Oil Pan Metal Stamping Process: The Complete Engineering Guide

TL;DR

The oil pan metal stamping process primarily utilizes deep draw technology to transform flat sheets of cold-rolled steel or aluminum into seamless, leak-proof reservoirs. This manufacturing workflow involves progressive steps including blanking, high-tonnage forming, precision trimming, and the resistance welding of internal baffles. Critical quality control measures, such as underwater leak testing and flange flatness verification, ensure these components meet strict automotive performance standards.

Phase 1: Material Selection and Preparation

The foundation of a durable, leak-free oil pan lies in selecting the correct raw material. Unlike cosmetic body panels, oil pans must withstand road debris, thermal cycling, and constant vibration. The most common material used in this process is Cold Rolled Steel (SPCC, DC04, DC06). These grades are favored for their excellent drawability—the ability to stretch significantly without tearing—and their cost-effectiveness for mass production.

For high-performance or luxury vehicles, Aluminum is often the material of choice due to its superior heat dissipation properties and lightweight characteristics, which contribute to overall fuel efficiency. However, aluminum requires more precise control during stamping to prevent cracking. Stainless steel is occasionally used for heavy-duty applications requiring extreme corrosion resistance, though its higher cost limits widespread adoption.

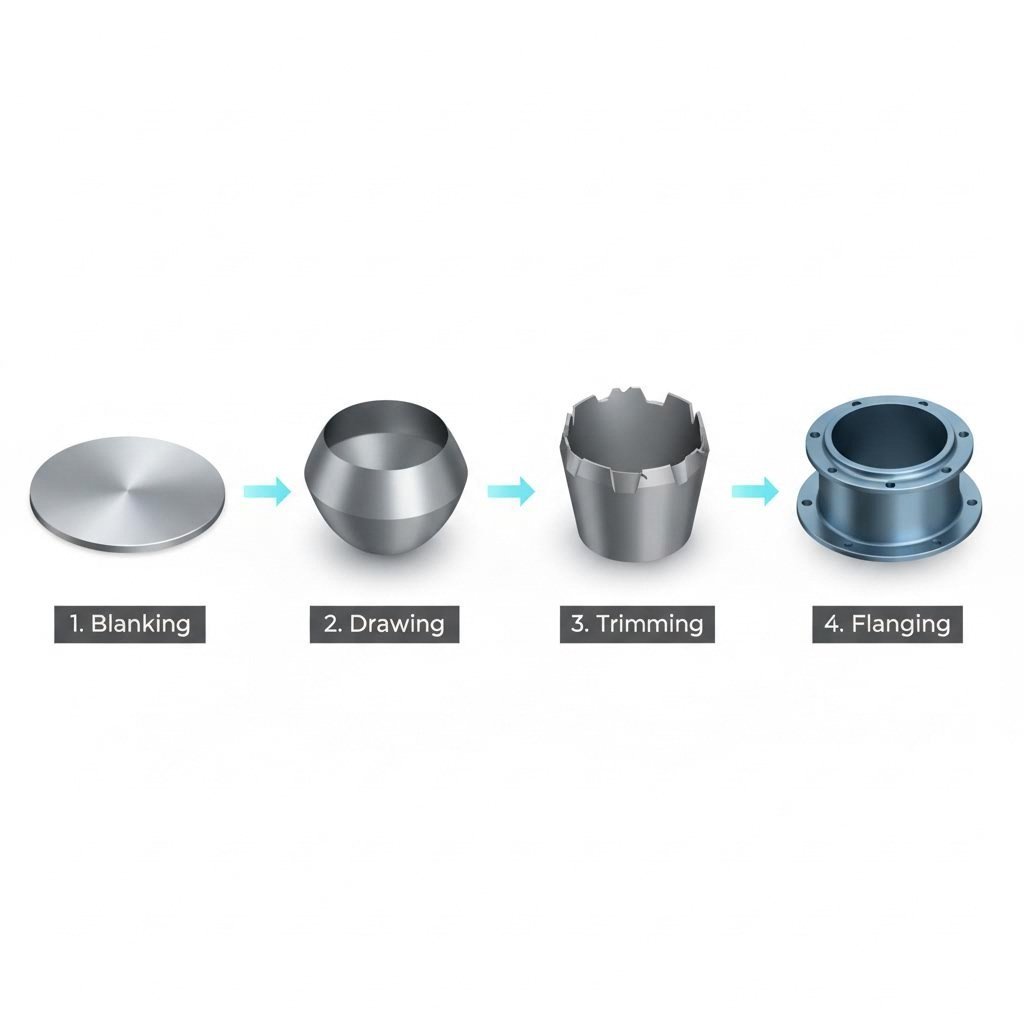

The process begins with blanking, where the initial shape is cut from a master coil. This is not merely cutting a rectangle; the blank's geometry is calculated to allow optimal material flow during the drawing phase. Using a pre-calculated shape minimizes waste and reduces the risk of wrinkles or tears during the subsequent deep draw operation.

Phase 2: The Deep Draw Stamping Workflow

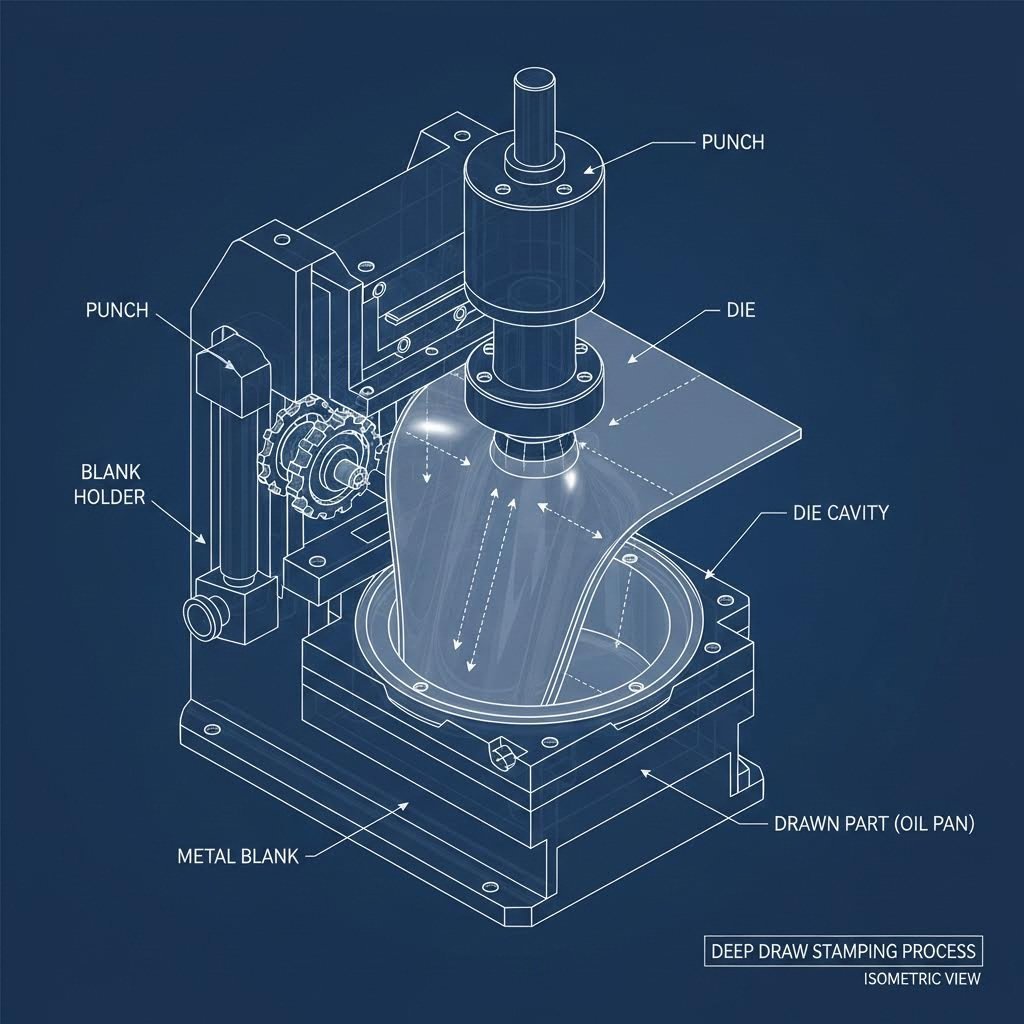

The core of oil pan manufacturing is deep draw stamping. This specific technique is defined by the depth of the part exceeding its diameter, distinguishing it from standard sheet metal bending. The process occurs in high-tonnage hydraulic or mechanical presses, where a punch forces the metal blank into a die cavity. Instead of stretching the metal until it thins dangerously, deep drawing encourages the material to flow plastically into the shape, maintaining structural integrity.

A typical deep draw sequence involves several critical actions:

- Die Positioning: The lubricated blank is secured over the die by a blank holder.

- Punch Descent: The punch descends with immense force, pushing the metal into the die.

- Material Flow Control: The blank holder applies precise pressure to prevent wrinkles (if too loose) or tearing (if too tight).

Achieving the complex geometry of a modern oil pan—often with varying depths to accommodate engine subframes—requires advanced machinery. For automotive OEMs requiring this level of precision—from rapid prototyping of 50 units to mass production of millions—partners like Shaoyi Metal Technology leverage IATF 16949-certified processes and presses up to 600 tons to ensure every component meets global standards. Their capabilities bridge the gap between initial design validation and full-scale manufacturing, ensuring that wall thickness and taper angles remain consistent throughout the draw.

Phase 3: Critical Secondary Operations

Once the basic cup shape is formed, the component undergoes secondary operations that differentiate a simple metal box from a functional engine oil sump. The first step is trimming, where the irregular edges left by the drawing process are cut away to establish the final dimensions.

Flanging is arguably the most critical secondary step. The mating surface of the oil pan must be perfectly flat to ensure a tight seal with the engine block gasket. Industry standards often dictate a flatness tolerance within 0.1mm over a 250mm length. Any deviation here can lead to catastrophic oil leaks in the finished vehicle.

Unlike simple stamped parts, oil pans are assemblies. This phase includes the integration of internal and external components:

- Baffle Welding: Internal baffles are spot-welded inside the pan to prevent oil slosh during acceleration or braking, which could starve the oil pickup tube.

- Drain Plug Mounts: A reinforced nut or seat is resistance-welded to the bottom, designed to withstand torque forces of over 80 N·m during routine maintenance.

- Surface Treatment: The final steel pans typically undergo e-coating (electrophoretic coating) or powder coating. This provides robust corrosion protection, essential for passing industry-standard salt spray tests of over 480 hours.

Phase 4: Quality Assurance and Testing

Before shipment, every oil pan must pass rigorous testing protocols to verify its reliability. Automotive standards require zero defects, as a failure in the field can ruin an engine.

| Test Method | Purpose | Standard Acceptance Criteria |

|---|---|---|

| Leak Testing | Verify seal integrity | No bubbles at 1.5 Bar air pressure (submerged 30s) |

| Flatness Inspection | Ensure gasket sealing | < 0.1mm deviation on flange surface |

| Salt Spray Test | Corrosion resistance | > 480 hours without red rust |

| Torque Testing | Drain plug durability | Withstand > 80 N·m torque without deformation |

Advanced facilities also utilize CMM (Coordinate Measuring Machines) and "Go/No-Go" gauges to verify complex geometric profiles. These inspections ensure that the pan will clear subframes, exhaust pipes, and suspension components when installed on the assembly line.

Integrated FAQ

1. What are the 7 steps in the stamping method?

The standard 7-step stamping workflow includes: (1) Design and simulation, (2) Tool and die manufacturing, (3) Material selection, (4) Blanking (cutting the initial shape), (5) Forming (deep drawing), (6) Secondary operations (trimming, piercing, welding), and (7) Finishing and inspection.

2. What is the process of hot stamping metal?

Hot stamping involves heating a steel sheet (often boron steel) to high temperatures (around 900°C) before stamping it in a cooled die. This rapidly cools (quenches) the part while forming it, creating an extremely hard and high-strength component. While common for safety-critical body pillars, standard oil pans are typically cold stamped.

3. Do you need a special hammer for metal stamping?

For industrial oil pan manufacturing, hammers are not used; hydraulic or mechanical presses do the work. However, in manual metal stamping or prototyping, a brass or plastic mallet is used to flatten or adjust metal without marring the surface, while a hardened steel hammer might be used with striking punches.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —