Laser Cutting Metals Exposed: CO2 Vs Fiber Vs Nd

What Is Laser Cutting and Why It Dominates Metal Fabrication

Imagine transforming a solid steel plate into an intricate aerospace component with tolerances as tight as 0.1mm—all without a single physical tool ever touching the material. That's exactly what laser cutting metals delivers. This technology has revolutionized modern manufacturing by using a concentrated beam of light to melt, burn, or vaporize material along a precisely programmed path, creating cuts that traditional mechanical methods simply cannot match.

At its core, metal laser cutting works through an elegantly simple principle: focus enough energy on a single point, and you can slice through virtually any metal with surgical precision. A high-powered laser beam, guided by computer numerical control (CNC) systems, follows exact coordinates from CAD files to produce components that meet exact specifications without costly tooling adjustments.

How Focused Light Transforms Raw Metal

When you direct a laser that cuts metal at a workpiece, something remarkable happens. The concentrated beam heats the material to its melting or vaporization point within milliseconds. Assist gases—typically oxygen, nitrogen, or compressed air—then blow away the molten material, leaving behind a clean edge. This non-contact process means there's no physical wear on cutting tools and minimal mechanical stress on the workpiece itself.

The laser beam's narrow width produces exceptionally clean cuts while optimizing material usage. Advanced nesting software arranges parts strategically on each sheet, minimizing gaps and reducing waste. This efficiency proves particularly advantageous when working with expensive or scarce materials, directly impacting your bottom line.

The Science Behind Precision Metal Fabrication

So, can laser cut metal really achieve the precision that manufacturers demand? Absolutely. Modern fiber laser systems can cut materials ranging from 20-gauge stainless steel to inch-thick carbon steel with flawless consistency. The focused laser beam can cut intricate shapes and patterns with minimal margin for error, making laser cutting metal the preferred choice for applications where even slight deviations could compromise safety or functionality.

Laser cutting is more than just a manufacturing tool—it's a transformative technology driving innovation in fabrication by combining precision, speed, and adaptability into a versatile solution for projects requiring high tolerances, intricate designs, or quick turnarounds.

What makes this technology truly dominant in metal fabrication? Speed and efficiency play crucial roles. Laser cutting cutting processes can swiftly move through materials at high speeds, with some systems exceeding 2000 inches per minute. This translates to shorter production durations, increased throughput, and the ability to meet tight deadlines that would be impossible with conventional methods.

The minimal heat-affected zones produced during laser cutting prevent warping, distortion, or material degradation—critical factors when working with heat-sensitive alloys or maintaining tight dimensional tolerances. Combined with seamless CNC integration that enables lights-out operation, this technology represents the gold standard for industries demanding both quality and efficiency.

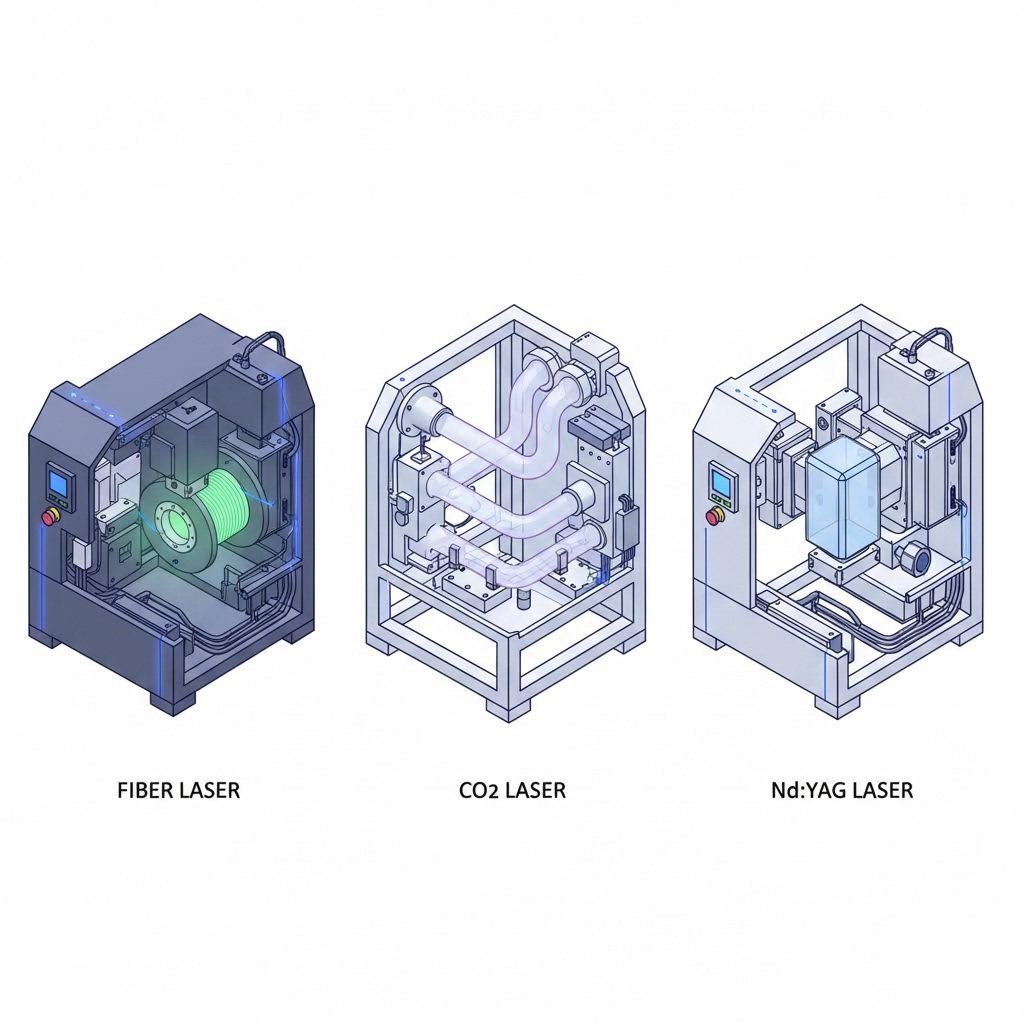

CO2 vs Fiber vs Nd YAG Laser Technologies Explained

Now that you understand how laser cutting metals works, the next question becomes: which laser type should you actually use? The answer depends entirely on your materials, thickness requirements, and production goals. Three primary technologies dominate the industrial landscape—CO2, fiber, and Nd:YAG lasers—and each brings distinct advantages to specific applications.

Think of these cutting lasers as specialized tools rather than one-size-fits-all solutions. A fiber laser excels where a CO2 laser struggles, and vice versa. Understanding these differences helps you match the right technology to your specific metal cutting needs.

Fiber Lasers and Their Dominance in Thin Metal Processing

Fiber laser cutting for metal has transformed the industry over the past decade. These solid-state systems use doped glass fibers and pump diodes to generate high-intensity beams at a 1.064 µm wavelength—approximately 10 times shorter than CO2 lasers. This shorter wavelength gets absorbed more efficiently by metals, translating to faster cuts and lower operating costs.

What makes fiber laser for cutting metal so compelling? The numbers tell the story. According to Xometry, fiber lasers deliver approximately 3 to 5 times the productivity of similarly capable CO2 machines on appropriate jobs. They also achieve over 90% energy efficiency, compared to just 5-10% for CO2 alternatives. This efficiency gap directly impacts your electricity bills and cooling requirements.

Fiber lasers truly shine when cutting reflective metals that would cause problems for other types of laser cutters. Materials like aluminum, copper, brass, and titanium—historically difficult to process—become manageable with fiber technology. The beam intensity can reach up to 100 times that of CO2 lasers, enabling deep engraving and clean cuts through challenging materials.

Another advantage? Maintenance. Fiber lasers boast lifespans exceeding 25,000 working hours—roughly 10 times longer than CO2 devices. There are no mirrors to align, no gas tubes to replace, and no consumable optics degrading over time.

When CO2 Lasers Still Make Sense

Despite fiber's dominance in metal applications, CO2 laser metal cutting maintains a strong foothold in specific scenarios. Operating at 10.6 µm wavelength, these versatile workhorses excel with mixed-material workshops processing both metals and non-metals.

CO2 laser cutting steel becomes particularly advantageous when working with thicker plates. For materials exceeding 10-20mm, CO2 systems with oxygen assist can efficiently process plates up to 100mm thick. The longer wavelength also produces smoother edges on certain materials, making CO2 the preferred choice for applications where edge quality matters more than speed.

The initial investment tells a different story too. CO2 laser cutter laser systems cost significantly less upfront—often 5 to 10 times cheaper than equivalent fiber machines. For shops with limited capital or lower production volumes, this accessibility makes CO2 a practical entry point into laser cutting.

Nd:YAG Lasers for Specialty Applications

Nd:YAG (neodymium-doped yttrium aluminum garnet) lasers occupy a niche but important position among types of laser cutters. Known for exceptional precision, these systems suit specialty applications like jewelry manufacturing, electronics fabrication, and micromachining where ultra-fine detail matters most.

However, Nd:YAG technology comes with limitations. These lasers work best on thinner materials and cannot match the cutting speed or thickness capabilities of fiber or CO2 alternatives. They've largely been superseded by fiber lasers in most industrial applications, though they remain valuable for specific precision work.

| Parameter | Fiber Laser | CO2 Laser | Nd:YAG Laser |

|---|---|---|---|

| Wavelength | 1.064 µm | 10.6 µm | 1.064 µm |

| Best Metal Applications | Steel, stainless, aluminum, copper, brass, titanium | Thick steel plates, mixed metal/non-metal shops | Jewelry, electronics, microfabrication |

| Typical Thickness Range | Up to 20-25mm (optimal for thin-medium) | Up to 100mm with oxygen assist | Thin materials only |

| Cutting Speed (vs CO2) | 3-5x faster on thin metals | Baseline | Slower than fiber |

| Energy Efficiency | >90% | 5-10% | ~15-20% |

| Lifespan | 25,000+ hours | ~2,500 hours | Moderate |

| Maintenance | Very low | Moderate (gas, mirrors, optics) | Moderate |

| Initial Cost | High | Low to moderate | Moderate to high |

| Reflective Metal Capability | Excellent | Limited | Good |

Choosing between these technologies ultimately comes down to matching capabilities to your specific requirements. Fiber lasers dominate for thin to medium metals, especially reflective materials. CO2 systems remain valuable for thick plate cutting and mixed-material operations. Nd:YAG serves precision niches where ultra-fine detail outweighs speed considerations.

With laser technology fundamentals covered, the next critical question becomes: exactly which metals can you cut, and how thick can you go with each?

Compatible Metals and Thickness Limitations for Laser Cutting

You've got a project requiring precision metal parts—but will your material actually work with laser cutting? This question trips up many manufacturers and designers. The truth is, laser cutting of metal sheets handles an impressive range of materials, but each metal comes with specific thickness limits and processing requirements you need to understand before committing to production.

Not all metals behave the same under a concentrated laser beam. Some absorb energy efficiently and cut cleanly. Others reflect so much light back that they can damage equipment or produce inconsistent results. Let's break down exactly what you can cut, how thick you can go, and what special considerations apply to each material type.

Steel and Stainless Steel Cutting Capabilities

Mild steel and stainless steel remain the workhorses of laser cutting operations. These ferrous metals absorb laser energy efficiently, making them ideal candidates for both fiber and CO2 systems. When you need to laser cut steel for structural components, enclosures, or precision parts, you're working with materials that respond predictably to the process.

According to industry specifications from DW Laser, mild steel laser cutting can handle material up to 25mm thick using laser power ranging from 1.5 to 6 kW. Stainless steel follows closely, with maximum thicknesses reaching 20mm at similar power levels. These figures represent practical working limits—you may achieve thicker cuts with higher-powered equipment, but edge quality and speed trade-offs become significant.

What makes laser cutting steel plate so effective? The material's thermal properties allow for clean melt ejection when combined with oxygen assist gas. The exothermic reaction between iron and oxygen actually adds energy to the cutting process, enabling faster speeds and thicker capacity than nitrogen cutting alone would allow.

For thin metal parts in stainless steel—think precision brackets, medical components, or electronic enclosures—fiber lasers deliver exceptional results. Their shorter wavelength produces narrower kerfs and tighter tolerances, making them the preferred choice for applications demanding accuracy within 0.1mm.

Aluminum and Reflective Metal Challenges

Here's where things get interesting. Aluminum, copper, brass, and other reflective metals have historically presented challenges for laser cutting operations. These materials can reflect up to 95% of laser energy directed at them, creating two serious problems: inefficient cutting and potential damage to laser equipment.

Why does reflectivity matter so much? When a laser beam bounces back instead of being absorbed, the energy that should be melting your workpiece travels back toward the laser source. Traditional CO2 systems are particularly vulnerable to this reflected energy, which can damage optics and reduce equipment lifespan.

Modern fiber lasers have changed the game for reflective materials. As noted by iGolden Laser, fiber lasers emit light at approximately 1.07 µm wavelength, which reflective metals absorb more effectively than the 10.6 µm wavelength of CO2 lasers. This shorter wavelength reduces reflection problems and allows for stable cutting processes on materials that would damage older equipment.

Laser cutter aluminum capabilities have expanded significantly with fiber technology. Current systems can process aluminum up to 12mm thick using 1.5 to 3 kW power settings. An aluminum cutting laser works best with nitrogen assist gas, which prevents oxidation and produces clean, bright edges suitable for visible applications.

Copper and brass present even greater challenges due to their exceptional thermal conductivity—heat disperses rapidly through the material instead of concentrating at the cut zone. Fiber lasers equipped with reflection absorption systems can now handle copper up to 6mm and brass up to 8mm thick. Using nitrogen as the cutting gas for brass helps reduce oxidation and improves edge quality, while oxygen assist can actually help with copper by creating a lower-reflectivity oxide layer.

| Metal Category | Material | Max Thickness (mm) | Recommended Laser Type | Special Considerations |

|---|---|---|---|---|

| Ferrous | Mild Steel | Up to 25 | Fiber or CO2 | Oxygen assist enhances speed and thickness capacity |

| Ferrous | Stainless Steel | Up to 20 | Fiber or CO2 | Nitrogen assist prevents oxidation for clean edges |

| Non-Ferrous | Aluminum | Up to 12 | Fiber (preferred) | Highly reflective; requires nitrogen assist gas |

| Non-Ferrous | Copper | Up to 6 | Fiber with protection | Extremely reflective and conductive; reflection protection essential |

| Non-Ferrous | Brass | Up to 8 | Fiber with protection | Nitrogen assist reduces oxidation; cleaner edges than oxygen |

| Alloy | Titanium | Up to 10 | Fiber | Requires inert gas shielding; aerospace-grade quality achievable |

Key Factors Affecting Maximum Cutting Thickness

The thickness values above represent typical capabilities, but your actual results depend on several interacting variables. Understanding these factors helps you predict what's achievable for your specific application:

- Laser Power: Higher wattage enables thicker cuts. A 1 kW fiber laser might handle 5mm stainless steel efficiently, while a 3 kW system can process up to 12mm of the same material with good edge quality.

- Material Reflectivity: Highly reflective metals require more energy to initiate cutting and may need specialized equipment with reflection protection systems.

- Thermal Conductivity: Materials like copper dissipate heat rapidly, requiring higher power density and slower speeds to maintain the melt zone.

- Assist Gas Selection: Oxygen creates exothermic reactions with steel, enabling thicker cuts. Nitrogen produces cleaner edges on stainless and aluminum but limits maximum thickness. Compressed air offers a cost-effective middle ground for less demanding applications.

These variables don't operate independently—they interact in complex ways. Cutting 20mm mild steel with oxygen requires different speed and power settings than cutting 10mm stainless with nitrogen. Experienced operators adjust multiple parameters simultaneously to optimize results for each specific material and thickness combination.

With material compatibility and thickness limits clearly mapped out, the next logical step is understanding how the entire cutting process works—from your initial CAD design through to the finished part leaving the machine.

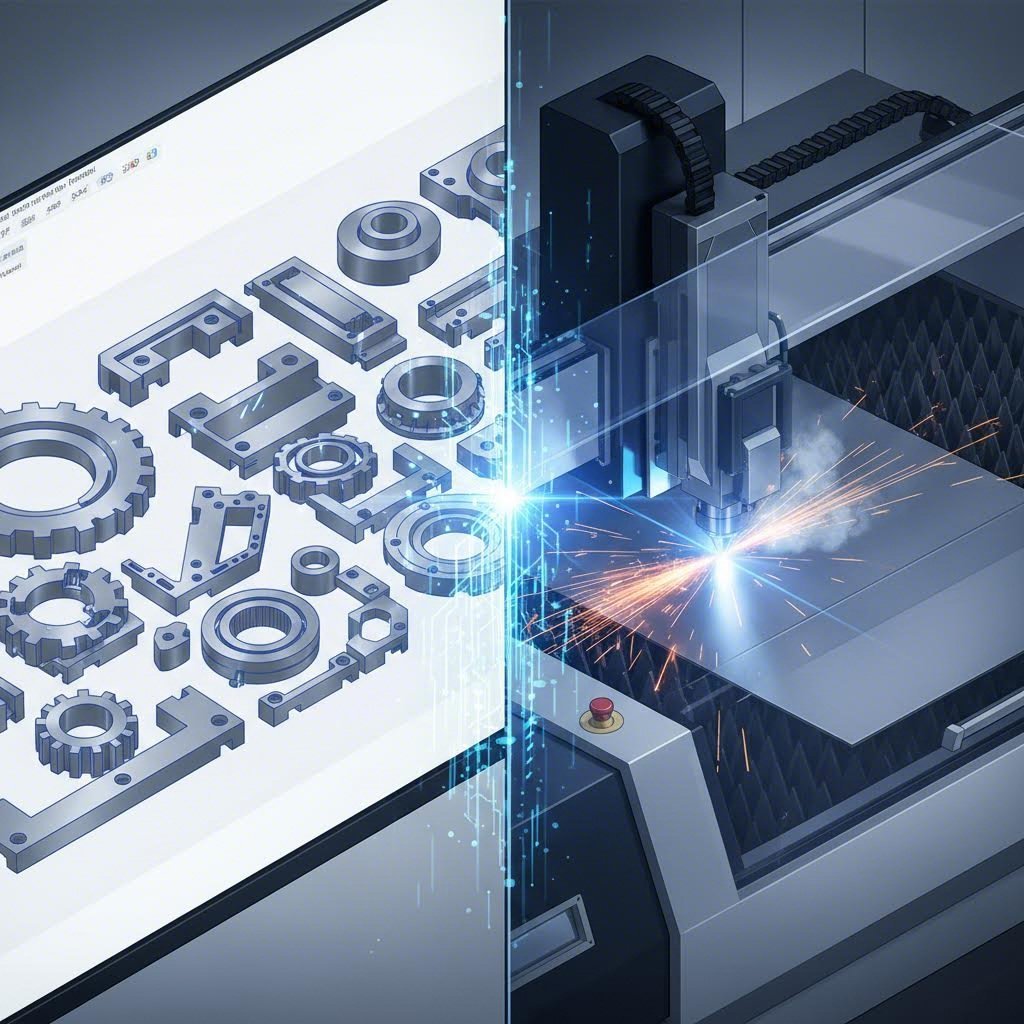

The Complete Laser Cutting Workflow from Design to Finished Part

So you've selected your laser type and confirmed your material is compatible—now what? Understanding the complete laser cutting process transforms you from a passive buyer into an informed partner who can communicate effectively with fabricators, troubleshoot issues, and optimize designs for manufacturability. Whether you're evaluating a laser cutting machine for metal in-house or working with an external service provider, knowing this workflow inside-out helps you get better results faster.

The journey from concept to finished component involves six distinct stages, each building on the previous. Skip or rush any step, and you'll likely encounter quality issues, wasted material, or costly rework. Let's walk through exactly what happens when you cut with laser technology—and the critical decisions that determine success or failure at each phase.

From CAD File to Cut Edge

Every laser cutting project begins with a digital design. Engineers and product designers create part geometry using CAD (Computer-Aided Design) software, defining dimensions, tolerances, and specifications the finished component must meet. This file becomes the master reference for everything that follows.

But here's what many people miss: your CAD file isn't directly readable by a metal cutting laser machine. It must first be converted into a format the equipment can interpret—typically a vector file or CAM (Computer-Aided Manufacturing) data. This conversion defines the exact cutting path, optimizing both speed and material usage while ensuring the laser machine to cut metal follows precise trajectories.

- CAD Design Creation: Define part geometry, dimensions, and specifications in CAD software. Include considerations for kerf width (the material removed during cutting) and any tolerances critical to your application.

- Design Review and DFM Analysis: Evaluate the design for manufacturability. Can the laser cutting metal machine actually produce these features? Are internal corners too sharp? Will thin sections warp from heat? Catching issues here saves significant time and cost downstream.

- Nesting Optimization: Arrange multiple parts strategically on sheet metal to minimize waste. Advanced nesting software considers part priorities, delivery deadlines, rotation constraints, and even center of gravity to prevent tilting during cutting.

- Machine Programming: Generate the machine code defining laser head trajectories, cutting sequences, lead-ins/lead-outs, and micro-joining positions if needed. The program must automatically calculate movements to avoid collisions with already-cut parts.

- Material Setup: Position raw sheet material on the cutting bed, ensuring proper alignment and flatness. An uneven cutting bed causes focus variations that degrade cut quality.

- Cutting Execution: The laser cutting machine for metal executes the programmed path. Cutting metal with a laser happens at remarkable speed—some systems exceed 2000 inches per minute on thin materials.

- Post-Processing: Remove finished parts from the skeleton (remaining sheet material). Depending on application requirements, additional operations like deburring, coating, or assembly may follow.

According to Artilux NMF, early collaboration between designers and fabricators to review CAD files for manufacturability reduces errors and shortens production time. This upfront investment pays dividends throughout the remaining process steps.

Critical Parameters That Determine Cut Quality

Sounds complex? It can be—but understanding the four primary cutting parameters gives you the foundation to evaluate results and communicate effectively with operators. These variables interact constantly, and mastering their relationships separates acceptable cuts from exceptional ones.

Laser Power: Measured in watts, power determines the energy delivered to your material. Higher power enables faster cutting speeds and thicker material processing. According to ACCURL, a 500-watt laser may struggle with thicker aluminum, producing slower cuts with rougher edges, while a 1000-watt system cuts the same material more quickly with higher precision and smoother edges. But more power isn't always better—excessive power on thin materials causes excessive heat damage and poor edge quality.

Cutting Speed: How fast the laser head moves across the material surface. Speed and power are directly linked: higher power allows faster speeds. Lower speeds improve precision for intricate designs but increase production time and can cause heat buildup on sensitive materials. Finding the optimal balance for each material and thickness is essential.

Focal Point Position: The laser beam must focus precisely on (or slightly below) the material surface. A well-focused beam concentrates power into a smaller area, increasing intensity and producing cleaner, more accurate cuts. If focus drifts even slightly—due to material warping, bed unevenness, or calibration issues—cut quality deteriorates immediately.

Assist Gas Pressure: Compressed gases like oxygen, nitrogen, or air blow molten material from the cut zone, prevent oxidation, and improve edge quality. Gas selection and pressure dramatically affect results:

- Oxygen: Creates exothermic reactions with steel, adding energy and enabling thicker cuts at faster speeds. Produces an oxide layer on cut edges.

- Nitrogen: Prevents oxidation for clean, bright edges on stainless steel and aluminum. Requires higher pressure but delivers superior edge quality for visible applications.

- Compressed Air: Cost-effective option for less demanding applications, offering a balance between oxygen and nitrogen performance.

These parameters don't exist in isolation—they form an interconnected system. Increase laser power, and you may need to increase cutting speed to prevent heat damage. Switch from nitrogen to oxygen assist, and optimal speed settings change entirely. Material type, thickness, and surface condition all influence the ideal parameter combination.

Proper parameter management directly impacts cut quality, machine longevity, and operating costs. An experienced operator adjusts power, speed, focus, and gas pressure simultaneously based on material properties—a skill that transforms theoretical capability into consistent, real-world results.

Machine calibration ties everything together. Aligning the laser beam, verifying focus accuracy, and confirming all mechanical components function correctly ensures parameters translate into consistent cutting quality. Poor calibration results in uneven cuts, reduced precision, and inefficient use of laser power—even when theoretical settings are correct.

Understanding this workflow and these parameters positions you to make informed decisions about your metal cutting projects. But how does laser cutting actually compare to alternatives like plasma, waterjet, or mechanical methods? The next section breaks down when laser technology offers the best value—and when other approaches might serve you better.

Laser Cutting vs Plasma Waterjet and Mechanical Alternatives

You've got a metal cutting project on your desk. The design is finalized, material selected, and now comes the pivotal question: which cutting method actually makes financial sense? Laser cutting metals delivers exceptional precision, but it's not always the most cost-effective choice. Understanding how laser technology stacks up against plasma, waterjet, mechanical cutting, and EDM helps you allocate budget wisely and avoid expensive mismatches between technology and application.

The reality? Each machine that cuts metal excels in specific scenarios and falls short in others. A decision based solely on precision ignores operating costs. A choice driven purely by equipment price overlooks long-term efficiency. Let's break down the true economics and help you determine when laser cutting deserves your investment—and when alternatives deliver better value.

Understanding the True Cost of Laser Cutting

When evaluating a metal cutting laser system, the sticker price tells only part of the story. According to Xometry, a quality waterjet cutting machine starts around $100,000, while smaller units begin near $60,000. Plasma systems typically cost significantly less—a complete plasma setup runs approximately $90,000 according to Wurth Machinery, compared to around $195,000 for a similarly-sized waterjet system. Fiber laser systems command premium prices, often 5 to 10 times higher than equivalent CO2 machines.

But initial investment only scratches the surface. Operating costs per hour vary dramatically between technologies. Plasma cutting offers the lowest per-foot costs when processing thick conductive metals. Laser cutting's energy efficiency—particularly with fiber systems achieving over 90% efficiency—reduces electricity expenses significantly compared to plasma or CO2 alternatives. Waterjet consumables (abrasive garnet, nozzles, and high-pressure components) add substantial ongoing expenses that can surprise first-time buyers.

If you're researching laser cutters for sale, factor in these hidden costs: assist gas consumption, lens and nozzle replacement, cooling system maintenance, and operator training. A machine for cutting metal looks attractive at $50,000 until you realize consumables and utilities add $30 per hour to your operating budget.

The cnc laser cutter price also reflects capability tiers. Entry-level systems handle basic sheet metal work, while production-grade equipment designed for continuous operation commands significantly higher investment. Match your actual production volume to equipment capability—overspending on capacity you'll never use wastes capital, while undersized equipment creates bottlenecks.

When Alternative Methods Offer Better Value

Here's what the marketing materials don't emphasize: laser cutting isn't always the right answer. Each cutting and welding machine technology occupies a specific performance envelope where it outperforms alternatives. Understanding these boundaries prevents costly misapplication.

Plasma cutting dominates thick conductive metal applications. As noted by Wurth Machinery, plasma cutters cut 1-inch steel approximately 3-4 times faster than waterjet, with operating costs roughly half as much per foot. For structural steel fabrication, heavy equipment manufacturing, and shipbuilding where precision requirements are moderate, plasma delivers the best speed-to-cost ratio.

Waterjet cutting becomes essential when heat damage cannot be tolerated. According to Flow Waterjet, this cold-cutting process leaves no heat-affected zones, stress marks, or material hardening—critical for aerospace components, medical devices, or heat-treated materials. Waterjet also cuts virtually any material up to 24 inches thick for rough cuts, offering unmatched versatility across metals, composites, stone, and glass.

EDM (Electrical Discharge Machining) serves specialty applications requiring extreme precision. Though the slowest of these processes, EDM produces exceptional surface finishes and handles advanced geometries that challenge other methods. For roughing extremely large parts or cutting hardened materials requiring specific edge finishes, EDM remains valuable despite its speed limitations.

Mechanical cutting—including saws, shears, and punches—offers the lowest equipment costs. According to Xometry, a hacksaw costs $6-$40, reciprocating saw $30-$95, and circular saw around $150. For simple straight cuts, high-volume blanking, or operations where precision isn't critical, mechanical methods remain cost-effective alternatives.

| Factor | Laser Cutting | Plasma Cutting | Waterjet Cutting | Mechanical Cutting | EDM |

|---|---|---|---|---|---|

| Initial Equipment Cost | $50,000-$500,000+ | ~$90,000 | $100,000-$195,000+ | $6-$5,000 | $50,000-$200,000+ |

| Operating Cost/Hour | Moderate (high efficiency) | Low | High (consumables) | Very Low | Moderate |

| Material Thickness Range | Up to 25mm (optimal thin-medium) | Best for 0.5"+ thick metals | Up to 24" (rough cuts) | Varies by tool | Up to 12" |

| Precision Level | Excellent (±0.1mm) | Good | Excellent | Moderate | Exceptional |

| Edge Quality | Excellent, minimal finishing | Requires secondary finishing | Satin smooth, no finishing | May require finishing | Excellent finish |

| Heat-Affected Zone | Minimal | Significant | None (cold process) | None | Minimal |

| Best Applications | Precision parts, complex shapes, thin-medium metals | Thick steel, structural fabrication | Heat-sensitive materials, mixed materials | Simple cuts, high-volume blanking | Hardened materials, extreme precision |

Decision Framework: Matching Technology to Application

Choosing the right machine for cutting metal requires honest assessment of your actual requirements—not aspirational capabilities you might someday need. Consider these scenarios where laser cutting provides clear advantages:

- High-precision requirements: When tolerances tighter than ±0.25mm matter, laser cutting's accuracy justifies premium costs. Medical devices, electronics enclosures, and aerospace components often fall into this category.

- Complex geometries: Intricate patterns, small holes, and tight internal corners that challenge plasma or mechanical methods are routine for laser systems.

- Thin to medium materials: For sheet metal under 10mm thick, laser cutting delivers unmatched speed and edge quality—especially with fiber technology.

- High-volume production: When amortizing equipment costs across thousands of parts, laser cutting's speed and consistency create compelling per-part economics.

- Minimal post-processing needs: Laser-cut edges often require no secondary finishing, eliminating labor and equipment costs for deburring or grinding.

Conversely, alternative methods may serve you better in these situations:

- Very thick materials: For steel plates exceeding 25mm, plasma cutting offers better speed and cost efficiency. Waterjet handles even thicker materials when precision matters.

- Heat-sensitive applications: When heat-affected zones are unacceptable—heat-treated materials, certain alloys, or applications near sensitive components—waterjet's cold cutting process is essential.

- Budget constraints: If capital is limited and precision requirements are moderate, plasma or mechanical cutting may deliver acceptable results at a fraction of laser equipment costs.

- Mixed material shops: Waterjet cuts virtually anything—metals, composites, stone, glass, rubber—making it ideal for shops processing diverse materials.

- Simple geometry, high volume: For straight cuts or basic shapes at high volume, mechanical shearing or punching often outperforms laser on cost-per-part basis.

The most successful fabrication operations often incorporate multiple technologies. Many shops start with plasma or laser for their primary applications, then add complementary methods as business grows. This hybrid approach covers more ground than any single technology could achieve alone.

Cost comparison only tells part of the story, though. Before investing in any metal cutting technology, you'll need to understand the safety protocols and regulatory requirements that govern industrial laser operations—a topic that surprisingly few competitors address comprehensively.

Safety Protocols and Regulatory Compliance for Laser Operations

You've evaluated costs, compared technologies, and identified the right laser system for your application. But here's what many buyers overlook until it's too late: industrial laser metal cutting equipment operates under strict safety and regulatory frameworks that can significantly impact your operations. Ignoring these requirements doesn't just risk fines—it puts your people and facility in genuine danger.

Unlike conventional machine tools, sheet metal laser cutting equipment generates invisible hazards that extend far beyond the cutting zone. High-intensity beams can cause permanent eye damage in milliseconds. Toxic fumes require specialized extraction. Electrical systems operate at lethal voltages. Understanding these risks—and the controls that mitigate them—is essential before any industrial metal laser cutting machine enters your facility.

Laser Safety Classifications and Operator Protection

Every laser system receives a hazard classification that determines required safety controls. According to OSHA's Technical Manual, industrial metal laser machines used for cutting metals fall into Class IV—the highest hazard category. These systems present direct ocular hazards, diffuse reflection hazards, and fire risks simultaneously.

What makes Class IV lasers particularly dangerous? The beam intensity can cause permanent blindness from even brief exposure to direct or reflected light. Diffuse reflections—light scattered off the workpiece surface—remain hazardous at distances that surprise many operators. And unlike visible light hazards where you'd instinctively look away, invisible infrared wavelengths from fiber and Nd:YAG lasers cause damage before you realize exposure has occurred.

The ANSI Z136.1 standard, referenced by the Laser Institute of America, serves as the foundation for industrial laser safety programs. This voluntary consensus standard—which many employers adopt as mandatory policy—establishes requirements for engineering controls, administrative procedures, and personal protective equipment.

- Laser Safety Eyewear: Optical density (OD) rated for your specific laser wavelength and power level. A cutting lab using a 1064nm fiber laser requires different protection than a CO2 facility operating at 10.6µm.

- Protective Housing and Interlocks: Class IV lasers must be enclosed during normal operation, with safety interlocks that disable the beam when access panels open.

- Warning Signs and Labels: Standardized laser warning signage posted inside and outside controlled areas, plus equipment labels specifying laser class, wavelength, and power output.

- Beam Path Controls: Beam stops, baffles, and enclosures that prevent stray reflections from reaching personnel or exiting the controlled area.

- Standard Operating Procedures (SOPs): Written protocols covering normal operation, maintenance, alignment, and emergency procedures specific to your equipment and applications.

A designated Laser Safety Officer (LSO) must oversee compliance in any facility operating Class IIIB or Class IV lasers. This individual—required by ANSI Z136.1—holds responsibility for hazard evaluation, control implementation, training verification, and incident investigation. The LSO role isn't ceremonial; it requires genuine technical competence and authority to enforce safety requirements.

Regulatory Compliance for Industrial Laser Operations

Multiple regulatory bodies govern laser cutting operations in the United States, each addressing different aspects of safety and compliance. Understanding this landscape prevents costly violations and ensures your cutting lab meets all applicable requirements.

The FDA's Center for Devices and Radiological Health (CDRH) regulates laser product manufacturing under 21 CFR Part 1040—the Federal Laser Product Performance Standard. Any laser product manufactured or imported after August 2, 1976 must comply with these performance and labeling requirements. While primarily a manufacturer obligation, end users should verify equipment compliance and maintain required documentation.

OSHA doesn't maintain a comprehensive laser-specific standard for general industry. However, the agency enforces laser safety through the General Duty Clause and references consensus standards like ANSI Z136.1 when citing violations. The construction industry faces more specific requirements under 29 CFR 1926.54 and 1926.102(b)(2), which mandates appropriate laser safety eyewear for exposed workers.

NFPA 115 addresses fire protection requirements specific to laser operations. This standard covers laser beam ignition potential evaluation, flammable gas and liquid handling, emergency preparedness, and fire safety training. Given that Class IV lasers present genuine fire hazards—they can ignite combustible materials and cutting byproducts—compliance with NFPA 115 represents both a safety imperative and potential insurance requirement.

Ventilation, Fume Extraction, and Environmental Considerations

When lasers vaporize metal, they don't just create clean cuts—they generate hazardous fumes and particulates requiring proper control. According to OSHA guidance, adequate ventilation shall reduce noxious or potentially hazardous fumes to levels below applicable Threshold Limit Values (TLVs) or Permissible Exposure Limits (PELs).

Different metals produce different hazards when laser-cut. Galvanized steel releases zinc oxide fumes. Stainless steel generates hexavalent chromium—a known carcinogen. Coated or painted materials may release volatile organic compounds. Your fume extraction system must be designed for your specific materials, not just generic "metalworking" applications.

- Local Exhaust Ventilation: Capture fumes at the source before they disperse into the workspace. Downdraft tables and localized extraction hoods prove most effective.

- Filtration Systems: HEPA filtration for particulates, activated carbon for organic vapors, and specialized media for specific metal fumes.

- Waste Disposal: Collected filter media, cutting slag, and contaminated coolants may qualify as hazardous waste requiring proper disposal documentation.

- Air Quality Monitoring: Periodic testing verifies extraction systems maintain exposure levels below regulatory limits.

Electrical safety deserves equal attention. High-powered laser systems operate at voltages that present electrocution hazards during maintenance and service. All installations must comply with the National Electrical Code (NFPA 70), and only qualified personnel should access electrical enclosures. Capacitor banks in some laser systems can store lethal charges even after power disconnection—a hazard that requires specific lockout/tagout procedures.

Comprehensive safety programs protect more than personnel—they protect your business from liability, regulatory penalties, and operational disruptions. The investment in proper training, equipment, and procedures pays dividends through reduced incidents and uninterrupted production.

Training requirements complete the safety framework. Operators must understand laser hazards, recognize warning signs, follow SOPs, and respond appropriately to emergencies. Medical surveillance may be required for personnel with significant laser exposure potential, particularly for eye examinations. Document all training thoroughly—regulatory agencies and insurers expect verifiable records demonstrating competency.

With safety and compliance frameworks established, the next consideration becomes practical: which industries actually benefit most from laser cutting's unique capabilities, and what specific applications justify the investment?

Industries and Applications Where Laser Cutting Excels

Now that you understand the safety requirements, a practical question emerges: where does this technology actually deliver the greatest return on investment? The answer spans industries you interact with daily—from the car you drive to the smartphone in your pocket. Laser cutting metal parts has become so embedded in modern manufacturing that removing it would halt production lines across nearly every sector.

What makes certain industries embrace laser cutting while others rely on alternative methods? It comes down to three factors: precision requirements, production volumes, and material characteristics. Industries demanding tight tolerances, complex geometries, and consistent repeatability find laser cutting indispensable. Let's examine where this technology creates the most value.

Automotive and Aerospace Precision Components

The automotive industry has fundamentally transformed its manufacturing processes through metal laser cutter technology. According to Xometry, tolerances in automotive applications are extremely tight, and laser cutting is well-suited to meet them. The technology's flexibility and capability to create complex shapes make it essential for producing car parts that once required expensive stamping dies.

What specific components benefit from this precision? Consider these automotive applications where laser cutting dominates:

- Chassis and structural components: Body panels, floor pans, and reinforcement brackets requiring consistent dimensional accuracy across thousands of units

- Powertrain brackets and mounts: Engine mounting components where vibration isolation depends on precise geometry

- Interior trim assemblies: Dashboard brackets, seat frames, and door panels combining multiple material gauges

- Heat shields and exhaust components: Stainless steel parts demanding clean edges without thermal distortion

Fiber lasers have become the preferred choice for automotive sheet metal, particularly for cutting reflective materials like aluminum and stainless steel that challenge traditional methods. The speed advantage proves critical when producing high volumes—laser metal profiles can be cut and ready for assembly faster than die-based alternatives allow for tooling changes.

Aerospace applications push precision requirements even further. As noted by ACCURL, the aerospace industry benefits from laser cutting's ability to produce components that meet strict tolerance levels while maintaining structural integrity. When you're manufacturing parts for aircraft where failure isn't an option, the consistency of laser cut metal becomes non-negotiable.

Lightweight high-strength materials dominate aerospace manufacturing—titanium alloys, specialized aluminum grades, and exotic metals that resist conventional cutting. Laser cutting handles these materials while producing the clean edges required for subsequent welding or bonding operations. The minimal heat-affected zone preserves material properties that heat-intensive processes would compromise.

Medical Device and Electronics Manufacturing

Imagine a surgical instrument that must function flawlessly inside a human body. Or a cardiac stent measuring mere millimeters across that expands to support an artery. These aren't theoretical examples—they're everyday applications where metal fabrication laser cutting proves irreplaceable.

According to Xometry, the medical device industry utilizes laser cutting to produce pacemakers, stents, and catheters with exceptional accuracy. The laser beam melts, vaporizes, or burns away material leaving clean, precise cuts critical for devices intended for use within the human body. Materials must be both sterilizable and biocompatible—requirements that laser cutting accommodates through its non-contact processing.

Medical applications demanding laser precision include:

- Surgical instruments: Scalpels, forceps, and specialized cutting tools requiring sharp, burr-free edges

- Implantable devices: Orthopedic plates, spinal fusion cages, and joint replacement components

- Diagnostic equipment: Enclosures and mounting brackets for imaging systems and laboratory instruments

- Prosthetics: Custom laser cutting metal enables patient-specific devices matching individual anatomy

The electronics industry faces different challenges—miniaturization demands precision at scales that push laser technology to its limits. According to ACCURL, laser cutting plays a pivotal role in the electronics industry, especially in the miniaturization of electronic devices where a fraction of a millimeter can make a significant difference.

Electronics applications span from visible enclosures to hidden internal components:

- Device enclosures: Smartphone frames, laptop chassis, and tablet housings combining strength with minimal weight

- Heat sinks and thermal management: Complex fin patterns maximizing surface area for heat dissipation

- EMI shielding: Precision shields preventing electromagnetic interference between components

- Connector housings: Micro-scale components requiring exact dimensional control

Architectural Metalwork and Custom Fabrication

Walk through any modern building and you'll encounter laser-cut metal—often without recognizing it. Decorative screens, custom railings, signage, and facade panels increasingly rely on custom laser cutting metal for both aesthetic appeal and structural function.

According to ACCURL, the technology's ability to cut through thick steel plates and produce precise cuts makes it invaluable in construction, whether for stainless steel structural support or decorative elements that combine strength with visual appeal. Architects now design features that would have been impossibly expensive to produce with traditional fabrication methods.

The construction and architectural sector benefits from laser cutting across diverse applications:

- Decorative panels and screens: Intricate patterns in building facades, privacy screens, and interior partitions

- Structural connections: Precisely cut gusset plates, brackets, and beam connections for steel construction

- Custom signage: Dimensional letters, logos, and wayfinding elements in various metal finishes

- Artistic installations: Sculptural elements and public art incorporating complex geometries

Rapid Prototyping and Product Development

Perhaps laser cutting's most transformative impact comes during product development—the phase where speed-to-market separates winners from also-rans. According to Rabbit Laser USA, laser cutting plays a pivotal role in rapid prototyping, offering a precise and swift method to transform digital designs into physical prototypes.

Traditional prototyping required tooling investments and extended lead times. Today, designers send CAD files directly to laser cutting systems and receive functional metal prototypes within days—sometimes hours. This acceleration fundamentally changes how products evolve from concept to production.

The efficiency extends beyond simple speed. As noted by Rabbit Laser USA, laser cutting eliminates bottlenecks common in traditional methods—cumbersome tool changes and intricate setups—allowing seamless transitions between design adjustments and physical realization. The unmatched accuracy ensures prototypes mirror digital designs with exceptional fidelity, reducing iteration cycles.

Laser cutting has proven to be a cornerstone of innovation in both rapid prototyping and small-scale manufacturing. Its efficiency, accuracy, and material versatility have set new standards for the industry.

This prototyping capability proves especially valuable for:

- Design validation: Testing form, fit, and function before committing to production tooling

- Iterative development: Quickly implementing design changes based on testing feedback

- Customer samples: Providing tangible prototypes for stakeholder review and approval

- Small-batch production: Manufacturing limited runs without tooling investment

Whether you're developing automotive components, medical devices, or architectural features, rapid prototyping through laser cutting compresses development timelines while maintaining the precision that production parts will require.

Understanding where laser cutting excels helps clarify whether your applications align with the technology's strengths. But a critical decision remains: should you invest in in-house equipment, or partner with an external service provider? The next section examines the factors that determine which approach delivers better value for your specific situation.

Choosing Between In-House Equipment and Outsourced Services

You've identified the perfect applications for laser cutting and understand exactly what the technology can deliver. Now comes a decision that will shape your operations for years: should you invest in your own metal laser cutting machine, or partner with an external service provider? This isn't just a financial calculation—it's a strategic choice that affects lead times, quality control, flexibility, and your team's focus.

The answer isn't universal. A high-volume automotive supplier with predictable demand faces entirely different economics than a design firm needing occasional prototypes. Let's break down the factors that determine which approach delivers better value for your specific situation.

Calculating Your Break-Even Point for Equipment Investment

Before signing a purchase order for a sheet metal laser cutting machine, you need to understand when—or if—that investment pays for itself. According to Arcuscnc, many shops are "bleeding cash" by outsourcing laser parts, paying a 300% markup to service bureaus while waiting two weeks for delivery. They don't realize that monthly equipment payments often cost less than a single outsourcing invoice.

Let's examine the real numbers. A complete laser cutting machine for sheet metal setup involves more than the sticker price:

- Machine hardware: Approximately $35,000-$100,000+ depending on power level and features

- Shipping and duties: Around $5,000 for freight, tariffs, and local delivery

- Auxiliary equipment: Roughly $4,000 for compressor and air dryer systems

- Site preparation: About $1,000 for electrical wiring and gas plumbing

A realistic total initial investment lands around $45,000-$110,000 for a production-capable system. But here's what changes the equation: operating costs for a cnc laser cutting machine for steel run approximately $30 per hour—including electricity, consumables, assist gas, and labor. Meanwhile, job shops typically charge $150-$300 per hour of beam-on time.

Consider this real-world scenario from Arcuscnc's analysis: A shop producing 1,000 custom brackets monthly pays $5.00 per piece outsourced—$60,000 annually. Bringing production in-house with a cnc laser metal cutter drops that cost to roughly $1,666 monthly ($19,992 annually) when factoring material and operating expenses. Annual savings of $40,008 means the equipment pays for itself in just 13 months.

But that calculation only accounts for replacing existing outsourcing. What happens when you utilize excess capacity? If you sell just 20 hours of cutting services weekly at $150/hour, monthly profit jumps to approximately $9,580—reducing break-even to under 5 months.

| Factor | In-House Equipment | Outsourced Services |

|---|---|---|

| Capital Investment | $45,000-$500,000+ upfront | None required |

| Lead Time | Same-day to next-day possible | Typically 5-14 days; expedited options available |

| Flexibility | Immediate design changes; no external scheduling | Dependent on provider capacity and scheduling |

| Quality Control | Direct oversight of all processes | Relies on provider's QC systems and certifications |

| Volume Requirements | Best with consistent, predictable demand | Ideal for variable volumes or one-off projects |

| Technical Expertise | Requires trained operators and maintenance staff | Provider handles all technical requirements |

| Operating Costs | ~$30/hour (electricity, consumables, labor) | $150-$300/hour billed |

| IP Protection | Designs stay in-house | Must share designs with third party |

Beyond pure economics, consider the "hidden ROI" that spreadsheets miss. Speed to market improves dramatically—prototype a part in the morning and ship finished product by afternoon. Quality control becomes direct rather than dependent on vendor performance. And your proprietary designs never leave your building, eliminating IP concerns about suppliers who might also serve competitors.

However, in-house production isn't universally superior. According to LYAH Machining, launching an internal fabrication department requires substantial spending on equipment, facility upgrades, and skilled labor recruitment. Many industries face long-term shortages of qualified CNC operators, welders, and technicians—making staffing a persistent challenge.

What to Look for in a Laser Cutting Service Provider

If outsourcing makes sense for your situation—variable demand, limited capital, or applications outside your core expertise—choosing the right partner becomes critical. Not all laser cutter machine metal providers deliver equal results. The difference between a mediocre vendor and an excellent partner can mean the difference between project success and costly failures.

Certifications provide the first screening criteria. For automotive applications, IATF 16949 certification demonstrates a provider meets the stringent quality management requirements of major automakers. According to Wrightform, a company familiar with your industry's standards and requirements can better anticipate your needs—laser cutting for architectural features differs significantly from cutting automotive components.

Turnaround capabilities directly impact your production schedules. Some providers offer expedited options for time-sensitive projects, while others maintain standard timelines regardless of urgency. Ask specifically about rush order policies, typical lead times for your material and thickness requirements, and their track record for on-time delivery.

Design for Manufacturing (DFM) support separates transactional vendors from true partners. Providers offering DFM review can identify potential issues before cutting begins—suggesting design modifications that improve manufacturability, reduce costs, or enhance part performance. This collaborative approach prevents expensive rework and accelerates development cycles.

Manufacturers like Shaoyi (Ningbo) Metal Technology exemplify the benchmarks you should seek when evaluating partners. Their capabilities—including 5-day rapid prototyping, IATF 16949 certification for automotive components, comprehensive DFM support, and 12-hour quote turnaround—demonstrate the service levels that distinguish premium providers from basic cut-to-print shops. When evaluating potential partners, use these capabilities as a measuring stick.

Prototyping services deserve special attention. According to Wrightform's guidance, prototyping allows you to validate a design before committing to full-scale production—invaluable for fine-tuning specifications and ensuring compatibility with other components. Providers who offer rapid prototyping alongside production services streamline your path from concept to volume manufacturing.

Essential Questions to Ask Potential Service Providers

Before committing to any cnc laser cutter for steel provider, gather answers to these critical questions:

- What materials and thicknesses can you process? Confirm they handle your specific metals at required gauges. High-power fiber lasers cut thicker and more reflective materials than traditional CO2 systems.

- What precision tolerances do you guarantee? Clarify cutting accuracy and their ability to produce clean edges without burrs—critical for industries requiring tight tolerances.

- How do you optimize material usage? Efficient nesting reduces your costs. Ask about their CAD/CAM software capabilities and waste reduction practices.

- What is your typical turnaround, and do you offer expedited options? Verify standard timelines match your needs and understand rush order availability.

- What file formats do you accept? Standard formats include DXF and DWG. Some providers work with PDFs or even hand-drawn sketches if you lack CAD capabilities.

- Do you offer finishing, assembly, or secondary services? One-stop providers handling deburring, coating, or assembly save logistics complexity.

- What quality control processes do you follow? Ask about inspection methods, dimensional verification, and part consistency assurance.

- What certifications do you hold? Industry-specific certifications (IATF 16949, ISO 9001, AS9100) demonstrate quality system maturity.

- Can you accommodate flexible order sizes? Whether you need one-off prototypes or high-volume production, reliable providers scale with your requirements.

- What is your experience with similar projects or industries? Past experience with applications like yours indicates they understand your specific requirements.

According to industry guidance, asking these targeted questions helps gauge expertise, flexibility, and reliability. The answers reveal whether a provider operates as a transactional vendor or a genuine manufacturing partner invested in your success.

With the in-house versus outsourcing decision framework established, one question remains: how do you synthesize everything you've learned into a clear action plan for your specific metal cutting needs?

Making the Right Decision for Your Metal Cutting Needs

You've absorbed a tremendous amount of information about laser cutting metals—from wavelength differences between fiber and CO2 systems to safety protocols that protect your team. Now comes the moment of truth: translating that knowledge into a concrete decision for your specific project. Whether you're fabricating automotive brackets, aerospace components, or architectural panels, the right choice depends on systematically evaluating your unique requirements against laser cutting's capabilities.

The good news? You don't need to memorize every technical detail. What you need is a clear framework that guides you through the critical decision points. Let's walk through exactly how to match your project requirements to the right technology, partner, or equipment—and avoid the costly mistakes that trip up unprepared buyers.

Matching Your Project Requirements to Laser Cutting Capabilities

Think of this evaluation process as a funnel. Each step narrows your options until the right solution becomes clear. Skip a step, and you risk investing in technology that doesn't match your actual needs—or partnering with a provider who can't deliver what you require.

- Assess Material and Thickness Requirements: Start with the fundamentals. What metals will you cut, and at what gauges? A laser cutter for metal handles steel, stainless, aluminum, copper, brass, and titanium—but each material has specific thickness limits. Fiber lasers excel with reflective metals and thin-to-medium gauges. CO2 systems handle thicker steel plates. If your materials exceed 25mm or include heat-sensitive alloys, alternatives like waterjet may serve you better.

- Determine Precision Needs: How tight are your tolerances? Sheet metal laser cutting achieves accuracy within ±0.1mm—exceptional for medical devices, electronics, and aerospace components. But if your application tolerates ±1mm or greater, plasma cutting delivers acceptable results at lower cost. Match technology to actual requirements, not aspirational specifications.

- Calculate Volume and Frequency: Production volume dramatically affects economics. High-volume, consistent demand justifies in-house equipment investment. Variable or occasional needs favor outsourcing. According to Bendtech Group, modern online laser cutting platforms have revolutionized accessibility—the global market hit USD 7.12 billion in 2023 and is projected to nearly double by 2032. This growth reflects how outsourcing has become increasingly viable for diverse production scenarios.

- Evaluate Budget Constraints: Be honest about available capital. A laser cutter for sheet metal requires $45,000-$500,000+ upfront investment plus ongoing operating costs. Outsourcing eliminates capital requirements but trades them for per-part expenses. Calculate your break-even point before committing either direction. If you're researching a laser cutter for steel, remember that operating costs around $30/hour in-house compare favorably to $150-$300/hour from service providers—but only if utilization stays high.

- Identify Qualified Partners or Equipment: Whether buying equipment or selecting a service provider, verify capabilities match your requirements. For laser cutters for metal, confirm the system handles your materials at required thicknesses. For service providers, ask about certifications, turnaround times, DFM support, and industry experience. The questions listed in the previous section serve as your evaluation checklist.

This systematic approach prevents the two most common mistakes: over-investing in capabilities you'll rarely use, or under-specifying and discovering limitations after production begins. Each step builds on the previous, creating a decision path grounded in your actual requirements rather than marketing claims.

Taking the Next Step Toward Precision Metal Fabrication

With your evaluation complete, you're positioned to act decisively. But before finalizing any commitment, synthesize the critical insights that should guide your final decision.

Laser metal cutting delivers unmatched precision for thin to medium metals, but success depends on matching technology to application. Fiber lasers dominate for reflective materials and thin gauges. CO2 systems remain valuable for thick plates and mixed-material operations. Alternatives like plasma, waterjet, and mechanical cutting serve specific niches where laser technology isn't optimal. The right choice balances precision requirements, material characteristics, production volume, and total cost of ownership.

For readers pursuing automotive, chassis, or structural metal components, specialized manufacturing partners can accelerate your path to production. Shaoyi (Ningbo) Metal Technology offers custom metal stamping and precision assemblies with IATF 16949 certification, 5-day rapid prototyping, comprehensive DFM support, and 12-hour quote turnaround—capabilities that demonstrate the service levels you should expect from qualified automotive fabrication partners.

What does the future hold for laser cutting technology? According to SF Material's industry analysis, the global laser cutting market is projected to reach USD 6.7 billion by 2025, expanding at a CAGR of 6.6%. Advancements continue across fiber and CO2 technologies, with automation and AI-driven optimization reshaping operational efficiency. The integration of IoT and real-time monitoring enables smarter, more efficient production processes.

These trends point toward increasingly accessible, capable, and cost-effective laser cutting solutions. As noted by FWINCNC's buyer's guide, choosing the right laser cutting machine is a strategic decision—one that positions your business for success by evaluating materials, size requirements, power needs, and supplier reliability. The technology you select today will serve as a cornerstone of your manufacturing capabilities for years to come.

Whether you invest in in-house equipment or partner with a qualified service provider, laser cutting opens doors to precision, speed, and design freedom that traditional methods simply cannot match. The framework you've built through this guide—understanding laser types, material compatibility, workflow parameters, cost factors, safety requirements, and application alignment—positions you to make that decision with confidence.

Your next step? Apply this evaluation framework to your specific project. Identify your materials and thicknesses. Define your precision requirements. Calculate your volumes. Set your budget boundaries. Then reach out to qualified equipment suppliers or service providers with clear specifications and informed questions. The precision metal fabrication capabilities you need are within reach—now you have the knowledge to claim them.

Frequently Asked Questions About Laser Cutting Metals

1. What metals can be cut with a laser cutter?

Laser cutters effectively process mild steel, stainless steel, aluminum, titanium, brass, and copper. Fiber lasers excel with reflective metals like aluminum and copper, achieving cuts up to 12mm and 6mm respectively. Mild steel can be cut up to 25mm thick, while stainless steel reaches 20mm. Each metal requires specific laser types and assist gases—oxygen for steel thickness capacity, nitrogen for clean aluminum edges. Modern fiber laser technology has significantly improved processing of historically challenging reflective materials by using shorter wavelengths that metals absorb more efficiently.

2. What materials cannot be cut on a laser cutter?

Metal laser cutters cannot safely process PVC, polycarbonate, Lexan, or certain plastics that release toxic chlorine gas when heated. Highly reflective materials posed historical challenges, though modern fiber lasers now handle copper and brass effectively. Extremely thick metals beyond 25-100mm (depending on material type) may require alternative methods like plasma or waterjet cutting. Heat-sensitive materials that cannot tolerate any thermal impact are better suited for waterjet's cold-cutting process, which leaves no heat-affected zones.

3. How much does metal laser cutting cost?

Laser cutting steel typically costs $13-$20 per hour for operating expenses when using in-house equipment, with total costs around $30/hour including labor and consumables. Service providers charge $150-$300 per hour of beam-on time. For perspective, a project requiring 15,000 inches of cutting at 70 inches per minute translates to approximately 3.57 hours of active cutting. Equipment investment ranges from $45,000-$500,000+ depending on power and capabilities. Break-even analysis often shows in-house equipment pays for itself within 5-13 months for high-volume operations.

4. What is the difference between CO2 and fiber lasers for metal cutting?

Fiber lasers operate at 1.064 µm wavelength—10 times shorter than CO2's 10.6 µm—enabling better metal absorption and 3-5x faster cutting speeds on thin materials. Fiber lasers achieve over 90% energy efficiency versus 5-10% for CO2 systems, with lifespans exceeding 25,000 hours compared to 2,500 hours. CO2 lasers cost 5-10x less upfront and excel at cutting thick steel plates up to 100mm with oxygen assist. Fiber dominates for reflective metals and thin-medium gauges, while CO2 remains valuable for thick plate work and mixed-material shops.

5. Should I buy laser cutting equipment or outsource to a service provider?

The decision depends on volume, capital, and expertise. In-house equipment suits high-volume operations with consistent demand—break-even often occurs within 5-13 months when replacing outsourcing costs of $150-$300/hour with operating costs around $30/hour. Outsourcing benefits variable demand, limited capital, or specialized applications outside core expertise. Key provider evaluation criteria include IATF 16949 certification for automotive work, rapid prototyping capabilities, DFM support, and turnaround times. Manufacturers like Shaoyi offer 5-day prototyping and 12-hour quotes, setting benchmarks for service expectations.

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —

Small batches, high standards. Our rapid prototyping service makes validation faster and easier —