Sheet Metal Fabrication Products: From Raw Material To Finished Part

What Are Sheet Metal Fabrication Products

Ever looked around your office, car, or kitchen and wondered how all those precise metal components came to be? From the sleek housing of your laptop to the sturdy brackets holding up industrial shelving, you're surrounded by sheet metal fabrication products. These manufactured items represent the transformation of flat metal sheets into functional, three-dimensional components through specialized processes like cutting, bending, punching, and welding.

Sheet metal fabrication products are manufactured components created by cutting, bending, and forming flat metal sheets into functional parts used across virtually every industry—from aerospace and automotive to medical devices and consumer electronics.

From Flat Sheets to Functional Products

The journey from raw material to finished product begins with flat metal sheets—typically ranging from 0.5mm to 6mm in thickness. Through a series of carefully orchestrated manufacturing steps, these sheets transform into everything from tiny, complex brackets to large panels and enclosures. According to Fathom Manufacturing, sheet metal fabrication involves using specialized equipment to cut, bend, roll, form, and assemble parts into finished products.

What makes this process so versatile? Metal sheets can be crafted from various materials—mild steel, stainless steel, aluminum sheet metal, brass, and more—each offering unique properties suited to specific applications. This flexibility allows manufacturers to produce components ranging from simple flat washers to intricate enclosures with tight tolerances.

The Building Blocks of Modern Manufacturing

Understanding sheet metal fabrication matters whether you're an engineer designing new products, a procurement specialist sourcing components, or a manufacturer optimizing your production processes. Here's why:

- Cost-effectiveness: Compared to machining solid blocks, working with metal sheets is significantly more affordable and provides flexibility during each fabrication step.

- Scalability: The same processes accommodate everything from single prototypes to high-volume production runs without major retooling investments.

- Precision: Modern CNC-controlled equipment cuts and forms parts to exact specifications, minimizing secondary processing needs.

- Short lead times: With fewer processing steps than many manufacturing methods, steel fabrication often delivers faster turnaround times.

The applications are nearly limitless. Cold-rolled steel finds its way into home appliances, furniture, and storage cabinets. Stainless steel sheets become surgical instruments and kitchen equipment. Aluminum sheet metal—prized for its strength-to-weight ratio—dominates transportation and consumer electronics. Every industry relies on metal fabrication to produce the components that keep operations running smoothly.

Essential Fabrication Processes Behind Every Product

How does a flat metal sheet become a precision bracket, enclosure, or structural component? The answer lies in a series of specialized manufacturing processes—each designed to shape, cut, and join materials with remarkable accuracy. Understanding these techniques helps you make smarter decisions about material selection, design optimization, and cost management.

Cutting Technologies That Shape Raw Materials

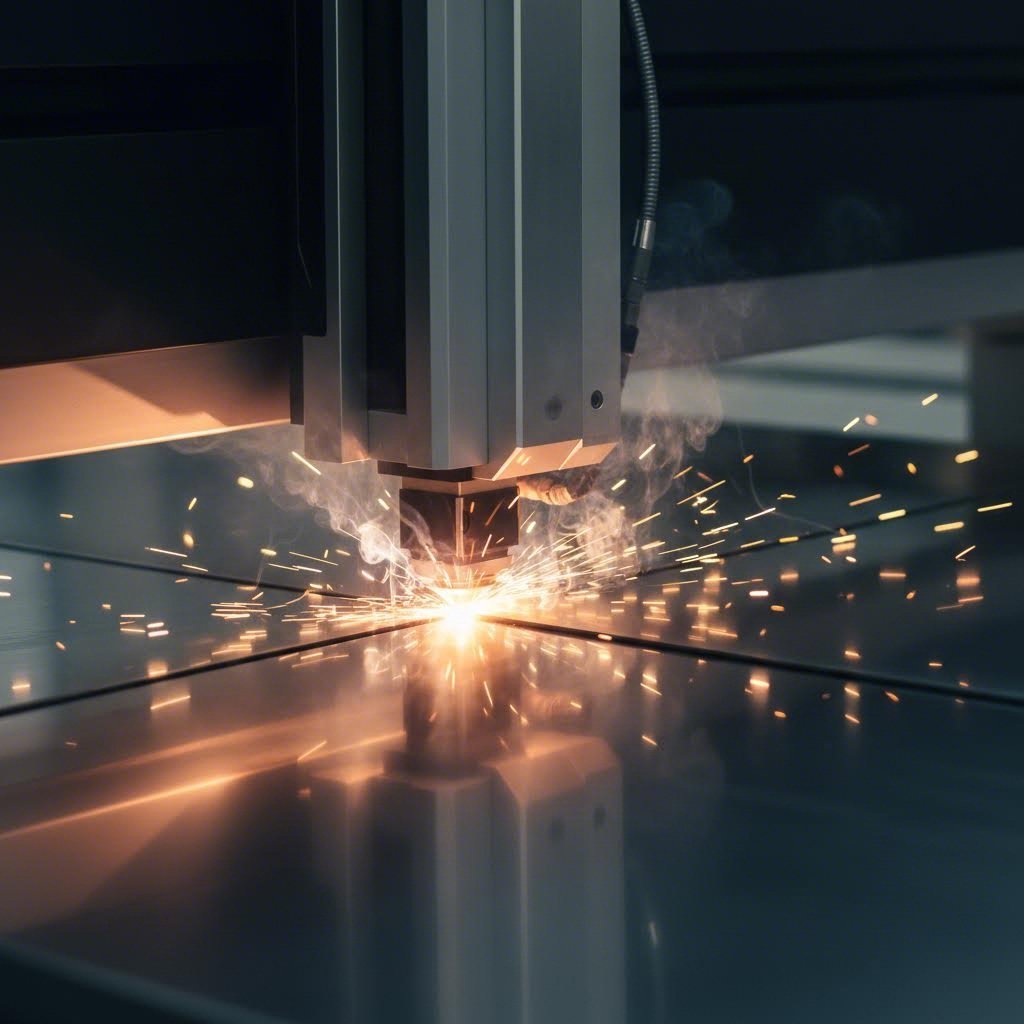

Before any bending or forming can happen, raw metal sheets must be cut to size. The choice of metal cutter technology directly impacts precision, edge quality, and production costs. Here are the primary cutting methods used in modern fabrication:

- Laser Cutting: Uses a concentrated laser beam to melt and separate material with exceptional precision. According to Xometry, laser cutters produce cuts with slot widths of approximately ±0.15 mm and precision of 0.01 mm or less. Ideal for intricate designs, thin to medium-thickness materials, and applications requiring smooth, burr-free edges.

- Plasma Cutting: Forces hot, electrically charged gas through a small nozzle at temperatures reaching 20,000°C. Best suited for thicker conductive metals—plasma cutters can handle plates up to 38 mm thick. However, the larger kerf width (greater than 3.8 mm) means less precision compared to laser cutting.

- Punching: Uses a punch and die set to create holes, slots, and shapes by shearing material. Excellent for high-volume production of parts with repetitive features like ventilation patterns or mounting holes.

One critical concept to understand is kerf—the width of material removed during cutting. A laser cutter produces a very thin kerf (around 0.15 mm), allowing for tighter nesting of parts and minimal material waste. Plasma cutting creates a significantly wider kerf, which affects dimensional accuracy and requires additional allowance in part design. When precision matters most, laser cutting typically delivers superior results, though at higher operational costs—approximately $20/hour versus $15/hour for plasma cutting.

Bending and Forming Techniques Explained

Once cut to size, flat pieces need shaping. The press brake is the workhorse of metal forming, using a punch and die to create precise bends. But not all bending is the same—different techniques offer trade-offs between accuracy, speed, and tooling requirements:

- Air Bending: The punch presses material into the die without bottoming out. This technique uses less force and allows flexible bend angles with the same tooling. However, you'll need to account for more springback—the material's tendency to return toward its original shape.

- Bottom Bending (Bottoming): Drives the punch further until material seats firmly at the die base. Delivers greater accuracy and reduced springback, making it ideal for high-volume runs requiring consistent angles.

- Coining: Applies extremely high tonnage to stamp material completely into the die, actually thinning it at the bend line. This achieves exceptional precision with minimal springback but increases tool wear significantly.

Standard tolerances for press brake bending typically fall within ±0.5 to ±1 degree for angles and ±0.25 mm to ±0.5 mm for length, according to 360 Automation. Material thickness, bend radius, and tooling condition all influence achievable precision.

Joining It All Together: Welding and Assembly

When components need permanent joining, welding becomes essential. Understanding the types of welding helps you specify the right approach for your application:

- MIG Welding (GMAW): Uses a continuously fed wire electrode and shielding gas. Fast, versatile, and easier to learn—excellent for production environments and thicker materials.

- TIG Welding (GTAW): Employs a non-consumable tungsten electrode for more precise control. Produces cleaner, stronger welds on thin materials and is preferred for visible joints requiring aesthetic appeal.

- Spot Welding: Joins overlapping sheets at discrete points using electrical resistance. Common in automotive and appliance manufacturing for high-speed assembly.

When comparing mig vs tig welding, consider your priorities: MIG offers speed and ease of use, while TIG delivers superior precision and weld quality—particularly important for stainless steel and aluminum applications.

The fabrication process you choose shapes everything from final tolerances to production costs. But equally important is selecting the right material for your application—a decision that affects performance, durability, and budget in ways that deserve careful consideration.

Material Selection Guide for Fabricated Products

You've nailed down the right fabrication process—but here's the thing: even the most precise cutting and bending won't save a project if you've chosen the wrong material. The metal you select determines everything from how well your product resists corrosion to whether it can handle structural loads without failure. So how do you navigate the options?

Let's break down the most common materials used in sheet metal fabrication, exploring their unique properties and ideal applications. Whether you're designing lightweight aerospace components or heavy-duty industrial enclosures, understanding these differences helps you balance performance, durability, and budget.

Steel Varieties and Their Strengths

Steel dominates the sheet metal world—and for good reason. According to Monroe Engineering, steel is the most common type of sheet metal produced globally, offering an unmatched combination of strength, formability, and corrosion resistance. But not all steel is created equal:

- Carbon Steel: The workhorse option. Affordable and strong, carbon steel works well for structural components, brackets, and frames. However, it requires protective coatings or paint to prevent rust in humid or outdoor environments.

- Galvanized Sheet Metal: Carbon steel coated with a protective zinc layer. This coating provides excellent corrosion resistance without the higher cost of stainless steel—making it ideal for HVAC ductwork, outdoor enclosures, and automotive components exposed to moisture.

-

Stainless Steel Sheet Metal: Contains chromium (typically 10-30%) that forms a self-healing oxide layer, protecting against corrosion even in harsh conditions. Common grades include:

- 304 Stainless Steel: The most versatile grade—excellent corrosion resistance and formability for food equipment, kitchen surfaces, and general fabrication.

- 316 Stainless Steel: Adds molybdenum for superior resistance to chlorides and acids. Essential for marine environments, chemical processing, and medical devices.

- 410/430 Stainless Steel: More affordable options with moderate corrosion resistance, suitable for automotive trim and appliance components.

When tensile strength matters most, steel delivers. A typical stainless steel sheet offers tensile strength ranging from 515-620 MPa for 304 grade, while 316 stainless steel provides similar strength with enhanced chemical resistance. This makes steel the go-to choice for load-bearing structures and high-stress applications.

When to Choose Aluminum Over Steel

Imagine you're designing components for an electric vehicle or aircraft. Every gram matters. This is where aluminum sheet metal shines—offering roughly one-third the weight of steel while maintaining impressive strength-to-weight ratios.

Aluminum naturally forms a protective oxide layer, providing excellent corrosion resistance without additional coatings. As Monroe Engineering notes, it's frequently used in applications where moisture is a problem, such as boat manufacturing. Common aluminum alloys include:

- 1100-H14 Aluminum: Highly formable with excellent corrosion resistance. Best for decorative applications and chemical equipment.

- 3003-H14 Aluminum: Good workability and moderate strength. Popular for general fabrication, HVAC components, and storage tanks.

- 5052-H32 Aluminum: Higher strength with excellent fatigue resistance. Ideal for marine applications, fuel tanks, and pressure vessels.

- 6061-T6 Aluminum: Heat-treatable with good machinability. Commonly used for structural components, frames, and aerospace applications.

The trade-off? Aluminum typically costs more than carbon steel and requires specialized welding techniques. But when weight reduction, corrosion resistance, or thermal conductivity are priorities, an aluminum sheet often proves more cost-effective over the product's lifecycle.

Copper and Brass: Specialized Applications

Not every application calls for steel or aluminum. When electrical conductivity or antimicrobial properties matter, copper and its alloys become essential.

Brass—an alloy of copper and zinc—offers excellent conductivity, corrosion resistance, and an attractive gold-like appearance. Monroe Engineering highlights that brass sheet metal is commonly used in electrical applications where steel and aluminum would perform poorly. You'll find brass in electrical terminals, decorative hardware, and musical instruments.

Wondering about brass vs bronze? While brass combines copper with zinc, bronze mixes copper with tin. Bronze offers superior hardness and wear resistance—making it preferred for bearings and marine hardware—while brass delivers better machinability and electrical properties for fabricated components.

Material Comparison at a Glance

Choosing between materials becomes easier when you can compare their key properties side by side:

| Material | Tensile Strength | Weight (Relative) | Corrosion Resistance | Cost Factor | Common Applications |

|---|---|---|---|---|---|

| Carbon Steel | 400-550 MPa | High | Low (requires coating) | $ | Structural frames, brackets, enclosures |

| Galvanized Steel | 400-550 MPa | High | Moderate-High | $$ | HVAC ductwork, outdoor equipment, automotive |

| 304 Stainless Steel | 515-620 MPa | High | Excellent | $$$ | Food equipment, medical devices, architecture |

| 316 Stainless Steel | 515-620 MPa | High | Superior | $$$$ | Marine, chemical processing, pharmaceuticals |

| Aluminum (5052) | 228-290 MPa | Low (~1/3 of steel) | Excellent | $$-$$$ | Aerospace, marine, electronics enclosures |

| Brass | 338-469 MPa | Moderate | Good | $$$ | Electrical components, decorative hardware |

Understanding Gauge Sizes and Thickness

Here's where material selection gets a bit counterintuitive. In sheet metal fabrication, thickness isn't always expressed in millimeters or inches—many specifications use gauge sizes instead. And here's the catch: a lower gauge number means thicker material.

According to Xometry, the gauge system developed from measuring sheet thickness relative to weight per square foot. For example, 10-gauge steel measures approximately 3.4 mm (0.1345 inches)—ideal for heavy-duty structural components. Meanwhile, 22-gauge material at roughly 0.76 mm suits lighter applications like HVAC ductwork and decorative panels.

Critical to understand: gauge sizes aren't universal across materials. A 10-gauge stainless steel sheet has a different actual thickness than 10-gauge aluminum because the system accounts for material density. Always reference the appropriate sheet metal gauge chart for your specific material when converting between gauge numbers and actual dimensions.

How does thickness relate to structural requirements? Thicker gauges handle greater loads and resist deformation better—but they also increase material costs, weight, and forming difficulty. The sweet spot depends on your application:

- Heavy-duty structural components: 10-14 gauge (2.0-3.4 mm)

- General fabrication and enclosures: 16-20 gauge (0.9-1.5 mm)

- Lightweight covers and decorative elements: 22-26 gauge (0.45-0.76 mm)

Remember, Xometry notes that sheet metal typically ranges from 0.5 mm to 6 mm—anything thicker is generally classified as plate rather than sheet. This distinction affects both manufacturing processes and equipment requirements.

With your material and thickness selected, you're ready to explore the actual products these combinations create. From industrial enclosures to precision automotive components, the possibilities span virtually every industry.

Common Sheet Metal Products by Category

So what exactly gets made from all those cutting, bending, and welding processes? While many resources focus on fabrication services, you're probably here because you need to understand the actual products—the tangible components that end up in factories, offices, vehicles, and homes. Let's explore the most common sheet metal fabrication products organized by their functional categories.

Industrial Enclosures and Protective Housings

Walk through any industrial facility or data center, and you'll see enclosures everywhere. These protective housings safeguard sensitive electrical components, control systems, and computing equipment from environmental hazards, unauthorized access, and electromagnetic interference. According to RFQ Line, custom enclosures represent one of the most common applications for metal fabrication.

Common enclosure products include:

- Electrical panels and junction boxes: House circuit breakers, switches, and wiring connections. Typically fabricated from galvanized or powder-coated steel for durability and corrosion resistance.

- Server racks and cabinets: Provide standardized mounting for IT equipment. Often feature precision-cut ventilation patterns and require tight tolerances for proper component fit.

- Control boxes: Protect PLCs, HMIs, and other automation equipment. Many incorporate a rubber gasket around door frames to achieve IP-rated sealing against dust and moisture.

- Instrument housings: Shield measurement devices and sensors in harsh environments. Stainless steel versions handle corrosive industrial settings.

- Custom metal signs: Range from simple identification plates to elaborate backlit displays—combining sheet metal fabrication with finishing processes like powder coating and screen printing.

The construction of these enclosures typically involves laser-cut metal plate components joined through a combination of welding, fasteners, and rivets. Smaller enclosures might use self-clinching hardware, while larger cabinets often rely on welded frames for structural rigidity.

Structural Components That Bear the Load

When products need to support weight, resist forces, or maintain precise alignment, structural sheet metal components step up. These load-bearing parts form the backbone of countless machines, vehicles, and installations:

- Brackets and mounting plates: Connect components to frames, walls, or other structures. Steel plate versions handle heavy loads, while aluminum options reduce weight in mobile applications.

- Frames and chassis: Provide the structural skeleton for equipment ranging from medical devices to industrial machinery. Complex chassis may incorporate dozens of individual fabricated parts joined by welding or rivets.

- Support beams and channels: Formed from heavier-gauge material to span distances and distribute loads across structures.

- Gussets and reinforcement plates: Strengthen joints and corners where stress concentrates.

- Corrugated metal panels: The wave pattern adds significant strength-to-weight ratio, making these ideal for roofing, siding, and structural decking applications.

Material selection proves critical for structural applications. High-stress components often specify 10-14 gauge steel plate for maximum load capacity, while lighter-duty brackets might use 16-18 gauge material to reduce costs without compromising function.

HVAC Products and Ductwork

Heating, ventilation, and air conditioning systems rely heavily on fabricated sheet metal. The industry demands components that move air efficiently while maintaining durability across decades of thermal cycling:

- Ductwork: Rectangular and round ducts transport conditioned air throughout buildings. Galvanized steel dominates this category due to its corrosion resistance and cost-effectiveness.

- Diffusers and grilles: Control airflow direction and velocity at supply and return points. Often feature decorative patterns cut by laser or punch press.

- Plenums: Large enclosures that distribute air from HVAC units to duct networks.

- Dampers: Regulate airflow through duct systems. Blade assemblies require precise fabrication for proper sealing and smooth operation.

- Transition fittings: Connect ducts of different sizes or shapes, requiring complex forming and welding operations.

Automotive and Transportation Parts

The automotive sector consumes massive quantities of sheet metal products—from structural components to aesthetic body panels:

- Body panels: Fenders, doors, hoods, and trunk lids formed from steel or aluminum. Modern vehicles increasingly use aluminum to reduce weight and improve fuel efficiency.

- Brackets and mounting hardware: Secure everything from engines to exhaust systems. These components often require tight tolerances and specific material certifications.

- Heat shields: Protect sensitive components from exhaust system temperatures. Typically fabricated from aluminized steel or stainless steel for heat resistance.

- Chassis components: Subframes, crossmembers, and reinforcement structures that provide crash protection and handling characteristics.

- Fuel tank components: Require specialized materials and welding techniques to ensure leak-free performance.

Consumer Goods and Appliances

Look around your home—sheet metal products are everywhere, often hidden inside the devices you use daily:

- Appliance housings: Refrigerators, washing machines, dishwashers, and ovens all feature fabricated steel or stainless steel enclosures.

- Furniture components: Filing cabinets, metal desks, shelving systems, and storage units rely on precision-formed sheet metal for structural integrity.

- Electronics enclosures: Computer cases, audio equipment housings, and telecommunications cabinets protect internal components while managing heat dissipation.

- Lighting fixtures: From industrial high-bay fixtures to decorative residential options, sheet metal provides durable, heat-resistant housings.

- Kitchen equipment: Commercial and residential sinks, countertops, range hoods, and prep surfaces—predominantly fabricated from stainless steel for hygiene and durability.

These product categories barely scratch the surface. Agriculture equipment, medical devices, aerospace components, marine hardware, and countless other applications depend on precision sheet metal fabrication. The key takeaway? Nearly every industry relies on these products—making material selection, process knowledge, and quality standards essential considerations regardless of your specific application.

Speaking of applications, let's examine how different industries leverage these fabricated products to meet their unique performance requirements and regulatory demands.

Industry Applications and Specialized Products

Now that you've seen the product categories, here's where things get interesting. Different industries don't just use different products—they demand entirely different performance standards, material specifications, and precision requirements. An enclosure for a data center looks nothing like one designed for a medical operating room, even if the basic fabrication processes remain similar.

Understanding these industry-specific demands helps you specify the right products for your application. Let's explore how five major sectors leverage sheet metal fabrication to meet their unique challenges.

Aerospace and Defense Applications

When failure isn't an option, aerospace sheet metal fabrication demands extraordinary precision. According to Premium Parts, aerospace components must match exactly the size, design, and functional aspects—any deviation, no matter how small, can negatively impact the aircraft and the lives that depend on it.

What makes aerospace fabrication so demanding? Components must endure extreme conditions: temperature swings from -60°C at altitude to over 500°C near engines, constant vibration, pressure differentials, and decades of service life. Common aerospace sheet metal products include:

- Aircraft skin panels: Form the exterior surface of fuselages and wings. Typically fabricated from aluminum alloys or titanium, these panels require exceptional surface finish quality and precise dimensional tolerances.

- Structural brackets: Connect major airframe components and must withstand tremendous stress loads. Often machined from high-strength aluminum or titanium alloys.

- Engine component housings: Protect and contain turbine elements. Heat-resistant alloys and specialized welding techniques like TIG welding ensure integrity under extreme temperatures.

- Fuel system components: Tanks, lines, and fittings require leak-proof fabrication with materials resistant to aviation fuels.

- Avionics enclosures: Shield sensitive electronics from electromagnetic interference while managing heat dissipation at altitude.

Material selection proves critical in aerospace applications. Premium Parts notes that aluminum, titanium, and high-strength steel alloys dominate because of their strength-to-weight ratios and ability to resist corrosion and extreme pressures. The anodizing process frequently enhances aluminum components—creating a harder, more corrosion-resistant surface layer that extends service life in demanding environments.

Defense applications add another layer of complexity. Armored vehicle components may specify AR500 steel plate—a specialized abrasion-resistant material with exceptional hardness for ballistic protection. These components require fabrication shops with specific material handling capabilities and security clearances.

Medical Device Manufacturing Requirements

Imagine the precision required when a fabricated component becomes part of a surgical instrument tray or diagnostic imaging device. Medical sheet metal fabrication combines tight tolerances with stringent cleanliness and biocompatibility requirements:

- Equipment housings: Enclose MRI machines, X-ray systems, and patient monitors. These often feature complex geometries with multiple access panels and integrated cable management.

- Surgical instrument trays: Must withstand repeated sterilization cycles without corrosion or degradation. 316 stainless steel dominates this application due to its superior resistance to harsh cleaning chemicals.

- Diagnostic device enclosures: House point-of-care testing equipment and laboratory analyzers. Surface finish requirements often specify electropolishing for cleanability.

- Patient support structures: Bed frames, wheelchair components, and mobility device parts require precise fabrication for safety and durability.

- Cleanroom equipment: Fabricated components for pharmaceutical manufacturing must meet strict particulate contamination standards.

Medical fabrication frequently incorporates non-metallic materials alongside sheet metal. Delrin (a high-performance acetal polymer) often appears in medical devices as bushings, bearings, and low-friction components where metal-to-metal contact would be problematic. Understanding how these materials integrate with fabricated metal housings helps designers create more functional medical products.

Electronics and Telecommunications

Heat management, electromagnetic shielding, and rapid product development cycles define electronics fabrication requirements:

- Server enclosures and rack systems: House computing equipment in data centers. Precision-cut ventilation patterns and cable management features require tight tolerances.

- Heat sinks: Dissipate thermal energy from processors and power electronics. Anodized aluminum heat sinks offer excellent thermal conductivity with enhanced surface area through fin geometries.

- Mounting brackets: Secure circuit boards, power supplies, and peripheral devices within enclosures.

- RF shielding enclosures: Block electromagnetic interference for sensitive telecommunications equipment. Seam welding and conductive gaskets ensure shield integrity.

- Chassis and backplanes: Provide structural support while facilitating electrical connections between modules.

The powder coat finishing process frequently enhances electronics enclosures—providing durable, attractive surfaces that resist scratches and corrosion while offering a wide range of color options for brand differentiation. Unlike paint, powder coating creates a thicker, more uniform finish that withstands the thermal cycling common in electronic equipment.

Automotive Manufacturing Standards

Automotive sheet metal fabrication combines high-volume production efficiency with demanding quality standards. Every component must perform reliably across temperature extremes, vibration, and years of service:

- Chassis components: Subframes, crossmembers, and structural reinforcements form the vehicle's skeleton. High-strength steel and advanced aluminum alloys reduce weight while maintaining crash protection.

- Suspension brackets: Connect suspension components to the vehicle body. These high-stress parts require precise fabrication and often specify specialized materials for fatigue resistance.

- Body panels: Exterior surfaces demand exceptional surface finish quality. Modern vehicles increasingly use aluminum welding techniques to join lightweight body structures.

- Heat shields: Protect underbody components and passenger compartments from exhaust system temperatures.

- Battery enclosures: Electric vehicle applications require complex fabricated housings with thermal management features and crash protection.

Automotive fabrication typically requires IATF 16949 certification—the automotive industry's quality management standard that ensures consistent, reliable production. This certification demonstrates a fabricator's capability to meet the rigorous demands of automotive supply chains.

HVAC and Building Systems

Commercial and industrial buildings depend on sheet metal products for climate control and air quality management:

- Ductwork systems: Rectangular and round ducts transport conditioned air throughout facilities. Galvanized steel provides durability and corrosion resistance.

- Dampers and control devices: Regulate airflow throughout duct networks. Precision blade fabrication ensures proper sealing and smooth operation.

- Air handling unit components: Housings, plenums, and internal structures for HVAC equipment.

- Diffusers and grilles: Control air distribution at supply and return points with decorative patterns and adjustable vanes.

- Custom fittings: Transitions, elbows, and specialty connections accommodate unique building layouts.

Industry Requirements at a Glance

When selecting fabricated products for specific applications, understanding each industry's typical requirements helps ensure you specify appropriately:

| Industry | Typical Products | Common Materials | Precision Requirements | Key Certifications |

|---|---|---|---|---|

| Aerospace | Skin panels, structural brackets, engine housings | Aluminum alloys, titanium, high-strength steel | ±0.05 mm or tighter | AS9100, NADCAP |

| Medical | Equipment housings, surgical trays, diagnostic enclosures | 316 stainless steel, aluminum | ±0.1 mm typical | ISO 13485, FDA compliance |

| Electronics | Server enclosures, heat sinks, RF shielding | Aluminum, cold-rolled steel | ±0.25 mm typical | ISO 9001, UL listing |

| Automotive | Chassis, suspension brackets, body panels | High-strength steel, aluminum | ±0.1 to ±0.5 mm | IATF 16949 |

| HVAC | Ductwork, dampers, air handling units | Galvanized steel, aluminum | ±1.0 mm typical | SMACNA standards |

Notice how precision requirements vary dramatically between industries. Aerospace components demand tolerances measured in hundredths of a millimeter, while HVAC ductwork typically allows much wider variation. These differences directly impact fabrication costs—tighter tolerances require more sophisticated equipment, additional quality checks, and experienced operators.

Understanding your industry's specific requirements helps you communicate effectively with fabrication partners and avoid both over-specification (which drives up costs unnecessarily) and under-specification (which risks product failure). Speaking of precision, let's examine exactly what tolerances mean in sheet metal fabrication and how quality standards ensure consistent results.

Precision Standards and Quality Considerations

You've selected your material, chosen the right fabrication processes, and identified the products your application requires. But here's a question that often gets overlooked until problems arise: how precise do those parts actually need to be? And how do you ensure every component meets those specifications consistently?

Tolerance—the acceptable deviation from specified dimensions—might sound like a minor technical detail. In reality, it determines whether parts fit together properly, assemblies function as designed, and products perform reliably over their service life. Understanding tolerance standards helps you specify requirements appropriately, avoiding both the cost of over-engineering and the failures that come from insufficient precision.

Understanding Tolerance Standards

Every fabrication process has inherent limits to the precision it can achieve. According to Yijin Hardware, tolerances for sheet metal manufacturing typically range from ±0.005" to ±0.060" (approximately ±0.13 mm to ±1.5 mm). But that's a wide range—where your parts fall within it depends on several factors.

Think of tolerance as a zone of acceptable variation. Tighter tolerances yield more precise parts but increase production costs significantly. Looser tolerances are economical but may cause alignment issues when components must work together. The key is specifying tolerances that match your functional requirements—no tighter than necessary, but tight enough to ensure proper performance.

Different fabrication methods deliver different precision levels:

| Fabrication Process | Typical Linear Tolerance | Angular Tolerance | Best Applications |

|---|---|---|---|

| Laser Cutting | ±0.05 mm to ±0.5 mm | N/A | Intricate shapes, thin to medium materials |

| Plasma Cutting | ±0.5 mm to ±1.5 mm | N/A | Thick materials, less critical dimensions |

| Press Brake Bending | ±0.4 mm to ±0.8 mm | ±0.5° to ±1° | Formed components, enclosures |

| Punching | ±0.1 mm to ±0.25 mm | N/A | Repetitive holes, high-volume production |

| Stamping | ±0.05 mm to ±0.5 mm | ±0.5° | High-volume, complex shapes |

| Welding | ±0.5 mm to ±2 mm | ±2° | Joining operations, assemblies |

Notice how laser cutting can achieve tolerances as tight as ±0.05 mm for smaller parts, while welding operations typically allow ±0.5 mm to ±2 mm variation. This explains why critical dimensions are often established before welding operations—relying on the more precise cutting and forming processes to set key features.

When Precision Matters Most

Not every dimension on a part requires the same level of precision. Experienced designers identify critical features—those that affect fit, function, or performance—and specify tighter tolerances only where necessary. This approach controls costs while ensuring reliable results.

Several factors determine achievable tolerances for any given part:

- Material properties: Different metals behave differently during fabrication. Yijin Hardware notes that stainless steel typically permits stricter tolerances (±0.005") than mild steel due to its lower malleability and higher strength. Aluminum, with its higher thermal expansion and lower elastic modulus, generally requires looser tolerances.

- Metal gauge thickness: Thinner materials are more susceptible to distortion during cutting and forming. A sheet metal gauge chart helps you understand how material thickness affects both structural performance and achievable precision. For reference, 14 gauge steel thickness measures approximately 1.9 mm (0.075")—thick enough to maintain dimensional stability during most forming operations.

- Part complexity: Simple, symmetrical parts typically permit tighter tolerances (±0.010") than complex geometries with multiple bends and features (±0.030"). Each additional operation introduces potential for cumulative variation.

- Equipment condition: Precision-ground dies and well-maintained tools produce parts with tighter tolerances consistently. High-end carbide dies can maintain tolerances up to five times longer than standard steel tooling.

- Machine calibration: Advanced CNC equipment can achieve tolerances up to ±0.001" when properly calibrated. Even a 0.1° misalignment in a press brake can cause noticeable deviation in bent parts.

When reviewing a gauge size chart for your application, remember that thicker gauges generally handle tighter tolerances more reliably. The relationship between gauge thickness and structural performance goes beyond just strength—thicker materials resist the minor distortions that can accumulate during multi-step fabrication processes.

Quality Certifications That Ensure Consistency

How do you know a fabrication partner can actually deliver the precision they promise? Certifications provide independent verification of quality management systems and manufacturing capabilities.

IATF 16949 certification—the automotive industry's quality management standard—represents one of the most rigorous requirements in manufacturing. Fabricators holding this certification demonstrate capabilities for:

- Statistical process control to maintain consistent tolerances across production runs

- Documented quality procedures with full traceability

- Regular calibration of measuring equipment and production machinery

- Continuous improvement processes that identify and correct variation sources

ISO 9001 provides a broader quality management framework applicable across industries, while specialized certifications like AS9100 (aerospace) and ISO 13485 (medical devices) add industry-specific requirements.

For demanding applications, look for fabricators who maintain detailed measurement capabilities. Much like referencing a drill bit size chart or drill size chart ensures you're using the right tool for precise holes, working with certified fabricators ensures you're partnering with shops equipped to verify and document the precision they achieve.

The bottom line? Tolerance specifications directly impact both product performance and manufacturing costs. Understanding these relationships helps you communicate requirements effectively and select fabrication partners capable of meeting your precision needs consistently. But precision is just one factor in successful sheet metal projects—cost considerations often determine whether a design is commercially viable.

Cost Factors in Sheet Metal Product Manufacturing

You've specified your tolerances, selected your materials, and identified the products you need. Now comes the question that often determines whether a project moves forward: what will it actually cost? Understanding the true cost of sheet metal fabrication products requires looking beyond simple per-piece pricing to examine the factors that drive manufacturing expenses throughout the concept-to-finished-product journey.

According to JLCCNC, pricing depends on multiple variables—from material choice to finishing options and production volume. A clear view of what drives sheet metal part pricing can help you make better design decisions early on and avoid unnecessary expenses later. Let's break down the key cost drivers you need to understand.

Design Decisions That Impact Your Budget

Here's something many engineers discover too late: the biggest cost-saving opportunities exist during the design phase—not during production. Every bend, hole, and weld you add increases setup time, tooling requirements, and machining operations. A simple laser-cut bracket costs far less to produce than an enclosure with multiple bends, countersinks, and welded corners.

How do specific design choices affect your bottom line?

- Material selection: The metal you choose has the biggest impact on cost. Cold-rolled steel typically offers the lowest price point, followed by aluminum. Stainless steel costs more but provides superior durability and corrosion resistance. JLCCNC notes that 1.2 mm stainless steel can cost 40-60% more to process than 0.8 mm mild steel due to increased machine load and slower cutting speeds.

- Material thickness: Thicker sheets require more force to bend and cut, increasing tool wear and production time. Choose the thinnest material that still meets your structural requirements—this balances strength with manufacturability.

- Bend complexity: Each additional bend adds setup time and increases the risk of cumulative tolerance errors. Simplified geometries reduce both production costs and quality issues.

- Hole patterns and features: Countersinks, complex cutouts, and tight hole spacing require more precise tooling and slower processing speeds.

- Welded joints: Every welded seam adds labor time, requires skilled operators, and may necessitate post-weld finishing operations.

- Tolerance requirements: Tighter tolerances (such as ±0.05 mm instead of ±0.2 mm) demand slower cutting speeds, additional quality checks, and more experienced operators—all of which increase costs.

The practical takeaway? If your design doesn't require extreme precision, relaxing certain tolerances is a straightforward way to reduce costs without affecting performance. When searching for fabrication shops near me or browsing platforms like Oshcut for instant quoting, you'll notice how tolerance specifications directly influence pricing.

Volume Considerations for Cost Optimization

Economies of scale significantly impact sheet metal fabrication costs. Why does a batch of 500 parts have a much lower unit price than a batch of 5? Because setup costs—programming, tooling configuration, material handling—get spread across more items.

Consider these volume-related factors:

- Setup and programming: Whether you're making 10 parts or 1,000, the initial CNC programming, tool setup, and first-article inspection take roughly the same time. Higher volumes amortize these fixed costs across more units.

- Tooling investments: Custom dies and fixtures make sense for high-volume production but add prohibitive costs to small runs. Standard tooling keeps prototype costs manageable.

- Material efficiency: Larger production runs allow better nesting optimization—fitting more parts onto each sheet with less waste. Single prototypes often sacrifice material efficiency.

- Lead time pressures: Standard production typically takes 5-7 days, but rush orders may include a 20-40% surcharge to prioritize your job on the factory floor.

If you need consistent parts across multiple projects, batch manufacturing proves more cost-effective in the long run. For one-off prototypes or engineering samples, on-demand fabrication services let you pay only for what you need without committing to minimum quantities.

Secondary Operations and Finishing Requirements

The fabrication process rarely ends with cutting and bending. Secondary operations and surface finishing often add 15-40% to base manufacturing costs—sometimes more for specialized requirements:

- Powder coating services: Typically add $2-5 per part depending on size and complexity. This durable finish provides excellent corrosion protection and aesthetic appeal in virtually any color.

- Anodizing: Ranges from $3-8 per part for aluminum components, creating a harder, more corrosion-resistant surface layer.

- Zinc plating: Generally $1-3 per part, offering economical corrosion protection for steel components.

- Hardware insertion: Self-clinching nuts, studs, and standoffs add per-piece costs plus insertion labor.

- Assembly operations: Multi-component assemblies require additional handling, fixtures, and quality verification.

Reducing Costs Through DFM Support

Design for Manufacturability (DFM) support represents one of the most valuable services a metal fabrication near me partner can offer. Experienced fabricators review your designs before production, identifying opportunities to:

- Simplify geometries without sacrificing function

- Standardize bend radii and hole sizes to use common tooling

- Optimize material utilization through better nesting

- Reduce tolerance specifications where tight precision isn't functionally necessary

- Suggest alternative materials that meet requirements at lower cost

By making these choices early in the design stage, you can achieve up to 30% cost savings without sacrificing part quality. The key is engaging with fabrication partners during design—not after drawings are finalized and changes become expensive.

Understanding these cost drivers helps you communicate effectively with potential fabrication partners and make informed decisions about design trade-offs. But knowing what drives costs is just the first step—selecting the right manufacturing partner determines whether your project delivers the quality, precision, and value you need.

Choosing the Right Fabrication Partner

You've designed your parts, specified materials, and established tolerance requirements. Now comes a decision that will determine whether your project succeeds or stumbles: selecting the right fabrication partner. Whether you're searching for metal fabricators near me or evaluating steel fabricators across the country, the evaluation process requires looking beyond price quotes to assess capabilities, quality systems, and production capacity.

According to Atscott MFG, true value lies in the fabricator's capabilities, reliability, and ability to meet your project requirements from start to finish. A partner who can deliver rapid prototypes, maintain consistent quality across production runs, and provide engineering support throughout the process will save you far more than any initial price difference might suggest.

Evaluating Fabrication Capabilities

Not every metal fab shop handles every project equally well. Before requesting quotes, get clear on your project requirements—then evaluate potential partners against those specific needs. Here's what to assess:

- Equipment and technology: Does the shop have the machinery your project requires? Look for CNC laser cutters, press brakes with adequate tonnage, automated welders, and plasma cutting systems appropriate for your materials and thicknesses. Advanced equipment enables precise, consistent production while reducing costly errors.

- Material expertise: Not every fabricator works with all metals. Whether your project uses stainless steel, aluminum, or specialized alloys, confirm the shop has experience with your specific materials. Ask about their material sourcing and storage practices—proper handling prevents contamination and ensures traceability.

- Capacity and scalability: Can the fabricator handle your volume requirements? As Metal Works notes, the right manufacturing partner should be able to scale production to meet your needs—whether you need low-volume rapid prototypes or high-volume production runs.

- Quality certifications: Verify certifications relevant to your industry. ISO 9001 provides baseline quality assurance, while IATF 16949 certification demonstrates automotive-grade quality systems. For aerospace or medical applications, look for AS9100 or ISO 13485 compliance respectively.

- Secondary services: One-stop facilities that offer in-house finishing, assembly, and hardware insertion streamline production and reduce lead times. When parts don't need to travel between multiple vendors, you avoid delays and maintain better quality control.

Think about the specialized equipment that supports quality fabrication. A well-equipped shop maintains proper fixtures—including sturdy welding table setups for consistent weld positioning—and invests in operator safety with equipment like auto darkening welding helmet protection. These details indicate a professional operation focused on quality and worker safety.

From Prototype to Production

Here's a scenario that plays out frequently: an engineer finalizes a design, sends it directly to production, and discovers during assembly that parts don't fit together properly. Changes at this stage are expensive—requiring new tooling, scrapped materials, and production delays.

Rapid prototyping solves this problem by validating designs before mass production begins. Metal Works highlights that their 1-3 day rapid prototypes allow customers to review tangible models to determine if designs are ready for large-scale production. This approach catches issues when changes are still inexpensive to implement.

What should you expect from effective prototype development?

- Speed: Look for partners offering rapid turnaround—ideally 5 days or less for initial prototypes. Faster iteration means quicker time-to-market.

- Production-equivalent processes: Prototypes should use the same fabrication methods planned for production. A prototype made with different equipment or techniques won't reveal manufacturing issues you'll face at scale.

- DFM feedback: Experienced fabricators review prototype designs and suggest improvements for manufacturability. Metal Works emphasizes that expert teams provide Design for Manufacturability aid free of charge, ensuring designs are fully optimized before production.

- Quick quote turnaround: The evaluation process shouldn't take weeks. Responsive partners provide quotes within hours—not days—allowing you to make timely decisions.

Complex parts sometimes require specialized forming equipment like a tube bender for curved components or dedicated tooling for unusual geometries. Confirm your fabrication partner has the specific capabilities your designs require before committing to production.

Essential Questions for Potential Partners

Before finalizing your selection, gather the information you need to make an informed decision. These questions help you evaluate whether a fabricator can truly deliver on their promises:

- What certifications do you hold, and can you provide documentation?

- What is your typical lead time for prototypes versus production runs?

- How do you handle design for manufacturability review?

- What is your on-time delivery rate, and how do you track it?

- Can you provide references from customers in my industry?

- What quality inspection processes do you use, and what documentation accompanies shipments?

- How do you handle engineering changes during production?

- What is your quote turnaround time, and how detailed are your estimates?

- Do you offer assembly and secondary finishing services in-house?

- What communication channels exist for project updates and issue resolution?

Pay attention to how potential partners respond. A skilled project manager or representative should walk you through their fabrication process with confidence and clarity, demonstrating genuine understanding of your requirements rather than just promising whatever you want to hear.

What Capable Partners Look Like in Practice

Concrete examples help illustrate what to look for in a fabrication partner. Consider Shaoyi (Ningbo) Metal Technology, which exemplifies the capabilities discussed throughout this section. They offer 5-day rapid prototyping that allows design validation before production commitment, backed by IATF 16949 certification demonstrating automotive-grade quality systems.

Their comprehensive DFM support helps optimize designs for manufacturability—catching potential issues before they become expensive production problems. A 12-hour quote turnaround enables fast decision-making, while their specialization in automotive chassis, suspension, and structural components demonstrates the focused expertise that comes from deep industry experience.

This combination of rapid response, verified quality systems, engineering support, and specialized expertise represents the standard you should expect from any serious fabrication partner—regardless of whether your application is automotive, industrial, or consumer-focused.

Making the Final Decision

Selecting a fabrication partner isn't just about finding the lowest quote. Consider the total value: Will they catch design issues before production? Can they scale with your growth? Do they have the quality systems your industry demands?

The right partner becomes an extension of your engineering team—providing expertise, solving problems proactively, and delivering consistent quality across every production run. That relationship delivers far more value than any initial price savings from choosing the cheapest option available.

Take the time to evaluate capabilities thoroughly, ask detailed questions, and request samples or facility tours when possible. The fabrication partner you select today will influence your product quality, production costs, and time-to-market for years to come.

Frequently Asked Questions About Sheet Metal Fabrication Products

1. What are the common materials used in sheet metal fabrication?

The most popular materials include carbon steel (affordable, strong, requires coating), galvanized steel (corrosion-resistant for HVAC and automotive), stainless steel 304 and 316 (excellent corrosion resistance for food and medical equipment), aluminum alloys (lightweight, ideal for aerospace and electronics), and brass/copper (superior electrical conductivity). Material selection depends on your application's requirements for strength, weight, corrosion resistance, and budget.

2. How much does it cost to fabricate sheet metal?

Sheet metal fabrication costs vary based on material choice, design complexity, volume, tolerances, and finishing requirements. Cold-rolled steel offers the lowest cost, while stainless steel can cost 40-60% more to process. Higher volumes reduce per-unit costs through setup amortization. Secondary operations like powder coating add 15-40% to base costs. Working with fabricators offering DFM support can reduce expenses by up to 30% through design optimization before production.

3. What products do sheet metal workers make?

Sheet metal fabrication produces diverse products including electrical enclosures, server racks, HVAC ductwork, automotive body panels and chassis components, medical equipment housings, surgical instrument trays, aerospace structural brackets, appliance housings, furniture components, and custom metal signs. These products span virtually every industry from consumer electronics to defense applications.

4. What tolerances can sheet metal fabrication achieve?

Tolerance capabilities vary by process: laser cutting achieves ±0.05 mm to ±0.5 mm, press brake bending delivers ±0.4 mm to ±0.8 mm linear and ±0.5° to ±1° angular tolerances, punching reaches ±0.1 mm to ±0.25 mm, and welding typically allows ±0.5 mm to ±2 mm. Material type and thickness also affect achievable precision, with stainless steel generally permitting tighter tolerances than aluminum.

5. How do I choose the right sheet metal fabrication partner?

Evaluate potential partners based on equipment capabilities (CNC lasers, press brakes, welding systems), relevant certifications (ISO 9001, IATF 16949 for automotive), material expertise, prototyping speed, production capacity, and in-house secondary services. Look for partners offering DFM support, rapid quote turnaround, and strong communication. Request references from customers in your industry and verify their on-time delivery track record.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —