Sheet Metal Bracket Manufacturer Secrets: What Suppliers Won't Tell You

What Sheet Metal Brackets Are and Why They Matter

Ever wondered what keeps your wall-mounted TV secure or holds heavy machinery in place? The answer often lies in a deceptively simple component that most people overlook: the sheet metal bracket. These unassuming connectors serve as the backbone of countless structures across industries, yet few buyers truly understand what makes them essential.

The Engineering Definition of Sheet Metal Brackets

So, what is a bracket in engineering? At its core, a bracket is a structural component designed to connect, support, or stabilize two or more surfaces along one edge. When crafted from sheet metal, these brackets gain unique properties that make them indispensable in modern manufacturing.

A sheet metal bracket is a formed metal support structure, typically manufactured from flat metal sheets ranging from 0.3 to 6 millimeters thick, shaped through processes like bending, stamping, and cutting to create rigid connections between components.

The simplest form you'll encounter is a rectangular flat piece bent at a 90-degree angle, creating that familiar L-shape. However, metal brackets extend far beyond this basic design. Depending on application requirements, manufacturers produce complex geometries featuring multiple bends, mounting holes, and reinforcement features.

Why Sheet Metal Outperforms Other Bracket Materials

You might ask: why choose sheet metal over cast brackets, machined parts, or plastic alternatives? The answer comes down to three critical advantages:

- Exceptional formability: Sheet metal can be bent, stamped, and shaped into virtually any configuration without compromising structural integrity. This flexibility allows metal support brackets to meet precise specifications that other materials simply cannot match.

- Superior strength-to-weight ratio: Compared to cast or machined alternatives, sheet metal brackets deliver comparable load-bearing capacity at a fraction of the weight. This matters tremendously in automotive, aerospace, and electronics applications where every gram counts.

- Cost-effective production: Sheet metal stamping and fabrication processes enable high-volume production at lower per-unit costs than casting or CNC machining, making these brackets economically viable for everything from prototypes to mass production runs.

Additionally, bracket construction from sheet metal offers inherent corrosion resistance when paired with appropriate surface treatments like powder coating, anodizing, or zinc plating.

Core Functions Brackets Serve Across Industries

Understanding what brackets actually do helps you appreciate their engineering significance. Every sheet metal bracket performs one or more of these primary functions:

- Load transfer: Brackets distribute weight and mechanical forces from one structural element to another. Think of how a shelf bracket transfers the weight of books from the shelf surface to the wall studs.

- Structural support: In machinery and construction, brackets provide the rigid framework that holds components in precise alignment. Without proper metal support, critical assemblies would shift, vibrate, or fail entirely.

- Component mounting: From securing electronic enclosures to attaching motors and sensors, brackets create the interface between functional components and their supporting structures.

These functions appear across remarkably diverse applications. In construction, brackets hold up shelves, cabinets, and structural elements. In machinery, they secure motors, electronic components, and critical equipment. Even in your home, sheet metal brackets work invisibly behind wall-mounted televisions and kitchen cabinets.

The versatility of these components explains why finding the right sheet metal bracket manufacturer matters so much. The difference between a well-engineered bracket and a poorly designed one can mean the difference between decades of reliable service and premature structural failure.

Complete Guide to Bracket Types and Their Applications

Now that you understand what sheet metal brackets do, the next question becomes: which type do you actually need? This is where many buyers get confused. Walk into any hardware store or browse a manufacturer's catalog, and you'll encounter an alphabet soup of shapes: L-brackets, Z-brackets, U-brackets, and more. Each serves distinct purposes, and choosing incorrectly can lead to mounting failures, wasted materials, or costly redesigns.

Let's break down the complete taxonomy of types of metal brackets so you can specify exactly what your application demands.

| Type | Shape Description | Primary Applications | Load Characteristics |

|---|---|---|---|

| L-Bracket | Single 90-degree bend forming an L shape | Corner mounting, shelf support, perpendicular connections | Strong in compression and tension along mounting surfaces |

| Z-Bracket | Two parallel bends creating offset flanges pointing opposite directions | Panel offsets, tiered mounting, airflow spacing | Handles shear loads between parallel planes |

| U-Bracket | Two bends at facing angles creating a channel shape | Component retention, parallel surface mounting, cable routing | Excellent for clamping and lateral containment |

| C-Bracket | Three bends forming a C or channel profile | Structural framing, equipment mounting, enclosure support | High rigidity for spanning distances |

| T-Bracket | T-shaped profile with perpendicular mounting surface | Junction connections, partition mounting, cross-bracing | Distributes loads across multiple attachment points |

| Angle Bracket | Similar to L-bracket but often with reinforcing features | Heavy-duty corner reinforcement, structural connections | Enhanced load capacity through added material or gussets |

L-Brackets and Angle Brackets for Corner Mounting

When you need to connect two surfaces at a perpendicular angle, l shape metal brackets are your go-to solution. Picture mounting a horizontal shelf to a vertical wall. The L-bracket's simple geometry creates a rigid 90-degree connection that transfers vertical loads into the mounting surface.

According to Protocase's bracket guide, L-brackets can actually be bent to angles beyond 90 degrees, up to 120 degrees, when your application requires non-perpendicular connections. This flexibility makes them incredibly versatile for custom installations.

Here's when to choose L-brackets:

- Mounting horizontal components to vertical surfaces

- Installing shelving inside electronic enclosures

- Creating perpendicular structural connections

- Supporting lightweight to medium loads where simplicity matters

Angle brackets function similarly but typically incorporate reinforcing features like gussets or thicker material gauges for heavier loads. When your application involves significant weight or vibration, upgraded angle brackets provide the extra strength margin you need.

Z-Brackets and U-Brackets for Offset Applications

What happens when you need to mount components at different heights or create spacing between surfaces? This is where metal z bracket configurations become essential.

Imagine you're designing an electronic enclosure where circuit boards need airflow beneath them. A Z-bracket creates that precise offset between the mounting surface and the component. The two parallel flanges point in opposite directions, creating a step that positions your part exactly where it needs to be.

Z-brackets excel in these scenarios:

- Anchoring components at different levels within enclosures

- Creating ventilation gaps for heat dissipation

- Mounting panels with offset requirements

- Positioning parts that require clearance from adjacent surfaces

The metal bracket u configuration, commonly called a U-channel bracket, takes a different approach. Instead of offsetting surfaces, the u shape brace creates a channel that hugs components from both sides. As noted by Approved Sheet Metal, U-brackets are ideal for mounting parallel surfaces together and retaining components like power supplies or hard drives.

Think of installing a power supply inside a server chassis. The U-bracket wraps around the component, securing it from multiple angles while providing stable mounting points on each flange.

Specialty Shapes Including T-Brackets and S-Brackets

Beyond the common shapes, specialty brackets address unique mounting challenges that standard configurations cannot solve.

The metal t bracket creates junction connections where three surfaces meet. You'll find these in partition systems, cross-bracing applications, and anywhere you need to distribute loads across multiple attachment points simultaneously. Their T-profile provides mounting surfaces in perpendicular planes, making them invaluable for complex assemblies.

The metal c bracket, sometimes called a hat channel bracket, serves a specialized purpose. According to industry sources, these hat-shaped brackets are typically welded inside parts made of weaker metal to prevent them from collapsing inward. You'll often encounter them reinforcing metal doors or thin-walled enclosures.

S bracket metal configurations feature an S-curve profile that creates offset mounting with smooth transitions. These find applications where gradual elevation changes are needed rather than sharp steps, particularly in architectural and decorative installations.

Gusset brackets deserve special mention. These triangular reinforcement brackets don't mount components directly. Instead, they're welded into structural joints to add rigidity between adjacent surfaces. Think of them as the invisible strength behind bridges, heavy equipment frames, and load-bearing assemblies.

Choosing the right bracket type isn't just about shape preference. It's about matching the geometry to your specific mounting requirements, load conditions, and space constraints. A reputable sheet metal bracket manufacturer will help you navigate these decisions, but understanding the fundamentals yourself ensures you ask the right questions from the start.

With bracket types clarified, the next critical decision involves material selection. Steel, stainless steel, and aluminum each bring distinct advantages depending on your application environment and performance requirements.

Material Selection for Sheet Metal Brackets

You've identified the right bracket shape for your project. Now comes a decision that will determine whether your brackets last decades or fail within months: material selection. This is where many buyers make costly mistakes, choosing based on price alone while ignoring critical factors like operating environment and load requirements.

The three dominant materials in bracket manufacturing are steel, stainless steel, and aluminum. Each brings distinct advantages, and understanding their trade-offs separates informed buyers from those who learn expensive lessons after installation.

| Property | Steel | Stainless Steel | Aluminum |

|---|---|---|---|

| Tensile Strength | 400-550 MPa (carbon steel) | 515-620 MPa (304/316 grades) | 90-310 MPa (depending on alloy) |

| Corrosion Resistance | Low (requires coating) | High (excellent in marine environments) | Good (natural oxide layer) |

| Weight | Heavy (7.85 g/cm³) | Heavy (8.0 g/cm³) | Light (2.7 g/cm³) |

| Relative Cost | Low | High | Medium |

| Best Applications | Indoor structures, heavy-duty industrial, cost-sensitive projects | Marine, food processing, outdoor, chemical exposure | Aerospace, electronics, portable equipment |

Steel Brackets for Maximum Strength and Economy

When raw strength and budget matter most, steel brackets deliver unmatched value. Carbon steel offers the highest tensile strength among common bracket materials, making it the default choice for heavy-duty industrial applications and structural steel supports.

According to Worthy Hardware's bracket guide, steel is known for its high tensile strength and durability, making it a common choice for heavy-duty applications while remaining quite cost-effective.

Here's where steel grades matter:

- Mild steel (A36/1018): Most common for general-purpose brackets. Easy to form and weld, suitable for indoor applications with proper coating.

- High-strength low-alloy (HSLA): When you need better strength without significant weight increase. Common in automotive and construction brackets.

- Tool steel: Reserved for brackets experiencing extreme wear or impact loads.

The critical consideration with any steel bracket is corrosion protection. Raw steel will rust when exposed to moisture, so surface treatment becomes mandatory for most applications:

- Galvanized steel: Hot-dip or electro-galvanized zinc coating provides excellent outdoor protection at moderate cost. Ideal for construction and agricultural applications.

- Powder-coated steel: Offers superior aesthetics with good corrosion resistance. Popular for visible applications like shelving and furniture hardware.

- Black steel brackets: These feature a black oxide or paint finish primarily for indoor use. The dark finish provides minimal corrosion protection but works well in controlled environments.

For gauge selection, heavier loads demand thicker material. A standard rule: 16-gauge steel handles light-duty mounting, 14-gauge suits medium loads, and 12-gauge or thicker becomes necessary for structural applications.

Stainless Steel Brackets for Corrosive Environments

When your brackets will face moisture, chemicals, or outdoor exposure, stainless steel mounting brackets become worth their premium price. The chromium content in stainless steel forms a self-healing oxide layer that resists corrosion far better than coated carbon steel.

As Monarch Metal explains, stainless steel offers high strength along with corrosion resistance, especially true when using 316 stainless steel in marine environments, making it a dependable solution for demanding environments.

The two grades you'll encounter most often:

- 304 Stainless Steel: The workhorse grade for most applications. Excellent corrosion resistance for indoor, outdoor, and food-contact environments. Suitable for most stainless steel bracket applications.

- 316 Stainless Steel: The marine-grade choice. Contains molybdenum for enhanced resistance to salt water, chlorides, and industrial chemicals. Essential for coastal installations and chemical processing equipment.

Beyond corrosion resistance, stainless steel offers another advantage: it requires no additional coating or finishing. The natural finish remains clean and professional, making it popular for visible applications in medical, food service, and architectural installations.

The trade-off? Stainless steel costs significantly more than carbon steel, sometimes two to three times as much. It's also harder to machine and form, which can increase manufacturing costs. Reserve stainless steel for applications where its properties genuinely justify the investment.

Aluminum Brackets When Weight Reduction Matters

Imagine mounting brackets in an aircraft where every gram affects fuel efficiency, or in portable equipment that workers carry daily. This is where aluminum brackets mounting solutions become invaluable.

Aluminum weighs roughly one-third as much as steel while offering respectable strength and natural corrosion resistance through its oxide layer. According to Monarch Metal, aluminum is lightweight, easy to fabricate, and naturally resistant to corrosion thanks to its protective oxide layer, making it ideal for both indoor and outdoor use.

Common aluminum alloys for brackets include:

- 6061-T6: The most popular choice, offering good strength, weldability, and corrosion resistance. Suitable for most bracket applications where weight matters.

- 5052: Excellent formability and corrosion resistance, particularly in marine environments. Slightly lower strength than 6061.

- 7075: High-strength aluminum approaching some steel grades. Reserved for aerospace and performance applications where maximum strength-to-weight ratio is critical.

Aluminum's lower strength compared to steel means you'll often need thicker material or additional reinforcement features to achieve equivalent load capacity. A bracket that works in 16-gauge steel might require 12-gauge aluminum for the same application.

For surface finishing, anodizing provides the gold standard for aluminum brackets. This electrochemical process creates a hard, durable oxide layer that enhances corrosion resistance while allowing color customization. Powder coating also works well on aluminum, though proper surface preparation is essential for adhesion.

Selecting the right material is only half the equation. How that material gets transformed into a finished bracket determines both quality and cost. Understanding manufacturing processes helps you specify brackets that balance performance requirements with budget realities.

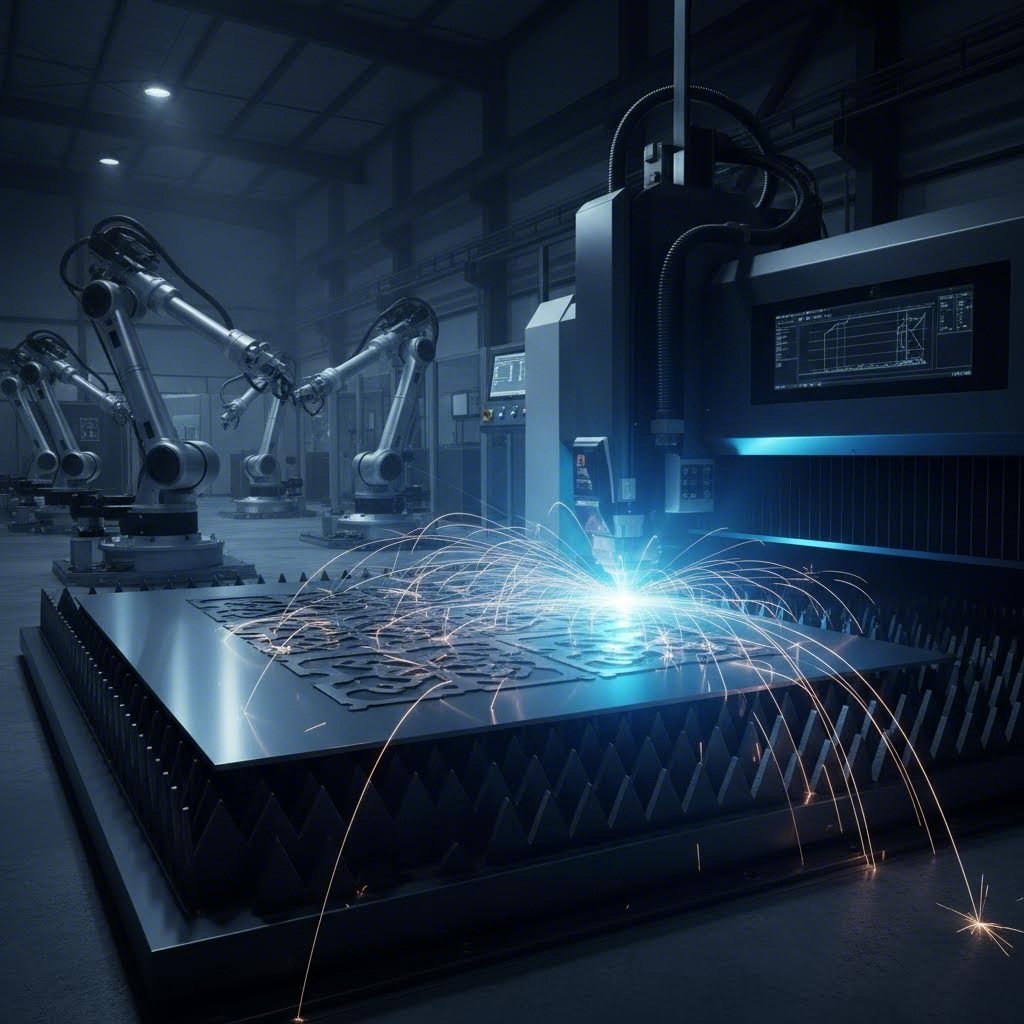

How Sheet Metal Brackets Are Manufactured

You've chosen your bracket shape and material. But here's what most suppliers won't tell you: the manufacturing method impacts everything from unit cost to dimensional accuracy. Understanding these processes puts you in control when evaluating quotes and negotiating with suppliers.

Two fundamentally different approaches dominate bracket fabrication: traditional sheet metal fabrication and metal stamping. According to Approved Sheet Metal, the number one reason fabricators decline quotes is because the part requires stamping capabilities instead. Knowing the difference prevents costly mismatches between your project needs and manufacturer capabilities.

Laser Cutting and CNC Bending for Precision Fabrication

When you need prototypes, low volumes, or frequently revised designs, bracket fabrication using CNC equipment delivers the flexibility you need. This approach uses standard tooling to create custom shapes without expensive die investments.

Here's how fabricated brackets come to life:

- Laser cutting: CNC laser cutters trace your bracket's flat pattern from sheet stock, achieving precise cuts with minimal material waste. Complex hole patterns and intricate contours pose no problem for modern fiber lasers.

- CNC bending: Press brakes equipped with computer-controlled back gauges form the flat blank into your specified shape. Operators program bend sequences to achieve accurate angles while accounting for material springback.

- Punch forming: For brackets requiring mounting holes, CNC punch presses create precise openings faster than laser cutting. Standard tooling handles common hole sizes and shapes.

- Bracket welding: When designs require joining multiple pieces or adding reinforcement, skilled welders apply MIG, TIG, or spot welding to create strong, durable connections.

The beauty of bracket CNC fabrication lies in its setup simplicity. Your first part costs essentially the same as your hundredth part because no custom tooling is required. This makes fabrication ideal for appliance bracket fabrication projects requiring customization or frequent design iterations.

However, industry data reveals important tolerance limitations. Fabrication typically achieves ±0.005" to ±0.015" accuracy, with bending operations introducing slight variances due to material springback. Welded assemblies often require additional machining to meet tight specifications.

Progressive Die Stamping for High-Volume Production

What happens when you need thousands or millions of identical brackets? This is where progressive die stamping transforms economics entirely.

Unlike fabrication's standard tooling approach, stamping uses custom dies designed specifically for your bracket. A single press applies a series of dies that cut, form, and shape the bracket in one continuous operation.

- Die design and construction: Engineers create custom tooling that replicates every feature of your bracket. This upfront investment can cost tens of thousands of dollars but pays dividends at volume.

- Coil feeding: Sheet metal feeds into the press from large coils rather than individual blanks, enabling continuous high-speed production.

- Progressive forming: The material advances through multiple die stations, with each station performing a specific operation until the finished bracket exits the press.

- Automatic ejection: Completed brackets drop into collection bins while the next piece is already forming, maximizing throughput.

The precision advantage of stamping is substantial. According to Approved Sheet Metal, stamping achieves tolerances as tight as ±0.001" to ±0.005", particularly for complex geometries. Every feature is formed with extreme repeatability because the custom tooling eliminates setup variations between parts.

Roll steel bracket production using progressive dies can achieve production rates of thousands of parts per hour. Deep draw presses handle complex shapes requiring significant material flow, while mechanical servo presses offer flexibility for varied production speeds.

How Manufacturing Method Affects Quality and Cost

Choosing between fabrication and stamping isn't just about preference. It's about matching the process to your specific requirements. Consider these decision factors:

- Volume threshold: CNC brackets make sense for quantities under a few thousand pieces. Above that threshold, stamping's per-unit cost advantages typically overcome tooling investments.

- Tolerance requirements: If your assembly demands tight fits with minimal adjustment, stamping's superior repeatability justifies the tooling cost. Fabrication works when designs accommodate slight variations.

- Design maturity: Prototyping and early production favor fabrication's flexibility. Once designs stabilize, transitioning to stamping optimizes long-term costs.

- Feature complexity: Deep draws, tiny parts under 1", and features exceeding sheet thickness capabilities require stamping. Fabrication handles traditional formed features like embossments and louvers effectively.

As Protolabs notes, precision varies across manufacturing methods. Designers cannot expect machining-like tolerances from sheet metal processes. Understanding this reality helps you specify realistic requirements and avoid costly rework.

One critical insight from Approved Sheet Metal: a customer once requested quotes for simple single-bend brackets, only to discover their curved bend design required a $13,000 custom tool. Consulting with manufacturers during the design phase prevents such surprises.

With manufacturing processes understood, the next challenge involves translating your functional requirements into precise engineering specifications. Getting design details right from the start saves both time and money throughout production.

Design Considerations for Custom Bracket Engineering

You've selected your bracket type, material, and manufacturing method. But here's what separates successful projects from costly failures: the engineering details. A bracket that looks perfect on paper can fail spectacularly in service if designers overlook fundamental principles like load capacity, stress distribution, and proper bracket dimensions.

Think of bracket design as a balancing act. You're optimizing strength against weight, cost against precision, and functionality against manufacturability. Understanding these trade-offs helps you communicate effectively with any sheet metal bracket manufacturer and avoid the redesigns that plague poorly specified projects.

Load Capacity Calculations and Safety Factors

How much weight can your bracket actually support? This question seems simple, but the answer involves more nuance than most buyers realize.

According to TZR Metal's design guide, material strength is a key factor in sheet metal bracket design. The material must handle the expected load without failing. Three strength measurements matter most:

- Tensile strength: The maximum pulling force the material can resist before breaking. This determines ultimate failure limits.

- Yield strength: The stress level where permanent deformation begins. Brackets should operate well below this threshold during normal use.

- Fatigue strength: Critical for brackets subjected to repeated loading cycles. A bracket might survive a single heavy load but fail after thousands of smaller cycles.

To ensure your bracket design handles real-world conditions, engineers apply safety factors. The formula is straightforward:

Safety Factor = Material Yield Strength ÷ Expected Maximum Stress

What safety factor should you specify? According to TZR Metal, standard applications typically use factors of 1.5 to 2, while critical applications like aerospace or structural supports require 2.5 to 3. Higher factors account for load variations, material inconsistencies, and unexpected stress events.

Material thickness directly impacts load capacity. Thinner materials offer flexibility and easier forming but sacrifice strength. As a practical guideline:

- Light-duty mounting: 18-20 gauge material

- Medium loads and general industrial use: 14-16 gauge

- Heavy-duty structural applications: 12 gauge or thicker

For bracket designs requiring strength without excessive weight, consider structural reinforcement alternatives. Ribbed stamping patterns, honeycomb designs, or flanged edges can dramatically increase rigidity without adding significant material thickness.

Mounting Hole Patterns and Fastener Selection

Sounds complex? It doesn't have to be. Proper hole placement and bracket fasteners selection follow logical principles that ensure reliable connections.

The placement and number of holes in bracket plates directly affect load distribution. According to TZR Metal, the size and spacing of holes must be carefully designed to ensure proper load distribution across the mounting surface.

Here's your design checklist for mounting features:

- Edge distance: Maintain minimum distance of 2-3 times the hole diameter from any edge. This prevents tear-out under load.

- Hole spacing: Space mounting holes at least 3 times the hole diameter apart to avoid stress concentration between fastener points.

- Hole size tolerance: Standard clearance holes allow ±0.005" to ±0.010" larger than fastener diameter for assembly flexibility.

- Pattern symmetry: Symmetric hole patterns distribute loads evenly and simplify installation.

According to Xometry's design tips, features placed too close to bend lines can cause deformation, stress accumulation, or tooling complications. Keep holes and slots at least 2.5 times material thickness away from any bend radius.

Fastener selection depends on your specific application:

- Through bolts with nuts: Maximum strength and adjustability. Ideal for heavy loads and applications requiring disassembly.

- Self-clinching fasteners: Pressed into the bracket material for permanent threads. Perfect for thin materials where tapping isn't practical.

- Weld nuts and studs: When back-side access is impossible, welded fasteners provide secure attachment points.

- Rivets: For permanent assemblies where vibration resistance matters more than adjustability.

Stress Distribution and Reinforcement Strategies

Imagine loading a bracket until it fails. Where does the crack start? Almost always at a stress concentration point, typically a sharp corner, small radius, or abrupt geometry change in the load path.

According to Fictiv's engineering guide, a stress concentration is defined as high localized stress compared to the average stress of the body, typically found in regions with abrupt geometric changes or discontinuities. The body tends to fail at these locations first.

The stress concentration factor quantifies this risk:

Stress Concentration Factor (Kt) = Maximum Stress ÷ Average Stress

Components with sharper corners have higher stress concentration factors and fail sooner. The good news? Simple design changes dramatically reduce stress concentrations:

- Increase bend radii: According to TZR Metal, the minimum bend radius should be at least 1.5 to 2 times the material thickness. Larger radii reduce stress concentration at bend points.

- Avoid sharp internal corners: Replace 90-degree internal angles with generous fillets. Even small radii improvements yield significant stress reduction.

- Add relief holes: At the end of slits or cuts, drill stress-relieving holes to prevent crack propagation.

- Limit size transitions: Gradual thickness changes perform better than abrupt steps between thick and thin sections.

As demonstrated in Fictiv's FEA analysis, increasing a corner radius from 0.010" to 0.080" reduced peak stress from 14,419 psi to 3,873 psi. That's nearly a 75% reduction from a simple geometry change.

Flanges deserve special attention in bracket designs. These extended edges help distribute loads more evenly and increase overall rigidity. Larger flanges spread force across wider areas, reducing stress at any single point.

When specifying tolerances, match your requirements to manufacturing realities. According to Xometry, general tolerancing guidelines suggest:

- Linear dimensions: ±0.010" to ±0.020" for most fabricated brackets

- Bend angles: ±1° to ±2° depending on material and process

- Hole positions: ±0.005" to ±0.015" from nominal

- Flatness: 0.010" per inch for unstressed areas

Stamped brackets achieve tighter tolerances, potentially ±0.001" to ±0.005", but fabricated parts require more generous specifications. Requesting machining-level precision from sheet metal processes leads to rejected parts and project delays.

Armed with proper design knowledge, your next challenge involves understanding how different industries apply these principles. Automotive, aerospace, and electronics each demand unique certifications and specifications that reputable manufacturers must meet.

Industry-Specific Bracket Requirements and Certifications

You've mastered bracket types, materials, and design principles. But here's what separates amateur buyers from professionals: understanding that a bracket perfect for one industry might fail catastrophically in another. The automotive brackets holding your car's exhaust system face entirely different challenges than the electronic bracket securing a server's power supply. And the certifications that prove a manufacturer can handle these differences? Most buyers don't know what they actually mean.

Let's decode the industry-specific requirements that bracket industries must meet and explain what those alphabet-soup certifications really guarantee about quality.

| Industry | Key Certifications | Typical Tolerances | Common Materials | Special Requirements |

|---|---|---|---|---|

| Automotive | IATF 16949, ISO 9001 | ±0.005" to ±0.015" | Steel, HSLA, galvanized steel | PPAP documentation, statistical process control, total productive maintenance |

| Aerospace | AS9100D, NADCAP | ±0.003" to ±0.001" | Titanium, 7075 aluminum, Inconel | Full material traceability, first article inspection, configuration management |

| Electronics | ISO 9001, IPC standards | ±0.010" to ±0.020" | Aluminum, stainless steel | EMI shielding, thermal management, precise mounting for PCB alignment |

| Construction | ISO 9001, building codes | ±0.030" to ±0.060" | Galvanized steel, hot-dip zinc | Corrosion resistance, load ratings per code, fire resistance ratings |

Automotive Bracket Requirements and IATF Certification

When you're sourcing automotive brackets, one certification matters above all others: IATF 16949. But what does this actually guarantee about your steel bracket manufacturer's capabilities?

According to Advisera's certification analysis, IATF 16949 extends beyond basic ISO 9001 requirements with automotive-specific controls. The standard, released by the International Automotive Task Force, mandates requirements around process design and control, competence for specific individuals, statistical tools usage, and measurement system analysis.

What does this mean for your brackets? An IATF-certified manufacturer must demonstrate:

- Statistical Process Control (SPC): Every critical dimension is monitored throughout production, not just inspected afterward. Trends get caught before they produce defective parts.

- Total Productive Maintenance: Equipment undergoes scheduled maintenance to prevent unexpected failures that could affect bracket quality.

- Measurement System Analysis: The gauges and instruments measuring your brackets are verified accurate and repeatable.

- PPAP Documentation: Production Part Approval Process ensures your bracket design is frozen and reproducible before mass production begins.

Automotive industrial brackets face punishing conditions: vibration, temperature cycling, road salt, and decades of service life. The IATF framework specifically addresses controls on external providers and very specific control requirements for nonconforming products.

Surface finishes for automotive brackets typically include electrodeposition coating (E-coat), zinc-nickel plating, or powder coating depending on exposure severity. Underbody brackets facing road salt require more robust protection than interior mounting brackets.

Aerospace and Defense Bracket Specifications

Imagine a bracket failing at 35,000 feet. The consequences are catastrophic, which explains why aerospace brackets face the most demanding specifications of any industry.

AS9100D certification represents the gold standard for aerospace manufacturing. According to Yijin Solution's aerospace guide, AS9100D certification establishes the quality management framework for aerospace machining companies, extending ISO 9001 requirements with aerospace-specific controls for configuration management and complete material traceability.

The differences from automotive requirements are substantial. Advisera's comparison explains that AS9100 additions focus on problems such as product safety, management of the exact configuration of each product, and the prevention of the use of counterfeit parts.

What makes aerospace brackets unique?

- Tighter tolerances: According to Yijin Solution, aerospace parts need tolerances within ±0.003" (±0.076 mm) or tighter, with critical dimensions achieving ±0.001" or better.

- Complete traceability: Every bracket must trace back to specific material heat lots, manufacturing dates, and operator records. This enables investigation if issues emerge years later.

- First Article Inspection: The first production bracket undergoes exhaustive dimensional verification before mass production proceeds.

- Configuration management: Any design change, no matter how minor, requires formal approval and documentation.

Material requirements differ dramatically from other industries. Yijin Solution notes that aerospace demands Ti-6Al-4V titanium, 7075 aluminum alloys, and Inconel 718 superalloy, each requiring specialized machining strategies based on thermal conductivity and work hardening characteristics.

Surface treatments for aerospace brackets include anodizing per MIL-A-8625, PVD coating for wear resistance, and shot peening per AMS 2430 to induce compressive stress layers that prevent fatigue cracking. These aren't optional enhancements; they're specified requirements tied to component longevity.

Electronics and Appliance Mounting Brackets

Electronic bracket applications present a different challenge entirely. Instead of withstanding extreme loads or temperatures, these brackets must provide precise alignment, thermal management, and sometimes electromagnetic shielding.

Consider a server rack bracket mounting multiple hard drives. The tolerance requirements center on alignment rather than load capacity. PCB mounting brackets must position circuit boards precisely to ensure connector alignment and proper airflow. Appliance bracket fabrication for consumer electronics prioritizes aesthetics alongside function.

Key requirements for electronics brackets include:

- Dimensional consistency: When mounting multiple components, even small variations accumulate. Tolerances of ±0.010" to ±0.020" ensure reliable assembly.

- Surface conductivity: For EMI shielding applications, brackets must maintain electrical continuity. Conductive finishes like zinc plating or chromate conversion preserve this property.

- Thermal considerations: Brackets mounting heat-generating components often incorporate features for heat sinking or airflow management.

- Cosmetic finish: Visible brackets in consumer products require consistent powder coating, anodizing, or plating with no surface defects.

Material choices for electronics lean toward aluminum for weight savings and thermal conductivity, or stainless steel for durability in commercial equipment. Powder coating dominates finish options, offering color consistency, durability, and electrical insulation when needed.

Brackets for construction applications occupy the opposite end of the precision spectrum. These brackets prioritize load capacity and corrosion resistance over tight tolerances. Hot-dip galvanizing provides decades of outdoor protection, while compliance with building codes ensures structural adequacy. Tolerances of ±0.030" to ±0.060" are typical since field installation accommodates minor variations.

Understanding these industry-specific requirements helps you evaluate whether a potential supplier can actually deliver what your application demands. A manufacturer excelling at high-volume automotive brackets may lack the traceability systems aerospace requires. Conversely, an aerospace-focused shop might not offer the cost efficiency construction projects need.

With industry requirements clarified, your next step involves translating all this knowledge into actionable specifications. Knowing how to communicate your requirements effectively ensures manufacturers quote accurately and deliver exactly what you need.

How to Specify Custom Brackets for Manufacturing

You've identified your bracket type, selected the right material, and understand the design principles. Now comes the moment of truth: communicating your requirements to manufacturers. This is where many projects derail. Incomplete specifications lead to misquoted prices, production delays, and brackets that don't fit your application.

Whether you're an experienced engineer or placing your first custom bracket order, following a structured specification process ensures manufacturers understand exactly what you need. According to TrueCADD's fabrication guide, sheet metal fabricators often face issues with technical drawings that carry insufficient information for executing processes with precision. Without accurately prepared drawings, fabricators are forced to rely on guesswork, leading to wasted material, costly rework, and project delays.

Here's your step-by-step process for specifying custom brackets that get quoted accurately and manufactured correctly:

- Define your bracket's function and load requirements before diving into dimensions. What forces will it experience? What components does it connect?

- Prepare complete dimensional documentation including all critical measurements, tolerances, and geometric relationships.

- Specify material type, grade, and thickness with any required certifications or test reports.

- Determine quantity requirements for both initial orders and projected annual usage.

- Define surface finish and secondary operations including coating type, color, and any post-processing needs.

- Compile supporting documentation such as CAD files, reference samples, or industry specifications.

Essential Dimensions and Drawing Requirements

Imagine sending a manufacturer a sketch on a napkin and expecting a perfect custom metal bracket in return. It won't happen. Technical drawings serve as the fabrication blueprint, and their quality directly determines your outcome.

According to TrueCADD, detailed sheet metal drawings help fabricators by providing them with a comprehensive view of the fabrication process aligned with the design intent. This is especially important for complex designs.

Your drawing package should include:

- Title block information: Drawing number, part description, company details, original scale, and revision level. For specialized materials or processes, include design approval signatures.

- Critical dimensions: All measurements affecting form, fit, or function. Use Geometric Dimensioning and Tolerancing (GD&T) for precise control of critical features.

- Tolerance specifications: General tolerances for non-critical features and specific tolerances for critical dimensions. As noted by LightSource, precise specifications enable direct comparison across supplier quotes and support data-driven selection.

- Multiple views: Primary orthographic views (front, top, side), section views for internal features, and isometric views for three-dimensional perspective.

- Bend specifications: Inside bend radius, bend angles, and any relief requirements. The inside bend radius should typically equal the material thickness as a starting point.

- Hole and cutout details: Diameter, position tolerances, and edge distances. Remember that minimum hole diameter should equal material thickness.

For custom metal brackets with welded features, your documentation must specify weld type, location, and any required heat dissipation techniques. According to TrueCADD, detailed welding specifications are crucial to ensure strong and reliable joints in the fabricated part.

Don't overlook hardware specifications. If your bracket requires PEM nuts, rivets, or other installed fasteners, clearly define all requirements including torque specifications where applicable.

Quantity Considerations for Prototyping vs. Production

Here's a secret most suppliers won't volunteer: your quantity dramatically affects which manufacturing process they'll use and what price you'll pay. A bracket quoted at $15 each for 100 pieces might drop to $2 each at 10,000 pieces, but only if you communicate your full requirements upfront.

According to LightSource's RFQ guide, initial order quantities plus projected usage patterns throughout the product lifecycle enable suppliers to determine pricing tiers and production capacity. A prototype order of 100 units prices differently than a production commitment of 100,000 units annually.

When specifying quantities, consider these factors:

- Prototype quantities: Typically 5-50 pieces for design validation. Expect higher per-unit costs due to setup time and manual processes.

- Bridge production: 100-1,000 pieces while transitioning from prototype to full production. Fabrication methods typically apply here.

- Production volumes: Above 1,000-5,000 pieces, stamping tooling investments often become economical.

- Annual forecasts: Share projected yearly volumes even if initial orders are smaller. This helps manufacturers plan capacity and potentially offer volume-based pricing.

According to All Metals Fab, moving from prototype to production is where ideas meet reality and where many programs stumble. Small DFM choices that were invisible in a one-off prototype can multiply cost, increase cycle time, and destabilize production once you go to volume.

The recommendation? Adopt a "prototype with production intent" mindset. Build prototypes using the material, thickness, and tooling assumptions you expect in production. If that's not possible, document where the prototype differs and require a delta review with manufacturing.

Surface Finish and Secondary Operation Specifications

Your metal mounting plate might function perfectly but look terrible if you don't specify finish requirements. Surface treatments affect both appearance and performance, so communicating these requirements precisely prevents expensive surprises.

According to TrueCADD, material and finish specifications must specify surface preparation requirements, primer specifications if applicable, and for any paint or powder coat finishes, provide the type and manufacturer designation numbers along with the desired coating thickness.

Your finish specification should address:

- Surface preparation: Required cleaning, deburring, or pre-treatment processes.

- Coating type: Powder coating, wet paint, plating (zinc, nickel, chrome), anodizing, or passivation.

- Color specification: RAL number, Pantone reference, or manufacturer color code.

- Coating thickness: Minimum and maximum acceptable thickness in mils or microns.

- Quality requirements: Surface roughness, reflectivity, or cosmetic acceptance criteria.

Secondary operations beyond finishing also require clear specification:

- Hardware installation: Self-clinching fasteners, weld nuts, or rivet insertion.

- Assembly requirements: If brackets ship as sub-assemblies with other components attached.

- Marking and identification: Part numbers, lot codes, or serial numbers per your traceability requirements.

- Packaging specifications: Bulk, individual wrapping, or custom packaging for sensitive surfaces.

According to LightSource, RFQs work best when you have clearly defined requirements. The standardized format enables objective comparison across multiple suppliers bidding on identical specifications. When every supplier receives identical finish and secondary operation requirements, you can compare quotes fairly and select based on best total value.

One final consideration: lead time expectations. According to LightSource, two to three weeks for standard components allows suppliers adequate time without delaying your sourcing cycle. Complex custom parts or tooling requirements may need four to six weeks. Always consider your suppliers' workload and communicate your timeline requirements clearly.

With your specifications complete and documented, you're ready to evaluate potential manufacturing partners. The next step involves understanding what separates capable suppliers from those who overpromise and underdeliver.

Choosing the Right Sheet Metal Bracket Manufacturer

Your specifications are complete. Your drawings are polished. Now comes the decision that determines whether your project succeeds or stumbles: selecting the right manufacturing partner. This choice impacts far more than unit price. It affects quality consistency, delivery reliability, and your ability to scale from prototype to production without costly disruptions.

Here's what most buyers discover too late: not all metal bracket suppliers operate equally. Some excel at quick-turn prototypes but lack the infrastructure for volume production. Others handle massive quantities efficiently but won't touch small runs. Choosing a partner mismatched to your needs creates bottlenecks that ripple through your entire supply chain.

According to Market Vistas' 2025 metal stamping analysis, different scenarios demand different vendor profiles. High-volume automotive production requires companies excelling in large-scale, consistent output with automotive-grade quality, while prototype and small batch runs need suppliers who can accommodate rapid prototyping and flexible orders.

Use this evaluation framework to separate capable partners from those who overpromise and underdeliver:

- Technical capabilities alignment: Does their equipment match your bracket complexity and volume requirements?

- Certification relevance: Do they hold certifications your industry demands?

- Prototyping-to-production transition: Can they support your journey from concept validation through mass production?

- Communication responsiveness: How quickly and thoroughly do they respond to technical questions?

- Geographic and logistical fit: Does their location and delivery infrastructure serve your supply chain needs?

Evaluating Manufacturing Capabilities and Equipment

Walk into any sheet metal shop and you'll see equipment. But can that equipment actually produce your custom steel brackets to specification? Answering this question requires looking beyond the sales pitch.

According to Market Vistas, technical capabilities assessment should evaluate the range of stamping processes offered, such as progressive die, deep draw, or fine blanking. Companies with advanced equipment can handle complex geometries and tight tolerances that basic shops simply cannot achieve.

Here's your capability evaluation checklist:

- Cutting technology: Do they operate fiber lasers for precision cutting, or rely on older CO2 systems? Fiber lasers deliver cleaner edges and faster processing for most sheet metal brackets.

- Press brake capacity: What tonnage and bed length can they handle? Larger brackets require more substantial equipment.

- Stamping infrastructure: For high-volume metal mounting brackets, do they have progressive die presses with coil feeding? This determines whether they can economically produce your quantities.

- Tooling capabilities: Can they design and build dies in-house, or must they outsource? In-house tooling accelerates timelines and reduces costs.

- Welding and assembly: Do they offer fastener brackets assembly, hardware installation, and welded sub-assemblies?

According to Fry Steel's supplier comparison guide, buying from a supplier with in-house, value-added services can streamline your procurement process and save you money. When your materials pass through fewer hands, you reduce the possibility of handling errors and other issues.

Don't overlook production capacity. According to Market Vistas, larger capacities are vital for high-volume needs, but flexibility matters for smaller or customized runs. A manufacturer running near capacity may struggle to accommodate rush orders or volume increases.

Understanding Lead Times from Prototype to Production

Here's a scenario that frustrates countless buyers: your prototype arrives in five days, but production quantities take twelve weeks. Why the dramatic difference?

According to Eabel's manufacturing analysis, rapid prototyping supports quick design cycles, making it ideal for early-stage development. Engineers can test, adjust, rework, and even re-cut metal parts within days. This speed helps teams validate concepts before investing in production tooling.

But mass production operates differently. The same source explains that in mass production, design changes are far more difficult. Any modification may require die rework or a completely new die, which increases both time and cost. This is why mass production works best for stable, finalized designs.

Understanding this distinction helps you select partners appropriately:

- Prototype lead times: Expect 3-10 business days for fabricated sheet metal brackets using standard tooling. Some manufacturers offer expedited services for urgent validation needs.

- Bridge production timing: As Eabel notes, some manufacturers use bridge tooling or soft tooling to test designs before committing to full production. This intermediate step typically requires 2-4 weeks.

- Production tooling: Custom progressive dies require 4-8 weeks for design and fabrication before production can begin.

- Volume production: Once tooling is complete, production lead times depend on quantity, capacity, and finishing requirements.

According to Fry Steel, longer than anticipated lead times can create a massive bottleneck in your business, contributing to greater downtime and more production delays. Evaluate prospective suppliers' lead time commitments carefully and verify their track record for on-time delivery.

The ideal manufacturing partner bridges both worlds. For example, Shaoyi (Ningbo) Metal Technology demonstrates this dual capability, offering 5-day rapid prototyping alongside automated mass production infrastructure. Their 12-hour quote turnaround and comprehensive DFM support exemplify what you should expect from a partner capable of supporting your entire product lifecycle. With IATF 16949 certification backing their automotive-grade quality for chassis, suspension, and structural components, they represent the type of manufacturer equipped to handle both prototyping flexibility and production-scale demands.

Quality Assurance and Certification Verification

Certifications look impressive on websites, but do they actually guarantee the quality your metal bracket application demands? Understanding what these credentials mean helps you separate genuine capability from marketing fluff.

According to Market Vistas, quality assurance evaluation should look for certifications like ISO 9001 or IATF 16949. Consistent quality reduces rework and scrap, saving costs in the long run.

But Fry Steel offers deeper insight: finding a supplier that complies with compulsory QA standards is essential, but the voluntary standards a supplier holds themselves to may say even more about their reputability. These independently verified certifications hold suppliers to rigorous standards.

Here's what key certifications actually guarantee:

- ISO 9001: Baseline quality management system demonstrating documented processes, customer focus, and continuous improvement. Necessary but not sufficient for demanding applications.

- IATF 16949: Automotive-specific requirements including statistical process control, total productive maintenance, and PPAP documentation. Essential for any metal mount destined for automotive applications.

- AS9100D: Aerospace requirements covering configuration management, complete traceability, and counterfeit parts prevention. Mandatory for aerospace bracket suppliers.

- NADCAP: Special process accreditation for heat treating, welding, or surface finishing. Verifies competence in critical secondary operations.

According to Market Vistas, validation involves real-world tests beyond paperwork review. Request sample production runs to evaluate quality, tolerances, and lead times before full-scale engagement. Conduct onsite inspections and review certifications to verify adherence to standards. Track delivery accuracy, defect rates, and responsiveness during initial projects to gauge reliability.

Don't overlook financial stability as a quality indicator. Fry Steel advises that a strong, long-lasting partnership with your supplier is key to your success, so it's important to find one with the financial strength to support long-term stability. Consider their market tenure, growth trajectory, and investment in new equipment as indicators of viability.

Finally, evaluate customer support quality. According to Fry Steel, it's essential to partner with a metal supplier with responsive and knowledgeable sales and customer support teams. A knowledgeable sales rep doesn't just order supplies for you but partners with you to help you find the perfect product. Expert guidance can prevent you from spending thousands only to find you've bought the wrong supplies.

Finding the right sheet metal bracket manufacturer takes effort, but the investment pays dividends throughout your product's lifecycle. The difference between a capable partner and a marginal one shows up in every delivery, every quality report, and every time you need to scale production or modify your design. Choose carefully, verify thoroughly, and build relationships with manufacturers who treat your success as their own.

Frequently Asked Questions About Sheet Metal Brackets

1. What is a bracket in engineering?

A bracket in engineering is a structural component designed to connect, support, or stabilize two or more surfaces along one edge. Sheet metal brackets are formed metal support structures manufactured from flat metal sheets typically 0.3 to 6 millimeters thick, shaped through bending, stamping, and cutting to create rigid connections between components. They perform three primary functions: load transfer between structural elements, structural support for maintaining component alignment, and component mounting for securing functional parts to supporting structures.

2. What types of metal brackets are available for custom fabrication?

Custom fabrication offers six main bracket types: L-brackets for corner mounting and perpendicular connections, Z-brackets for panel offsets and tiered mounting, U-brackets for component retention and cable routing, C-brackets for structural framing and equipment mounting, T-brackets for junction connections and cross-bracing, and angle brackets for heavy-duty corner reinforcement. Each shape serves distinct load characteristics and applications, with Z-brackets handling shear loads between parallel planes while L-brackets excel in compression and tension along mounting surfaces.

3. How do I choose between steel, stainless steel, and aluminum brackets?

Material selection depends on your application environment, load requirements, and budget. Steel brackets offer maximum strength and economy for indoor and heavy-duty industrial applications but require coating for corrosion protection. Stainless steel brackets (304 or 316 grades) provide excellent corrosion resistance for marine, outdoor, or chemical exposure environments at higher cost. Aluminum brackets deliver the best strength-to-weight ratio at roughly one-third the weight of steel, making them ideal for aerospace, electronics, and portable equipment applications.

4. What certifications should a sheet metal bracket manufacturer have?

Required certifications depend on your industry. ISO 9001 provides baseline quality management for general applications. IATF 16949 is essential for automotive brackets, requiring statistical process control, PPAP documentation, and total productive maintenance. AS9100D certification is mandatory for aerospace applications, covering configuration management and complete material traceability. NADCAP accreditation verifies competence in special processes like heat treating and welding. Always verify certifications match your specific industry requirements before selecting a manufacturing partner.

5. What information do I need to provide when requesting a custom bracket quote?

Prepare complete dimensional documentation including all critical measurements, tolerances, and GD&T specifications. Specify material type, grade, and thickness with any required certifications. Include quantity requirements for initial orders plus projected annual usage to optimize pricing. Define surface finish requirements including coating type, color codes, and thickness specifications. Provide CAD files in standard formats, and communicate lead time expectations clearly. According to industry experts, incomplete specifications lead to misquoted prices and production delays.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —