Titanium Stamping Automotive Performance: Engineering Guide

TL;DR

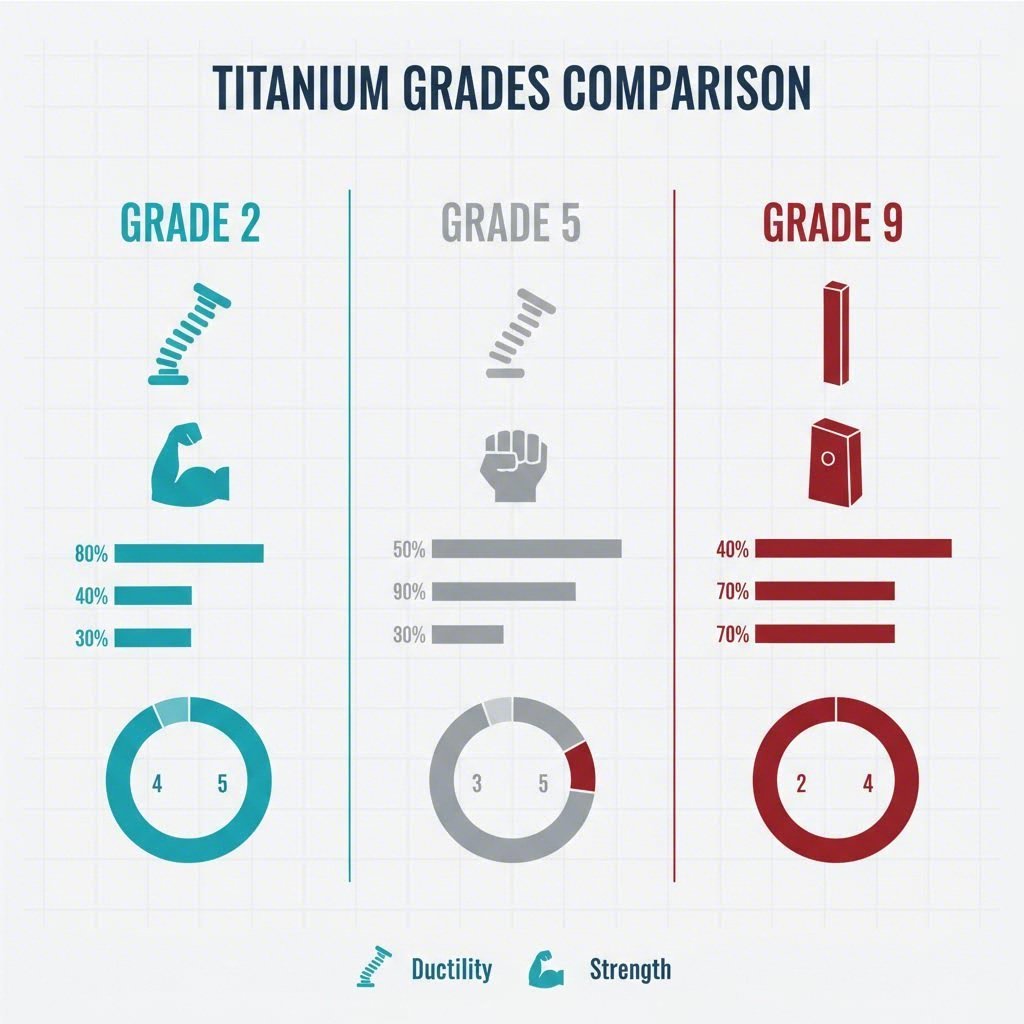

Titanium stamping for automotive performance offers a critical advantage in modern vehicle engineering: achieving a 40–50% weight reduction compared to steel while maintaining superior heat and corrosion resistance. For engineers and procurement officers, the viability of this process hinges on selecting the correct grade—typically Grade 2 (CP) for deep drawing or Grade 9 (Ti-3Al-2.5V) for tubing—and mastering the manufacturing challenges of Grade 5 (Ti-6Al-4V).

While titanium allows for lighter exhaust systems, valve retainers, and suspension components, it requires specialized stamping techniques to manage high springback and galling. Successful implementation demands tooling expertise, appropriate lubrication, and often hot forming capabilities to deliver precision parts that withstand the rigors of high-performance environments.

The Physics of Performance: Why Stamp Titanium?

In the pursuit of automotive performance, mass is the enemy. Titanium offers a density of approximately 4.51 g/cm³, roughly 56% that of steel (7.8 g/cm³), without sacrificing structural integrity. This specific strength (strength-to-weight ratio) makes it indispensable for reducing vehicle weight, which directly translates to improved acceleration, braking distances, and fuel efficiency.

Beyond static weight reduction, titanium plays a pivotal role in reducing reciprocating and unsprung mass. In engine applications, lighter valve train components (like stamped valve spring retainers) allow for higher RPM ceilings and faster throttle response. In suspension systems, replacing steel brackets or springs with titanium reduces unsprung weight, allowing the suspension to react more quickly to road surface changes, thereby enhancing grip and handling precision.

Thermal stability is another decisive factor. Unlike aluminum, which loses significant strength above 150°C, titanium alloys maintain their mechanical properties at temperatures exceeding 400°C. This makes stamped titanium ideal for heat shields and exhaust components that must endure extreme thermal cycling without warping or failing.

Material Selection: Matching Grade to Geometry

Not all titanium is suitable for every stamping operation. The success of a project often relies on selecting a grade that balances the component's performance requirements with its formability.

- Grade 1 & 2 (Commercially Pure): These are the "workhorses" of titanium stamping. Grade 2 offers a balanced combination of strength and ductility, making it the preferred choice for parts requiring deep drawing, such as muffler shells, heat shields, and intricate brackets. It can often be cold stamped with standard tooling adjustments.

- Grade 5 (Ti-6Al-4V): The most common alloy for high-strength applications, Grade 5 offers superior tensile strength but presents significant stamping challenges. Its poor room-temperature ductility often necessitates hot stamping (forming at elevated temperatures) to prevent cracking. It is typically reserved for high-stress structural components like fasteners and connecting rod shims.

- Grade 9 (Ti-3Al-2.5V): Often called the "middle ground," Grade 9 bridges the gap between the formability of Grade 2 and the strength of Grade 5. It is extensively used in hydraulic tubing, exhaust piping, and lightweight structural stampings where higher pressure resistance is needed than CP grades can provide.

- Beta Alloys (e.g., Ti-15-3): These alloys are cold-formable and heat-treatable, making them excellent candidates for stamped springs and complex clips where high elasticity is required.

Engineering Challenges: Springback and Galling

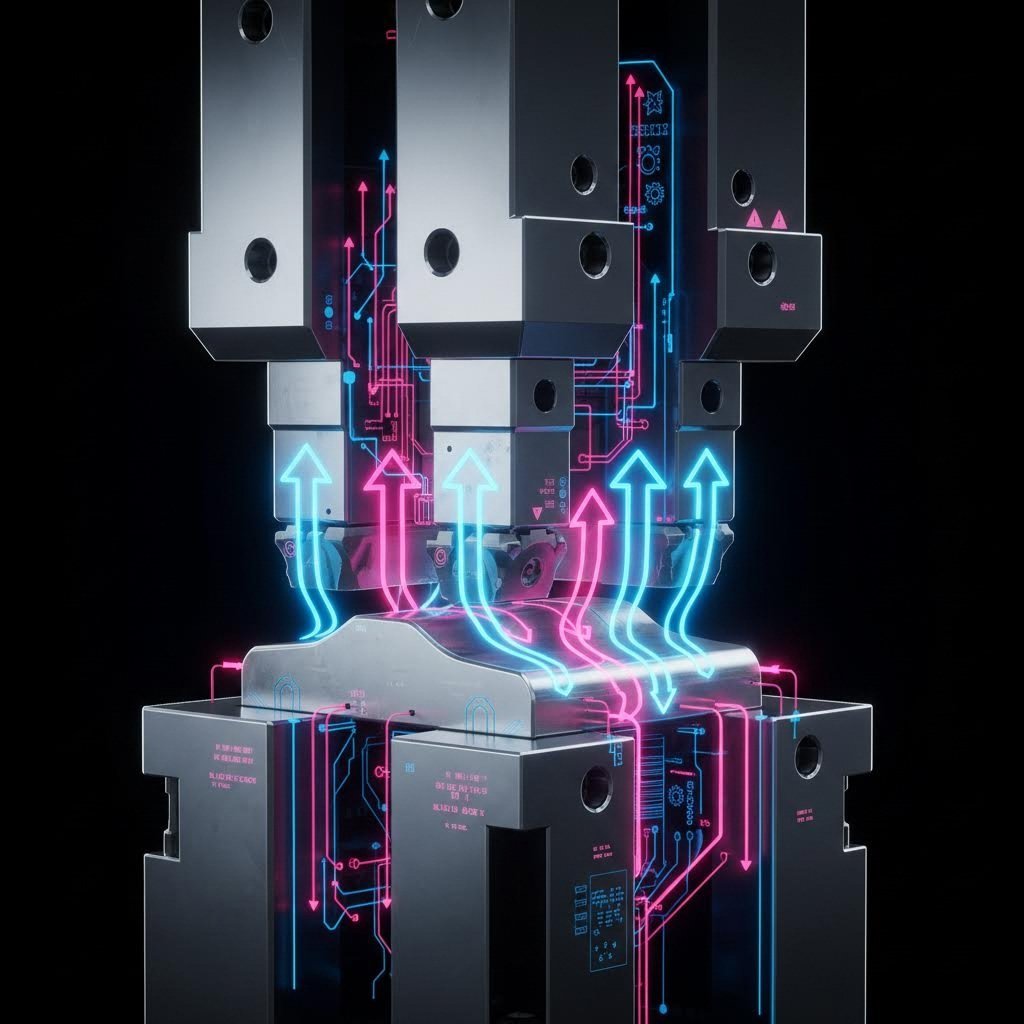

Stamping titanium is fundamentally different from stamping steel or aluminum due to two primary physical characteristics: a lower modulus of elasticity and high chemical reactivity.

Managing Springback

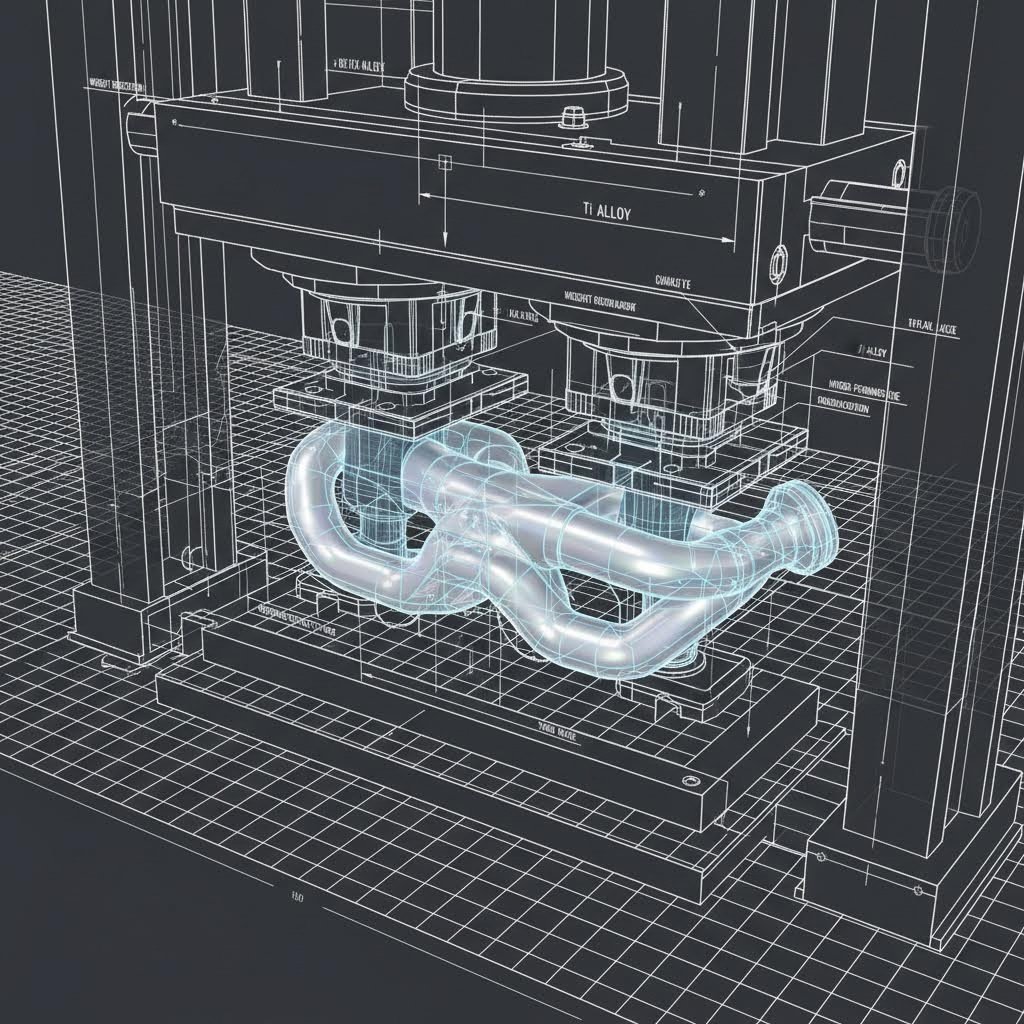

Titanium’s Young’s modulus is roughly half that of steel. This "springiness" means the material has a strong tendency to return to its original shape after forming. In stamping operations, this manifests as severe springback. Engineers must compensate for this by designing dies with significant overbending allowances. For complex geometries, hot sizing (holding the part in the die at temperature) is often required to set the final shape and relieve internal stresses.

Preventing Galling

Titanium is notorious for its tendency to seize or "gall" against tool steel. Under high pressure, the protective oxide layer strips away, causing the reactive metal to cold-weld to the die. To mitigate this, manufacturers employ advanced lubrication strategies, such as Molybdenum Disulfide (Moly) or graphite-based lubricants. Furthermore, tooling is often coated with Titanium Carbo-Nitride (TiCN) or Diamond-Like Carbon (DLC), and in some cases, bronze die inserts are used to provide natural lubricity and prevent adhesive wear.

Key Automotive Applications

Titanium stamped parts are found where the trade-off between cost and performance is justified. In high-performance and luxury vehicles, these components are critical for meeting weight targets.

| System | Component | Common Grade | Performance Benefit |

|---|---|---|---|

| Exhaust | Muffler shells, heat shields | Grade 2 (CP) | Corrosion resistance, 40% weight cut vs. stainless |

| Engine | Valve spring retainers, shims | Grade 5 / Beta | Higher RPM limit, reduced friction |

| Chassis | Brake shims, brackets | Grade 2 / 9 | Reduced unsprung weight, thermal isolation |

| Fasteners | Washers, clips | Grade 5 | High clamp load retention, no corrosion |

Cost Analysis and Sourcing Strategy

The economic reality of titanium stamping involves higher upfront costs. Raw material prices can be 10 to 20 times that of steel, and tooling life is shorter due to the abrasive nature of the metal. However, for performance applications, the lifecycle value—measured in fuel savings, durability, and competitive advantage—often outweighs the initial expense.

When vetting suppliers, look for partners who understand the nuances of hot forming and controlled atmosphere annealing. Shaoyi Metal Technology, for instance, offers specialized automotive stamping capabilities ranging from rapid prototyping to high-volume production. Their IATF 16949-certified facilities are equipped with presses up to 600 tons, bridging the gap for OEMs who need precision titanium components delivered with strict adherence to global standards. Verify their engineering services here to see how they handle complex material challenges.

Always verify a supplier's ability to perform secondary operations, such as trimming and surface finishing, as titanium burrs can be difficult to remove and require specialized deburring processes.

Summary: Is Titanium Stamping Feasible?

Titanium stamping is no longer reserved solely for aerospace and Formula 1. With the right grade selection and process control, it is a viable mass-production technology for high-performance automotive applications. The key lies in balancing the desire for Grade 5 strength with the manufacturing realities of formability, often finding the sweet spot with Grade 9 or optimized Grade 2 designs. As automakers continue to chase lightweighting goals for EV range and emissions compliance, stamped titanium components will play an increasingly central role.

Frequently Asked Questions

1. Why isn't titanium used for the entire car body?

While titanium offers an exceptional strength-to-weight ratio, its high raw material cost and complex processing requirements make it economically impractical for mass-market vehicle bodies. Manufacturing large panels would require immense press forces and expensive hot-forming tooling, driving the vehicle price far beyond consumer reach.

2. What are the main disadvantages of stamping titanium?

The primary disadvantages are high springback, which complicates tolerance control, and the risk of galling, which increases tooling wear. Additionally, titanium has lower formability than steel, meaning deep draws often require multiple stages with intermediate annealing to prevent cracking.

3. Can titanium stamped parts be welded?

Yes, titanium is weldable, but it requires a strictly controlled environment. Oxygen is the "enemy" of hot titanium; it absorbs oxygen rapidly above 400°C, causing embrittlement. Therefore, welding must be performed in an inert argon atmosphere or a vacuum chamber to maintain the material's ductility and strength.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —