From Zero To Profitable: Launch Your Sheet Metal Fabrication Business Right

Understanding the Sheet Metal Fabrication Industry

Ever watched a flat piece of metal transform into a car door panel, an aircraft fuselage section, or the ductwork running through a building's ceiling? That's sheet metal fabrication at work. Whether you're exploring entrepreneurship opportunities or simply trying to understand this industry landscape, grasping what this sector truly involves is your essential first step toward building a profitable operation.

What Sheet Metal Fabrication Actually Involves

At its core, a sheet metal fabrication business creates functional parts, components, and structures from flat metal sheets. Think of it as industrial origami—except instead of paper, you're working with steel, aluminum, copper, and specialty alloys. The process encompasses multiple operations that transform raw materials into everything from tiny electronic enclosures to massive industrial containers.

This industry spans an impressive range of operations. You'll find small custom shops with a handful of skilled fabricators serving local contractors, and you'll see large-scale manufacturing facilities running automated production lines for major automotive suppliers. Both business models thrive because the demand for fabricated metal products touches nearly every sector of the economy.

The primary fabrication processes include:

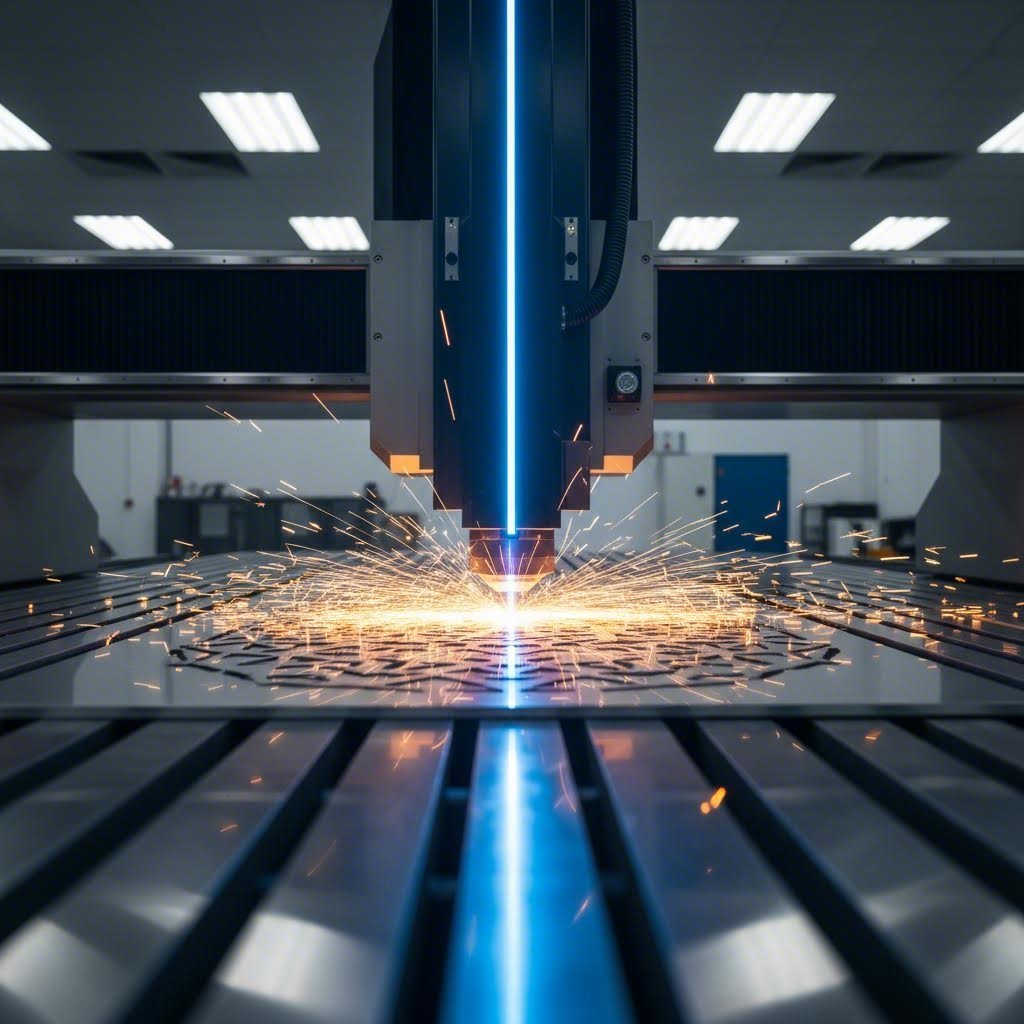

- Cutting — Using laser, plasma, waterjet, or mechanical methods to slice sheets into precise shapes

- Punching — Creating holes, patterns, and cutouts through controlled force application

- Bending — Forming angles and curves using press brakes and specialized tooling

- Welding — Joining separate pieces through TIG, MIG, or other fusion techniques

- Finishing — Applying surface treatments like powder coating, anodizing, or electroplating

From Raw Material to Finished Product

Imagine receiving a stack of flat aluminum sheets and a customer's CAD drawing. Your team's expertise transforms those raw materials through a carefully orchestrated sequence. First, designers analyze the specifications and generate machine-readable code. Then, operators execute cutting operations to create blanks. Those blanks move through forming stations where they gain three-dimensional shapes. Finally, assembly and finishing bring everything together into a completed product.

What makes sheet metal fabricating particularly valuable is its versatility. The same shop can produce architectural panels one week and precision brackets for aerospace applications the next. This adaptability explains why the industry continues expanding—Research and Markets estimates the global sheet metal fabrication services market will surpass £15 billion by 2030.

The Business Behind the Bends

Why does this industry remain essential? Consider how many sectors depend on fabricated metal components:

Automotive manufacturers need body panels, chassis components, and engine parts. Over 50% of vehicle components come from sheet metal fabrication processes.

Construction projects require structural elements, roofing, HVAC ductwork, and architectural features. Whether it's commercial HVAC in Fort Worth or residential projects in New York, contractors need reliable fabrication partners.

Aerospace companies demand lightweight yet incredibly strong components for aircraft and spacecraft, often fabricated from titanium and aluminum alloys.

Medical device manufacturers rely on precision fabrication for surgical instruments, diagnostic equipment housings, and hospital furniture—all requiring biocompatible materials and exacting standards.

For aspiring business owners, this diversity represents opportunity. You can specialize in serving one industry deeply or position your operation as a versatile job shop handling varied projects. Either approach can succeed when backed by solid market research and the right equipment investments—topics we'll explore in the sections ahead.

Market Research and Business Positioning Strategies

So you understand what sheet metal fabrication involves—but how do you actually find customers willing to pay for your services? Here's where most aspiring fabrication business owners stumble. They invest in equipment before understanding who they'll serve. Smart entrepreneurs flip that sequence, conducting thorough market research before signing any equipment leases.

Identifying Your Ideal Customer Base

Your customer base determines everything—from the equipment you'll need to the certifications you'll pursue. Metal fabrication NYC shops serving architectural firms operate completely differently from custom fabrication NYC operations supporting manufacturers. The key is finding customers whose needs match your strengths.

Start by asking two critical questions, as marketing consultant Mark Coronna recommends:

- What market segments have genuine demand for fabricated metal components?

- Within those segments, which specific companies would value what you offer?

The second question matters more than the first. A $2 billion market sounds attractive, but those numbers won't help you land your first contract. Instead, narrow your focus to specific company types. Consider exercise equipment manufacturers needing tube frames, restaurant chain operators requiring custom kitchen fixtures, or construction firms building commercial spaces.

Here's a proven approach: identify what Coronna calls a "lead customer"—a company representing your target market that's known for operational excellence. These organizations constantly seek better suppliers and often welcome conversations with promising fabricators. Cultivating one or two lead customer relationships provides invaluable market intelligence while potentially generating reference accounts.

Analyzing Local Competition and Market Gaps

Understanding your competitive landscape prevents you from entering saturated markets unprepared. Visit competitor websites. Attend local tradeshows. Talk to contractors and manufacturers about their current suppliers and pain points.

What are existing metal fabrication New York operations doing well? More importantly, where are they falling short? Common gaps include:

- Lead times that don't meet urgent project needs

- Minimum order quantities excluding smaller customers

- Limited design-for-manufacturability (DFM) support

- Inconsistent quality or delivery reliability

Your competitive advantage emerges from these gaps. Maybe local shops focus exclusively on high-volume work, leaving custom one-off projects underserved. Perhaps existing fabricators lack engineering support, forcing customers to figure out manufacturing details themselves.

Choosing Your Fabrication Specialty

The fabrication industry accommodates wildly different business models. As one industry analysis notes, shops range from high-volume producers handling millions of identical parts to bespoke architectural fabricators creating one-of-a-kind luxury installations.

Consider three distinct customer types:

General contractors need fabricated components for construction projects—structural steel, custom brackets, architectural metalwork. They value reliability, competitive pricing, and the ability to meet construction schedules.

Manufacturers require ongoing component supply for their products. They prioritize consistency, quality certifications, and long-term partnership potential.

Direct consumers seek custom pieces—decorative metalwork, furniture, specialty fixtures. They value craftsmanship, design collaboration, and unique outcomes.

Each customer type demands different capabilities, equipment, and business processes. The table below compares key market segments to help you evaluate where your operation fits best:

| Market Segment | Typical Order Size | Margin Potential | Equipment Requirements |

|---|---|---|---|

| Automotive | High volume (10,000+ units) | Lower margins per unit; profit through volume | High-speed lasers, automated press brakes, robotic welding |

| Architectural | Low to medium (1-500 pieces) | Higher margins; value-based pricing | Precision bending, finishing capabilities, 3D rendering software |

| Industrial | Medium volume (100-5,000 units) | Moderate margins; relationship-dependent | Versatile cutting, heavy forming equipment, welding stations |

| HVAC | Varies widely (project-based) | Moderate margins; repeat business potential | Duct forming machines, plasma cutting, spot welding |

Notice how equipment requirements align with market focus. A shop chasing high-volume automotive contracts needs entirely different machinery than one pursuing custom architectural work. Your market research directly informs your capital investment decisions—which brings us to the regulatory requirements you'll need to navigate before opening your doors.

Licensing Permits and Regulatory Compliance

You've identified your target market and mapped out your competitive positioning. Now comes the part that trips up countless aspiring fabricators—navigating the regulatory maze. Unlike many businesses where you simply register and open your doors, a sheet metal fabrication business faces layered compliance requirements spanning federal, state, and local jurisdictions. Skip any of these, and you could face shutdowns, fines, or worse.

Essential Permits and Licenses for Metal Shops

Before your first piece of equipment even arrives, you'll need several foundational permits in place. The specific requirements vary by location, but steel fabricators NYC operators face many of the same core requirements as those launching metal fabrication Albany NY shops—just with different issuing agencies.

Here are the typical permits you'll need to secure:

- Business license — Your basic authorization to operate commercially in your municipality

- Zoning permit — Confirmation that your chosen location allows industrial manufacturing operations

- Air quality permit — Required for operations generating fumes, dust, or particulate emissions

- Stormwater permit — Addresses runoff from your facility that could carry metal particles or chemicals

- Fire department approval — Covers welding operations, compressed gas storage, and flammable material handling

Zoning deserves special attention. Many entrepreneurs find the perfect building at an attractive price, only to discover the zoning classification prohibits metalworking operations. Industrial zones typically accommodate fabrication shops, but you'll need to verify that your specific activities—welding, grinding, plasma cutting—are permitted. Some jurisdictions require conditional use permits for operations generating noise or emissions above certain thresholds.

When searching for your facility, you might also need to coordinate with an electrician near me search to assess whether the building's electrical infrastructure can support your equipment. Heavy fabrication machinery requires substantial power—often 480-volt three-phase service—and upgrading electrical systems adds significant costs to your buildout budget.

Environmental Compliance Requirements

Environmental regulations represent the most overlooked—and potentially most costly—compliance area for new fabrication businesses. The EPA's National Emission Standards for Hazardous Air Pollutants (NESHAP Rule 6X) directly applies to metalworking operations.

According to EPA compliance guidelines, this rule targets Metal Finishing Hazardous Air Pollutants (MFHAPs)—materials containing 0.1% by weight cadmium, chromium, lead, or nickel, or 1.0% by weight manganese. If your welding rods, wire, or other materials contain these substances, you're subject to NESHAP 6X requirements.

The rule specifically affects operations including:

- Dry abrasive blasting

- Welding processes

- Spray painting and coating

- Metal grinding and cutting

To determine compliance, you must perform a Method 22 Fugitive Emissions Test. An observer watches your exhaust stack for 15 minutes. If visible emissions appear during 20% or more of that period (3 minutes), Rule 6X applies to your facility.

What happens if you fail? You'll need to implement management practices, install appropriate control devices like cartridge filtration systems, and maintain ongoing documentation. Many steel fabricators in New York have invested in dedicated dust and fume collection systems that filter welding fumes and recirculate cleaned air back into the facility. This approach eliminates NESHAP 6X requirements altogether while recovering heated or cooled air—a strategy that can generate five- to six-figure annual energy savings.

Beyond air quality, consider waste disposal requirements. Metal shavings, cutting fluids, and finishing chemicals often qualify as hazardous waste requiring special handling. Your state environmental agency provides guidance on classification and disposal requirements.

OSHA Standards Every Fabricator Must Follow

Workplace safety isn't optional—OSHA regulations carry the force of law and apply to every fabrication operation. Understanding these requirements protects your workers and shields your business from costly penalties.

Machine guarding tops the priority list. Every press brake, shear, punch press, and grinding wheel needs appropriate guards preventing operator contact with moving parts. OSHA's machine guarding standards (29 CFR 1910.212) specify requirements based on equipment type and hazard points.

Personal protective equipment (PPE) requirements include:

- Eye protection — Safety glasses for general work, welding helmets with appropriate shade lenses for arc welding

- Hearing protection — Required when noise levels exceed 85 decibels (common with grinding and cutting operations)

- Respiratory protection — Needed when engineering controls don't adequately control fume exposure

- Hand protection — Cut-resistant gloves for material handling, heat-resistant gloves for welding

You'll also need a written safety program covering hazard communication (chemical safety), lockout/tagout procedures for equipment maintenance, and emergency action plans. OSHA provides compliance assistance through free on-site consultation programs—a valuable resource for new business owners establishing their safety protocols.

One commonly overlooked requirement: OSHA's permissible exposure limits (PELs) for welding fumes and metal dust. Even if your air filtration system satisfies EPA requirements, you must ensure worker breathing zones meet OSHA standards. This sometimes requires additional local exhaust ventilation at specific workstations beyond your general shop ventilation system.

With your regulatory compliance roadmap in hand, you're ready to tackle the physical requirements of your operation—starting with how to design a shop layout that maximizes efficiency while meeting safety standards.

Facility Requirements and Shop Layout Planning

Picture this: you've secured your permits, identified your target market, and you're ready to set up shop. But here's where many new fabrication businesses stumble—they treat their facility as just a room with equipment rather than a carefully orchestrated production system. A smart shop layout doesn't just hold machines; it moves metal efficiently from receiving dock to shipping bay while keeping workers safe.

Whether you're launching a new york sheet metal operation or setting up a metal cutting nyc facility, your floor plan directly impacts profitability. Industry experts note that a custom fabricator has a smart layout when its design maximizes unidirectional flow and minimizes the cost of that flow. Let's break down exactly how to achieve that.

Designing an Efficient Shop Floor Layout

Before placing a single piece of equipment, sketch out your step-by-step process from raw material to finished product. Your shop isn't just a room—it's a production line. Every decision about where to position equipment should eliminate backtracking and reduce unnecessary movement.

Here's the logical workflow sequence your layout should follow:

- Material delivery and receiving — Dock area where incoming sheet metal enters your facility

- Stock storage — Organized racks holding raw materials close to your first processing station

- Cutting and preparation — Laser cutters, plasma tables, or shears positioned near material storage

- Forming operations — Press brakes and bending equipment arranged for natural material progression

- Fit-up and welding — Welding bays located close to forming stations

- Grinding and cleaning — Finishing area positioned before final inspection

- Quality inspection — Dedicated space with proper lighting and measuring equipment

- Delivery staging and shipping — Outbound area separate from incoming materials

Notice the pattern? Each station feeds directly into the next. Workflow optimization specialists recommend placing your cutting station near steel racks, welding bays close to fit-up tables, and assembly near final inspection. Use carts or rollers to move material between stations faster.

How much space do you actually need? That depends on your equipment and production volume. A basic sheet metal nyc job shop might operate effectively in 2,500 to 5,000 square feet. However, if you're running multiple CNC machines, automated press brakes, and robotic welding cells, you'll need 10,000 square feet or more. Always plan for future expansion—most fabricators underestimate their growth trajectory.

Safety Zones and Material Flow Planning

A well-designed layout does more than optimize production—it protects your team. Walking paths should be at least three feet wide, clearly marked, and free from obstructions. Equipment swing zones need buffer space preventing accidental contact with operators passing nearby.

Consider these critical safety elements when planning your floor:

- Fire extinguisher placement — Accessible within 50 feet of any welding or cutting operation

- First aid stations — Visible and stocked at multiple locations throughout the shop

- Emergency exit visibility — Clear sightlines from any workstation to the nearest exit

- Equipment isolation zones — Marked areas around hazardous machinery requiring PPE

Here's a pro tip from experienced fabricators: invest in mobile equipment. Welding carts, grinding tables, and assembly benches on wheels help you reconfigure your layout as needed. This flexibility proves invaluable when handling high-volume runs one week and custom one-off projects the next. You can bring the work to the welder rather than forcing operators to move between fixed stations.

Material storage deserves special attention. Sheet metal inventory takes up significant floor space, and disorganized storage creates safety hazards while wasting time. Vertical racks maximize square footage utilization while keeping different materials—steel, aluminum, stainless—separated and easily identifiable. Position your storage adjacent to receiving doors to minimize forklift travel distance.

Utility Requirements for Fabrication Equipment

Your equipment determines your utility infrastructure—and underestimating these requirements creates expensive headaches. Most fabrication machinery demands substantially more power than typical commercial buildings provide.

Electrical requirements vary dramatically by equipment type:

- Welding equipment — MIG and TIG welders typically require 240V single-phase or 480V three-phase circuits with 30-60 amp capacity

- Plasma cutters — Industrial units often need 480V three-phase power with 60-100 amp service

- CNC machines — Laser cutters and punch presses may require 480V three-phase service with 100+ amp capacity

- Press brakes — Hydraulic units draw substantial power during operation, requiring dedicated circuits

Before signing any lease, verify the building's electrical service. Upgrading from single-phase to three-phase power—or increasing amperage capacity—can cost tens of thousands of dollars. Position your machines where utilities already exist, or plan for cost-effective installation of power drops at each station.

Compressed air infrastructure runs throughout most fabrication shops. Plasma cutters, pneumatic tools, and many automated systems require consistent air pressure—typically 80-120 PSI. Install overhead air lines that drop down to individual workstations, keeping hoses off the floor and out of traffic paths. Your compressor sizing depends on total cubic feet per minute (CFM) demand across all connected tools.

Ventilation systems address both worker safety and regulatory compliance. Welding fumes, grinding dust, and cutting smoke require extraction. Options range from portable fume extractors at individual stations to centralized systems with ductwork connecting multiple workstations to filtration units. Remember those EPA NESHAP requirements from the previous section? Your ventilation design directly impacts compliance.

Overhead crane considerations become relevant as your operation scales. Moving heavy sheet metal bundles and large fabricated assemblies by hand creates injury risks and slows production. Many established shops install bridge cranes or jib cranes at key workstations. If you're leasing space, verify ceiling height and structural capacity before assuming crane installation is feasible.

The goal? Every station should be plug-and-play—no tangled cords, no hoses across walkways, no workers hunting for air connections. Your layout should support your tools, minimize motion, and build rhythm into every production day.

With your facility properly planned and utilities mapped out, you're ready to tackle the next critical decision: which equipment to purchase first and how to prioritize investments that match your market positioning.

Essential Equipment and Technology Investments

You've mapped your market, secured permits, and designed your shop layout. Now comes the decision that will define your capabilities for years to come—choosing which equipment to purchase first. Here's the reality: your equipment determines which customers you can serve, which contracts you can bid on, and ultimately, how profitable your sheet metal fabrication business becomes.

The temptation? Buying the most advanced machinery available. The smarter approach? Building your equipment arsenal strategically, matching purchases to your market positioning and scaling up as revenue justifies investment.

Core Equipment Every Shop Needs First

Before chasing laser cutters and robotic welding cells, every fabrication shop needs foundational equipment that handles the essential processes. Think of this as your minimum viable toolset—the machinery required to accept your first projects and deliver quality work.

Start with these essentials:

- Manual or mechanical shear — Your primary cutting tool for straight-line cuts on sheet metal. Mechanical shears handle thicker materials and higher volumes than manual alternatives.

- Press brake — The heart of any forming operation. Even a basic hydraulic press brake allows you to create bends, angles, and formed shapes essential for most fabrication work.

- MIG and TIG welders — MIG handles high-volume production work efficiently, while TIG provides precision for thinner materials and visible welds requiring aesthetic quality.

- Grinders and finishing tools — Angle grinders, belt sanders, and deburring equipment prepare parts for delivery or coating.

- Measurement and layout tools — Precision squares, calipers, tape measures, and marking equipment ensure accuracy from cut to assembly.

This basic setup enables you to handle custom metal fabrication NYC projects, architectural metalwork, and general job shop orders. Many successful fabricators in steel fabrication New York started with exactly this configuration—proving their capabilities before investing in automation.

Don't overlook tooling requirements. Your press brake needs dies matched to your typical bending applications. Your shear blades require regular sharpening or replacement. Budget for tooling as a percentage of equipment cost—typically 10-20% of your initial machinery investment.

When to Invest in CNC Technology

Here's the progression most successful fabricators follow: manual equipment first, then CNC automation as volume and complexity justify the investment. But when exactly does that transition make sense?

Consider CNC technology when you encounter these situations:

- Repeat orders requiring identical parts—CNC eliminates setup time on subsequent runs

- Complex geometries that manual equipment can't produce accurately

- Customer requirements for certified dimensional consistency

- Labor constraints where automation compensates for skilled worker shortages

- Competitive pressure from shops offering faster turnaround on precision work

The equipment hierarchy typically progresses like this:

- CNC press brake — Often the first CNC investment, providing repeatable bends with programmed angle control and backgauge positioning

- CNC punch press — Handles hole patterns, louvers, and complex cutouts faster than manual methods

- Fiber laser cutter — Delivers precision cutting with minimal material waste, opening doors to intricate designs and tight tolerances

- Robotic welding cells — Makes sense for high-volume repetitive welding applications

According to industry analysis of metal machinery suppliers, modern CNC machining centers combine automation, precision feedback, and software for nesting or toolpath optimization. These integrated capabilities increase shop productivity while maintaining consistency across production runs.

What about shops serving metal Albany NY markets or similar regional areas? The same principles apply—your customer base determines your technology needs. A shop focusing on custom architectural work may thrive with a quality CNC brake and manual cutting, while one pursuing automotive contracts needs high-speed laser cutting and automated forming.

Buy vs Lease Decisions for Major Equipment

Sounds complex? This decision affects your cash flow, tax position, and operational flexibility for years. Neither buying nor leasing is universally better—the right choice depends on your specific situation.

Financial analysts note that when you buy industrial equipment, you own the asset outright until you decide to sell or dispose of it. When you lease, you make payments to access the equipment for the lease term without ownership—then return it or exercise a purchase option.

Pros of Buying Equipment

- Build equity in assets you can sell or use as collateral

- No restrictions on usage, modifications, or operating hours

- Lower total cost over the equipment's full lifespan

- Potential depreciation tax benefits

Pros of Leasing Equipment

- Lower monthly payments preserve cash flow for operations

- Maintenance often included, reducing unexpected costs

- Easier access to newer technology when lease terms end

- Flexibility to scale equipment up or down with project demands

Here's a critical insight: leasing may enable you to afford better or newer equipment than purchasing outright allows. Maybe your budget only supports buying used press brakes. But leasing could put you in new CNC equipment with the latest technology at comparable monthly costs.

Equipment-as-a-service (EaaS) financing has emerged as another option. These arrangements often include maintenance through subscription models—routine checks, preventive care, and corrective repairs bundled into predictable payments.

The following table compares equipment categories to help you prioritize investments based on your service offerings and budget:

| Equipment Category | Approximate Investment Level | Capabilities Added | Typical ROI Timeline |

|---|---|---|---|

| Manual Shear & Press Brake | Low ($15K-$50K total) | Basic cutting and forming for job shop work | 6-12 months with steady orders |

| CNC Press Brake | Moderate ($75K-$200K) | Repeatable precision bending, reduced setup time | 12-24 months |

| CNC Punch Press | Moderate to High ($100K-$300K) | Complex hole patterns, louvers, high-volume punching | 18-30 months |

| Fiber Laser Cutter | High ($150K-$500K+) | Precision cutting, intricate designs, minimal waste | 24-36 months |

| Robotic Welding Cell | High ($100K-$400K) | Automated welding for repetitive assemblies | 18-36 months depending on volume |

Notice how investment levels connect to market positioning. A shop serving metal sheets NYC customers with custom one-off projects may never need a robotic welding cell. But one pursuing automotive production contracts can't compete without automation.

Maintenance considerations factor into your equipment decisions too. CNC machines require calibration, software updates, and specialized service. Industry experts emphasize that heavy-duty cycles are endured through robust castings, balanced drives, and protected ways—but even the most durable equipment needs preventive maintenance schedules and trained technicians.

When evaluating suppliers, request on-site demonstrations and verify spare parts accessibility. A machine tool that performs brilliantly becomes a liability if replacement components take weeks to arrive. Consider manufacturer-backed dealers with proven installation histories and training programs for your operators.

Your equipment choices set the boundaries for your business—but they're not the only factor determining success. Understanding the materials you'll work with creates another layer of competitive advantage, enabling better customer consultation and more profitable operations.

Material Selection Expertise as a Competitive Advantage

Here's something that separates thriving fabrication shops from struggling ones: material expertise. When a customer describes their application, can you immediately recommend the right metal for the job? Can you explain why aluminum won't work for their specific environment, or why switching from standard steel to HSLA could save them money long-term? This knowledge transforms you from a commodity service provider into a trusted manufacturing partner.

Whether you're running metal fabrication Buffalo NY operations or serving customers across sheet metal New York markets, your understanding of materials directly impacts customer satisfaction, waste reduction, and profit margins. Let's explore how material expertise becomes your competitive edge.

Matching Materials to Customer Applications

Every fabrication project starts with a fundamental question: what metal best serves this application? The answer depends on understanding how different materials behave under real-world conditions.

When consulting with customers, you'll evaluate these key material considerations:

- Tensile strength — How much pulling force can the material withstand before breaking? Structural applications demand high tensile strength.

- Corrosion resistance — Will the finished part face moisture, chemicals, or outdoor exposure? This determines whether standard steel, stainless, or aluminum makes sense.

- Weldability — Some metals fuse easily while others require specialized techniques and skilled operators, affecting production costs.

- Cost — Material pricing fluctuates, and choosing alternatives can dramatically impact project profitability.

- Availability — Can you source the material quickly, or will lead times delay your customer's project?

According to metal fabrication experts at Metaltech, the material chosen for a fabrication project affects whether it will function as expected. Every metal has properties that determine how it can be processed—selecting the right metal ensures component parts handle their environment and end use.

Consider common scenarios you'll encounter in buffalo metal fabricating work:

Carbon steel remains the most popular choice for general fabrication. It's strong, durable, and simple to weld—plus it costs less than most alternatives. However, carbon steel contains iron, making it susceptible to rust. Any outdoor or moisture-exposed application requires protective coatings or finishing.

Stainless steel solves the corrosion problem through its chromium content. When chromium oxidizes, it creates a protective layer preventing rust and staining. Food processing equipment, medical devices, and architectural features often specify stainless for this reason. The tradeoff? Higher material costs and slightly more challenging welding requirements.

Aluminum offers exceptional corrosion resistance without protective coatings—it contains no iron to rust. Its lightweight properties make aluminum essential for aerospace and automotive applications where weight reduction matters. But aluminum has lower tensile strength than steel and requires more skill to weld effectively.

Copper excels as an electrical and thermal conductor, making it ideal for electrical components and heat exchangers. Its natural patina—that distinctive green layer developing over time—also makes copper popular for decorative architectural elements.

Understanding Gauge Thickness and Formability

Imagine a customer asks for a complex bracket with tight bends and multiple flanges. Before quoting, you need to assess whether their specified material and thickness will actually form without cracking. This is where understanding gauge thickness and formability separates knowledgeable fabricators from order-takers.

Gauge numbers work counterintuitively—higher numbers mean thinner material. A 10-gauge steel sheet measures approximately 0.135 inches thick, while 20-gauge measures only 0.036 inches. Each material type has different gauge-to-thickness conversions, so always verify actual dimensions rather than assuming equivalence across metals.

Formability describes how easily metal bends, stretches, and shapes without breaking. Several factors influence this:

- Material type — Mild steel and copper form easily; high-carbon steel and some aluminum alloys resist bending

- Grain direction — Bending perpendicular to the rolling direction typically produces better results

- Bend radius — Tighter bends stress material more; minimum bend radius varies by material and thickness

- Temperature — Some materials form better when heated, while others become brittle

As material science research confirms, metals have layers of ions that roll over one another when force is applied. A metal's bonds let electrons move freely, allowing bending and shaping—but some metals handle this stress better than others.

For metal fabrication Buffalo operations, understanding these principles prevents costly mistakes. Quoting a project requiring tight bends in thick high-carbon steel? You'll need to factor in potential cracking, slower production speeds, or alternative material recommendations.

Building Supplier Relationships for Better Margins

Your material knowledge creates value for customers—but supplier relationships determine whether that value translates to healthy margins for your business. Strategic sourcing goes beyond finding the lowest price per pound.

Consider what strong supplier partnerships provide:

- Volume pricing — Committed relationships unlock discounts unavailable to occasional buyers

- Priority allocation — During material shortages, established customers get served first

- Technical support — Good suppliers help you select appropriate grades and specifications

- Flexible terms — Payment arrangements that improve your cash flow

- Just-in-time delivery — Reducing inventory carrying costs while ensuring material availability

Here's a practical approach: develop primary relationships with two or three metal service centers serving your region. Having backup suppliers protects against stockouts and provides competitive pricing leverage. But don't spread purchases so thin that no supplier considers you a priority customer.

Track your material usage patterns carefully. Knowing your monthly consumption of specific gauges and alloys allows you to negotiate blanket orders—commitments to purchase set quantities over time at locked pricing. This protects against market fluctuations while demonstrating reliability that suppliers reward.

Material expertise also reduces waste—a direct profit driver. When you understand how different metals behave during cutting, forming, and welding, you minimize scrap from processing errors. Proper nesting of parts on sheet stock maximizes material utilization. Knowing which offcuts have resale value versus scrap value affects your true material costs.

The fabricators who thrive long-term aren't just skilled at running equipment—they're consultants who help customers make better material decisions. This expertise builds relationships, reduces costly rework, and positions your operation as an indispensable partner rather than an interchangeable vendor.

Of course, material expertise means nothing without skilled operators who can translate that knowledge into quality finished products. Building and retaining a capable workforce presents one of the industry's greatest challenges—and opportunities for differentiation.

Workforce Development and Talent Acquisition

You've invested in equipment, secured materials, and designed an efficient shop layout. But here's the uncomfortable truth facing every sheet metal fabrication business: none of it matters without skilled people operating those machines. The fabrication industry faces a genuine workforce crisis—and how you address it determines whether your operation thrives or struggles to meet customer commitments.

According to the American Welding Society, there's substantial demand for welders but an insufficient workforce to meet it. As aging professionals retire, younger entrants aren't filling the gap fast enough. This "silver tsunami" affects steel fabricators Buffalo NY operations just as much as shops in major metropolitan areas. The solution? Proactive workforce development strategies that attract, train, and retain skilled fabricators.

Finding and Retaining Skilled Fabricators

Where do you find qualified welders, machine operators, and fabrication specialists when everyone's competing for the same talent pool? The answer requires looking beyond traditional job postings.

Effective recruitment channels include:

- Specialized industrial staffing agencies — Agencies like FlexCrew maintain databases of pre-verified welders with relevant certifications, reducing hiring timelines by up to 40%

- Technical school partnerships — Build relationships with welding and manufacturing programs to access graduating talent before competitors

- Industry-specific job boards — Platforms focused on trades and manufacturing attract candidates actively seeking fabrication work

- Employee referral programs — Your current team knows skilled fabricators—incentivize them to make introductions

- Union halls and apprenticeship programs — Excellent sources for certified welders with verified credentials

But finding talent is only half the challenge. Retention requires intentional effort because metal fabrication shops often experience high turnover as workers leave for better opportunities. What keeps skilled fabricators from walking out your door?

Compensation matters—but it's not everything. The Bureau of Labor Statistics reports median annual wages for welders around $47,000, with top performers earning over $71,000. Specialized welders in high-demand sectors command even more. Metal fabrication Rochester NY shops competing for talent need competitive base pay plus:

- Performance bonuses tied to quality and productivity

- Comprehensive health insurance and retirement plans

- Tool allowances and safety equipment provisions

- Flexible scheduling options where feasible

Here's what many owners miss: younger workers prioritize work-life balance and career development over maximum pay alone. Shops offering compressed workweeks, flexible start times, or parent-friendly shifts attract candidates that competitors overlook.

Building an Apprenticeship Program

Can't find enough skilled workers? Build them. Apprenticeship programs solve the talent shortage while creating loyal employees who understand your specific processes and standards.

According to METAL's apprenticeship initiative, nearly 3,000 manufacturers across the country now offer apprenticeships, recognizing it as a proven solution for recruiting, training, and retaining world-class manufacturing talent. Participants earn while they learn, with wage increases tied to skill gains. Upon completion, they receive national credentials from the U.S. Department of Labor.

What can a structured apprenticeship program do for your metal fabrication Syracuse NY operation or wherever you're located?

- Train employees for higher-skilled positions matching your equipment

- Develop clear career paths that attract ambitious candidates

- Standardize training across your operation

- Improve productivity, safety practices, and overall capacity

- Build loyalty and retention through genuine investment in workers

Partnerships with technical schools and community colleges amplify your efforts. Many institutions welcome curriculum input from local employers, ensuring graduates arrive with relevant skills. Internship opportunities let you evaluate potential hires before making permanent commitments—essentially a try-before-you-hire arrangement.

Companies supporting welders' continued education and certification advancement see 35% higher retention rates than those that don't. That statistic alone justifies investment in formal development programs.

Cross-Training for Operational Flexibility

Imagine your best welder calls in sick on the day a major project ships. If nobody else can handle that welding station, you're in trouble. Cross-training builds operational resilience while giving employees variety and growth opportunities.

Effective cross-training approaches include:

- Rotating employees through different stations during slower periods

- Pairing experienced operators with trainees for hands-on mentorship

- Documenting procedures so knowledge isn't trapped in individual heads

- Setting skill milestones tied to compensation increases

When employees understand multiple processes—cutting, forming, welding, finishing—they see how their work connects to the whole production flow. This perspective improves quality because operators recognize how upstream decisions affect downstream operations.

Ready to develop your own internal training program? Follow these steps:

- Assess current skill gaps — Identify which positions lack backup coverage and which capabilities your shop needs to develop

- Define competency standards — Document what "proficient" looks like for each station and process

- Create structured training modules — Combine classroom instruction with hands-on practice under supervision

- Pair trainees with mentors — Experienced fabricators transfer knowledge that can't be captured in manuals

- Track progress and certify completion — Formal recognition motivates learners and documents capabilities

- Connect advancement to compensation — Reward employees who expand their skill sets with pay increases or bonuses

- Review and update regularly — Training programs should evolve as equipment and customer requirements change

Steel Rochester NY fabricators and shops everywhere face the same fundamental reality: workforce quality directly impacts product quality and customer satisfaction. A technically skilled team produces better work, catches problems earlier, and serves customers more effectively than undertrained operators struggling with equipment they don't fully understand.

The fabricators who solve the labor challenge don't just survive—they build competitive advantages their competitors can't easily replicate. Equipment can be purchased. Materials can be sourced. But a skilled, loyal workforce takes years to develop and becomes your most valuable asset.

With your team in place, the next critical step is ensuring your financial foundation supports sustainable growth—from startup costs through the cash flow challenges inherent in project-based work.

Financial Planning and Startup Cost Considerations

You've assembled your team, selected equipment, and mapped out your facility. But here's the question that keeps aspiring fabricators awake at night: how much money do you actually need to launch? And once you're operational, how do you avoid the cash flow traps that sink otherwise promising operations?

Unlike retail businesses with predictable daily sales, a sheet metal fabrication business operates on project-based revenue. You might complete a $50,000 job in January and not see payment until March—while still covering payroll, materials, and overhead every week. Understanding these financial dynamics before you launch prevents the liquidity crises that force promising shops to close their doors.

Calculating Your True Startup Investment

Most business planning guides offer vague ranges that don't help you build a realistic budget. Let's break down the actual capital requirements by category so you can develop funding strategies matched to your specific situation.

According to industry startup analysis, metal fabricators face significant upfront expenses spanning several major categories. The table below organizes these investments with relative cost levels to help you prioritize:

| Cost Category | Investment Level | What It Covers | Planning Notes |

|---|---|---|---|

| Equipment | $50,000 - $500,000+ | Shears, press brakes, welders, cutting tables, tooling | Largest variable; depends on CNC vs manual and new vs used |

| Facility Improvements | $20,000 - $150,000 | Electrical upgrades, ventilation, flooring, safety equipment | Existing industrial space reduces costs significantly |

| Initial Inventory | $15,000 - $50,000 | Sheet metal stock, welding supplies, consumables | Start lean; expand as customer patterns emerge |

| Operating Reserves | 3-6 months expenses | Rent, utilities, payroll, insurance during ramp-up | Most underestimated category; plan for slow initial sales |

| Permits & Professional Fees | $5,000 - $25,000 | Licenses, legal setup, accounting, insurance deposits | Varies significantly by location and business structure |

Notice the wide ranges? Your positioning decisions from earlier chapters directly impact these numbers. A shop launching with used manual equipment to serve local contractors might start under $100,000 total. Metal fabricators NYC operations pursuing precision manufacturing contracts could easily exceed $500,000 before completing their first project.

Here's what catches many entrepreneurs off guard: operating reserves matter more than equipment quality during your first year. You can survive with adequate equipment while building your customer base. You cannot survive running out of cash before revenue materializes.

Financial experts specializing in manufacturing businesses emphasize paying extra attention to financial projections—being realistic about startup costs, operating expenses, and revenue forecasts. This section proves crucial for securing funding, whether from banks, investors, or SBA loan programs.

Managing Cash Flow in Project-Based Work

Imagine this scenario: you land a $75,000 contract from a manufacturer. You purchase $25,000 in materials, spend three weeks fabricating components, and deliver the finished order. Your customer's payment terms? Net 45. That means you've fronted material costs, covered six weeks of labor, and won't see revenue for another month and a half after delivery.

This timing gap defines the cash flow challenge in fabrication businesses. Manufacturing flow experts note that cash flow and manufacturing flow are closely linked—a smooth production process improves cash flow by reducing costs and accelerating revenue timing. But project-based work inherently creates gaps between expenses and income.

Strategies for managing these cash flow dynamics include:

- Deposit requirements — Request 30-50% upfront on larger projects to cover material purchases

- Progress billing — Structure payments at project milestones rather than waiting for final delivery

- Material terms negotiation — Arrange supplier payment terms that extend beyond your customer collection cycle

- Working capital lines — Establish credit facilities before you need them, not during a cash crisis

- Invoice factoring — Convert outstanding receivables to immediate cash (at a discount) when necessary

Successful steel fabrication NYC operations and nyc metal fabrication shops manage this by maintaining financial discipline from day one. Track every project's actual costs against estimates. Monitor days sales outstanding (DSO) religiously. Build cash reserves during profitable months to cover lean periods.

Consider this insight from experienced fabricators: if manufacturing processes are inefficient or prone to delays, they tie up cash in inventory or cause delays in receiving revenue from sales. Operational efficiency isn't just about productivity—it directly impacts your financial health.

Pricing Strategies for Profitability

How do you price fabrication work so you actually make money? Underpricing kills more shops than poor quality ever does. Yet many fabricators guess at pricing rather than building systematic approaches that ensure profitability.

Cost estimation specialists emphasize that sheet metal fabrication cost is not just about raw material—it combines materials, processes, labor, tooling, and overhead. Missing any component leads to underquoting and profit erosion.

Build your pricing using these interconnected elements:

Material costs extend beyond the metal itself. Calculate based on actual sheet utilization, not just finished part weight. Poor nesting increases scrap percentage, raising true cost per part. Add a material surcharge buffer and limit quote validity to protect against price fluctuations.

Labor rates should reflect fully loaded costs—not just hourly wages. Include benefits, payroll taxes, supervision, and indirect shop support. Don't forget setup time, material handling, and quality inspection when estimating labor hours.

Machine rates capture equipment investment, maintenance, power consumption, and allocated overhead. Processing cost equals cycle time multiplied by machine rate. Complex parts, tighter tolerances, and thicker materials increase cycle time and cost.

Overhead allocation distributes indirect expenses across jobs. Utilities, maintenance, quality control, administration—these costs don't attach to specific projects but must be recovered through pricing. Most fabricators build overhead into their shop rate rather than itemizing it per project.

Profit margin ensures business sustainability. After covering all costs, what remains? A consistent margin strategy prevents underpricing and supports long-term growth. Industry margins typically range from 10-25% depending on competition and specialization.

The final quoted price per part combines material, processing, labor, tooling, finishing, and overhead—then applies your target margin.

Common pricing mistakes that erode profitability include:

- Ignoring scrap percentage when calculating material needs

- Skipping setup time on small batch orders

- Using outdated material prices in quotes

- Failing to adjust per-part pricing based on order quantity

- Underestimating tooling costs, especially for custom dies and fixtures

Brooklyn custom metal fabrication inc New York operations and similar established shops survive because they've mastered this pricing discipline. They know their true costs, maintain healthy margins, and adjust pricing as market conditions change.

One final consideration: volume changes everything. High-volume production spreads setup costs across more units, improves labor efficiency, and maximizes material utilization. Your per-part pricing for 10,000 units should look dramatically different from pricing for 100 units of the same component. Build quantity breaks into your quoting process to reflect these real cost differences.

With your financial foundation established—startup costs understood, cash flow strategies in place, and pricing methodology defined—you're positioned to build a sustainable operation. But launching is just the beginning. The next challenge? Scaling that operation while maintaining the quality and reliability that earned your customers' trust in the first place.

Growth Strategies and Building Long-Term Success

You've launched your operation, established your customer base, and mastered the fundamentals. Now comes the question every successful fabricator eventually faces: how do you grow without losing what made you successful in the first place? Scaling a sheet metal fabrication business requires more than simply adding equipment and hiring more welders. It demands strategic thinking about quality systems, partnership networks, and market positioning that sustains profitability through every growth phase.

Whether you're running a sheet metal NY operation or building metal fabrication Albany capabilities, the path from startup to established player follows predictable patterns. Understanding these phases—and recognizing when you're ready to advance—separates fabricators who thrive long-term from those who plateau or stumble.

Scaling Production Without Sacrificing Quality

Here's the uncomfortable reality: growth breaks things. Processes that worked perfectly at $500,000 annual revenue often fail at $2 million. The informal quality checks your experienced fabricators performed naturally become inconsistent when you're training new hires and running multiple shifts.

According to manufacturing growth specialists, expanding a metal fabrication business can lead to improved economies of scale—with increased production levels, you benefit from lower average costs per unit, ultimately boosting profitability. But this cost advantage only materializes when quality remains consistent.

Before pursuing aggressive growth, ensure these foundations are solid:

- Documented procedures — Every critical process should have written instructions that new employees can follow without relying on tribal knowledge

- Quality checkpoints — Build inspection steps into your workflow rather than catching problems at final inspection

- Measurement systems — Track reject rates, rework hours, and customer complaints to identify problems before they escalate

- Equipment maintenance schedules — Preventive maintenance prevents the breakdowns that derail production when you're running at capacity

How do you know when your operation is ready to scale? Watch for these growth indicators that signal expansion readiness:

- Consistently turning away work due to capacity constraints

- Customer retention rates exceeding 80% with minimal complaints

- On-time delivery performance above 95%

- Profit margins stable or improving over consecutive quarters

- Cash reserves sufficient to fund growth without threatening operations

- Management bandwidth available to oversee expansion without neglecting current customers

Missing these indicators? Focus on strengthening fundamentals before adding capacity. Rapid steel NY operations and Excel Sheet Metal shops that scaled prematurely often regret it—new equipment sits underutilized while quality problems alienate existing customers.

Strategic Partnerships and Supply Chain Integration

You can't do everything yourself—and you shouldn't try. Strategic partnership research confirms that collaborating with other companies, suppliers, and stakeholders allows metal businesses to leverage each other's strengths and achieve mutual success.

Consider three partnership categories that accelerate growth:

Supplier partnerships go beyond transactional purchasing. Developing strategic relationships with material suppliers provides access to priority allocation during shortages, better pricing through volume commitments, and technical support that improves your material selection expertise. When steel fabricators New York operations cultivate these relationships, they gain competitive advantages that purely transactional buyers never access.

Complementary service providers expand your capabilities without capital investment. Maybe you excel at forming and welding but lack finishing capabilities. Partnering with powder coating or plating specialists lets you offer complete solutions while each party focuses on their core competencies.

Manufacturing partners handle specialized work beyond your equipment or certification scope. This is where strategic outsourcing becomes particularly valuable for growing fabrication businesses.

Imagine landing an automotive contract requiring precision stamping and IATF 16949 certification—capabilities you don't possess and can't quickly develop. Rather than declining the opportunity, partnering with certified manufacturers lets you expand into new markets while maintaining customer relationships. Companies like Shaoyi (Ningbo) Metal Technology specialize in exactly this niche—providing IATF 16949-certified custom metal stamping parts and precision assemblies for chassis, suspension, and structural components. Their 5-day rapid prototyping and comprehensive DFM support enable growing fabricators to pursue automotive opportunities without building those specialized capabilities in-house.

When evaluating potential partners, partnership specialists recommend looking for complementary strengths, shared goals and values, and proven reliability. Conduct due diligence to ensure partners can deliver on their commitments before staking your customer relationships on their performance.

Certifications That Open New Market Doors

Some markets remain locked until you hold the right credentials. Automotive and aerospace sectors particularly demand certifications that demonstrate systematic quality management—not just good intentions.

IATF 16949 stands as the international standard for automotive quality management systems. According to NSF, this certification provides a standardized Quality Management System focusing on driving continuous improvement, with emphasis on defect prevention and reduction of variation and waste in the automotive supply chain.

Why does IATF 16949 matter for your growth strategy? Most major automotive Original Equipment Manufacturers mandate this certification for their supply chain. Without it, you're locked out of automotive contracts regardless of your fabrication capabilities. The certification signals your commitment to:

- Systematic quality management embedded throughout operations

- Continuous improvement processes that reduce defects over time

- Risk management approaches that identify problems proactively

- Customer-focused thinking at every organizational level

The certification process follows a three-year cycle with annual audits ensuring continued compliance. Yes, it requires significant effort—documentation, process standardization, and organizational commitment. But organizations achieving certification report improved customer satisfaction, increased efficiency, and better market access.

Beyond IATF 16949, consider how other certifications align with your target markets:

- ISO 9001 — The foundational quality management standard applicable across industries

- ISO 14001 — Environmental management certification increasingly required by large manufacturers

- AS9100 — Aerospace quality standard for shops pursuing aviation contracts

- AWS certifications — Welding-specific credentials that validate operator competency

For ny sheet metal operations considering automotive expansion but lacking IATF 16949 certification, partnering with certified manufacturers provides immediate market access while you develop internal capabilities. This hybrid approach—serving customers directly for standard work while outsourcing certified requirements—lets you capture opportunities that would otherwise go to competitors.

The fabricators who build lasting success think beyond next month's orders. They invest in quality systems that scale, cultivate partnerships that expand capabilities, and pursue certifications that unlock premium markets. Whether you're an Excel Sheet Metal startup or an established operation ready for the next level, these strategic foundations determine whether growth strengthens your business or destabilizes it.

Your sheet metal fabrication business journey started with understanding the industry and identifying your market. Along the way, you've navigated permits, designed facilities, selected equipment, mastered materials, built teams, and established financial discipline. Now, with growth strategies in hand, you're equipped to transform that foundation into a profitable, sustainable operation that serves customers for years to come.

Frequently Asked Questions About Starting a Sheet Metal Fabrication Business

1. Is sheet metal fabrication a good business?

Yes, sheet metal fabrication is a profitable business opportunity. The industry supports lucrative sectors including automotive, aerospace, construction, and HVAC. The global market is projected to surpass £15 billion by 2030, with over 50% of vehicle components coming from sheet metal fabrication. Success depends on strategic market positioning, proper equipment investment, and building relationships with reliable customers who value quality and delivery consistency.

2. How much does it cost to start a sheet metal fabrication business?

Startup costs range from under $100,000 for a basic manual equipment shop to over $500,000 for operations with CNC technology. Major cost categories include equipment ($50,000-$500,000+), facility improvements ($20,000-$150,000), initial inventory ($15,000-$50,000), operating reserves (3-6 months of expenses), and permits ($5,000-$25,000). Your positioning—whether serving local contractors or pursuing precision manufacturing—directly impacts these numbers.

3. What equipment do I need to start a metal fabrication shop?

Essential startup equipment includes a manual or mechanical shear for cutting, a hydraulic press brake for forming, MIG and TIG welders for joining, grinders and finishing tools, plus measurement equipment. As your business grows, consider CNC press brakes for repeatable precision, CNC punch presses for complex patterns, and fiber laser cutters for intricate designs. Equipment choices should align with your target market and service offerings.

4. What licenses and permits are required for a metal fabrication business?

Required permits typically include a business license, zoning permit for industrial operations, air quality permit for emissions, stormwater permit, and fire department approval. Environmental compliance under EPA NESHAP Rule 6X applies to operations generating welding fumes or metal dust. OSHA standards mandate machine guarding, PPE requirements, and written safety programs. Requirements vary by location, so consult local authorities during planning.

5. How do I price sheet metal fabrication work profitably?

Build pricing using five components: material costs (including scrap percentage), fully-loaded labor rates, machine rates covering equipment investment and overhead, overhead allocation for indirect expenses, and profit margin (typically 10-25%). Factor in setup time, material handling, and quality inspection. For volume orders, adjust per-part pricing to reflect economies of scale. Always track actual costs against estimates to refine your pricing methodology over time.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —