sheet metal production, these insights help you make smarter decisions.

Volume Economics in Sheet Metal Production

Quantity dramatically affects your per-unit cost—but perhaps not in the ways you expect. Every production run involves fixed setup costs that get distributed across all parts produced.

Consider what happens before a single part gets cut: CNC programs must be created and verified, tooling must be installed and calibrated, and first-article inspection validates that everything runs correctly. A single prototype or small batch run will cost more per unit than a large-volume order because these setup and programming costs spread across fewer parts.

The breakeven math works like this: if setup costs $500 and you order 10 parts, each part carries $50 in fixed costs before material or labor. Order 500 parts from the same setup, and that fixed cost drops to $1 per unit. This explains why doubling your order quantity rarely doubles your total price.

However, there's a strategic consideration many buyers miss. Rapid sheet metal prototyping—getting functional parts in your hands within 5 days rather than weeks—can actually reduce overall project costs despite higher per-unit pricing. Why? Because catching design issues early prevents expensive tooling changes and production delays downstream. Manufacturers offering comprehensive DFM support alongside quick-turn capabilities help you identify problems when fixes cost least.

Primary Cost Drivers in Sheet Metal Projects

Material, labor, and overhead combine in predictable patterns across sheet metal fabricators. Here's what actually moves your quote up or down:

- Material type and thickness: Stainless steel offers high strength and durability but costs more per pound than carbon steel and often demands specialized finishing. Thicker materials take longer to cut, bend, and weld—directly impacting production time and cost.

- Design complexity: Parts with multiple bends, intricate cutouts, or tight tolerances require more programming, setup, and inspection time. Each additional operation adds handling and potential for quality issues.

- Tolerance requirements: The tighter your specifications, the higher your cost. Meeting stringent dimensional requirements involves more frequent inspections, slower machining speeds, and advanced measuring tools like CMMs.

- Secondary operations: Finishing processes including powder coating, anodizing, and plating add time and cost depending on coating type, surface area, and durability requirements. Assembly operations—welding sub-assemblies, inserting fasteners, or integrating components—increase labor hours and inspection points.

- Lead time pressure: Rush orders requiring accelerated delivery often involve overtime or production schedule adjustments, adding premium charges that planned orders avoid.

Design Choices That Control Costs

Your design decisions lock in the majority of manufacturing costs before production begins. According to industry analysis, the design phase typically accounts for approximately 5% of total product costs—but it significantly influences the final price because early decisions either inflate or reduce costs at every subsequent stage.

Where can you find savings? Start with these proven strategies:

Standardize whenever possible. Standard sheet sizes, thicknesses, and grades are your friends. While making a unique piece with custom dimensions is tempting, every custom spec can increase the price tag. Using standard materials reduces costs and lead times significantly.

Simplify geometry. The more straightforward your design, the smoother fabrication runs. Before finalizing complex features, question whether each adds genuine functional value or simply manufacturing cost. Custom sheet metal fab projects benefit enormously from early design reviews with experienced fabricators.

Use consistent bend radii. Specifying the same radius for all bends eliminates tooling changes between operations. Different radii for each bend might look elegant in CAD, but they add time and expense in production.

Right-size your tolerances. Default CAD tolerances designed for machining are far tighter than sheet metal processes require. Over-specifying tolerances doesn't improve functionality—it just increases inspection time and rejection rates. Focus precision requirements on critical mating surfaces and functional features only.

Optimize for nesting. Designing parts that pack efficiently on standard sheet sizes reduces scrap and material costs. Some metal fab services offer DFM feedback specifically addressing nesting optimization.

The Hidden Value of Early Collaboration

Here's where project economics get interesting. The cheapest quote doesn't always deliver the lowest total cost. Consider what happens without proper DFM support:

- You finalize designs based on assumptions about manufacturability

- Production begins, revealing issues that require design changes

- Tooling modifications, program updates, and schedule delays add unplanned costs

- Parts ship late, disrupting your downstream operations

Contrast this with manufacturers offering comprehensive DFM support and rapid prototyping capabilities. When you can get functional custom metal parts in hand within days rather than weeks, you validate designs before committing to production tooling. Partners like Shaoyi demonstrate how 5-day rapid prototyping combined with thorough DFM review catches issues early—when changes cost little compared to mid-production modifications.

Quote turnaround time also matters more than many buyers realize. Waiting weeks for pricing delays your decision-making and extends project timelines. Manufacturers offering 12-hour quote turnaround enable faster iteration and earlier production starts—time savings that translate to real competitive advantage.

Cost-Quality Tradeoffs: An Honest Assessment

Not every cost reduction makes sense. Here's how to evaluate tradeoffs without sacrificing what matters:

Material substitution: Switching from stainless to galvanized steel saves money but changes corrosion performance. Aluminum reduces weight but may require different forming techniques. Evaluate whether the cost savings justify any functional compromises.

Tolerance relaxation: Loosening non-critical dimensions reduces inspection costs and improves yields. But relaxing tolerances on functional features creates assembly problems downstream. Know which dimensions actually matter.

Finish elimination: Skipping powder coating saves money upfront but may require replacement parts sooner in corrosive environments. Calculate total lifecycle cost, not just initial purchase price.

Volume commitment: Larger orders reduce per-unit cost but increase inventory carrying costs and obsolescence risk. Find the quantity that balances unit economics against cash flow and design stability.

Industrial fabrication services that provide transparent pricing help you make these tradeoffs intelligently. When manufacturers explain exactly why options cost what they do, you can optimize based on your actual priorities rather than guessing.

With cost factors understood, the final piece of the puzzle becomes selecting a manufacturing partner whose capabilities align with your specific project requirements—a decision that deserves careful evaluation.

Selecting the Right Manufacturing Partner

You've optimized your design, selected appropriate materials, and understand the cost factors at play. Now comes the decision that determines whether your project succeeds or stumbles: choosing the right metal fabrication shop to bring your parts to life.

Finding sheet metal fabrication shops near me through a quick search returns dozens of options. But how do you separate genuinely capable partners from shops that will leave you with missed deadlines, quality issues, or unexpected costs? The evaluation criteria that follow help you assess manufacturing partners systematically—whether you're sourcing locally or working with custom metal fabricators across the country.

Certification Requirements by Industry

Certifications serve as your first filter when evaluating potential partners. They indicate a manufacturer's commitment to standardized processes and continuous improvement—not just their ability to produce parts.

ISO 9001 represents the baseline for professional manufacturing operations. This quality management system certification confirms documented procedures, regular audits, and systematic approach to preventing defects. If a fabricator lacks ISO 9001, consider it a red flag regardless of their quoted pricing.

IATF 16949 matters critically for automotive applications. As Xometry explains, this certification "is built for any company that's involved in manufacturing automotive products. While it's not necessarily required or enforced, you might find that suppliers, contractors, and customers won't want to collaborate or work with you if you aren't registered." For chassis, suspension, and structural components, IATF 16949 certification isn't optional—it's mandatory for most major automakers' supply chains.

Beyond certifications, verify that your potential partner's specialization matches your industry. Fabricators familiar with your industry understand relevant codes, standards, and best practices. They can foresee potential challenges and provide proactive solutions during the design phase, saving you time and resources.

Evaluating Technical Capabilities

Certifications confirm process quality—but equipment capabilities determine what's actually possible. When evaluating aluminum fabricators, precision sheet metal specialists, or general fabrication shops, dig into their technical infrastructure.

Equipment age and condition matter as much as equipment types. Modern equipment in good shape ensures precision and quality, while outdated machinery may fall short on complex or precise projects. Ask about maintenance schedules and calibration practices—well-maintained older equipment often outperforms neglected newer machines.

Press brake capabilities deserve particular attention if your parts require bending operations. According to industry guidance, you should focus on "the brand of machine, age, maintenance history, and richness of mold library." Advanced CNC press brakes with real-time angle measurement and automatic springback compensation deliver consistent results that manual equipment cannot match.

Prototyping speed reveals operational efficiency. Manufacturers offering rapid prototyping—functional parts in 5 days rather than weeks—demonstrate streamlined processes and responsive production scheduling. This capability proves invaluable when you need to validate designs quickly or respond to market opportunities. Partners like Shaoyi combine 5-day rapid prototyping with IATF 16949-certified production capabilities, enabling automotive projects to move from concept to qualified production without changing suppliers.

DFM support quality often separates adequate suppliers from exceptional partners. Request a specific process plan based on your drawings to verify the reliability of their promises with technical details. Comprehensive DFM review catches costly design issues before tooling commits—and manufacturers offering 12-hour quote turnaround demonstrate the responsiveness that keeps projects moving forward.

Essential Questions for Potential Manufacturing Partners

Before committing to any supplier—whether you found them searching steel fabrication shops near me or through industry referrals—gather answers to these critical questions:

- What certifications do you hold, and when were they last audited? Verify current status directly; certifications can lapse.

- Which industries represent your primary customer base? Experience in your sector indicates familiarity with relevant standards and common challenges.

- What inspection equipment and quality control procedures do you use? CMM capabilities, optical measurement systems, and documented inspection protocols indicate commitment to quality.

- What is your typical lead time for prototypes versus production quantities? Understanding standard timelines helps you plan realistically and identify when rush charges apply.

- How do you handle design changes and communicate project status? Clear communication prevents misunderstandings that derail projects. Ask about dedicated project managers and update frequency.

- Can you provide references from projects similar to mine? References should include projects similar in scope, complexity, and industry to your requirements.

- How is pricing structured, and what factors could change the quoted price? Transparent pricing prevents surprises. Understand how material cost fluctuations, design changes, or quantity adjustments affect your final invoice.

- What DFM feedback do you provide before production begins? Proactive design review identifies optimization opportunities and prevents manufacturing issues.

Matching Specialization to Project Requirements

The best manufacturer for your project isn't necessarily the largest or cheapest—it's the one whose capabilities align precisely with your needs. A custom sheet metal fabrication near me search might return shops specializing in HVAC ductwork, architectural panels, or precision electronics enclosures. Each excels in their niche but may struggle with unfamiliar applications.

Consider these alignment factors:

- Volume compatibility: High-volume stamping operations may not efficiently handle prototype quantities, while job shops optimized for custom work may lack capacity for large production runs.

- Material expertise: Fabricators experienced with mild steel may lack the specialized knowledge required for titanium, Inconel, or exotic aluminum alloys.

- Tolerance capabilities: General fabrication shops delivering ±0.015" tolerances cannot reliably achieve the ±0.005" precision that aerospace or medical applications demand.

- Secondary operation capacity: If your parts require welding, powder coating, or assembly, verify in-house capabilities versus outsourced operations that add lead time and coordination complexity.

When searching for a sheet metal fabricator near me for automotive applications specifically, prioritize partners demonstrating IATF 16949 certification, documented experience with chassis and structural components, and comprehensive DFM capabilities. The combination of quality certification, relevant expertise, and responsive communication—exemplified by features like 12-hour quote turnaround—indicates a partner equipped to support demanding automotive supply chain requirements.

Selecting the right manufacturing partner requires upfront investment in evaluation, but the payoff comes through consistent quality, reliable delivery, and projects that stay on budget. The nine essential points covered throughout this guide—from understanding core processes to evaluating potential partners—provide the framework for making informed decisions that cut costs while maintaining the quality your applications demand.

Frequently Asked Questions About Sheet Metal Product Manufacturing

1. What is the manufacturing process of sheet metal products?

Sheet metal product manufacturing involves three primary stages: cutting (using laser, plasma, waterjet, or shearing), forming (bending, stamping, deep drawing, roll forming), and joining (welding, riveting, adhesive bonding). The process starts with flat metal sheets typically 0.5mm to 6mm thick, which are cut into blanks, shaped into three-dimensional components, and assembled into finished products. Each stage requires specific equipment and expertise, with modern CNC-controlled machinery enabling precise tolerances and consistent quality across production runs.

2. What products are made from sheet metal?

Sheet metal manufacturing produces an extensive range of products across multiple industries. Common applications include automotive components (chassis, brackets, body panels), electronics enclosures (computer cases, control panels with EMI shielding), HVAC ductwork, kitchen appliances, aerospace structural parts, industrial equipment housings, and architectural elements. The versatility of sheet metal fabrication allows manufacturers to create everything from simple flat panels to complex curved enclosures with remarkable precision and material efficiency.

3. How do I choose the right material for sheet metal fabrication?

Material selection depends on your application requirements including formability, corrosion resistance, strength, and budget. Mild steel offers excellent formability at low cost but requires protective coatings. Stainless steel 304 works well for general applications, while 316 excels in marine or chemical environments. Aluminum 5052-H32 provides outstanding formability for lightweight applications, whereas 6061-T6 offers higher strength but cracks more easily during bending. Consider material thickness carefully as it affects bend radii requirements and manufacturing process options.

4. What certifications should a sheet metal manufacturer have?

ISO 9001 certification represents the baseline requirement for professional sheet metal fabricators, confirming documented quality management procedures. For automotive applications, IATF 16949 certification is essential as major automakers require it from suppliers. Aerospace projects demand AS9100 and often NADCAP accreditation for special processes. Partners like Shaoyi (Ningbo) Metal Technology demonstrate industry-leading standards with IATF 16949 certification, comprehensive DFM support, and capabilities ranging from 5-day rapid prototyping to automated mass production.

5. How can I reduce costs in sheet metal manufacturing?

Cost reduction strategies include using standard sheet sizes and thicknesses, maintaining consistent bend radii throughout your design, specifying appropriate tolerances only where functionally necessary, and optimizing part geometry for efficient nesting. Early collaboration with manufacturers offering comprehensive DFM support catches expensive design issues before production. Rapid prototyping capabilities—such as 5-day turnaround services—validate designs quickly, preventing costly tooling changes. Volume consolidation spreads fixed setup costs across more parts, significantly reducing per-unit pricing.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —